Patents

Literature

248results about How to "Solve the labor-intensive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

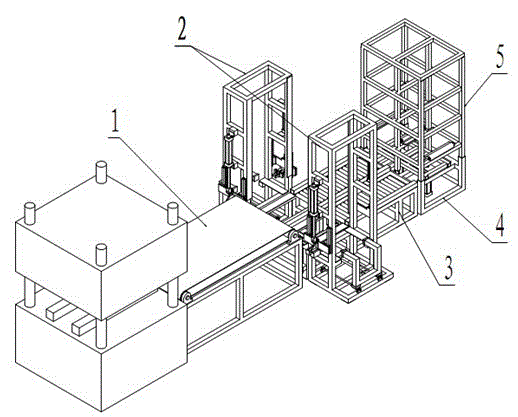

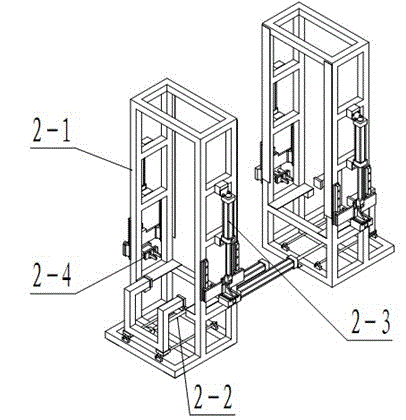

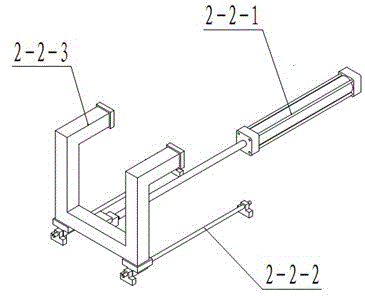

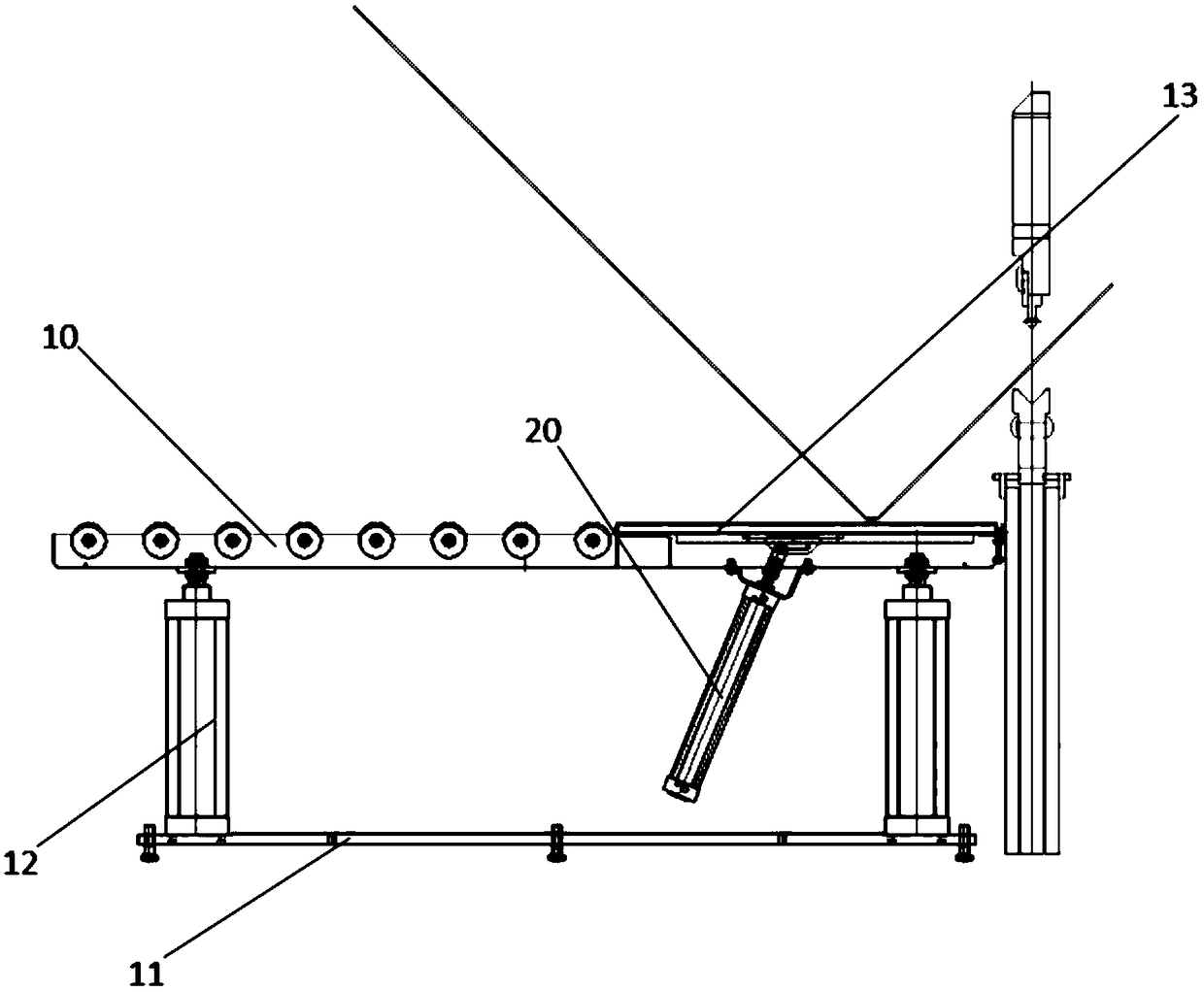

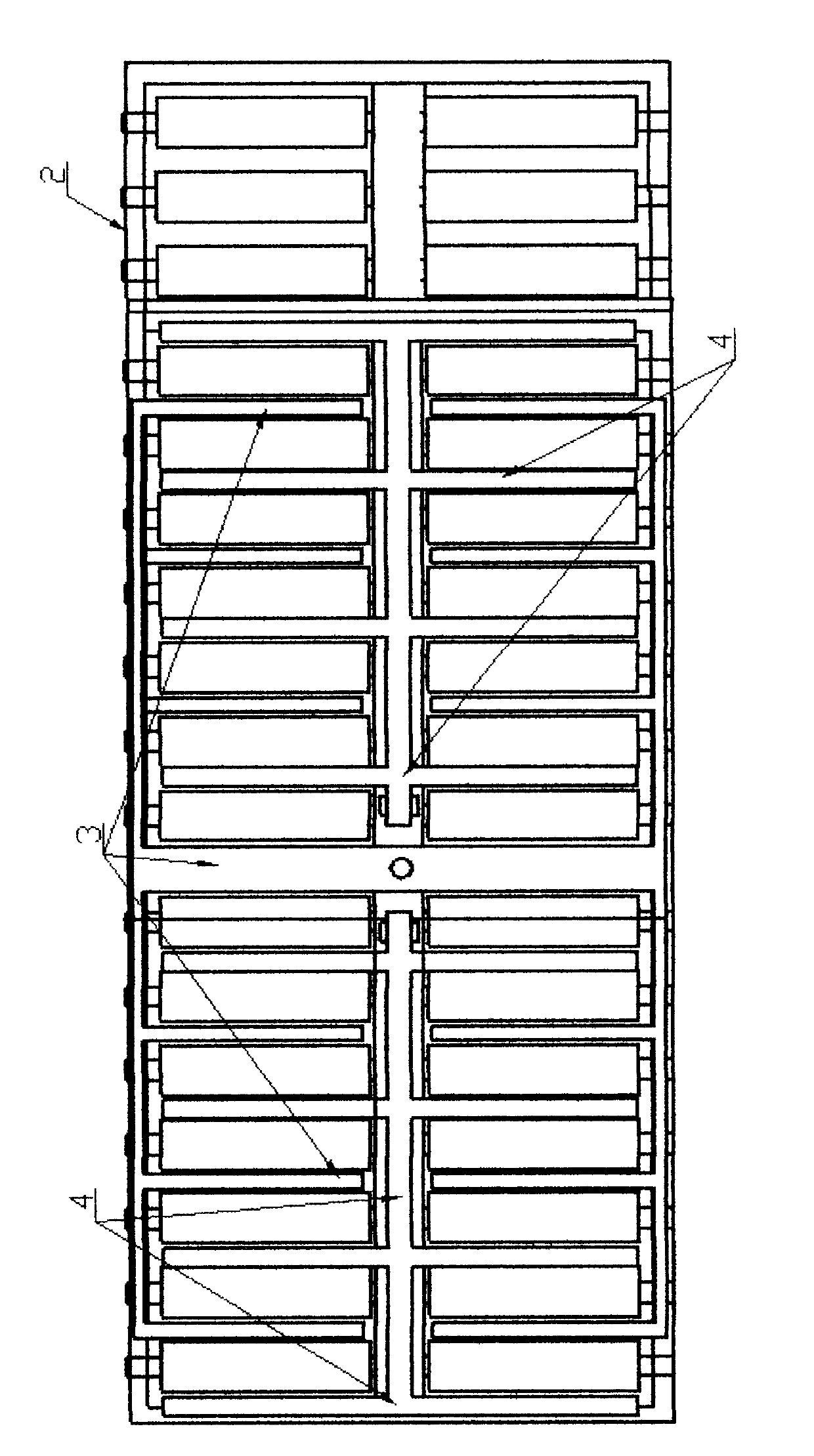

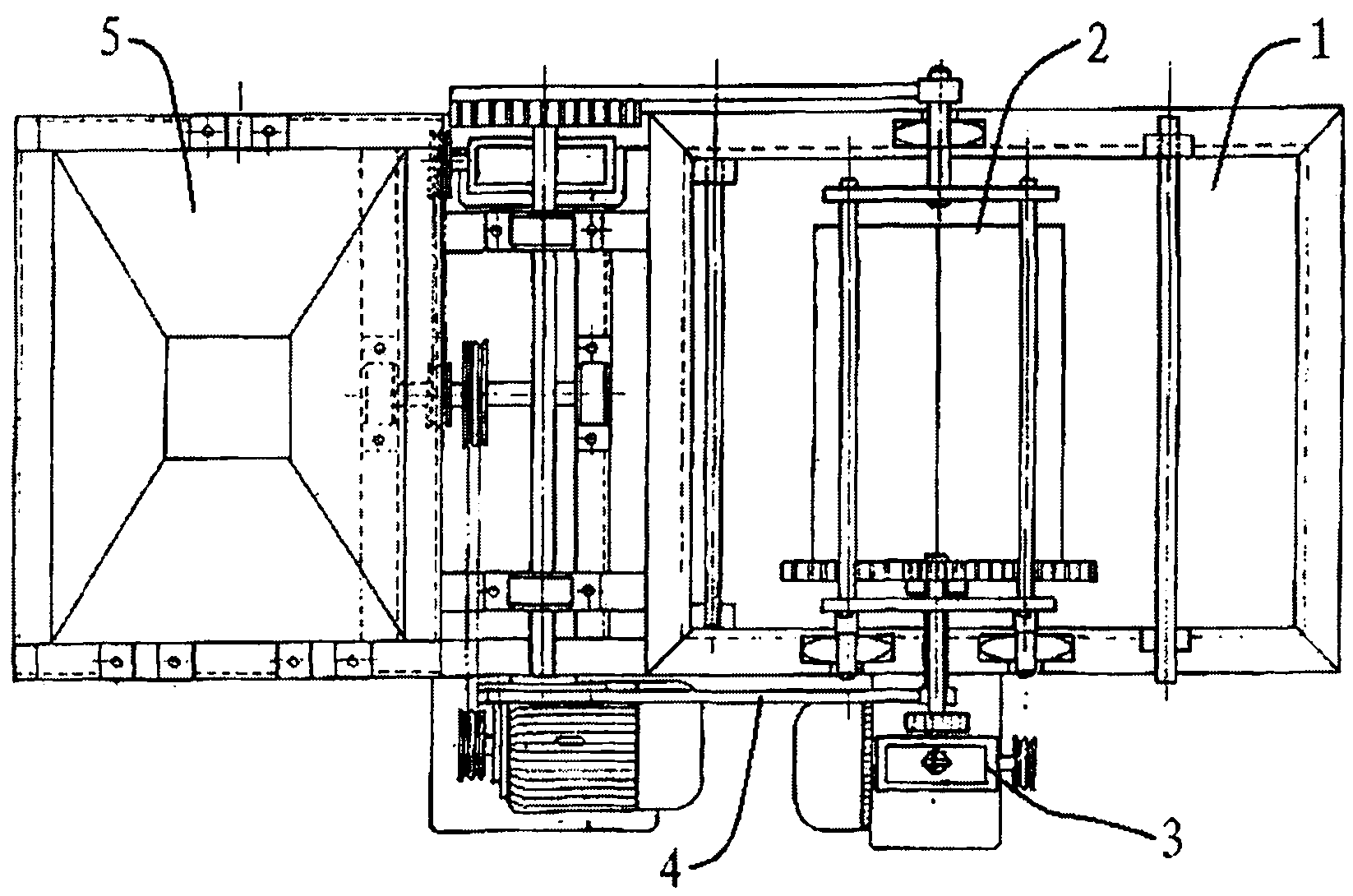

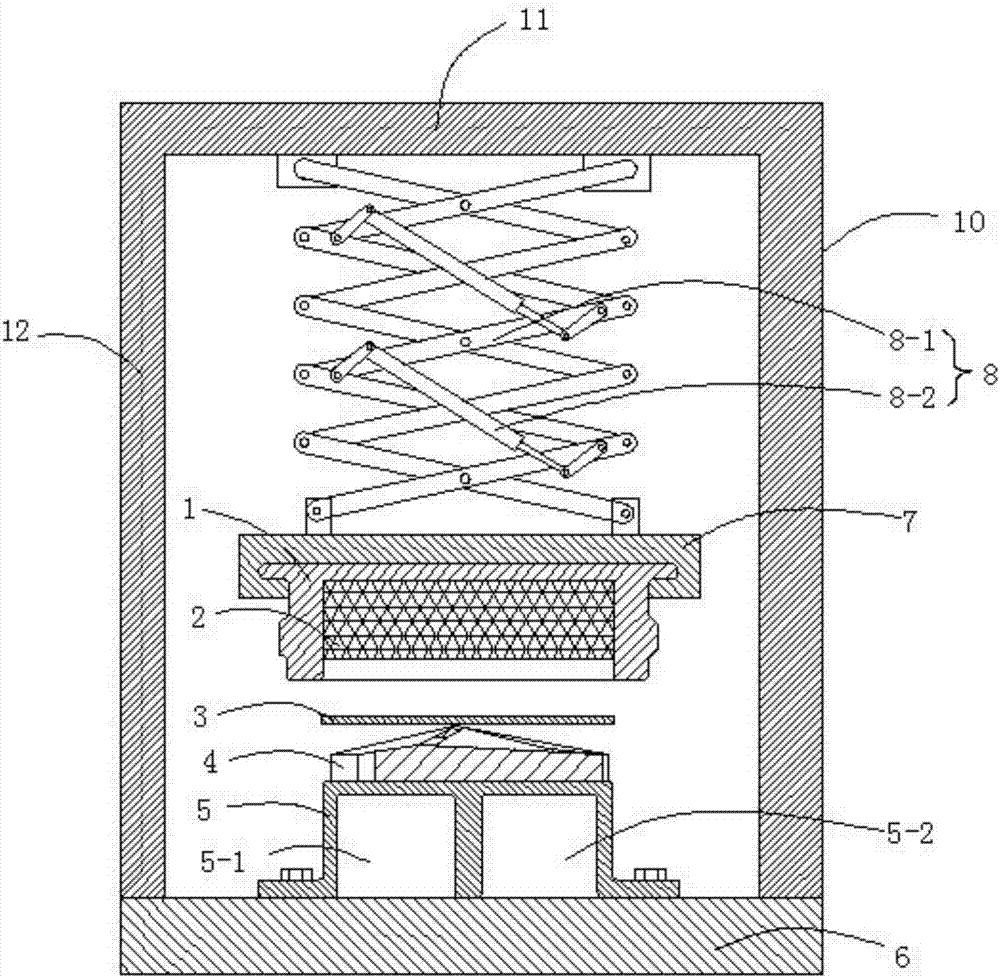

Automatic conveying and stacking device for material boxes

The invention discloses an automatic conveying and stacking device for material boxes, and solves the problem of workpiece conveying of a matched small punching machine. The automatic conveying and stacking device comprises an empty box replacement mechanism, a full box conveying mechanism, a full box stacking mechanism and a full box shelf, wherein the empty box replacement mechanism is arranged between a conveying platform of the small punching machine and the full box conveying mechanism; the full box conveying mechanism is positioned in front of the full box stacking mechanism; the full box stacking mechanism and the full box shelf are mounted in a matched way; and the full box shelf is arranged above the full box stacking mechanism. The automatic conveying and stacking device has the characteristics of high automation level and strong practicality, and not only solves the problems of low conveying efficiency of the workpieces of the small punching machine and high labor intensity of operators but also guarantees the control on the whole production rhythm.

