Powdering and then grinding type pulping equipment

A technology of pulping and first-pulverization, applied in pulp beating/refining method, textile and papermaking, raw material separation, etc., can solve the problems of insufficient stirring, intermittent production cycle, low pulping efficiency, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

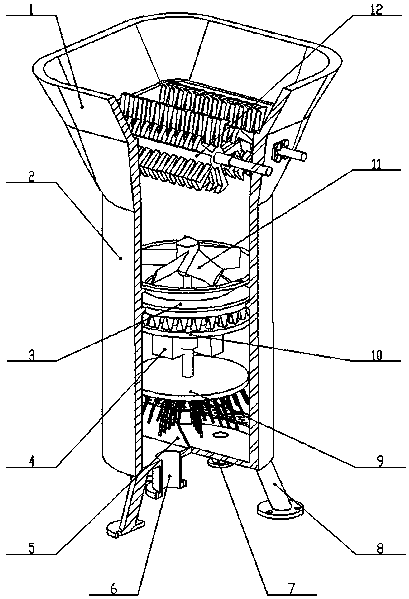

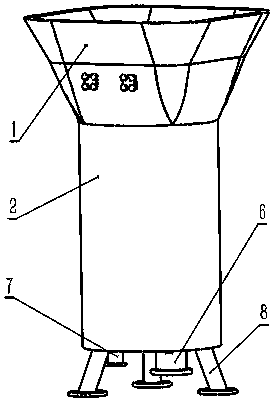

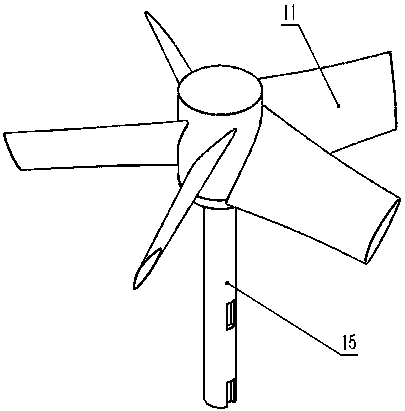

[0027] like figure 1 As shown, a pulverizing first and then grinding type pulping equipment of the present invention mainly includes a conical feed inlet device, a rectangular toothed roller device, a stirring device, a conical grinding roller device, a bevel gear transmission device and an inclined filtering device. The tapered feed inlet device is mainly composed of a tapered coil 1 and an atomizing water nozzle. The rectangular toothed roll device is mainly made up of sawtoothed roll 12, positioning bearing, bearing sleeve, end cover and fixing bolt, and two sawtoothed rolls are matched in clearance. Stirring device is mainly made up of trapezoidal rotor 11 and transmission shaft 15. The conical grinding roller device is mainly composed of the upper grinding roller 3 and the lower grinding roller 10. The circular steel plate of the upper grinding roller is fixed on the inner wall of the material cylinder through bolts, the large circle in the middle is stuck on the raised...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com