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

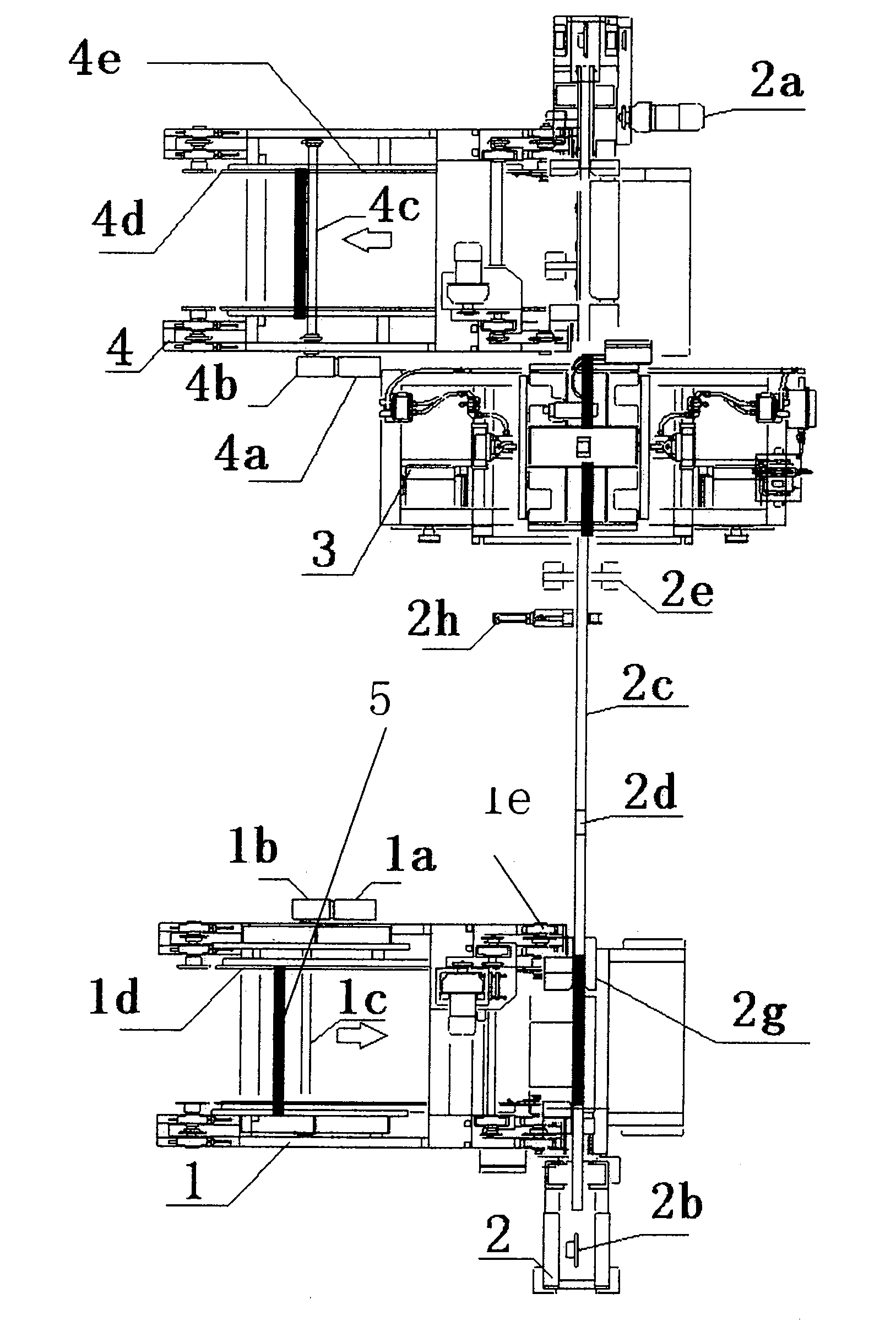

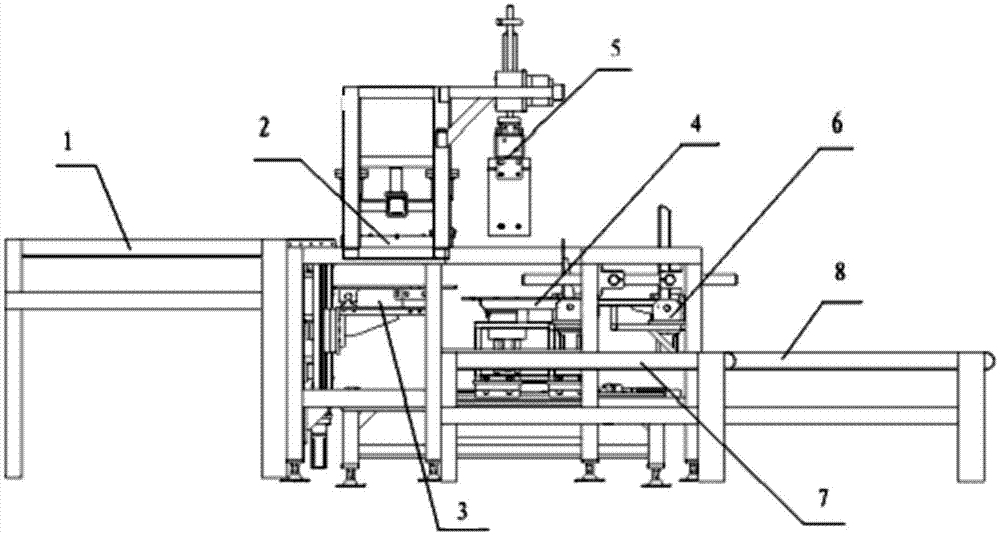

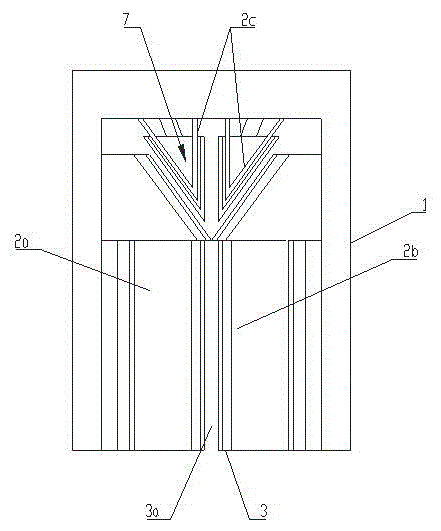

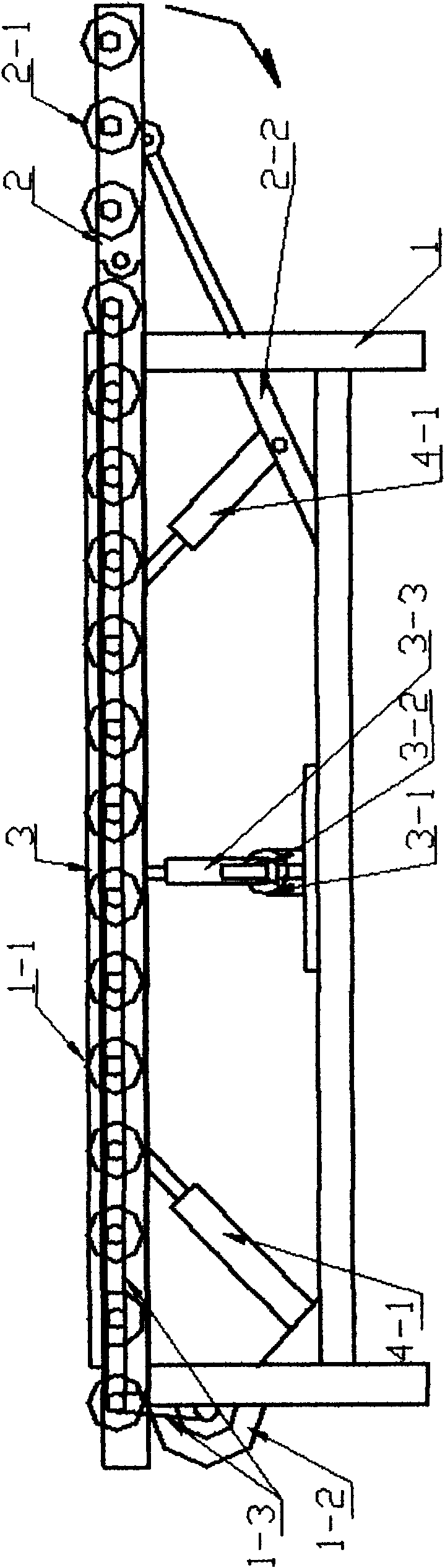

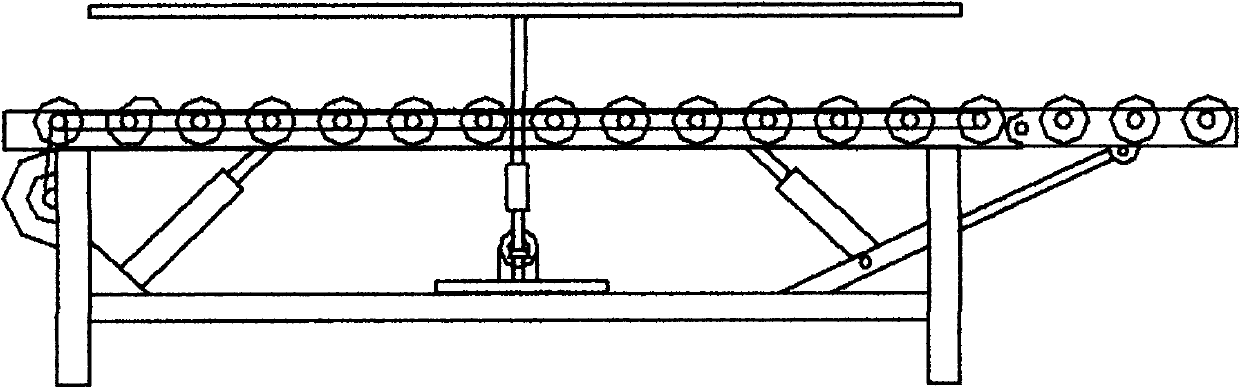

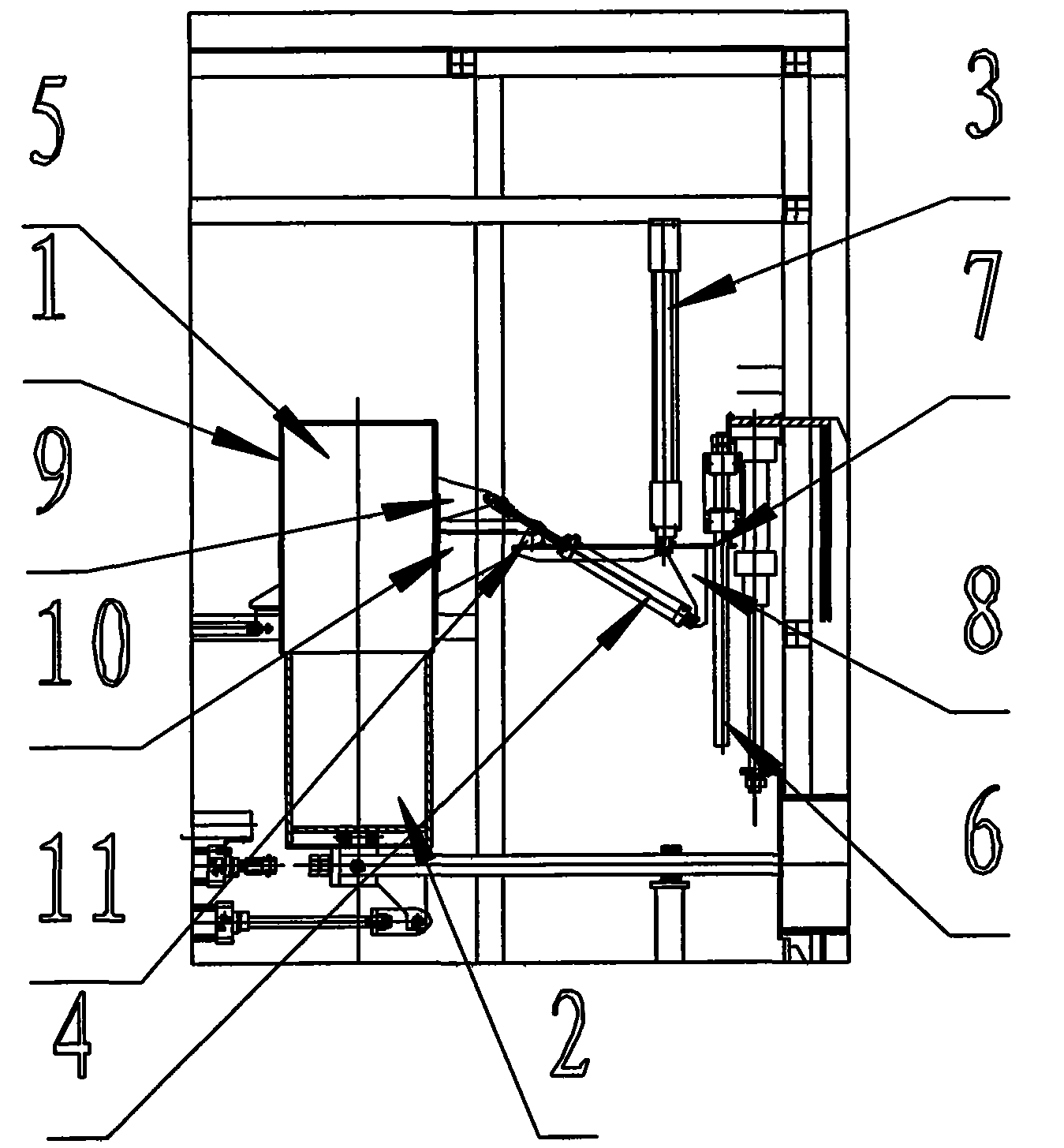

Automatic brush plate machine of zinc electrolysis cathode plate

The invention discloses an automatic brush plate machine of a zinc electrolysis cathode plate, comprising an intaking-plate distance-arranging device (1) and a chain transmission device (2) which are sequentially arranged, a roller brush-plate device (3) and an unloading plate release device (4) which are sequentially arranged along a transmission chain (2d) of the chain transmission device (2), wherein, the roller brush-plate device (3) is located above the chain transmission device (2). The invention can continuously clean a plurality of cathode plates, and has advantages of simple operation, high brush-plate efficiency, and reliable working.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

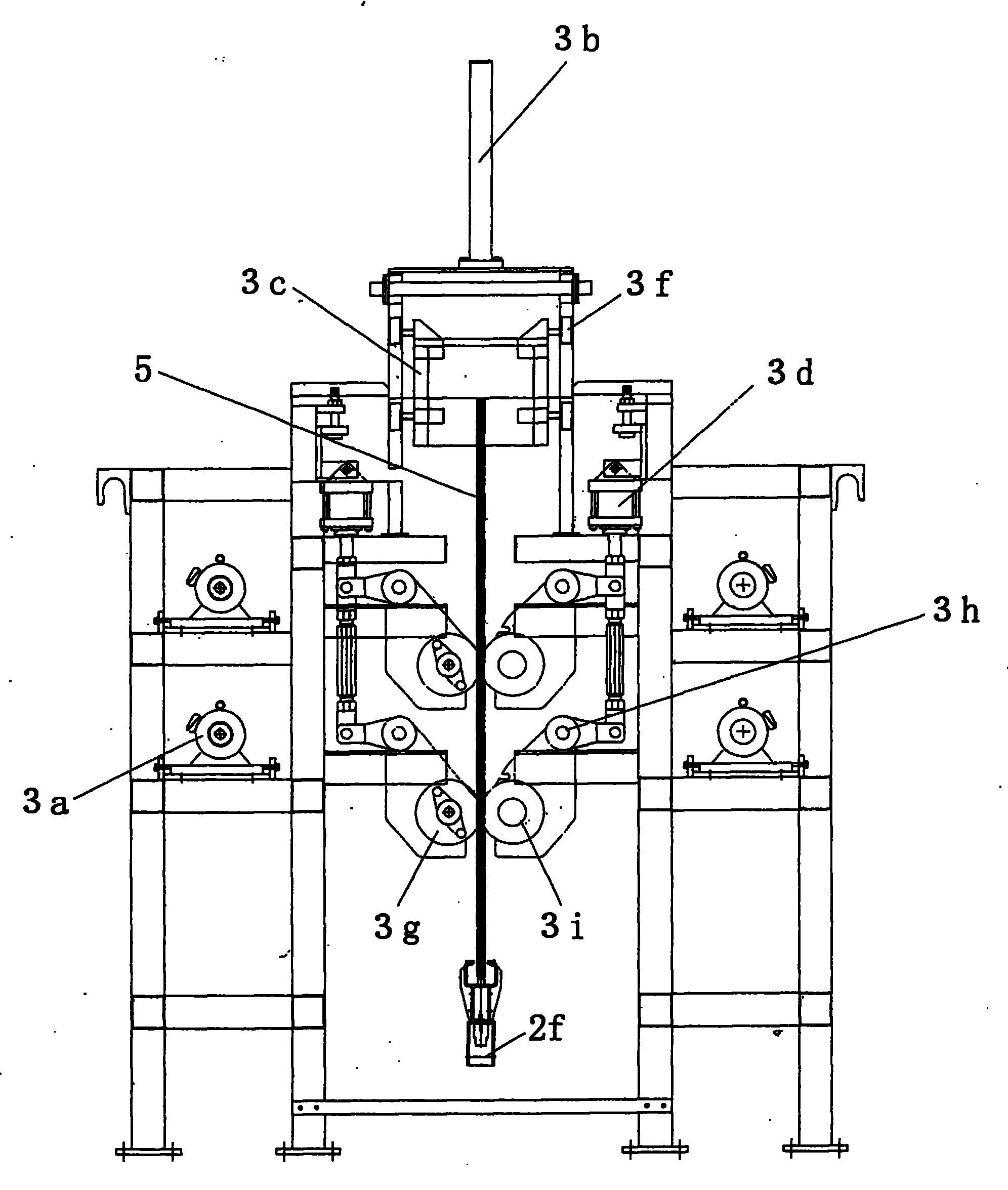

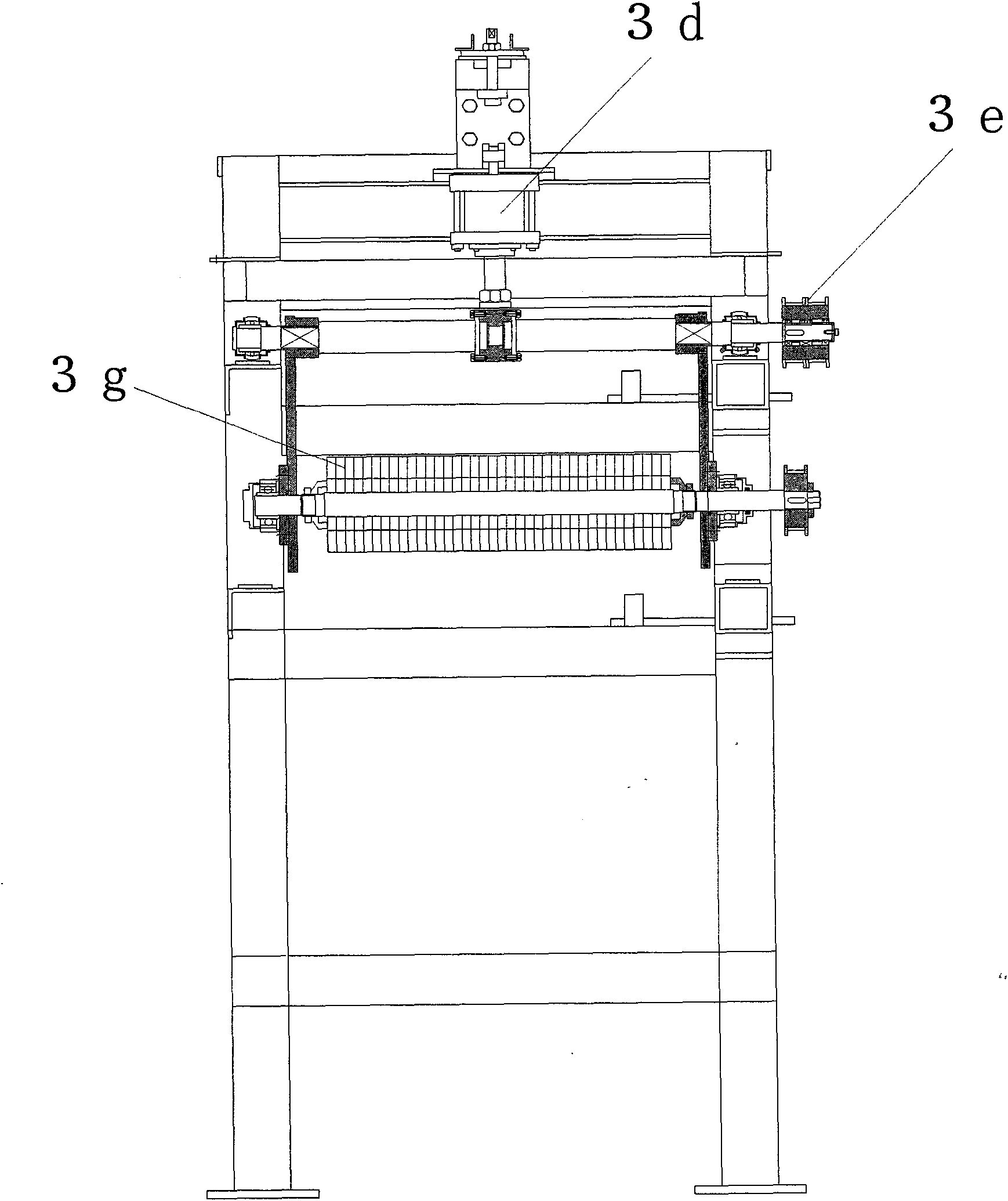

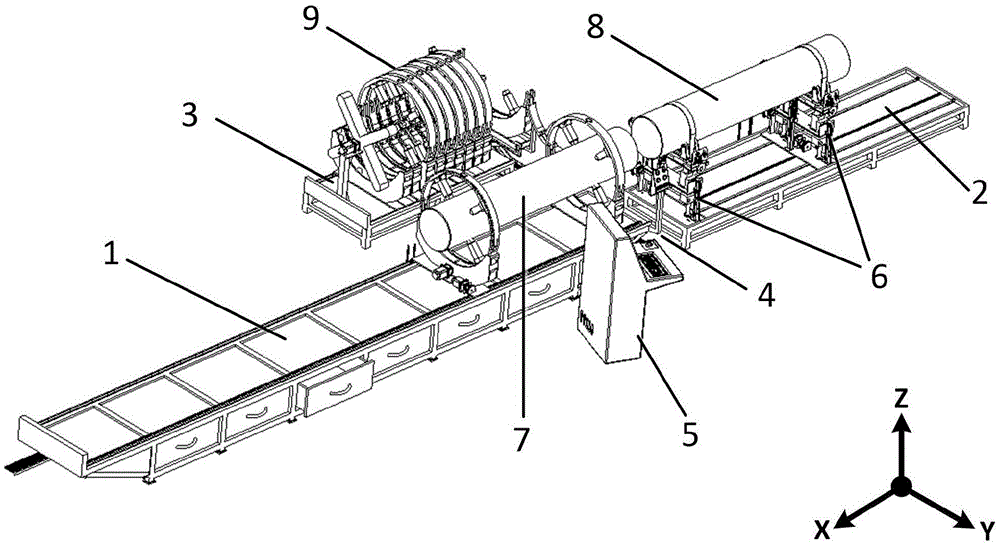

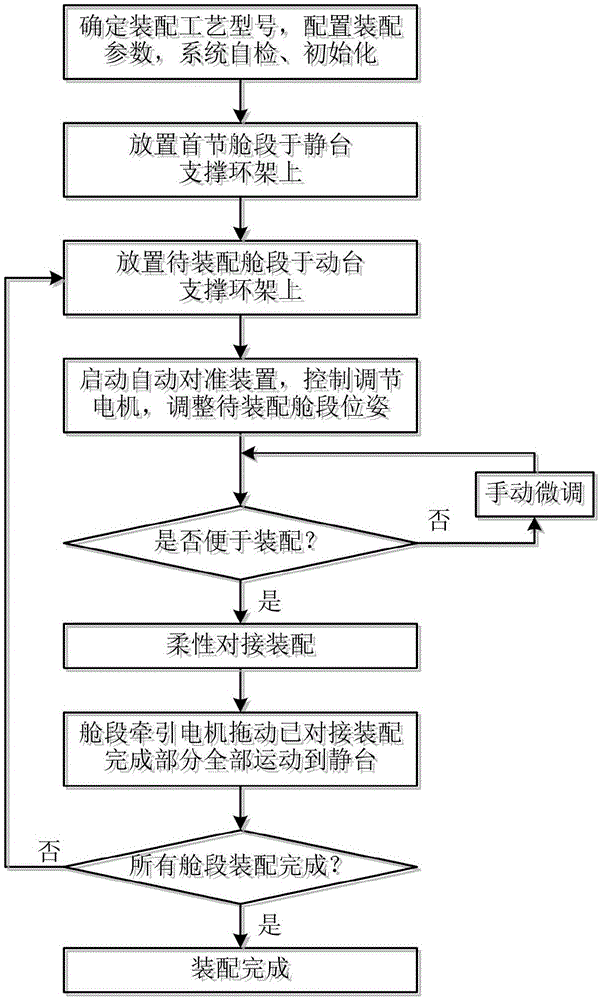

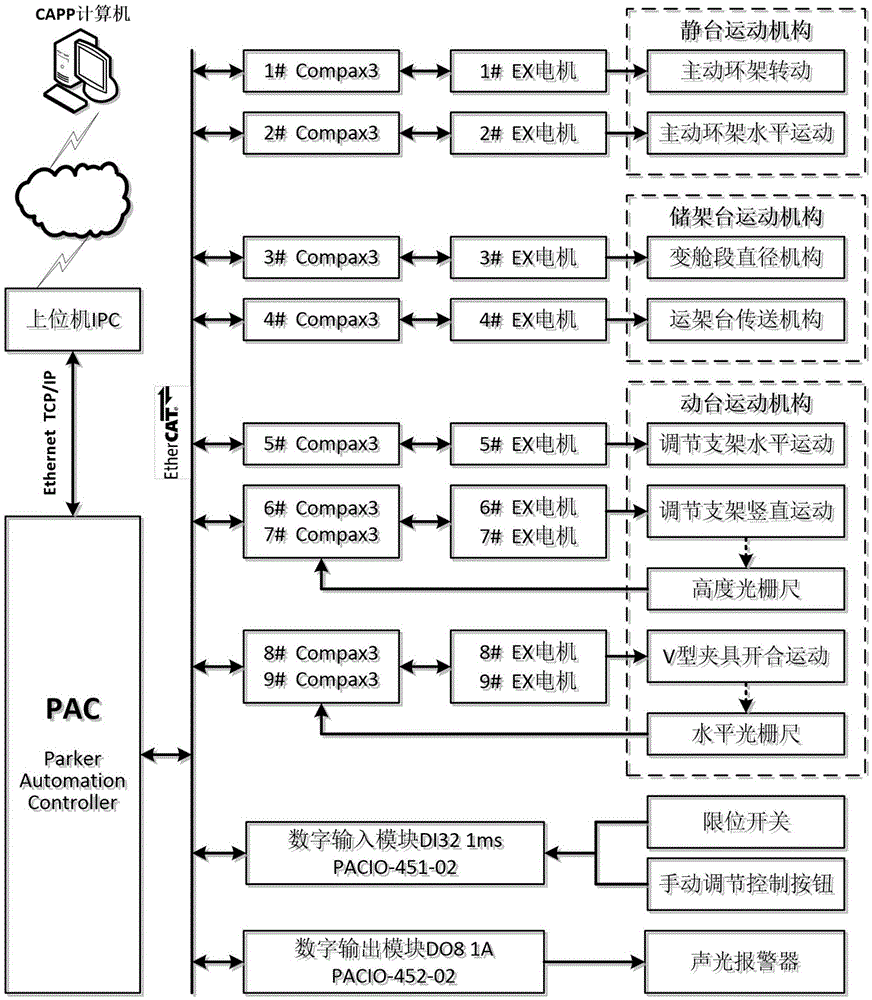

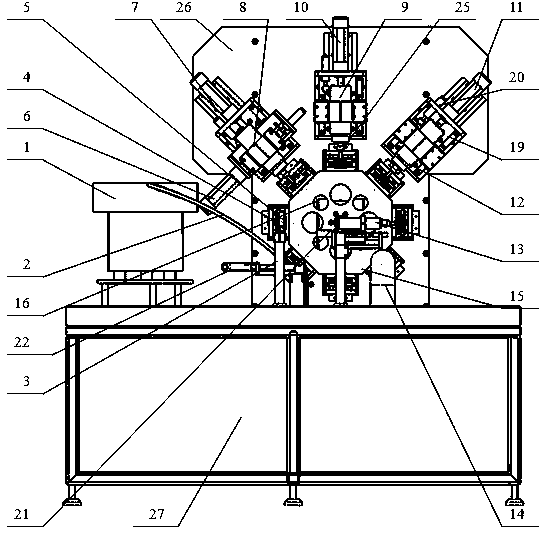

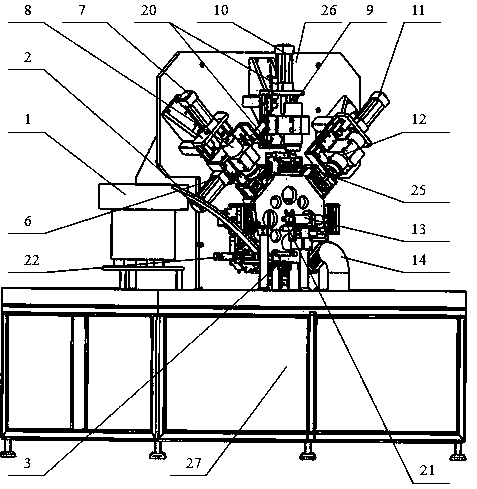

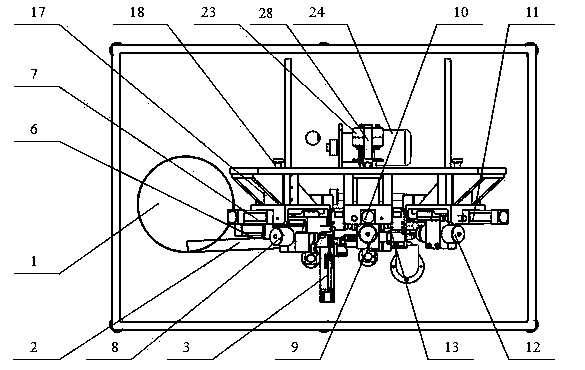

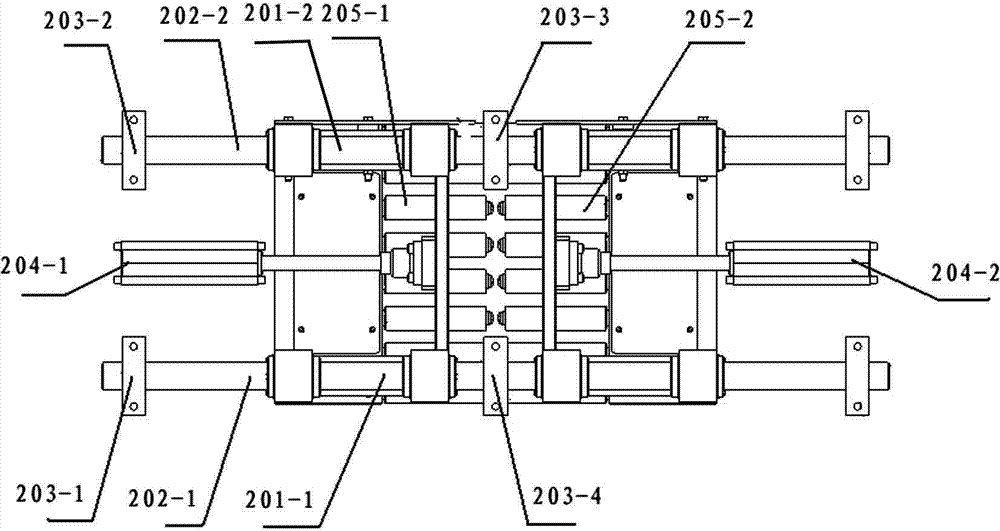

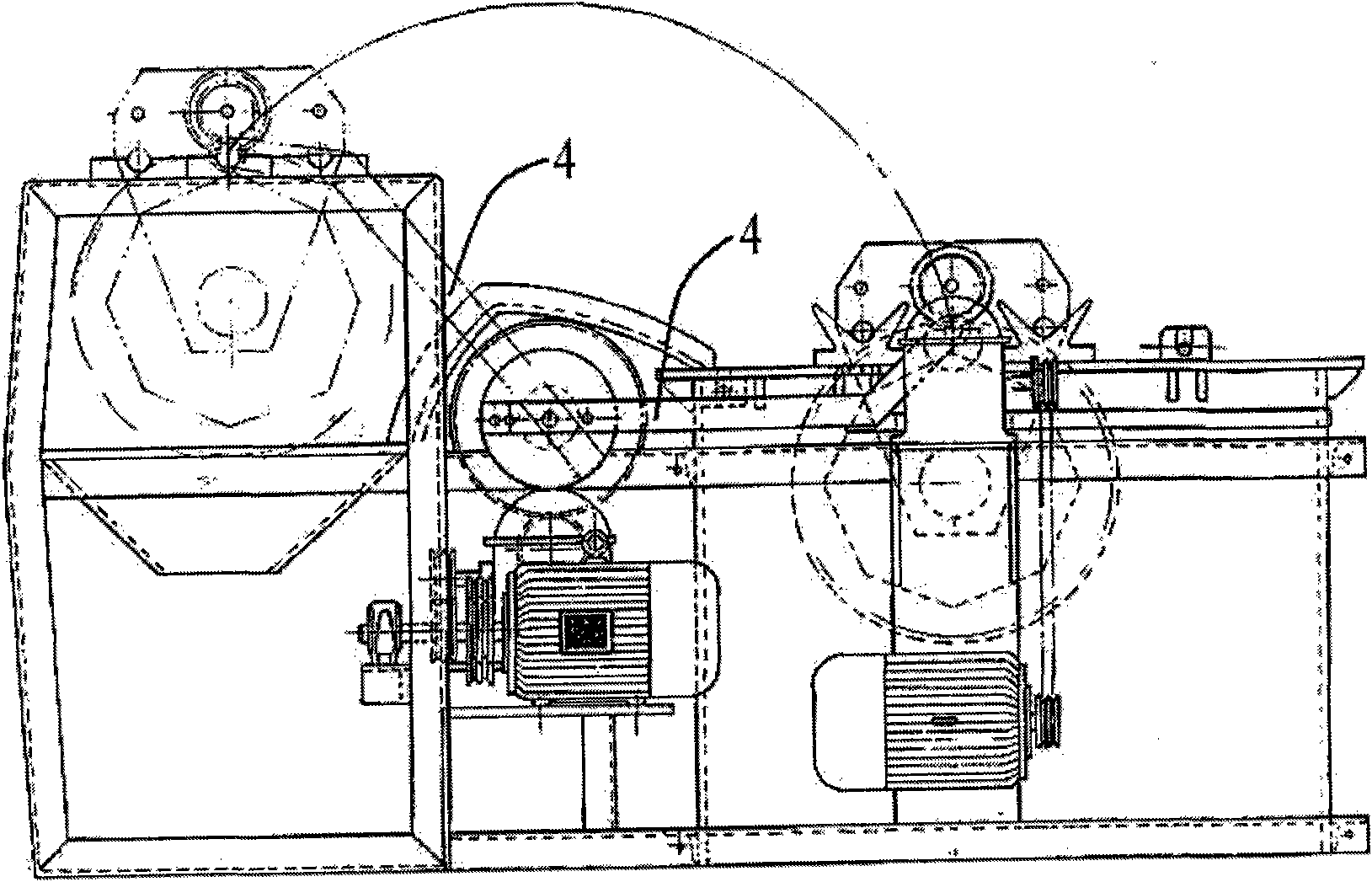

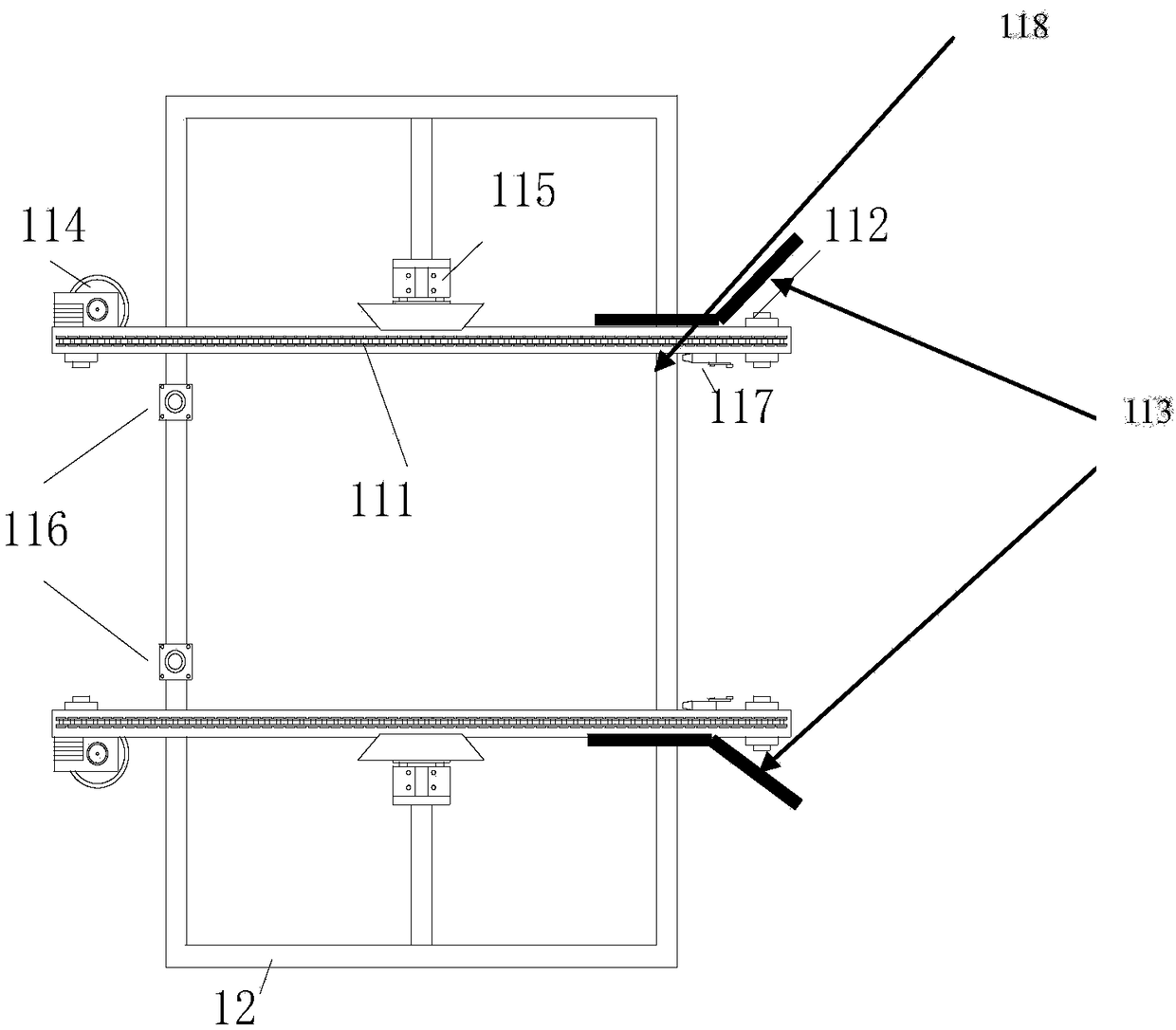

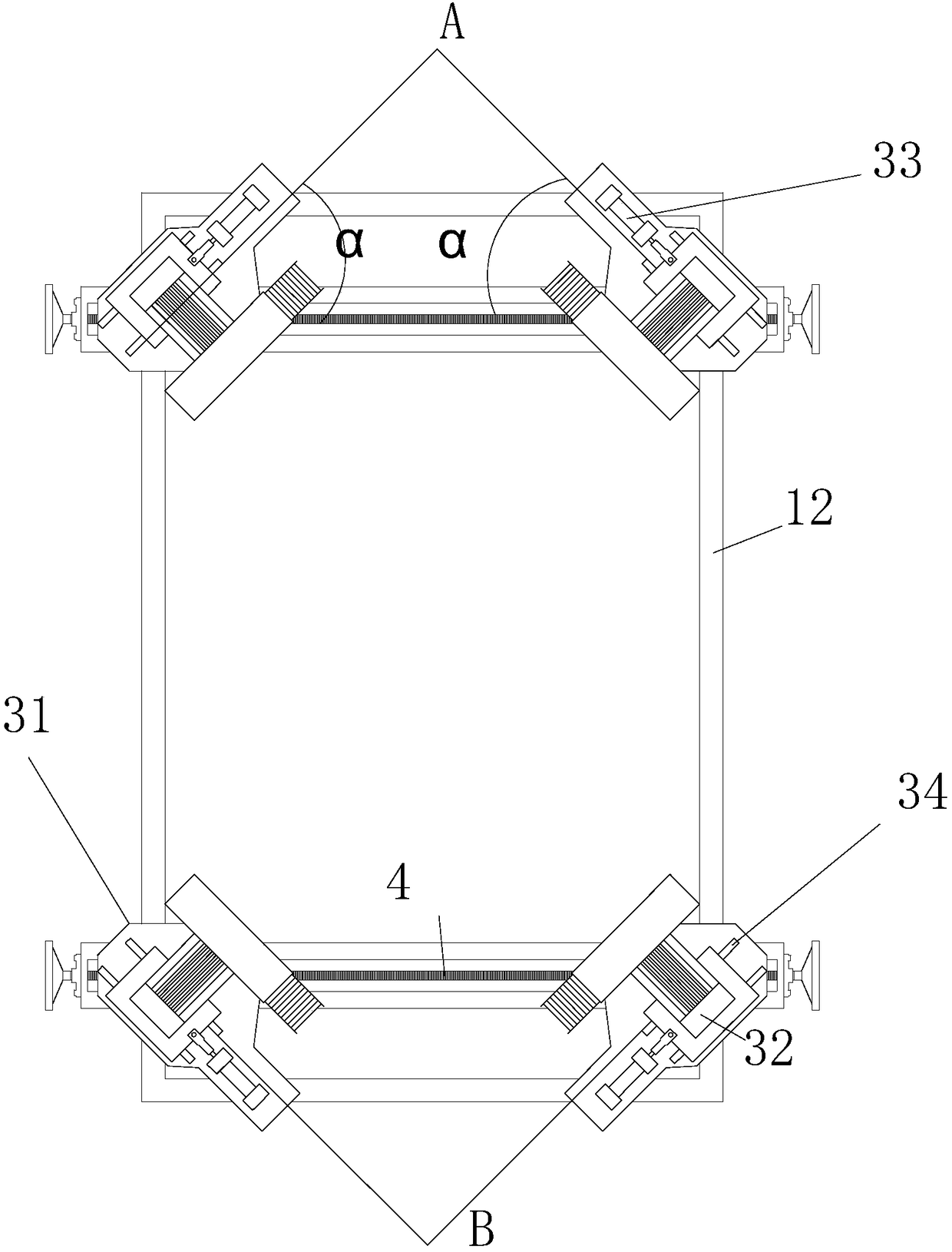

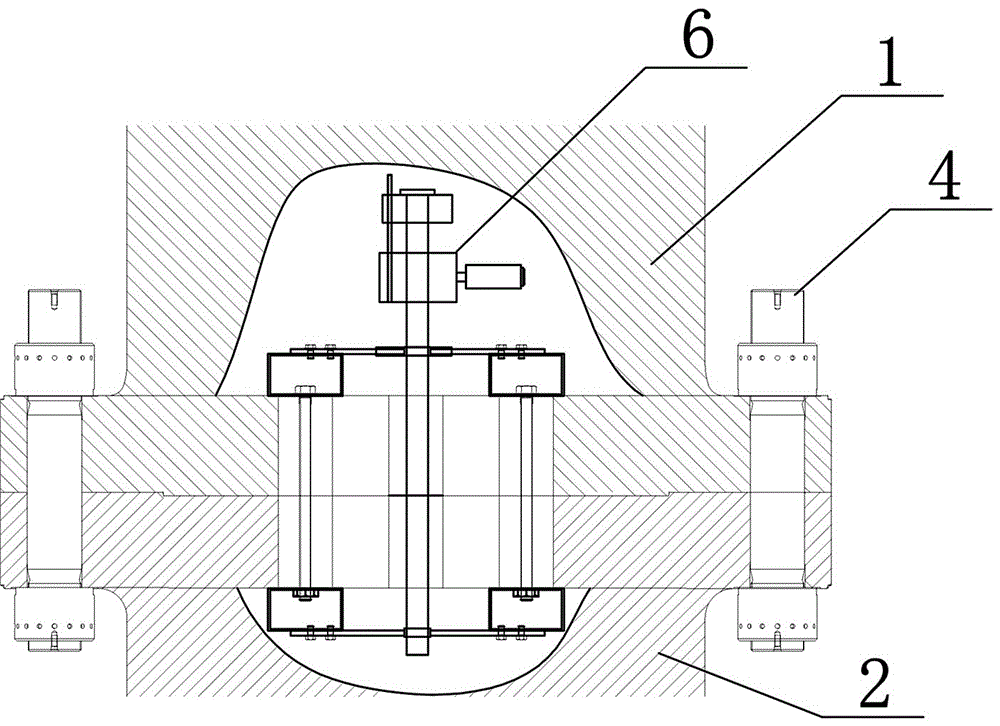

Cylindrical cabin section flexible docking device control system and method

ActiveCN105629944ASolve the labor-intensiveReduce power consumptionTotal factory controlProgramme total factory controlControl systemSimulation

The invention discloses a cylindrical cabin section flexible docking device control system and method. The method comprises the following steps: to begin with, determining cylindrical cabin flexible docking assembling process model, configuring assembly parameter, and carrying out self-detection and initialization to enable each assembly mechanism to move to a preset position; placing a first cabin section on a static bench support ring frame; placing a cabin section to be assembled on a movable bench support ring frame; starting an automatic alignment device, and adjusting pose of the cabin section to be assembled on a movable bench to enable the cabin section to be assembled and the assembled cabin section on a static bench to reach a preassembly state; observing whether the cabin sections are convenient to assemble, and if not, carrying out fine tuning manually until the cabin sections are convenient to assemble; carrying out flexible docking assembling; dragging the docking-assembling-finished part by a cabin traction motor to move along the cabin axial direction to the static bench; and judging whether all cabin sections finish assembling. The cylindrical cabin section flexible docking device control system and method solve the problems that in the existing assembling process, labor intensity of workers is large, automation degree of equipment is low and assembly is done fully depending on experience of the workers, and realize flexible tool automation.

Owner:XIDIAN UNIV

Coilia ectenes step type breeding method

ActiveCN104472412ASolve the shortageSolve the labor-intensiveClimate change adaptationPisciculture and aquariaYolkFresh water organism

A coilia ectenes step type breeding method comprises the nine steps of reserved parent pool simulated ecological cultivation, parent pool intensive culture, parent selection for induced spawning, parent induced spawning, natural insemination, germ cell collection, germ cell incubation, indoor intensive fry rearing in a cement pool and large-scale fry culture in an outdoor pool. The method is characterized in that filial-generation coilia ectenes adult fishes which are more than 2 years old and cultured by manpower are used as reserved parents for artificial propagation, and a natural ecology cultivation mode is simulated; the selected parents are transported and placed in an induced spawning pool, after parent induced spawning is conducted, the germ cells are collected, counted and transferred to an incubation pool, after the germ cells are collected, the germ cells are placed in the incubation pool with water, fries open the mouths 5-6 days after membrane rupture is conducted, yolks and freshwater rotifers which are filtered through a 80-mesh silk net are fed to the fries, after the fries are cultivated for 15 days, the fries are divided to different pools, and when the fries are as long as 20-30 mm, the fries are placed to outdoor pools to be cultivated.

Owner:上海市水产研究所(上海市水产技术推广站)

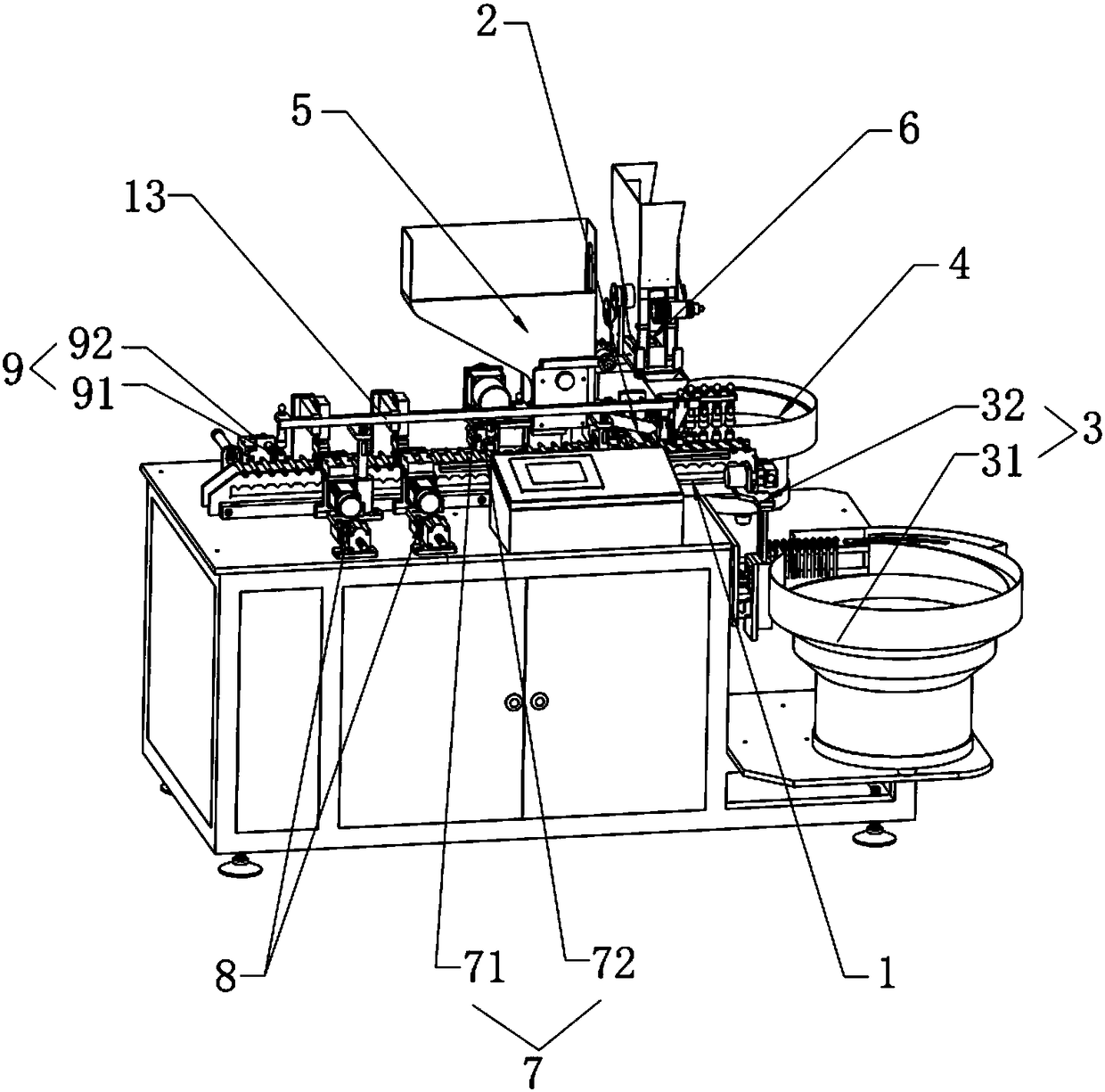

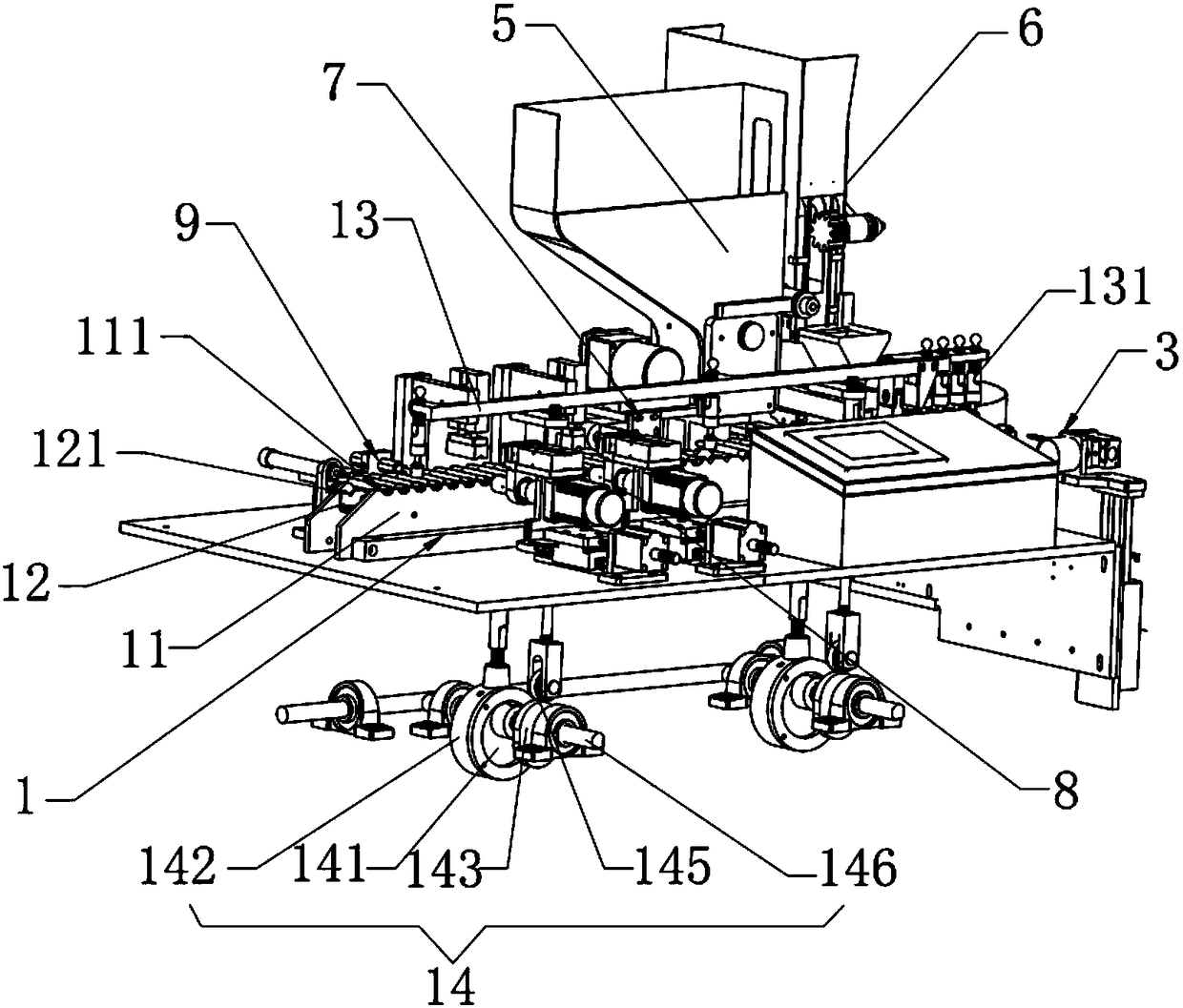

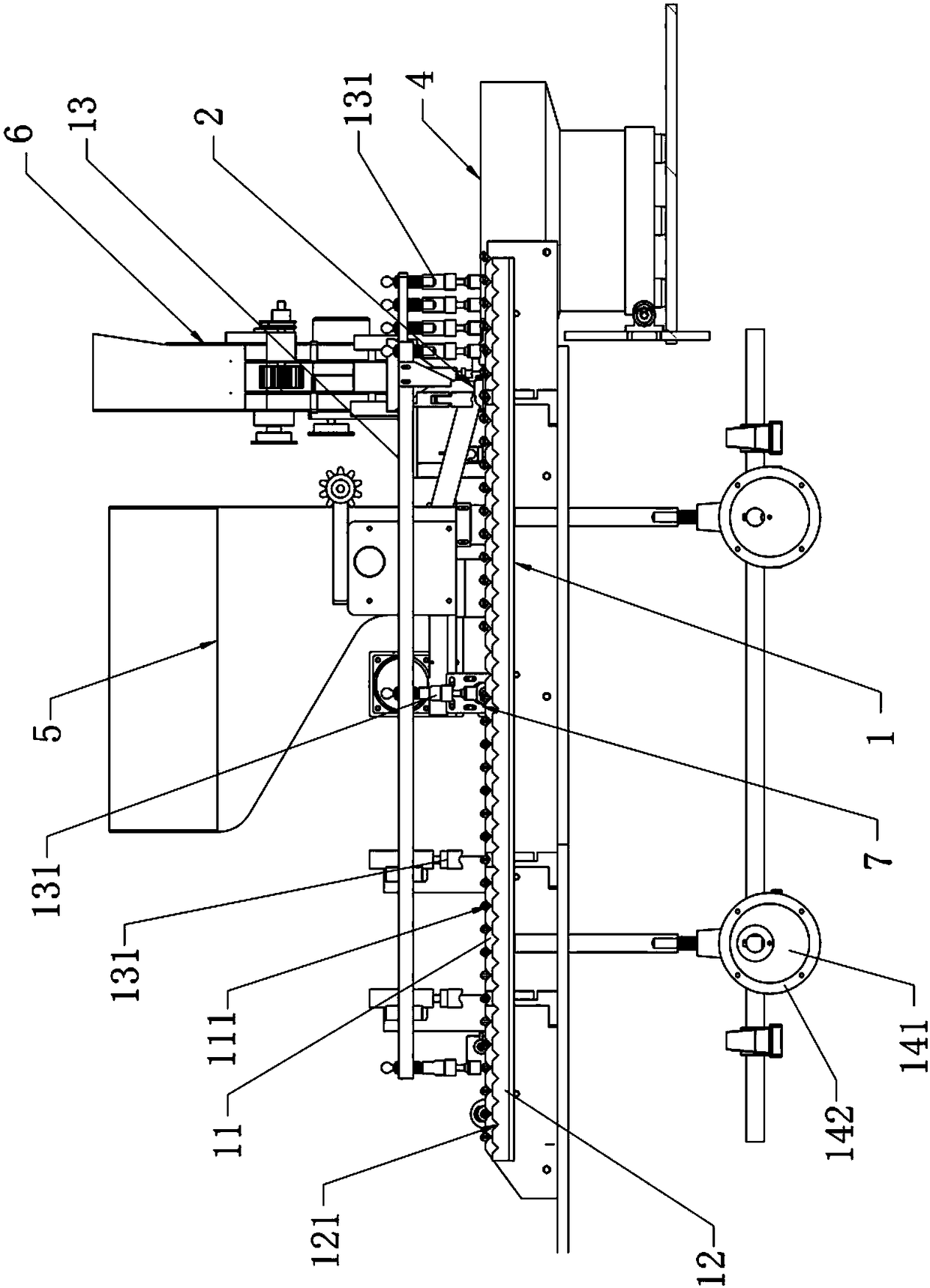

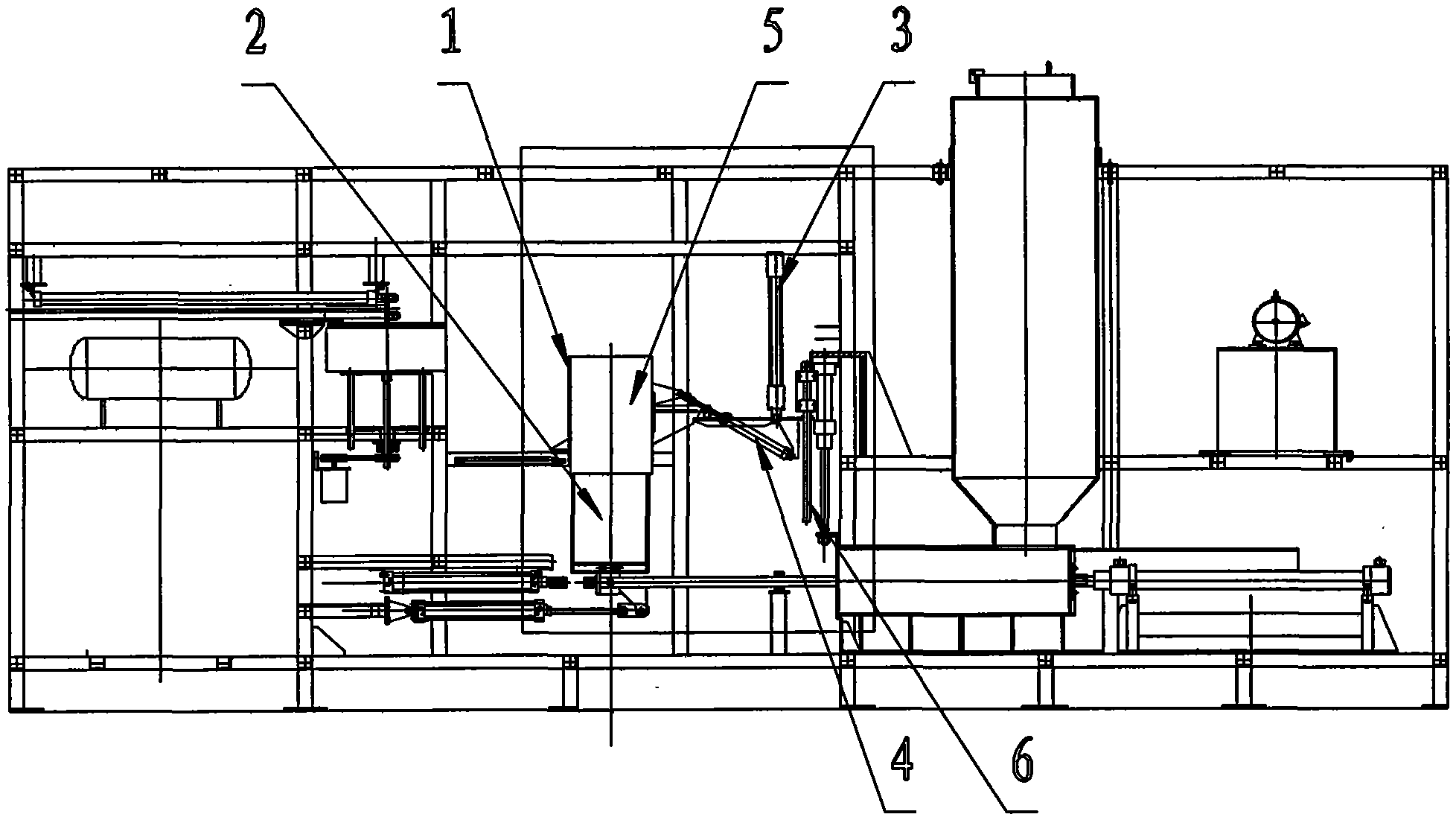

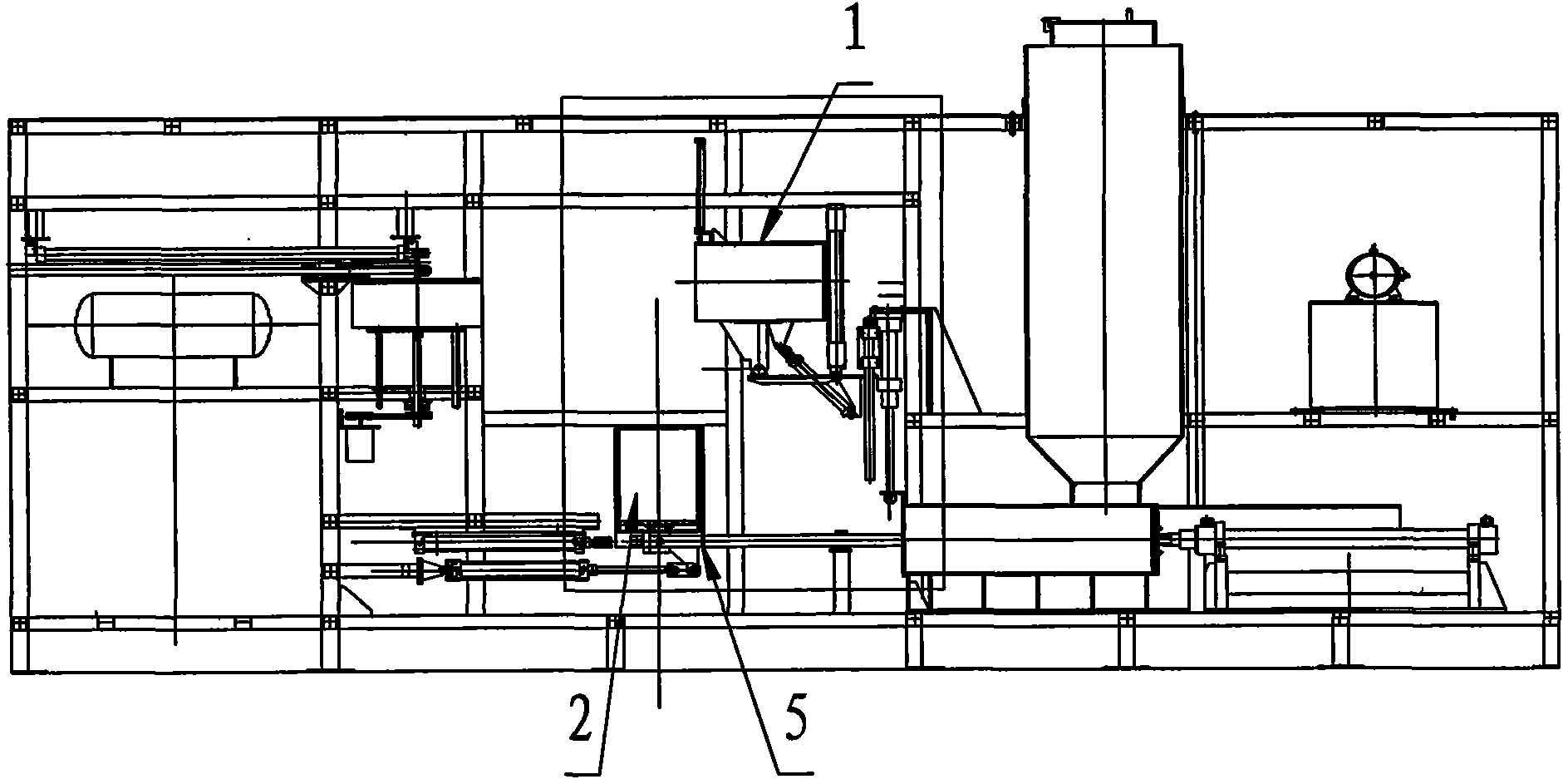

Automatic drilling and milling machine for chain connecting pin shaft

InactiveCN103921121AAchieving installation design complex issuesSolve the labor-intensiveOther manufacturing equipments/toolsMetal working apparatusEngineeringCam

An automatic drilling and milling machine for a chain connecting pin shaft is mounted on a rack table face, the automatic drilling and milling machine comprises a vibration disc, a feeding guide rail, an air cylinder, clamping jigs, a flat table milling mechanism, a central hole drilling mechanism, a small hole drilling mechanism, a chamfering mechanism, an octagonal eight-station rotating disc, a precise cam indexer, an electric motor and an automatic drilling and milling machine body support. The octagonal eight-station rotating disc is arranged on the front side of the automatic drilling and milling machine body support, the precise cam indexer is arranged behind the octagonal eight-station rotating disc, the electric motor is arranged on the rear side of the automatic drilling and milling machine body support, the electric motor is provided with a compressed air flow divider, the vibration disc is arranged on one side of the octagonal eight-station rotating disc, the eight clamping jigs are mounted on the octagonal eight-station rotating disc, the flat table milling mechanism, the central hole drilling mechanism and the small hole drilling mechanism are arranged on the upper side of the octagonal eight-station rotating disc, and the chamfering mechanism is mounted on the front side of the octagonal eight-station rotating disc. According to the technology, the full-automatic production process of part machining is achieved, and production efficiency and product quality are improved greatly.

Owner:肖闯

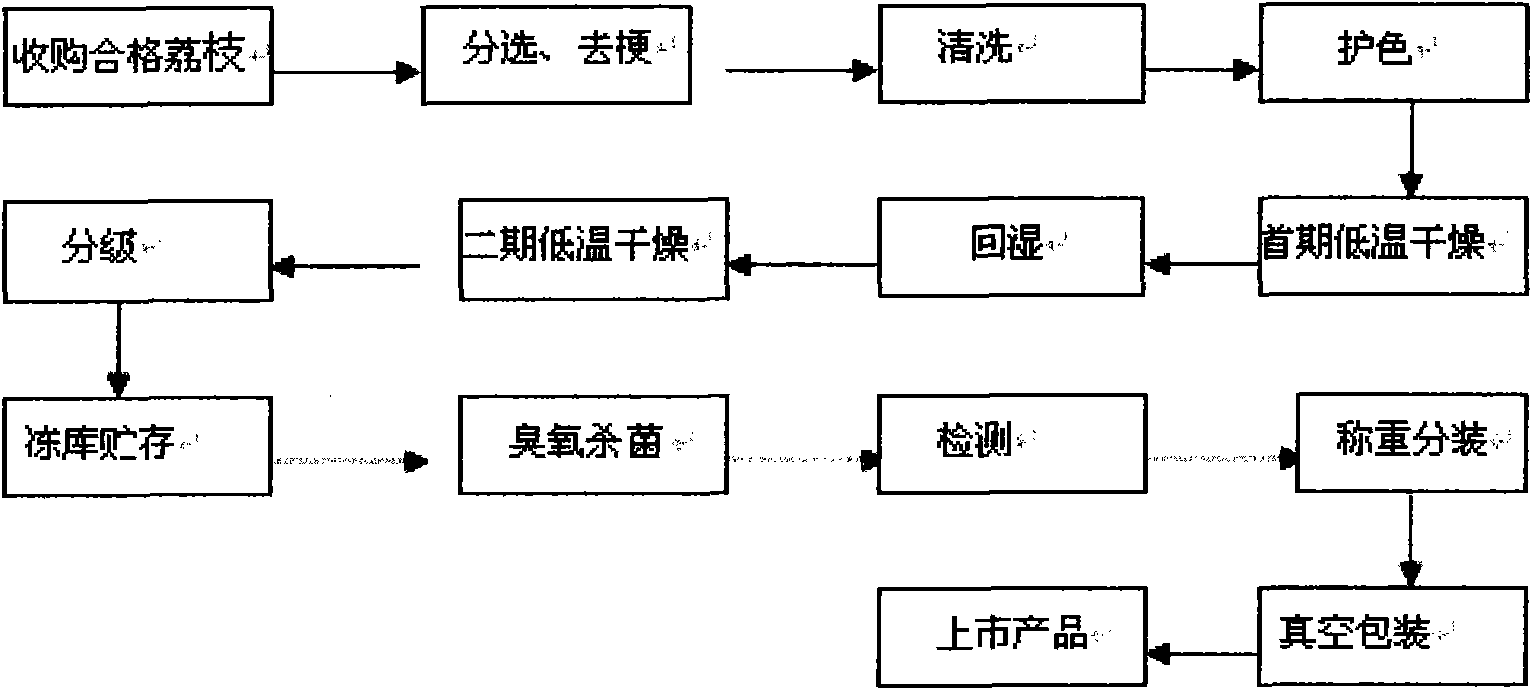

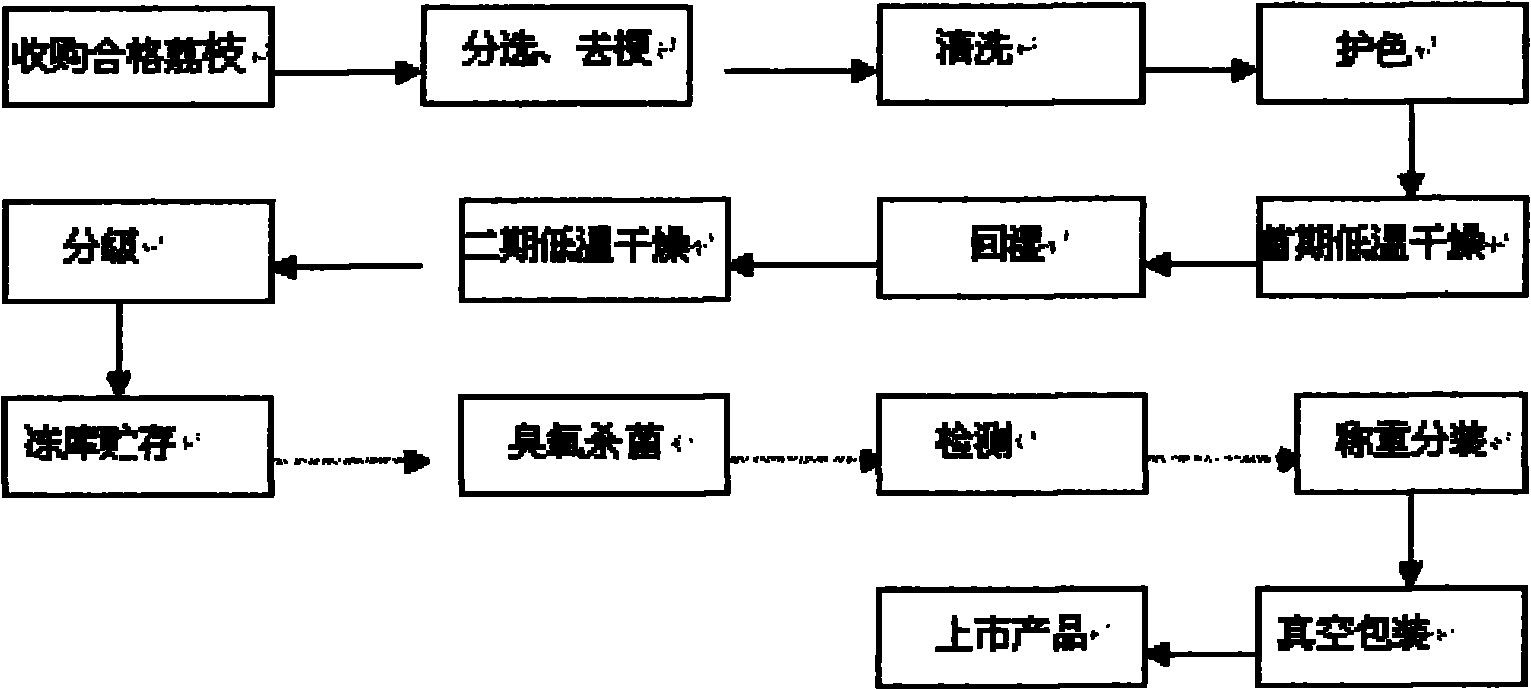

Dried lichees with original color and taste and processing method thereof

InactiveCN102100249APure qualitySolve pollutionFood processingFruits/vegetable preservation by freezing/coolingAdditive ingredientComputer science

The invention relates to dried lichees with original color and taste and a processing method thereof and also relates to a low-temperature dehydration processing technology for the dried lichees. Low-temperature dehumidification is circulated among the lichees forcibly, so that water content is gradually reduced until the lichees are dry, and color, flavor, taste, shape and nutritional ingredients of the original lichees are maintained. The technical scheme overcomes the defects of the conventional technology and solves the problems of poor quality, high cost and environmental pollution in the traditional processing method for the dried lichees in China.

Owner:HUIZHOU SIJIXIAN GREEN FOOD

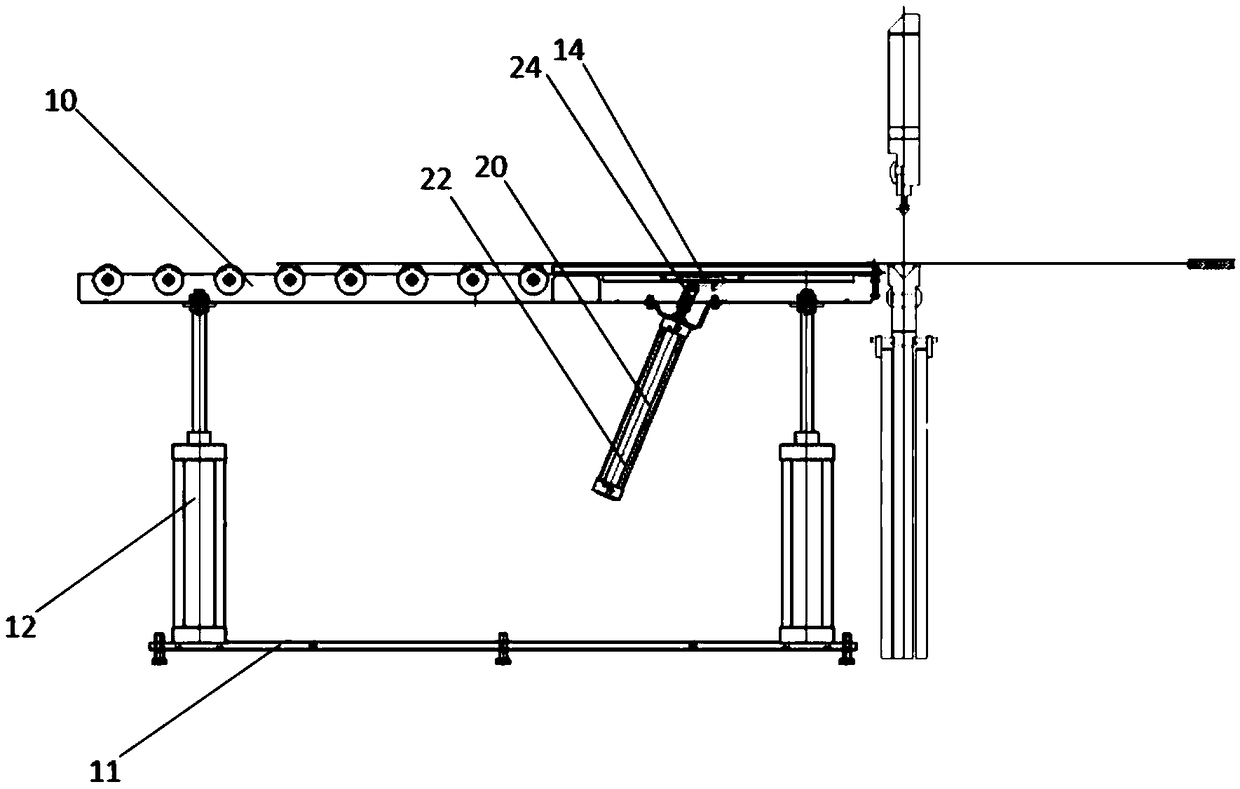

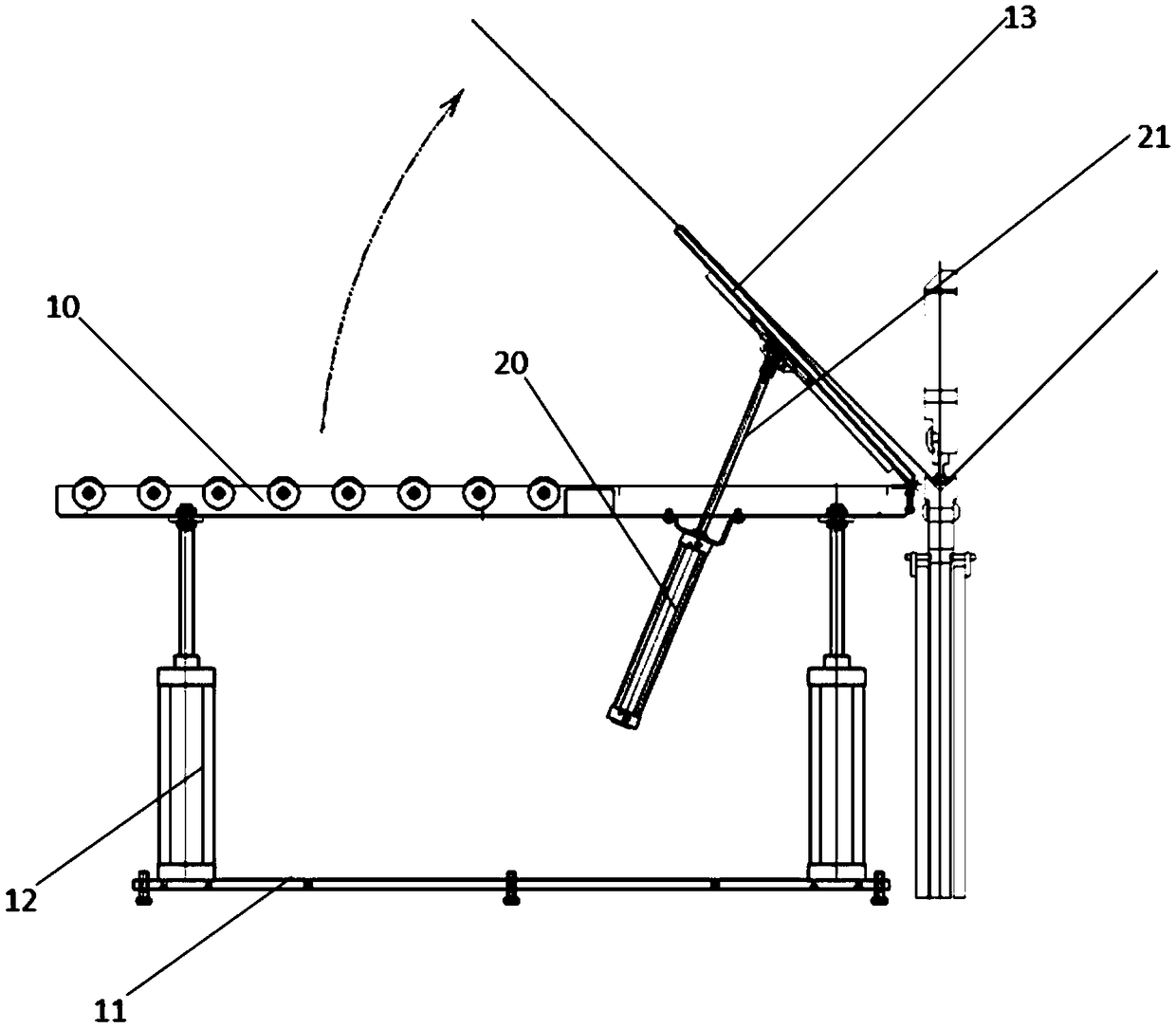

Follow-up supporting device, upward moving type bender and plate bending method

PendingCN108856382AImprove bending efficiencyReduce work intensitySolenoid valveUltimate tensile strength

The invention discloses a follow-up supporting device, an upward moving type bender and a plate bending method. The follow-up supporting device comprises a lifting table, wherein the lifting table isrotatably connected with a lifting flip; the lifting table is fixedly connected with a push rod device; the push rod device is provided with a push rod; the push rod pushes the lifting flip to rotate;and the push rod slides on the side surface, which faces the push rod, of the lifting flip. The upward moving type bender comprises an upper sliding block, a bending upper mold and a bending lower mold, the bending upper mold and the bending lower mold are arranged oppositely, the upper sliding block is fixedly connected with the bending upper mold, a follow-up supporting device is arranged in the feeding direction of the bending upper mold and the bending lower mold, a sensor is arranged on the side surface, which faces away from the push rod, of the lifting flip; the sensor is used for detecting whether a plate begins to be bent or not, the push rod device is provided with a solenoid valve, the solenoid valve drives the push rod to push the lifting flip to rotate when the sensor detectsthat the plate begins to be bent, the work intensity of an operator when a large plate is bent by the bender is relieved, and the plate bending efficiency is improved.

Owner:大连小松雄连机械制造有限公司

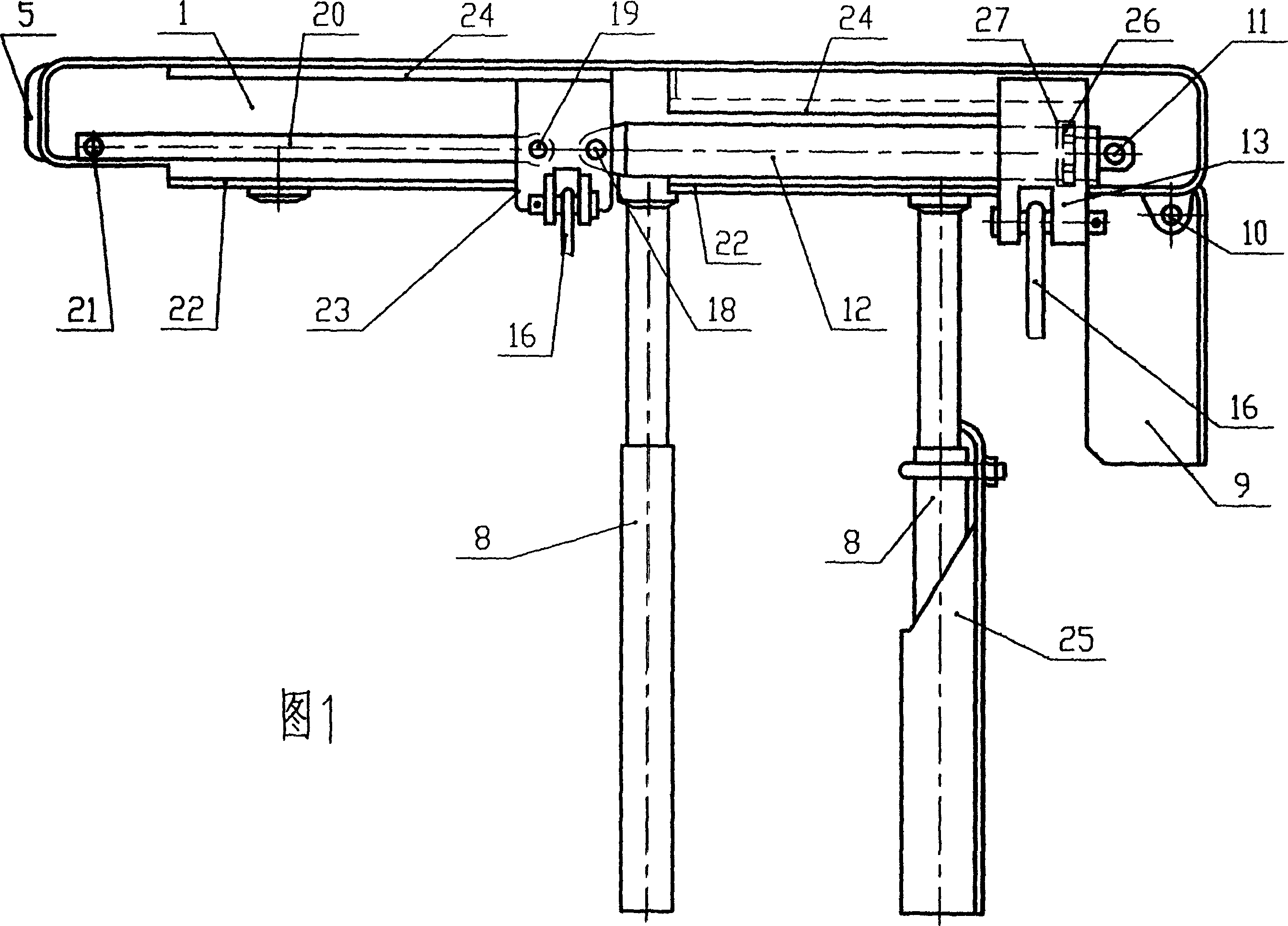

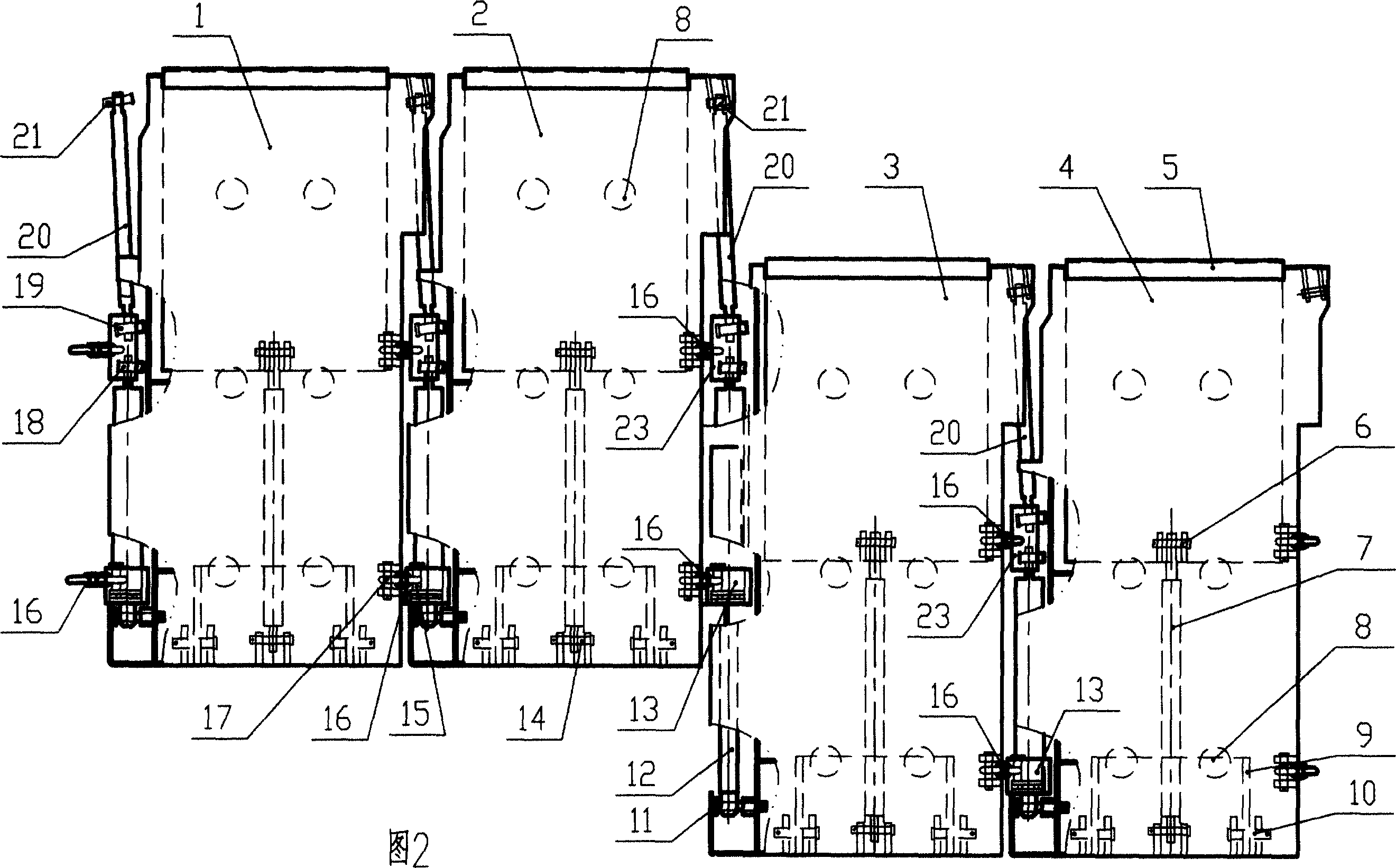

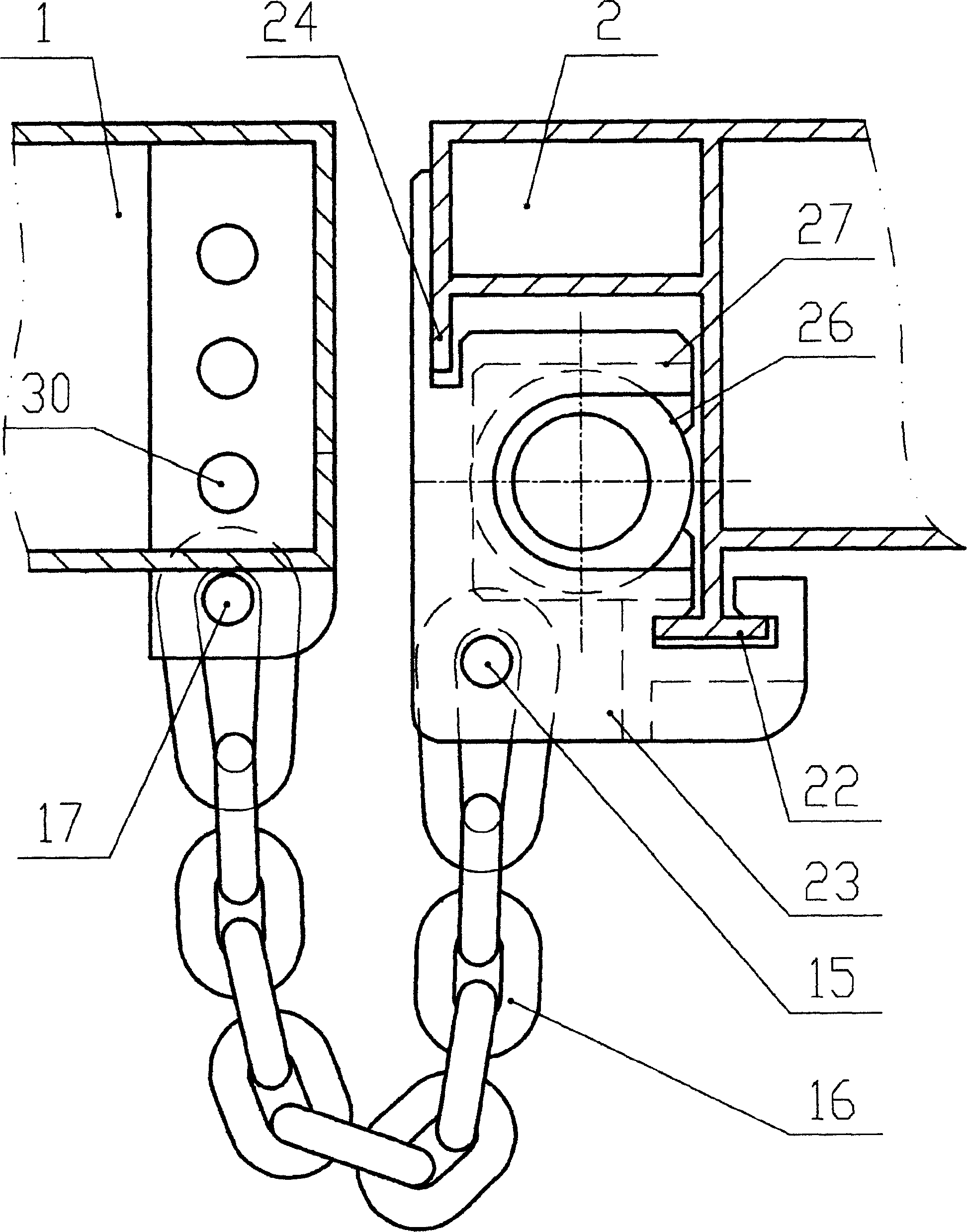

Chain suspension type hydraulic support

ActiveCN1865661ASolve the labor-intensiveEffort-saving moving frameProps/chocksStructural engineeringEngineering

The invention relates to a chain suspension hydraulic support for supporting the top plate of working surface under the coal well. Wherein, it comprises an integrated top beam 1, a hydraulic support post 8 downward vertical to the top beam 1, a forward beam and forward beam cylinder 5, an upper baffle device 9 hinged at the back of top beam 1, and a lower baffle device 25 connected with the back hydraulic support post 8. The invention is characterized in that; it can slide along the side edge of top beam 1 and is connected to at least one flexible element as chain or steel line of the slide elements 13 and 23 that connected with moving cylinder; another end of said flexible element is connected to nearby hydraulic support; the inventive chain suspension hydraulic support can be arranged in one transverse row, while moving it, using flexible element 16 to suspend the discharge support, to move it pushed by moving cylinder 12; and via controlling the flexibility of moving cylinder 12, said support can be moved with lower force.

Owner:李泽宇

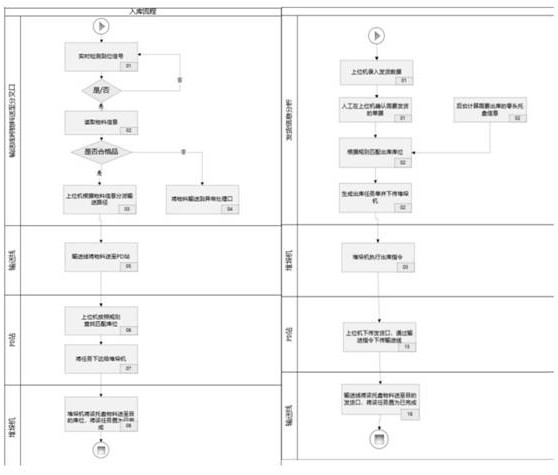

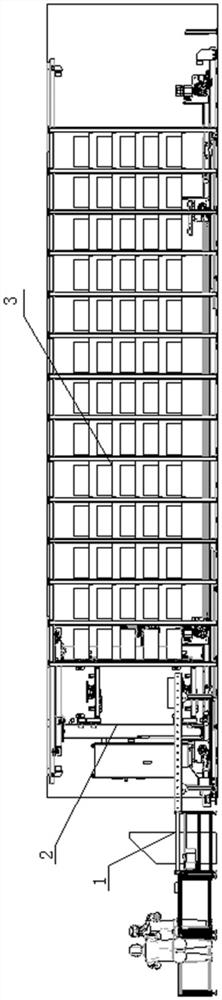

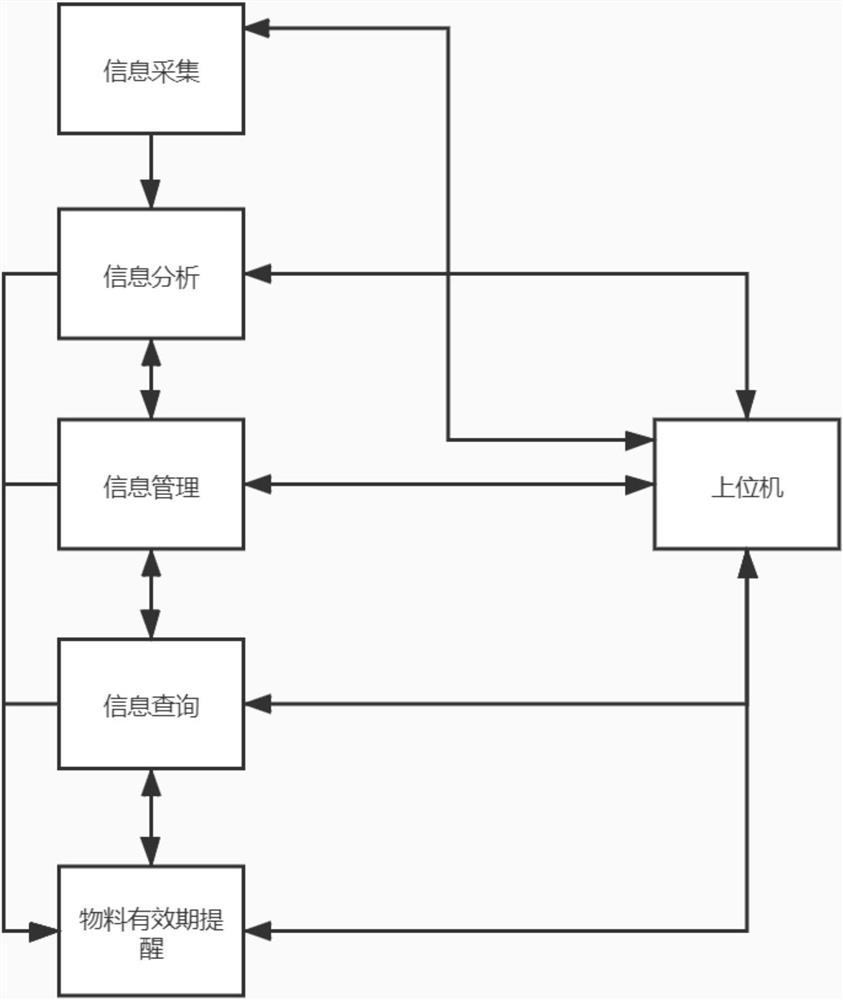

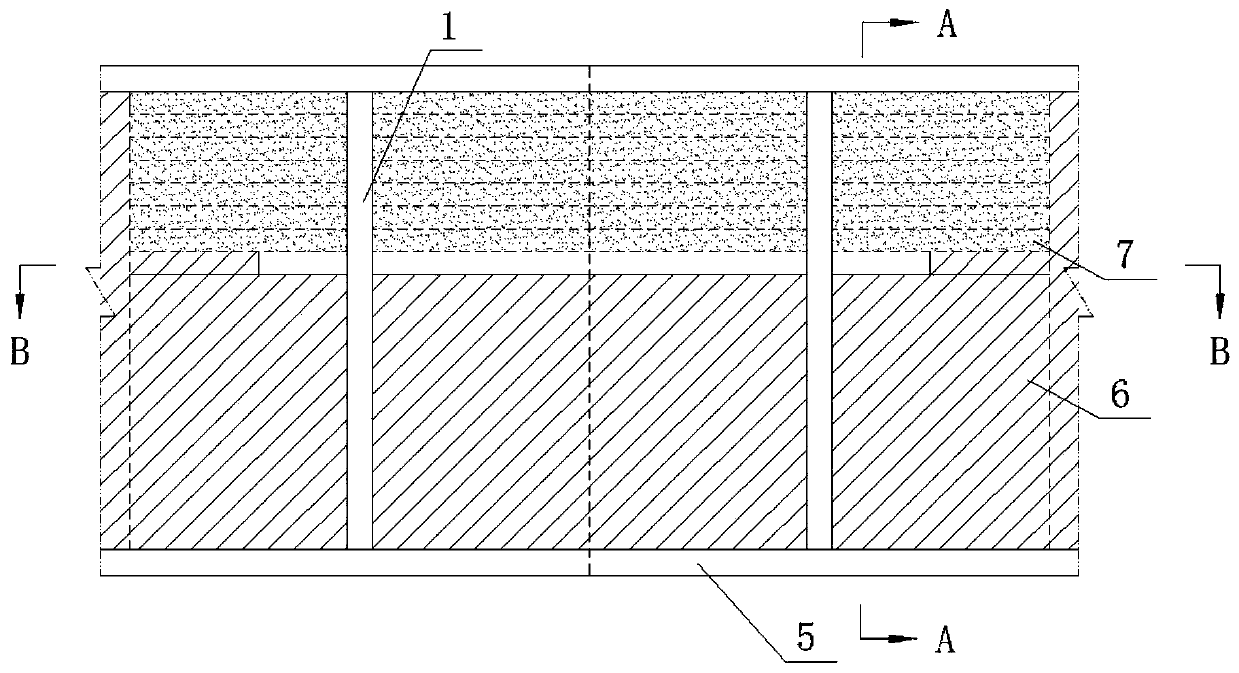

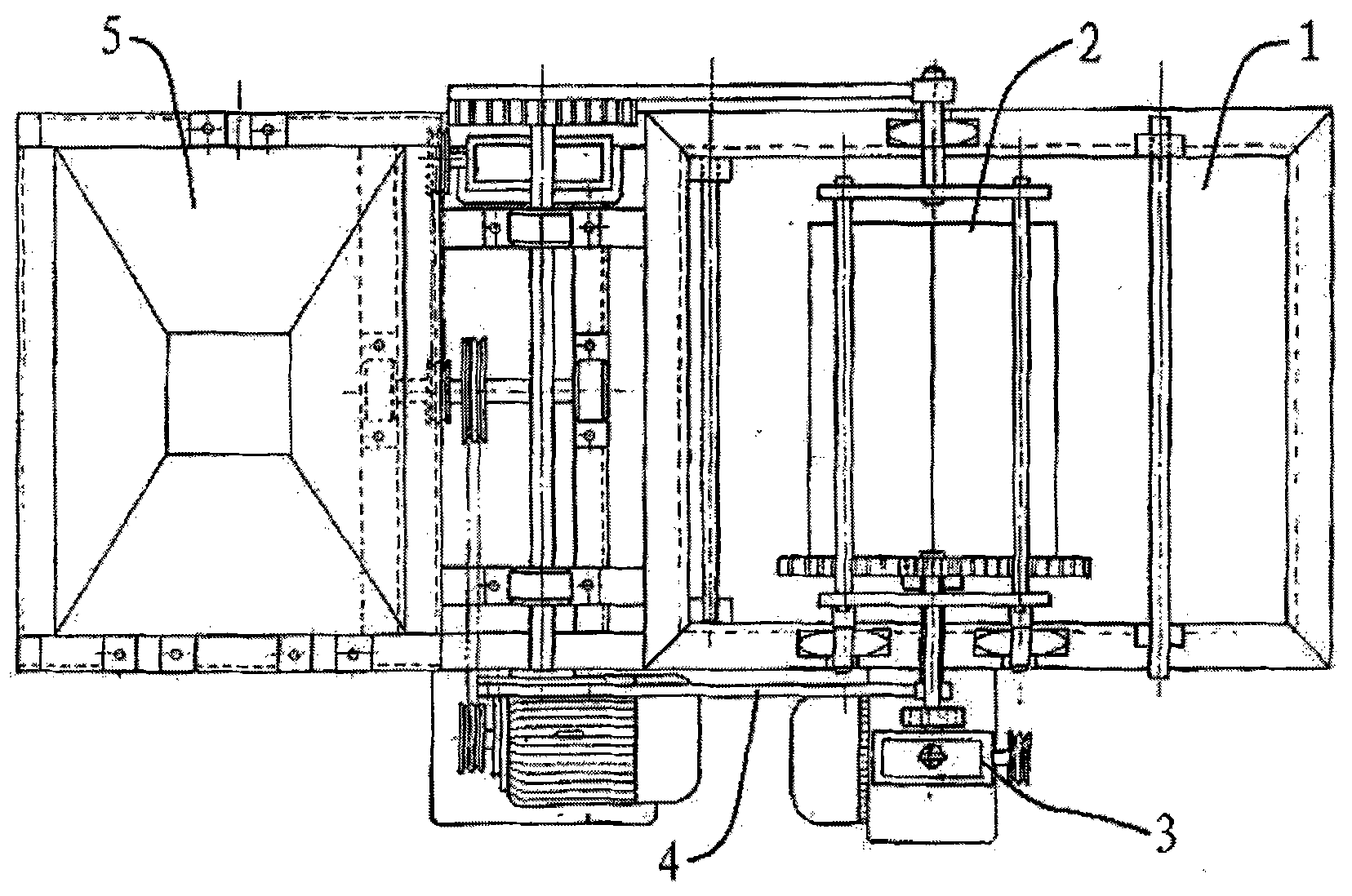

Material warehouse-in and warehouse-out device and system thereof

InactiveCN112249574ASolve the labor-intensiveReduce backlogStorage devicesSoftware systemControl system

The invention discloses a material warehouse-in and warehouse-out device which comprises a conveying line, a transfer device and a roadway stacking machine, the conveying line, the transfer device andthe stacking machine are all connected with an upper computer through a PLC and a network server, and a WMS-based material warehouse-in and warehouse-out system and a WCS control system are arrangedin the upper computer. The material warehouse-in and warehouse-out device and the material warehouse-in and warehouse-out system therein are used for carrying out material warehouse-in, inventory andwarehouse-out work, all products and equipment are connected with product storage labels in series through a software system, the whole warehouse-in and warehouse-out process is digitized and displayed through the software system, the warehouse-in and warehouse-out conditions of materials or cargos in a storage workshop are reflected in detail, the materials or the cargos are sequentially discharged according to the length of storage time, the problem of material or cargo overstock caused by long-term storage is reduced, the materials are evenly distributed at different warehouse positions ina warehouse through storage scheduling of inventory commodities, and multiple warehouse positions can work at the same time during warehouse-out working. The production efficiency is improved, and product tracing is facilitated.

Owner:青岛星华智能装备有限公司

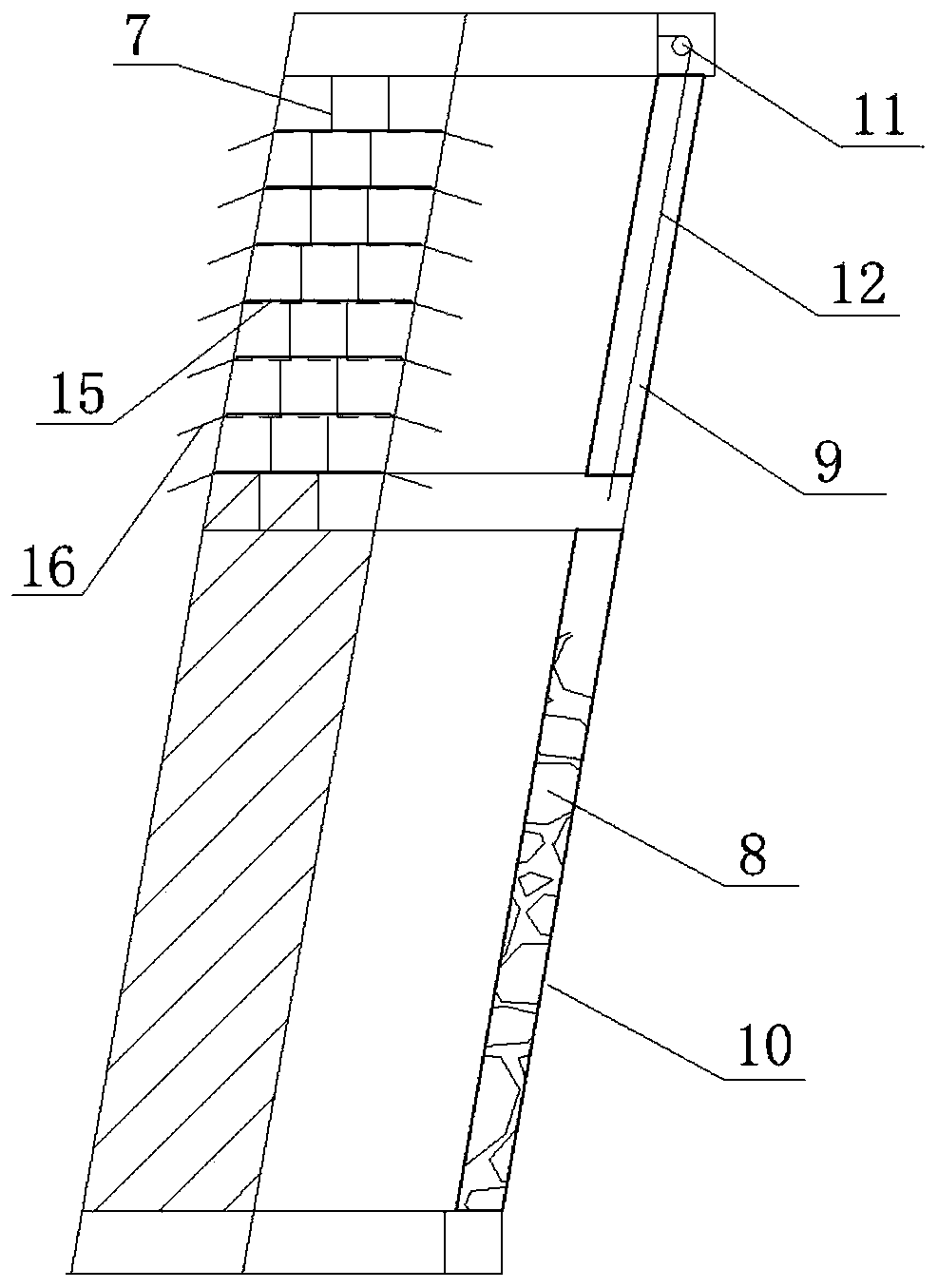

Combined downward mechanized filling mining method used for steeply inclined and extremely broken ore vein

ActiveCN111255459AReduce the amount of mining and cuttingReduce mining costsUnderground miningTunnel/mines ventillationMining engineeringSlag

The invention discloses a combined downward mechanized filling mining method used for a steeply inclined and extremely broken ore vein. According to the combined downward mechanized filling mining method used for the steeply inclined and extremely broken ore vein, the downward drift filling mining method is adopted, stopes are arranged along the ore body trend, a plurality of routes are divided, each stope is equipped with a extravein raise, pedestrian ventilation and ore pass are realized through the extravein raise, a layered connection road is constructed to the ore body from the extraveinraise, a stope layered connection road is continuously constructed in the ore body, a connection access is constructed from the stope layered connection road to a connected stope, because of the smallwork amount of mining and cutting work, the two stopes can be combined into one stope for stopping, so that the stopping efficiency is improved, the mining cost is saved, mechanized ore removal is carried out through a minitype slag raking machine + self powered electric tipper or a sliding type loader, personnel does not be requires to enter the connection road, the mechanization degree is high,the safety is high, the mining and cutting work amount do not be increased, because the method do not need large cross-section when working, and the method can not only solve the problem of large quantities of the mining and cutting work amount caused by high mechanization, but also solve the problem of high labor intensity caused by low mechanization.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

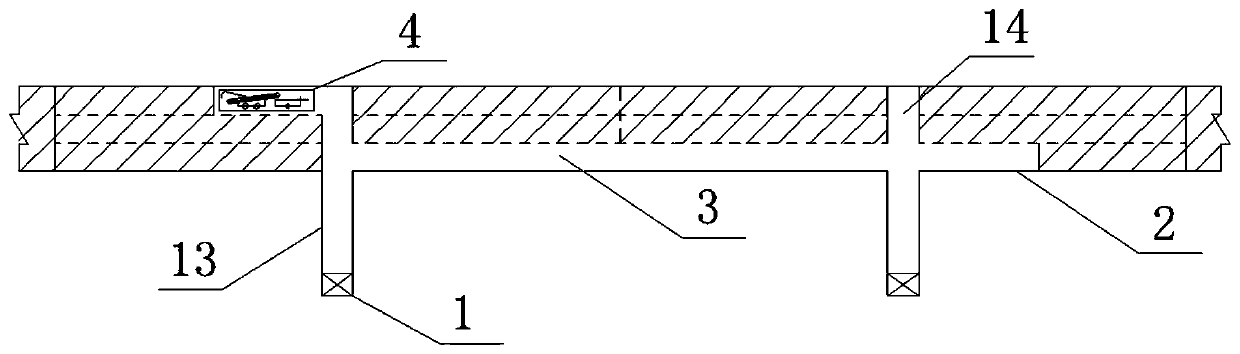

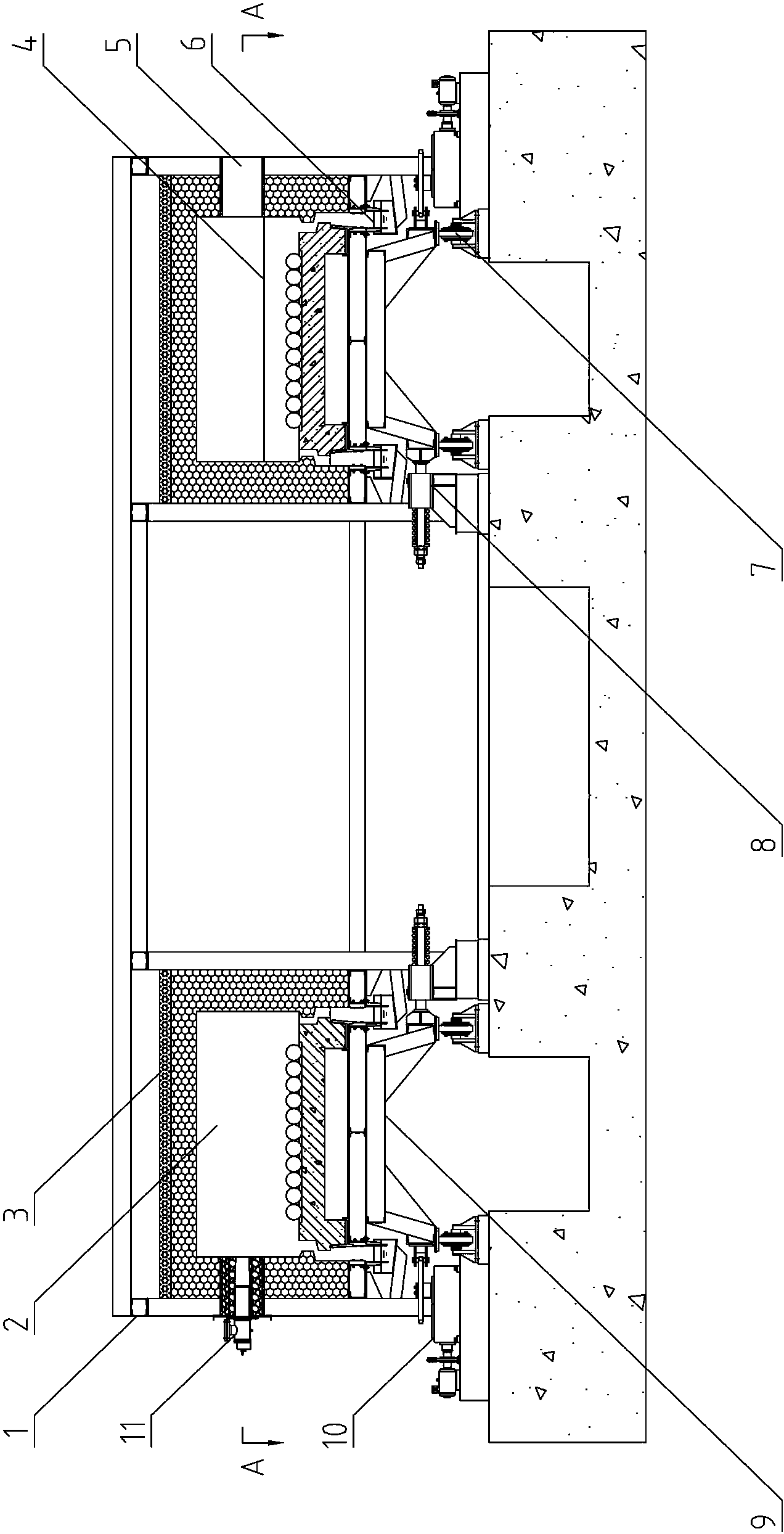

Annular heating furnace with rotary furnace bottom

InactiveCN103773922AImprove heating qualitySolve the labor-intensiveFurnace typesCombustorHigh energy

The invention relates to an improvement of a wear resistant steel ball heat treatment heating furnace, and concretely relates to an annular heating furnace with a rotary furnace bottom. The annular heating furnace is provided with a furnace body, feeding and discharging ports, combustors, a maintenance furnace gate and a smoke outlet; and the bottom of the furnace body is respectively provided with a rotary driving mechanism, a lateral positioning mechanism and a support raceway; a hearth has an annular structure, the bottom of the hearth is a water seal tank provided with a furnace bottom, and the furnace bottom is composed of a heat insulation panel, a skirt rim sealing plate, a structural support, a tooth ring, an annular rail surface and a baffle ring. The problems of large labor intensity of an operator, low work efficiency, large hidden safety trouble, unstable heating quality and high energy consumption per unit output of present wear resistant steel ball quenching treatment heating furnace with inclined-bottom hearths are solved, and present wear resistant steel ball heat treatment heating furnaces are mainly improved in the invention.

Owner:湖北中冶窑炉有限公司

Full-automatic ghee boxing equipment

Owner:秦皇岛视听机械研究所有限公司

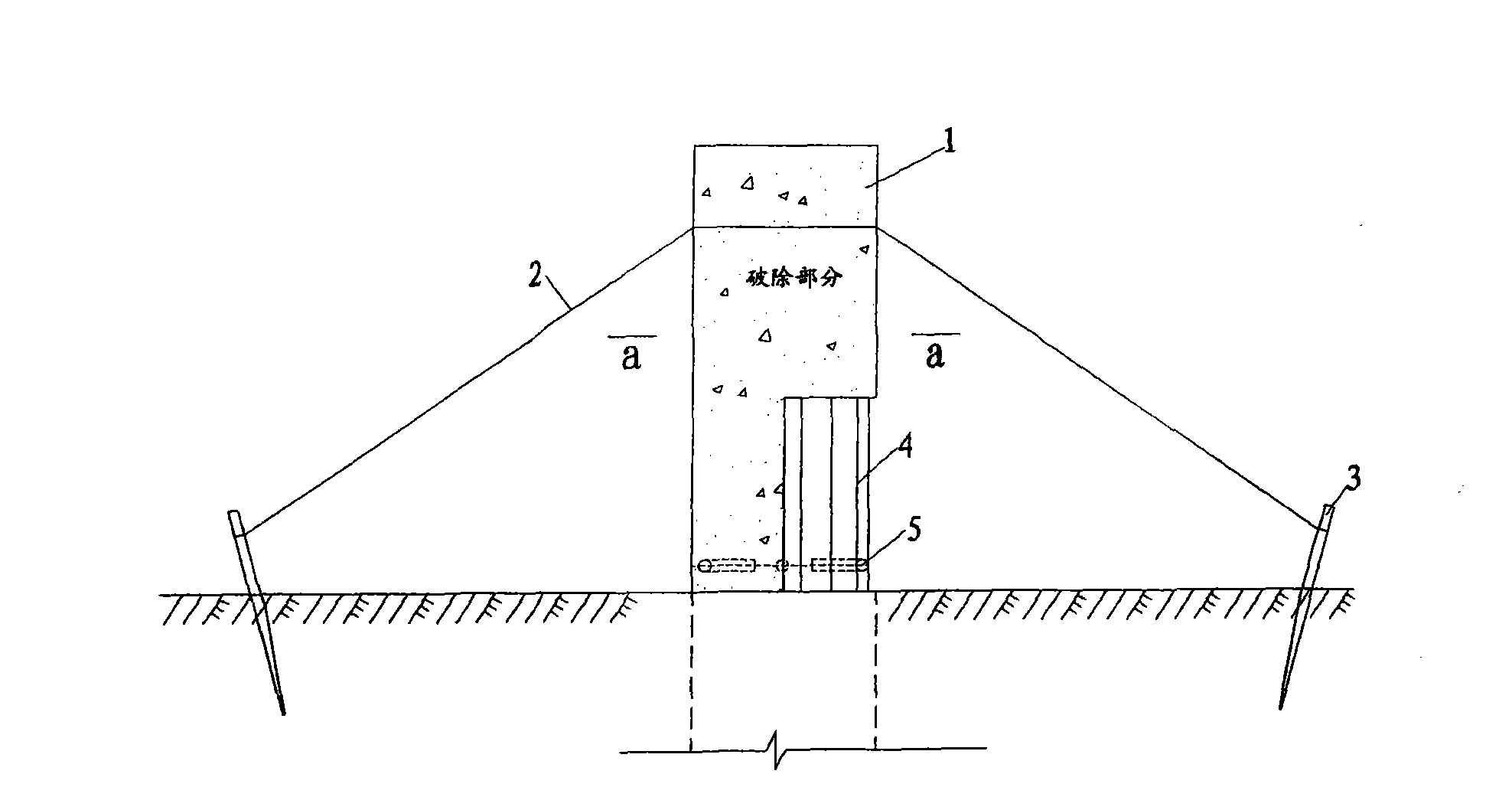

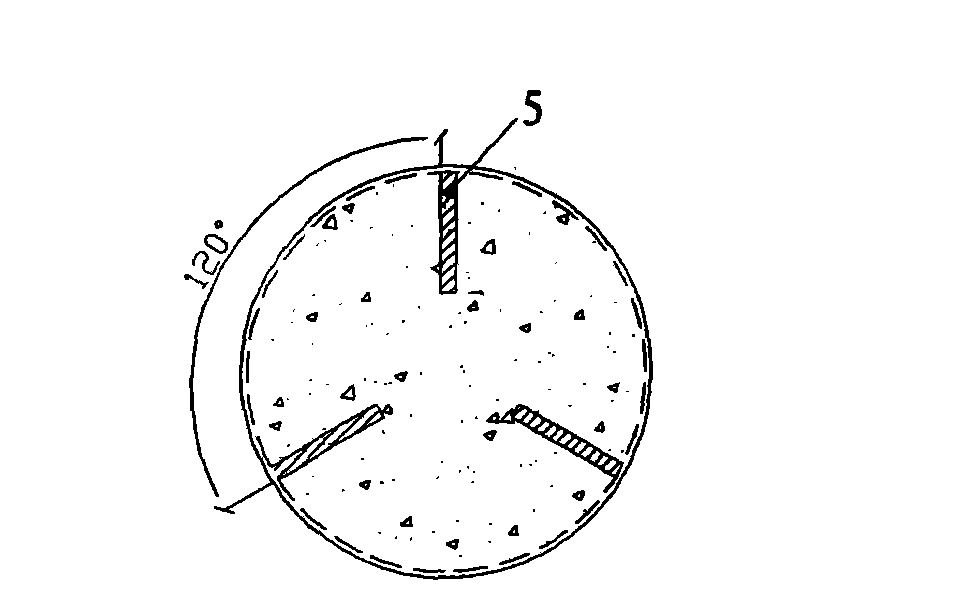

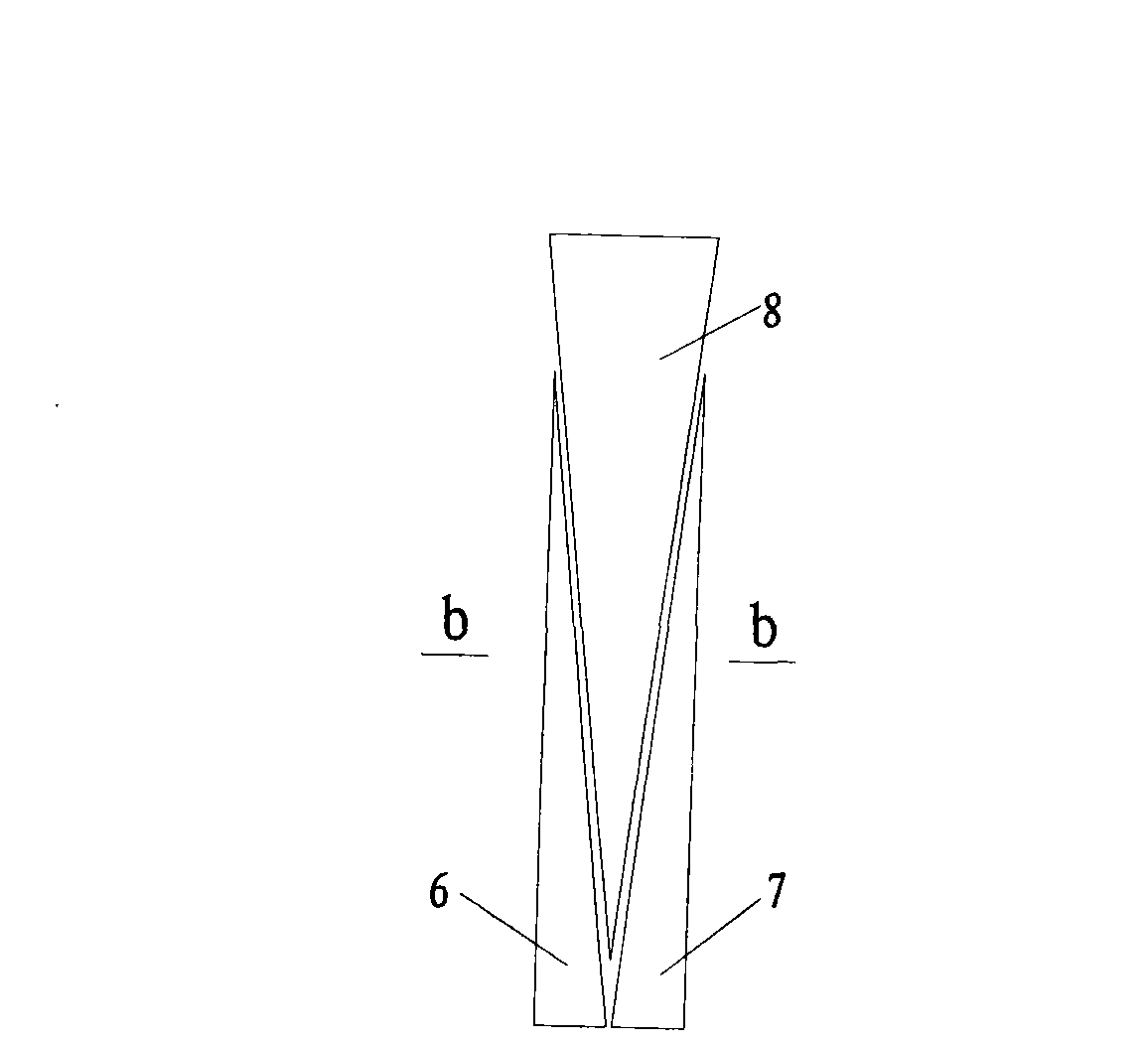

Method for demolishing ultra high cast-in-place pile head

The invention relates to a method for demolishing an ultra high cast-in-place pile head. Operation steps include excavating an ultra cast-in-place pile head after pile driving construction is completed, measuring drawn lines to determine the part to be demolished, binding pile block and fixing a hemp rope, chiselling pile longitudinal reinforcement cover, cutting off longitudinal steel and spiral stirrup, demolishing a pile hole, inserting a combination steel wedge side block in to the hole, inserting a combination steel wedge intermediate block into the middle of the steel wedge side block and driving the intermediate block into the steel wedge side block forcibly and gradually, the ultra high pile head is broken under extrusion force, and the pile head is pulled down by part of the fixed hemp rope. The invention is simple and convenient in procedure, practical in operation and low in labour intensity when being applied, construction speed is fast, construction is safe, cost is low, and the pile top surface of the demolished ultra high pile head is flat. The invention is successfully applied to construction of demolishing ultra high pile head of new 2# blast furnace overhaul modification work foundation of Wuhan Iron and Steel Corporation and 4# coke oven foundation of Nanjing Meishan Iron and Steel Corporation, wherein the pile is cast-in-place reinforced concrete bored pile.

Owner:MCC SHIJIU CONSTR

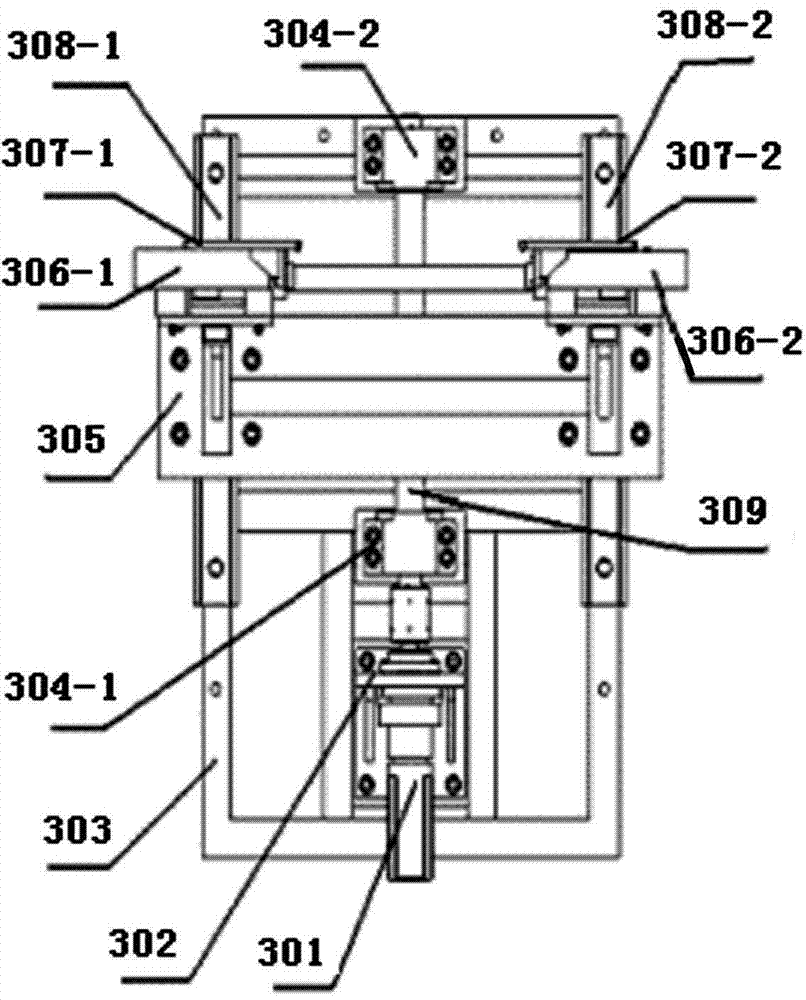

Automatic assembly machine of rotating crayon

PendingCN108237399AFits securely and neatlySolve the labor-intensiveAssembly machinesMetal working apparatusEngineeringAssembly machine

The invention relates to the technical field of automatic equipment, particularly to an automatic assembly machine of a rotating crayon. The automatic assembly machine comprises a rotating crayon assembly conveyer line, a crayon inner sleeve feeding device, a rotating part feeding device, a crayon barrel feeding device, a refill feeding device, an assembly device used for assembling a rotating part, a crayon barrel and a refill to a crayon inner sleeve, an integration device used for integrating all accessories of the rotating crayon, a rotating integration device used for performing rotatingintegration on the rotating crayon, and a refill integration device used for integrating the refill. According to the automatic assembly machine, the structure is simple and compact, a manual assemblymanner is completely replaced, and the entire assembly process of the rotating crayon is automatic, so that the problem that labor intensity of workers is high is solved, and besides, labor cost canbe effectively reduced, and production efficiency is improved; and all the accessories of the rotating crayon are assembled more firmly and neatly through the integration device, the rotating integration device and the refill integration device, and production quality of the rotating crayon is greatly improved.

Owner:东莞市嘉旭机械设备制造有限公司

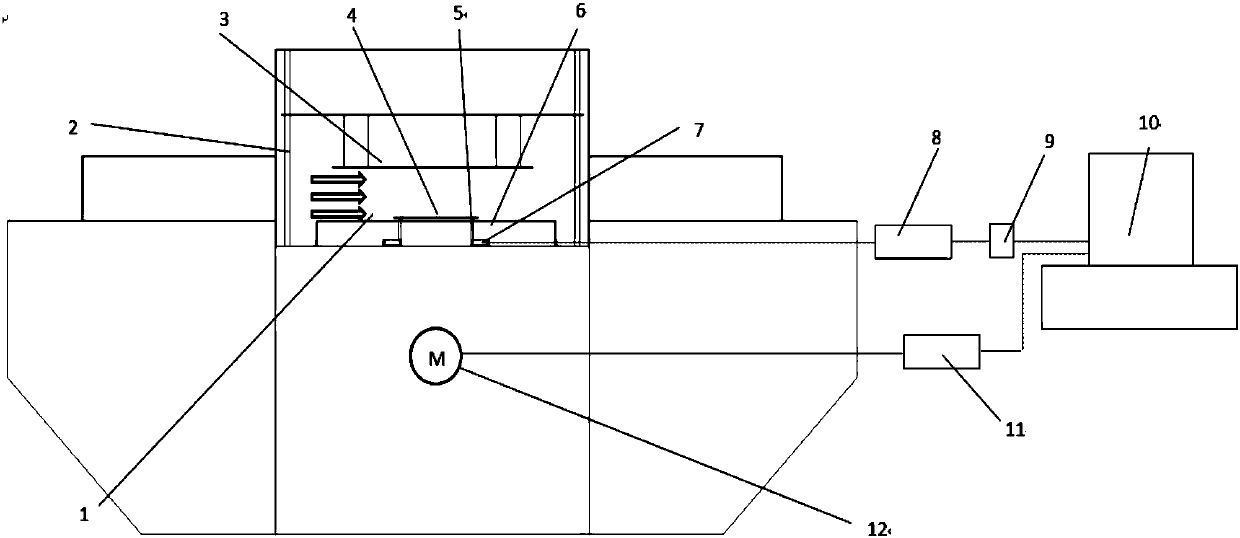

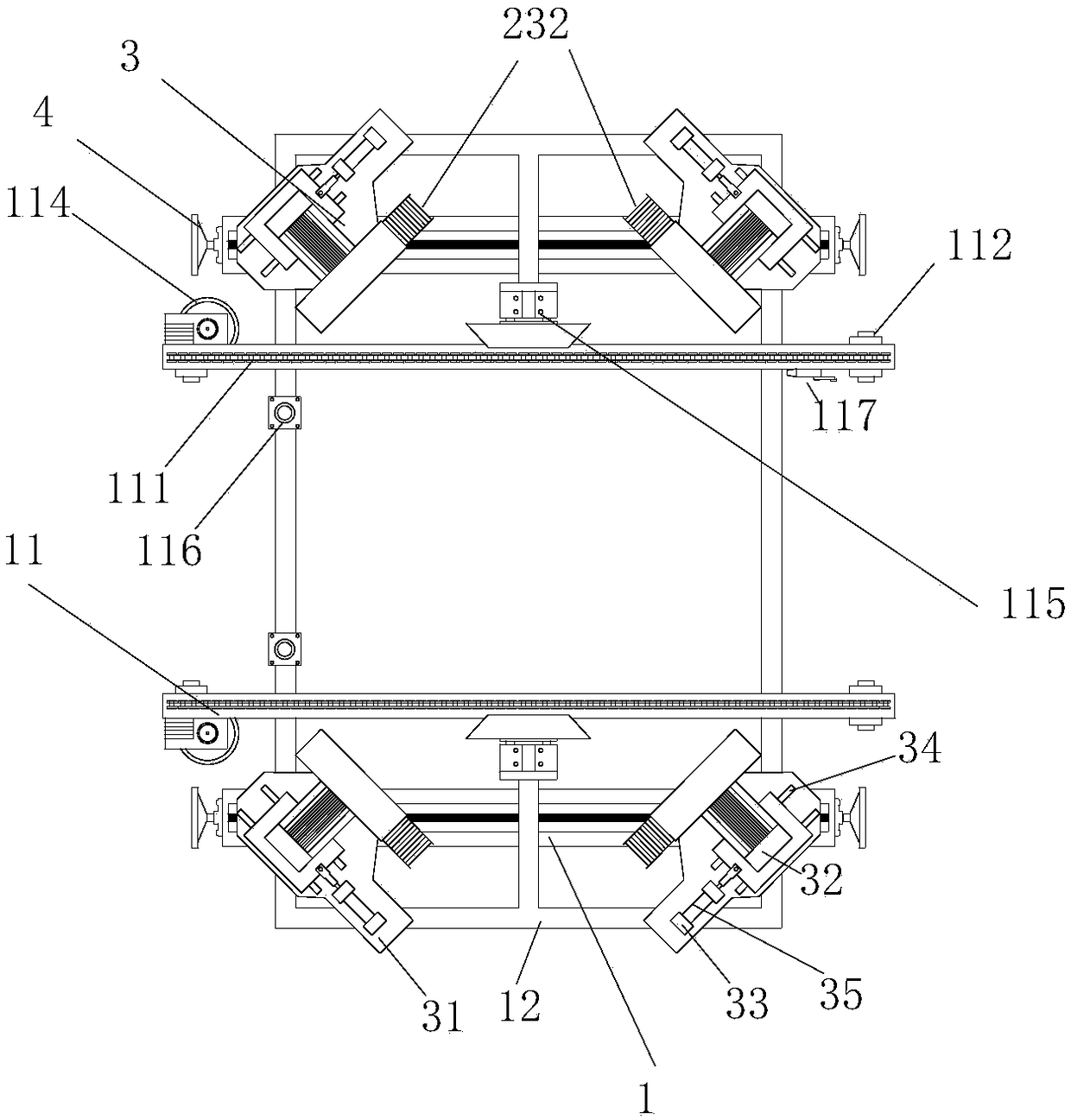

Online weighing control system for radio frequency-hot air combined drying equipment

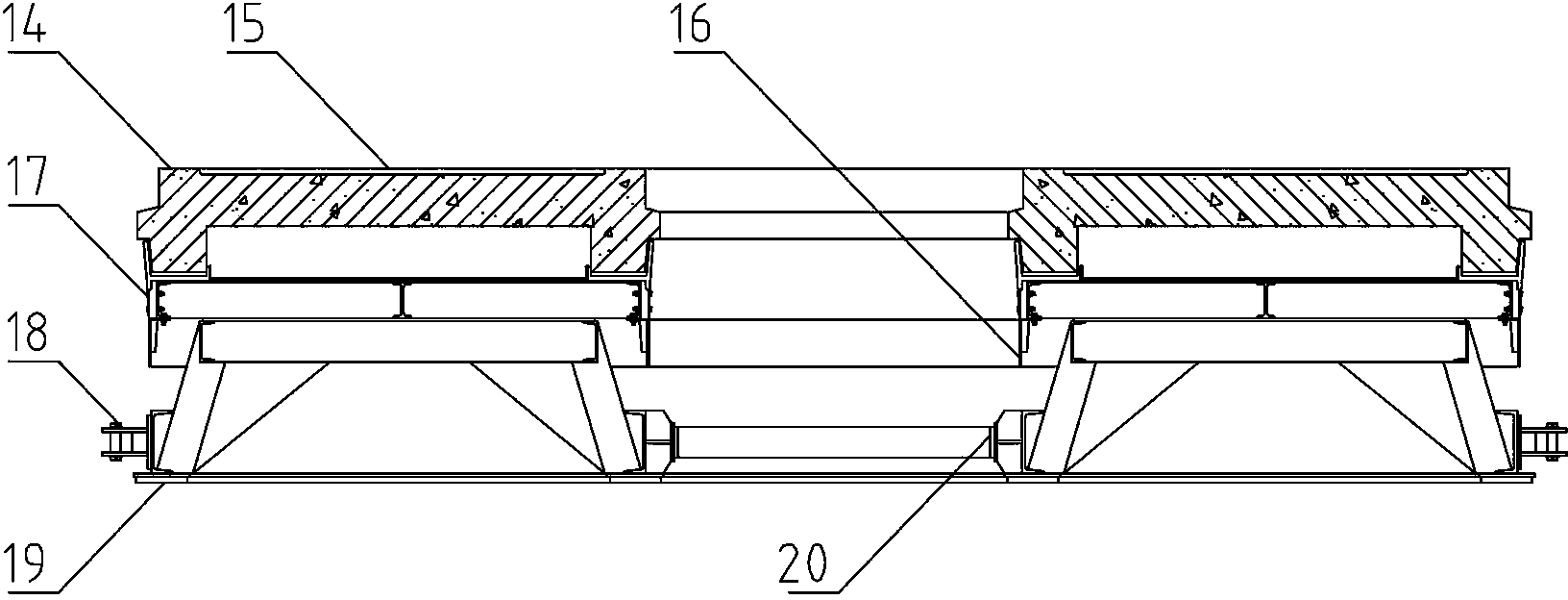

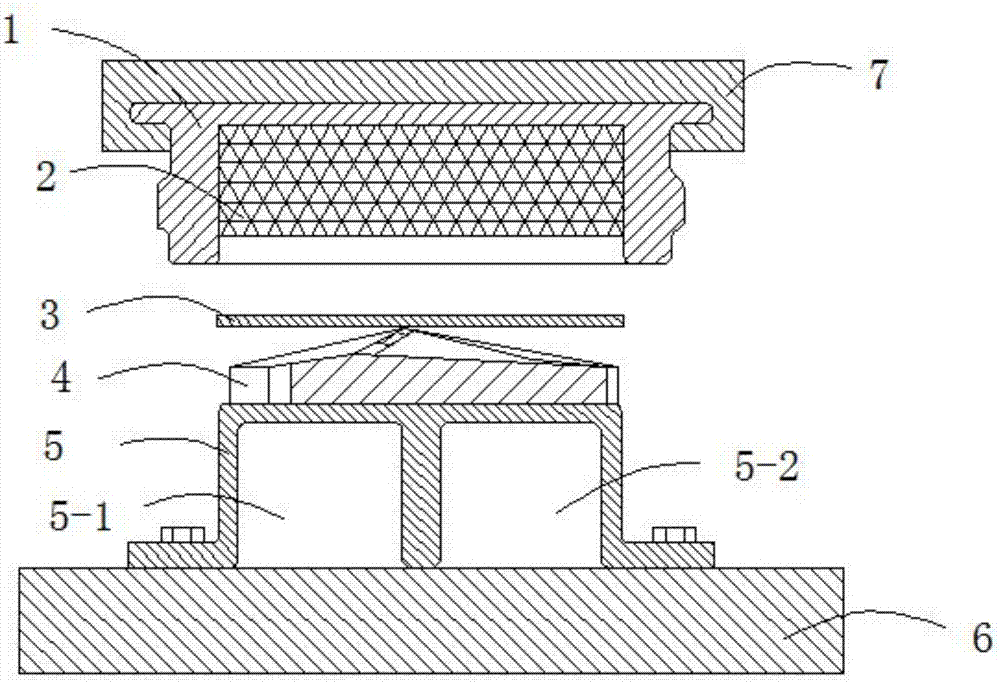

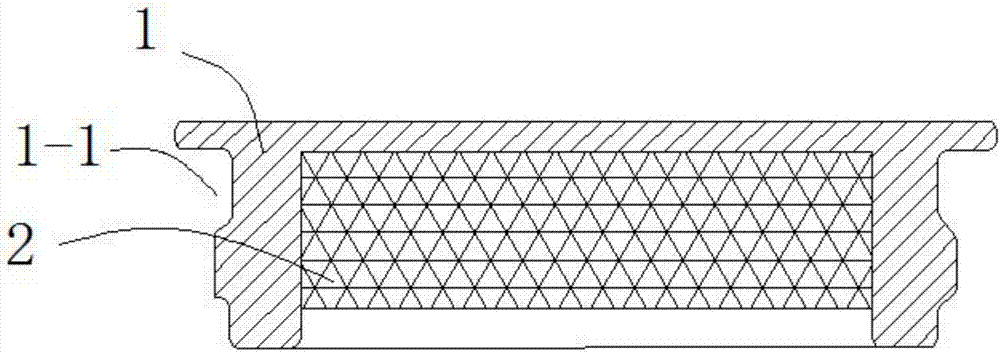

ActiveCN107505224ASimple structureEasy to useWeighing by removing componentWeighing apparatus using elastically-deformable membersControl systemState parameter

The invention belongs to the technical field of radio frequency drying and particularly relates to an online weighing control system for radio frequency-hot air combined drying equipment. Aiming to realize self-adaptive control of radio frequency output power and air speed in a radio frequency-hot air combined drying process, the online weighing control system for the radio frequency-hot air combined drying equipment comprises an execution device, an online weighing device and a weighing control device. The online weighing control system is simple in structure and convenient to use, mass of materials can be acquired in real time, the material drying rate can be obtained according to mass change, then the execution device is controlled by the weighing control device to adjust polar plate spacing or the air speed automatically, moisture diffusion in the materials is matched with outside convective mass transfer, and the material drying rate can be increased greatly. Besides, influence of external environmental conditions on state parameters of the materials and a drying chamber in material pick-and-place processes during manual intermittent weighing and in radio frequency equipment starting and stopping processes is avoided, and the control precision is improved.

Owner:CHINA AGRI UNIV

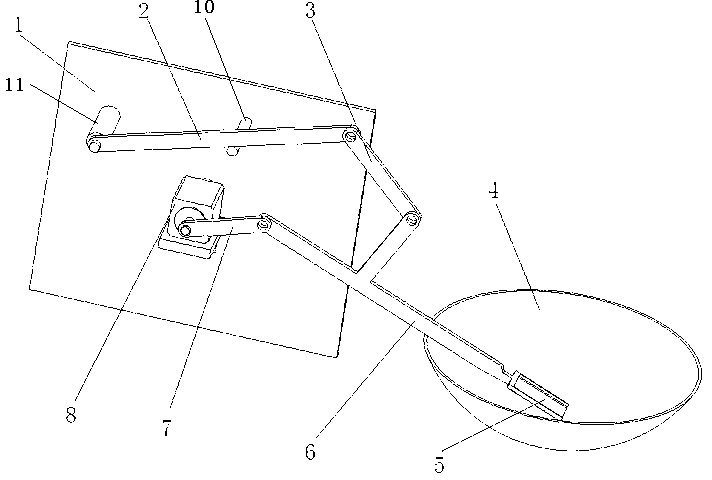

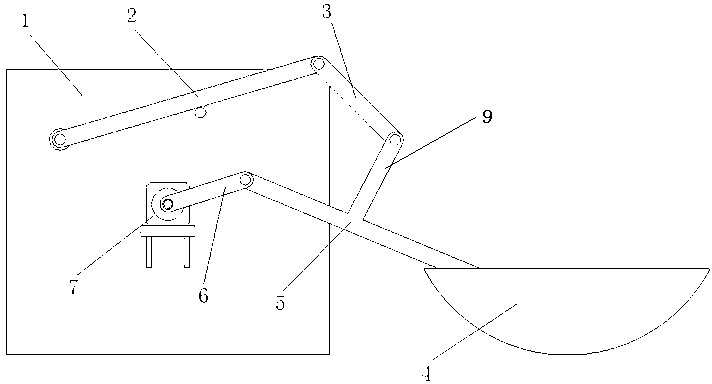

Stir-frying mechanism of automatic dried fruit fryer

InactiveCN103190686ASolve the problem of frying paste or uneven fryingSolve the labor-intensiveFood treatmentDried fruitsEngineering

The invention relates to a stir-frying mechanism of an automatic dried fruit fryer. The stir-frying mechanism comprises a support, a motor, a crank, a connecting rod, a swing rod, a traveling rod and a shovel, wherein the motor is fixed on the support, an output shaft of the motor is connected with the crank, the other end of the crank is hinged with the connecting rod, the other end of the connecting rod is fixedly connected with the shovel, one side of the connecting rod extends outwards to form a side arm which is perpendicular to the connecting rod, a fixed shaft is further arranged on the support, one end of the swing rod is hinged with the fixed shaft, and the traveling rod is hinged with the swing rod and the side arm respectively. Automatic stir-frying by the frying shovel is realized through five-rod transmission, burnt food or uniform stir-frying and the like is avoided, and the problem of large labor intensity of manual dried fruit frying is solved.

Owner:NORTHEAST GASOLINEEUM UNIV

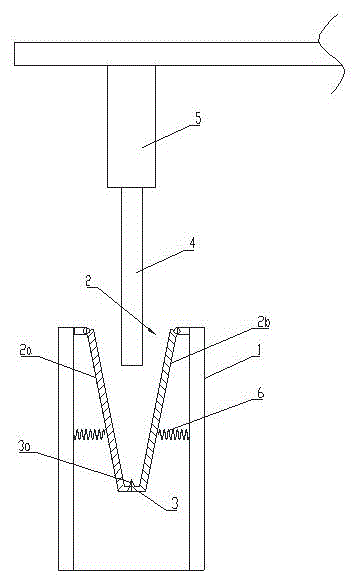

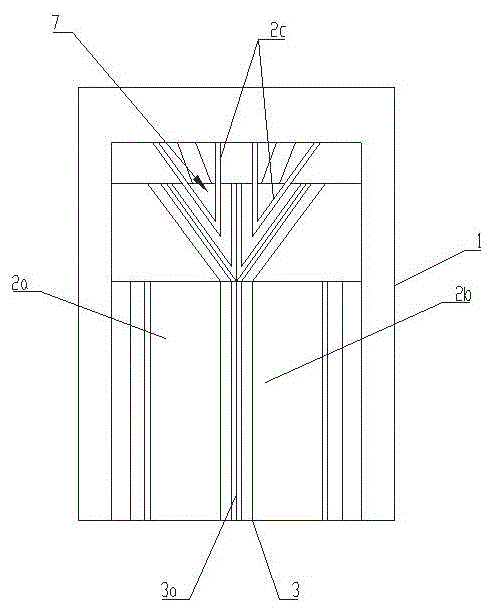

Chicken claw bone removing machine

ActiveCN105028591ASolve the labor-intensiveFully automatedPoultry processingBiomedical engineeringUltimate tensile strength

The invention discloses a chicken claw bone removing machine. The machine comprises a frame, a chicken claw positioning device and a punching device, wherein the chicken claw positioning device and the punching device are arranged on the frame; the chicken claw positioning device comprises a hopper shaped chicken claw positioning cavity and bone removing hooks which are arranged at the bottom of the chicken claw positioning claw; the chicken claw positioning cavity mainly comprises a left shell and a right shell; bottom edges of the left shell and the right shell are respectively bent inward to form the bone removing hook; the hook end part of each bone removing hook is edged to form the hook edge, and the hook end parts of the two bone removing hooks are closely arranged; the punching device comprises a punching head and a linear actuation mechanism which is used for driving the punching head to move up and down. The chicken claw bone removing machine can be used for realizing automatic chicken claw bone removing, and solving the technical problems of high labor intensity, high labor cost and low production efficiency of current manual bone removing.

Owner:海门华夏时丽网络科技服务有限公司

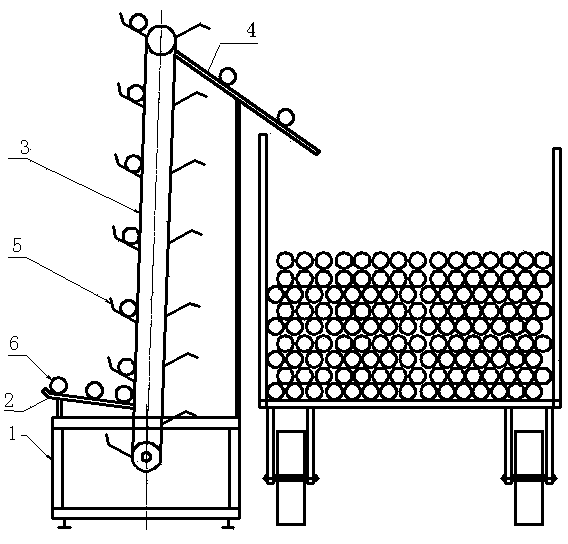

Semi-automatic loading device of PVC drainage pipes

InactiveCN103395637ACompact structureSolve the labor-intensiveLoading/unloadingTube drainageSemi automatic

The invention discloses a semi-automatic loading device of PVC drainage pipes. The semi-automatic loading device of the PVC drainage pipes comprises a machine frame, a pipe feeding mechanism, a chain conveying mechanism and a pipe discharging mechanism, wherein the entire semi-automatic loading device is installed on the ground through a supporting frame, the pipe feeding mechanism is located at one side of the lower end of the chain conveying mechanism, the pipe discharging mechanism is located at the other side of the upper end of the chain conveying mechanism, and a plurality of grabbing clamps are distributed on the chain conveying mechanism. According to the working process of the semi-automatic loading device of the PVC drainage pipes, the PVC drainage pipes are manually placed on the pipe feeding mechanism, the chain conveying mechanism is started for circular rotation, the pipes are grabbed through the grabbing clamps on the chain conveying mechanism, the drainage pipes move upwards, the drainage pipes fall into a compartment when reaching the top end, and therefore pipe loading is achieved. The pipe loading process solves the problem that loading in a manual shoulder bearing mode is high in labor intensity. Meanwhile, the grabbing clamps are installed on the chain conveying mechanism, so that the problem that a conveying belt on the chain conveying mechanism affects the loading process due to product sizes is solved. The semi-automatic loading device of the PVC drainage pipes has low requirements for a field.

Owner:LIANSU TECH DEV WUHAN

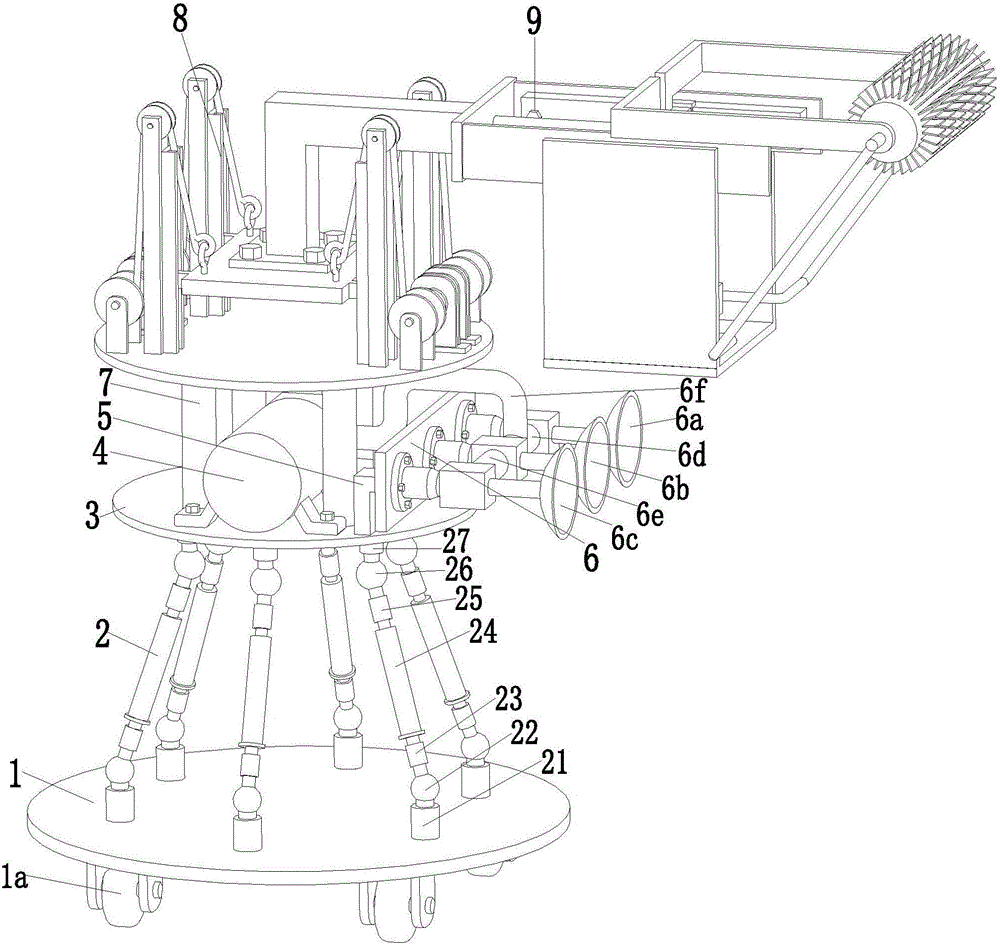

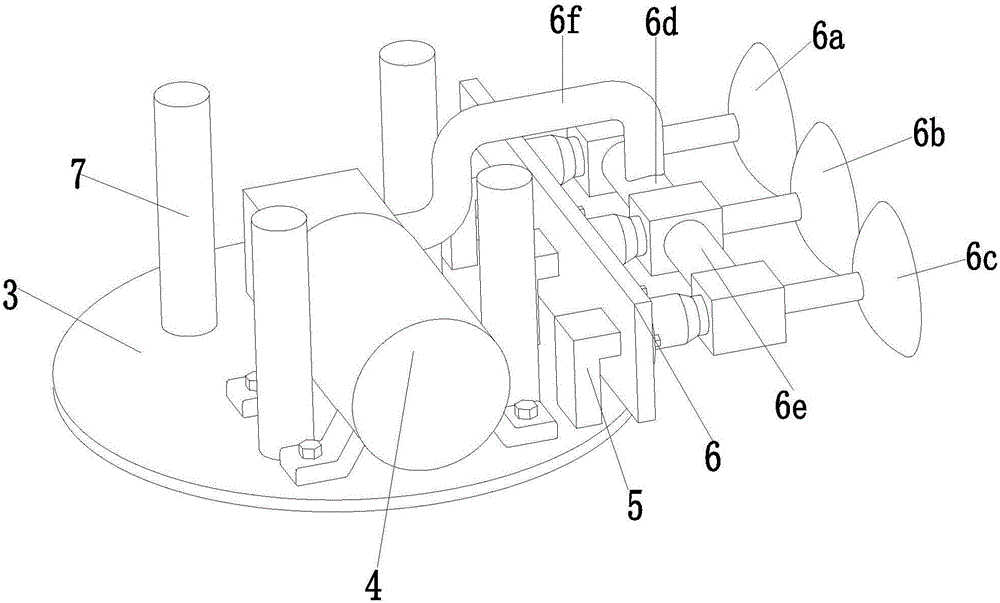

Intelligent whitewashing robot used for indoor building wall decoration

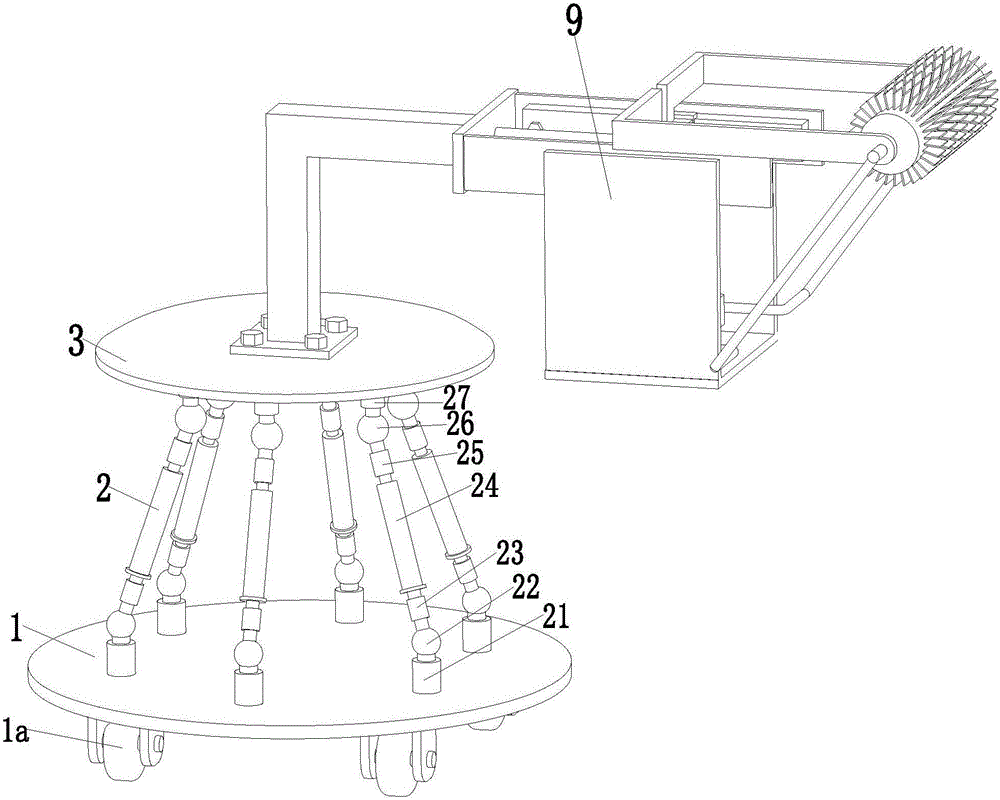

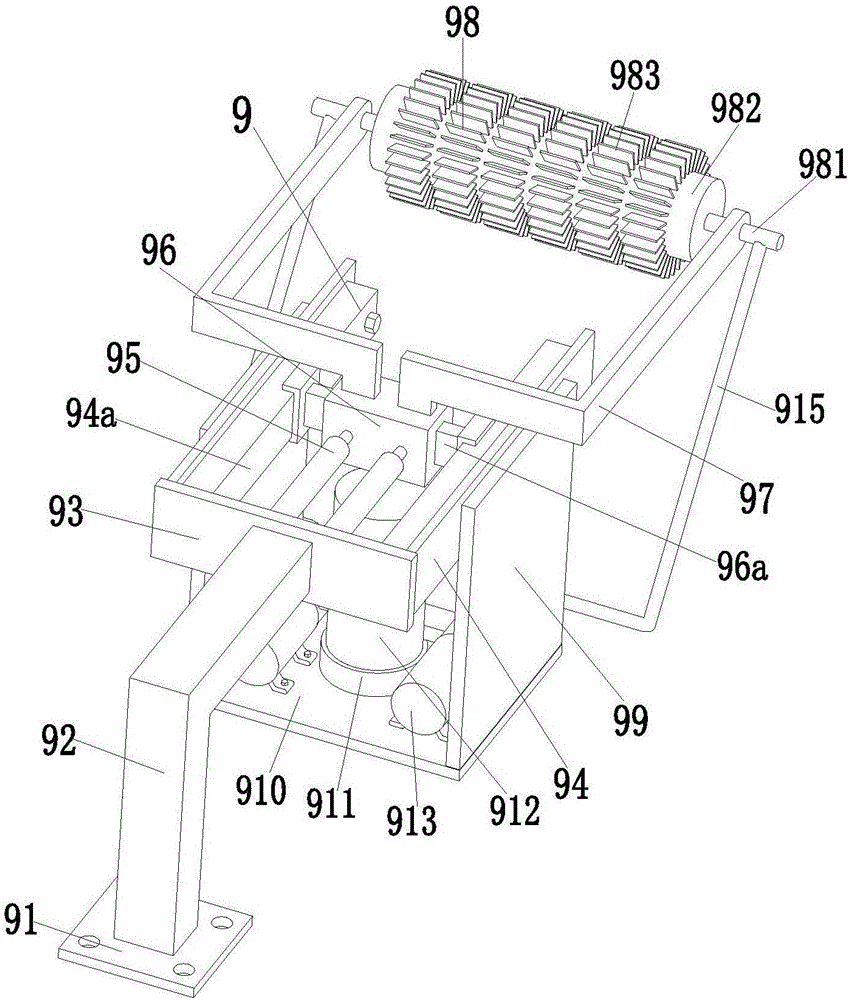

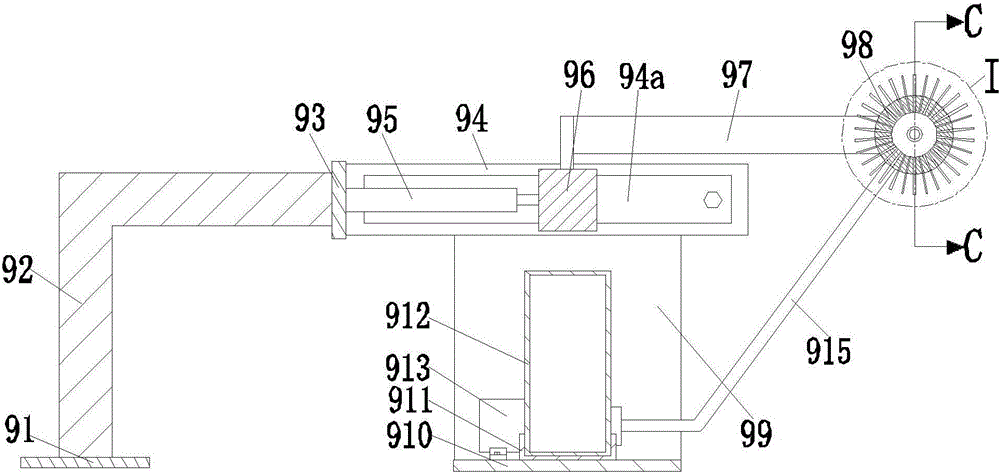

ActiveCN105952118AImprove work efficiencyEliminate jitter conditionsBuilding constructionsEngineeringManipulator

The invention relates to an automatic coating-pouring-type whitewashing robot used for indoor building wall decoration. The automatic coating-pouring-type whitewashing robot comprises a lower platform, the lower end surface of which is provided with four universal wheels symmetrically. By means of the four universal wheels, the automatic coating-pouring-type whitewashing robot can move at will to below a to-be-whitewashed wall surface. The lower platform is uniformly provided with six parallel branched chains. Upper ends of the six parallel branched chains are uniformly installed on an upper platform. The middle part of the upper end surface of the upper platform is equipped with an air extracting pump through screws. The right side of the upper end surface of the upper platform is uniformly welded with three L-shaped support columns, tail ends of which are welded with air extracting support boards. Inner walls of the air extracting support boards are respectively equipped with a first sucker, a second sucker and a third sucker through screws. The upper end surface of the upper platform is symmetrically welded with four air extracting top columns. The upper end surfaces of the four air extracting top columns are welded with an elevating table, the upper end of which is equipped with a whitewashing manipulator through screws. The intelligent whitewashing robot used for the indoor building wall decoration has functions of stably elevating and automatically whitewashing. A new way for mechanically and automatically whitewashing wall surfaces is provided.

Owner:闻天地装饰科技有限公司

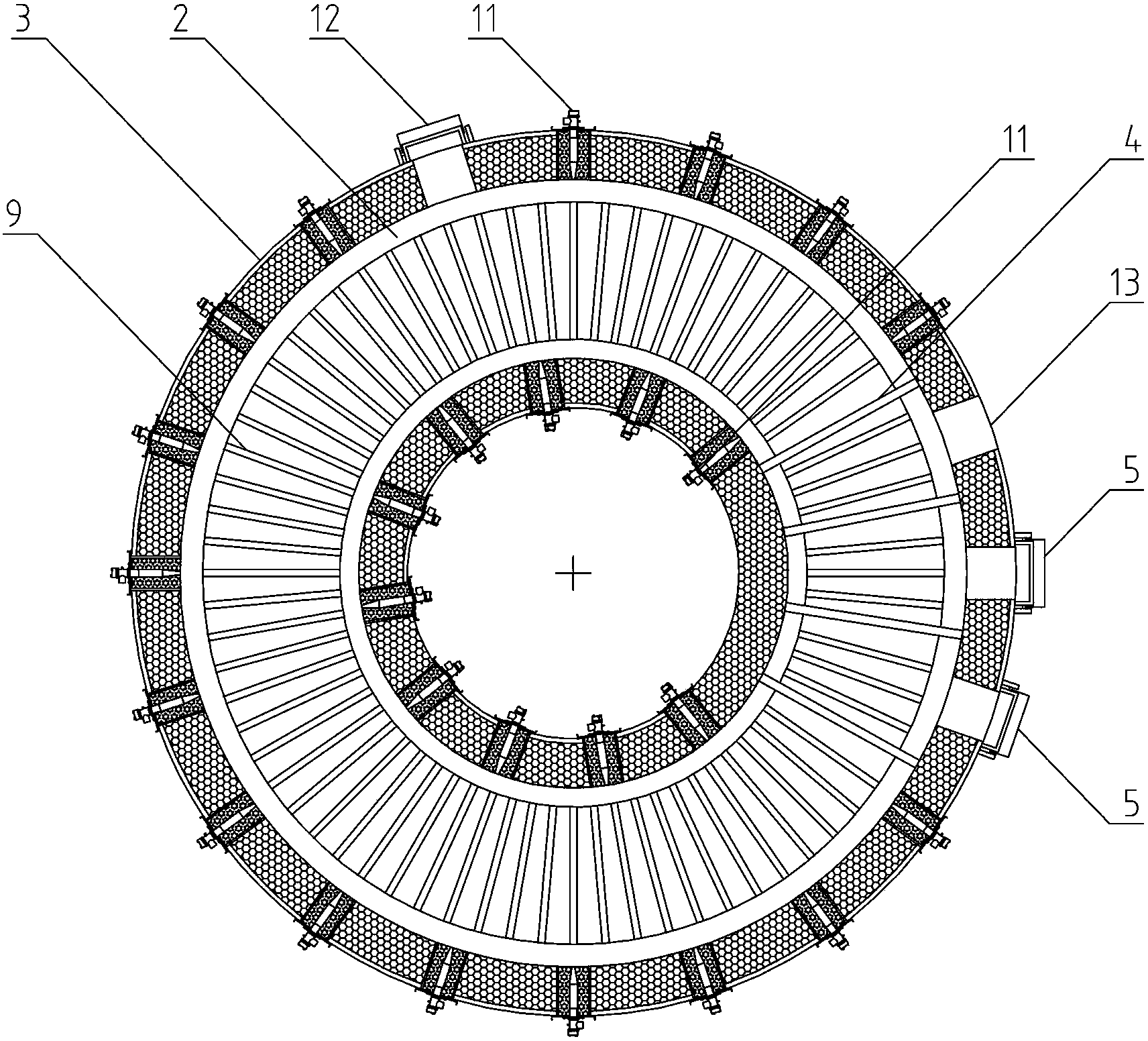

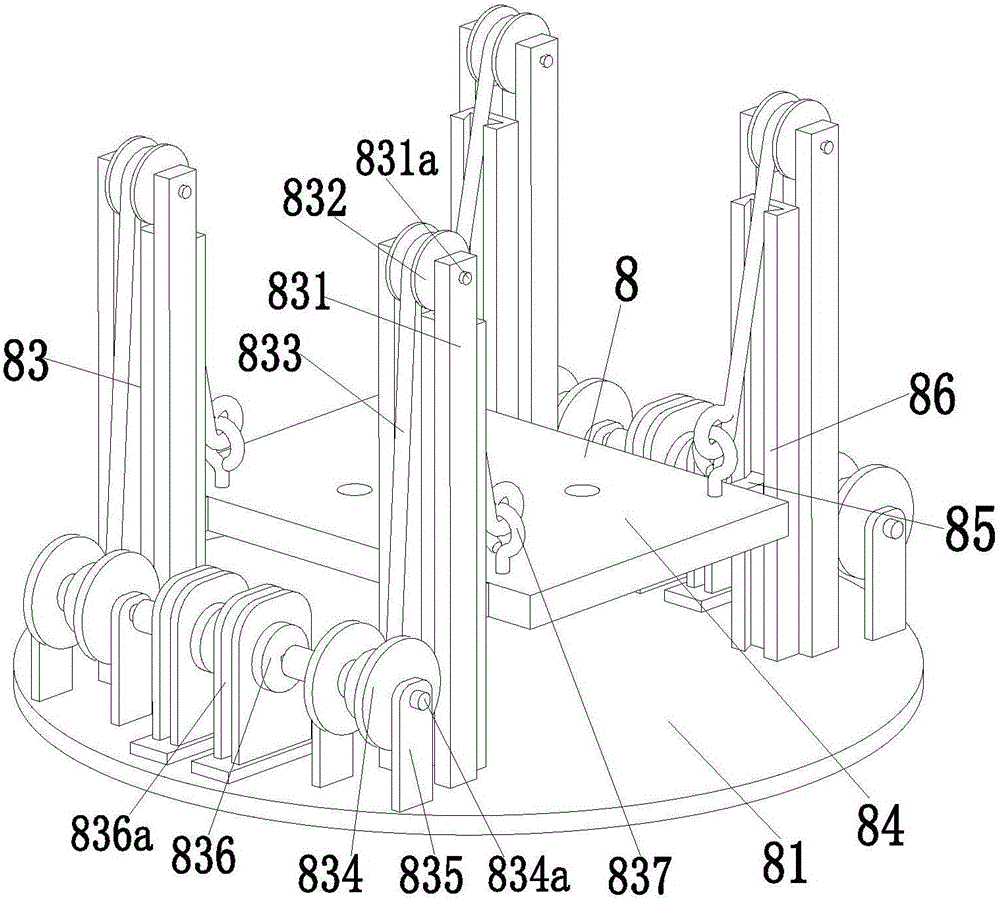

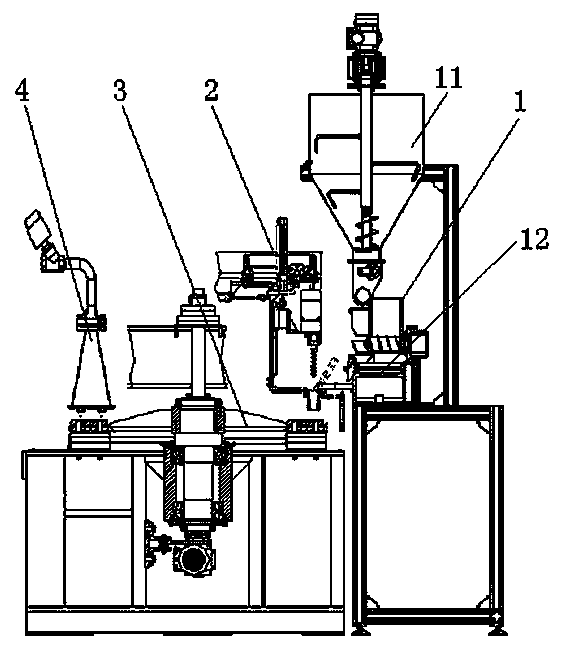

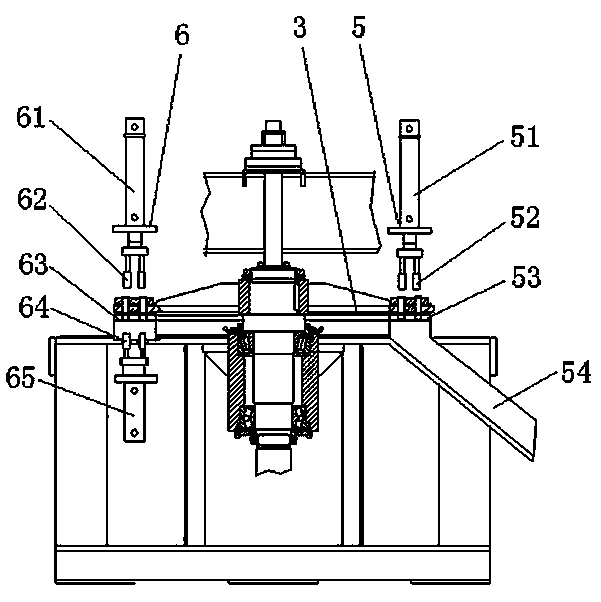

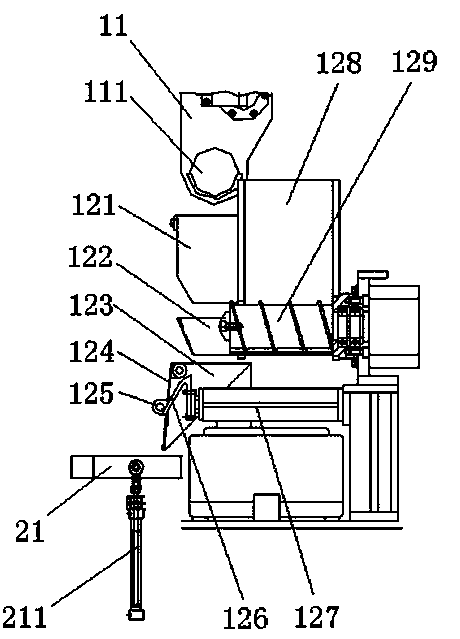

Automatic precisely-weighing tea pressing machine

InactiveCN103875831ASolve the labor-intensiveSimple structurePre-extraction tea treatmentAgricultural engineeringElectricity

The invention provides an automatic precisely-weighing tea pressing machine. The automatic precisely-weighing tea pressing machine is characterized by comprising a turntable with tea containing holes, a charging flattening mechanism, a tea steaming softening mechanism, a tea pressing mechanism, a demolding mechanism and a weighing mechanism connected with the charging flattening mechanism in a matching manner, wherein the charging flattening mechanism, the tea steaming softening mechanism, the tea pressing mechanism and the demolding mechanism are distributed at the periphery of the turntable and connected with the tea containing holes in the turntable in the matching manner; different workstations can be changed conveniently by rotating the movable turntable with multiple groups of tea containing holes on an annular bottom plate, so that the steps of tea charging, tea steaming and softening, tea pressing, demolding and tea discharging can be automatically performed and are cycled continuously; the automatic precisely-weighing tea pressing machine can automatically produce compressed tea with constant weight in a batch manner, so as to radically solve the problems that the labor intensity is high, the working efficiency is low, the hygienic security is difficult to guarantee, the tea product has low quality and the weight is non-uniform caused by the factor that existing compressed tea is produced manually, and meet the market requirements of tea products. The automatic precisely-weighing tea pressing machine has a simple structure, convenience for maintenance, stability in running, low electricity consumption and high automation degree.

Owner:云南研联机电有限公司

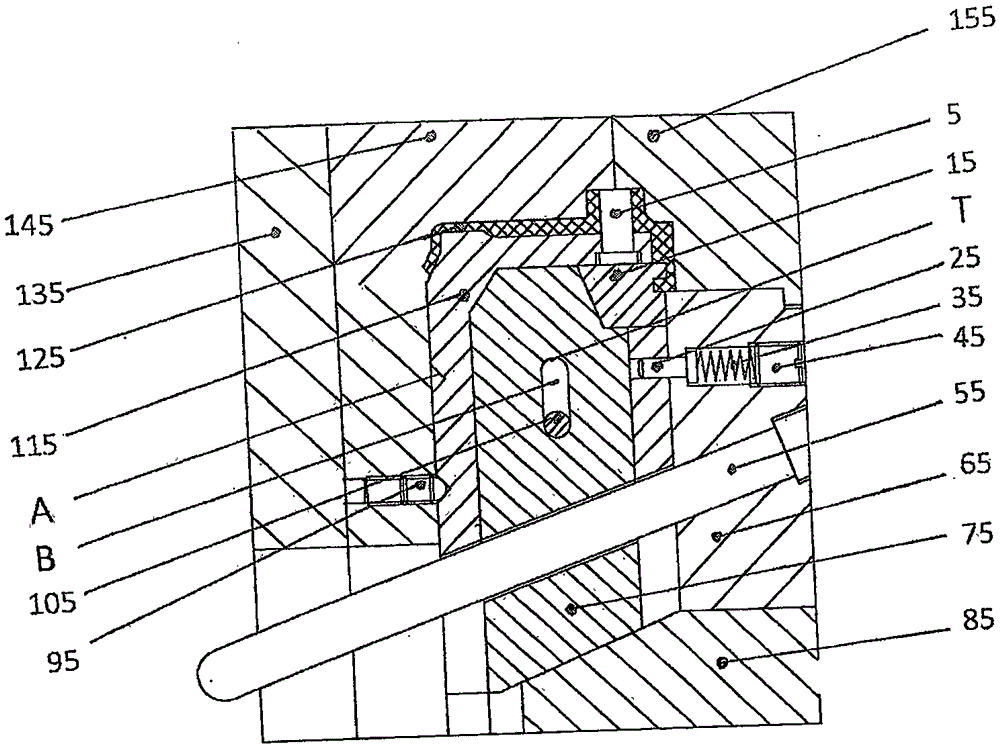

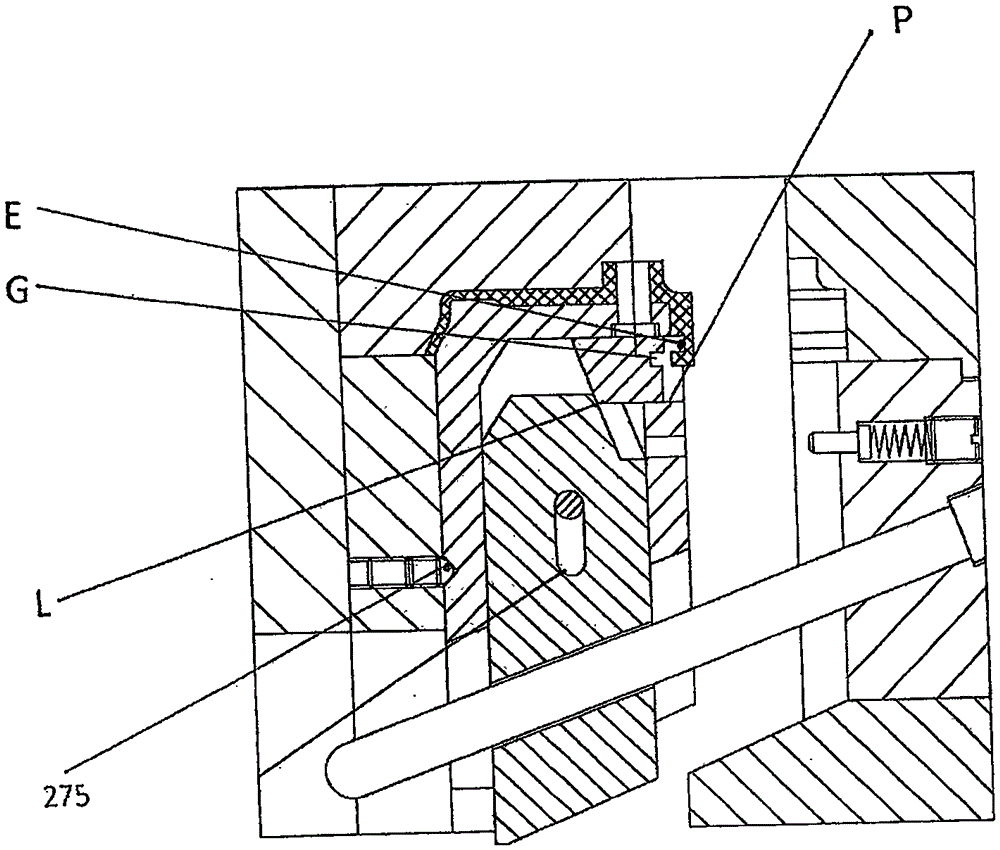

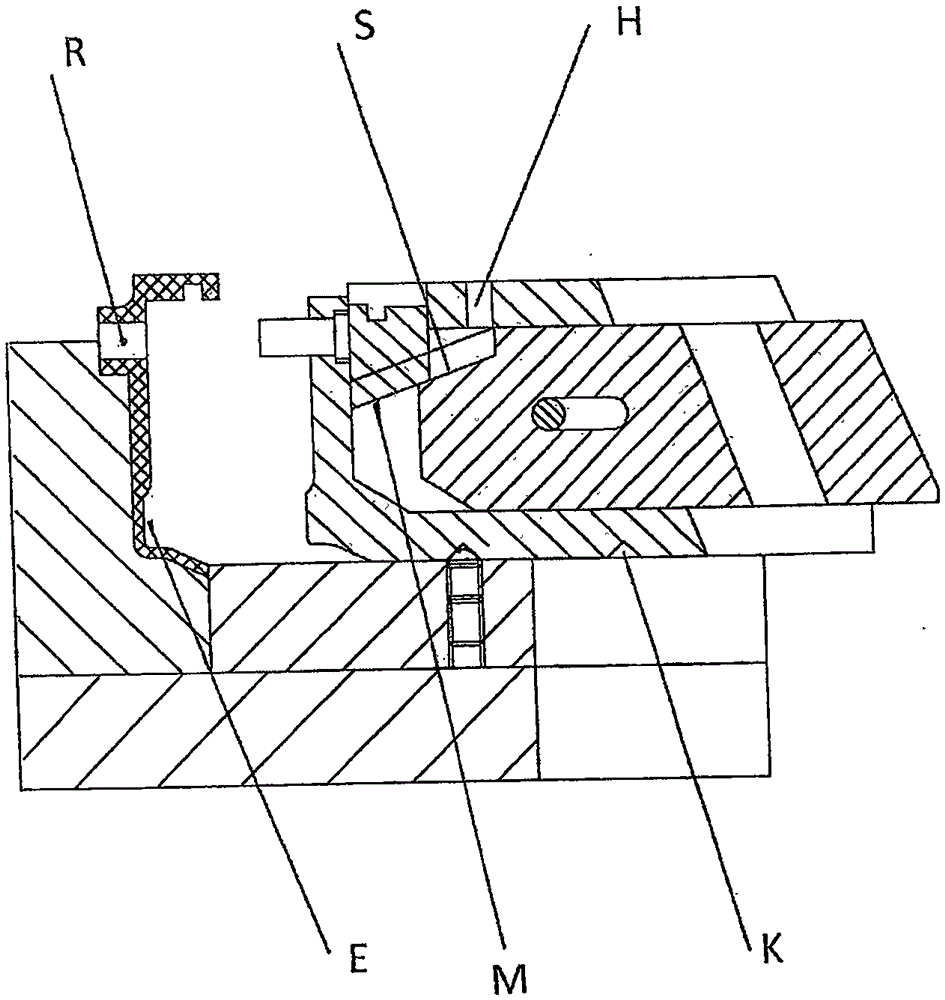

Die mechanism with sliding blocks provided with sliding block pulling cores

InactiveCN106626273ALarge mold opening core pulling forceCompact structureEngineeringMechanical engineering

The invention provides a die mechanism with sliding blocks provided with sliding block pulling cores. The die mechanism is formed by the large sliding block (115), the inner sliding block (75), the small sliding block (15), an inclined guide column (55), an inclined pressing block (85), a mold core (5), a cylindrical pin (105) and a stop pin (25); the inner sliding block (75) is installed inside the large sliding block (115) and is provided with a circular groove B, the circular groove B is in slide clearance fit with the cylindrical pin (105) installed on the large sliding block (115), a slope at the back end of the inner sliding block (75) is tightly attached to a lope of the inclined pressing block (85) during die assembly, and an inclined hole is formed in the inner sliding block (75) and is in slide fit with the inclined guide column (55) installed in an inclined step hole of a fixed mold plate (65). The mechanism is high in motion continuity, the die intelligent degree is high, and products are good in quality.

Owner:牟维军

Production workbench for mattress

The invention discloses a production workbench for a mattress, and relates to production equipment for a mattress. The production workbench is composed of a conveying workbench, a pneumatic folding table, a lifting-rotating frame and pneumatic turnover frames; a row of rollers capable of rotating along the length direction of a frame is respectively arranged at both sides of a middle beam of the workbench; a roller motor is used for driving the rollers to rotate via a chain transmission device; the pneumatic folding table is installed at one end or two ends of the frame of the workbench, and the pneumatic folding table is propelled by a cylinder to be folded downwards and erected towards the horizontal direction; the lifting-rotating frame is inlaid on the frame of the workbench, and a device for propelling the lifting-rotating frame to ascend and horizontally rotate is installed in the middle of the lower part of the workbench; and the pneumatic turnover frames are respectively installed at the left end and the right end of the frame of the workbench, and the outer ends of the pneumatic turnover frames are propelled by a turnover frame cylinder to be erected upwards. According to the production workbench, the problems of low working efficiency and high labour intensity of workers existing in conventional production of the mattress are solved.

Owner:佛山市顺德区友力帮机械有限公司

Tipping bucket barrel plating machine

The invention relates to a tipping bucket barrel plating machine which mainly comprises a plating bath, a roller, a roller transmission device, a tipping bucket device, a material discharging rack, bath surface conducting equipment and electric control equipment, wherein the roller is positioned in the plating bath; the bath surface conducting equipment is arranged on both sides in the plating bath; the plating bath is connected with the roller transmission device which is used for controlling the rotation of the roller; the tipping bucket device is tipped by a motor to drive a boom; and accordingly, the boom is used for driving the roller to tip between the material discharging rack and the plating bath. The tipping bucket barrel plating machine is applicable to most of shapes of parts and plating kinds and has larger loading. Compared with a single horizontal barrel plating machine, the tipping bucket barrel plating machine can omit complicated machine lifting equipment, has convenient and flexible manual operation and greatly alleviates the labor strength of workers. In the tipping bucket barrel plating machine, a dump boom is used for lifting the roller to a level from the plating bath; in short automatic staying, after bath in the roller is drained, the bath is automatically tipped out of the material discharging rack; the material is discharged and charged manually; and reliable operation and convenient use are realized.

Owner:无锡出新环保设备有限公司

Use method for bagging device of automatic garbage packaging unit

The invention discloses a use method for the bagging device of an automatic garbage packaging unit. According to the use method, before the bagging device runs, garbage bags are filled in the bag opening box of the bagging device, and a vacuum device is attached to the inner wall; a turnover cylinder between a turnover cylinder support and a bag opening box turnover plate pushes the bag opening box to turn over; meanwhile, a packaging box is turned upwards by an oil cylinder until the box opening is upward; the box opening of the packaging box is coaxial with the box opening of the bag opening box while being corresponding to the same, an upper cylinder and a lower cylinder between a guide rod slide plate and an upper big frame are started to push the guide rod slide plate and drive the bag opening box to run downwards, and the garbage bags in the bag opening box completely sleeve outside the packaging box; the garbage bags separate off from the adsorption of the bag opening box, the upper cylinder and the lower cylinder push upwards the guide rod slide plate and the bag opening box to run upwards to completely leave from the garbage bags, and then bagging is finished. The working efficiency is increased, the labour intensity is reduced, the enterprise cost is optimized, the safe production is guaranteed, and garbage packaging realizes automation.

Owner:洛阳盛豫重工机械有限公司

Automatic building wall plastering device based on six-freedom-degree parallel mechanism

ActiveCN106013742AEliminate manual operationEliminate jitter conditionsProgramme-controlled manipulatorBuilding constructionsHydraulic cylinderEngineering

The invention relates to an automatic building wall plastering device based on a six-freedom-degree parallel mechanism. The automatic building wall plastering device comprises a lower platform. Four universal wheels are symmetrically arranged on the lower end face of the lower platform. Six parallel branch chains are evenly installed on the lower platform in the axis direction. The upper ends of the six parallel branch chains are all evenly installed on an upper platform. A plastering mechanical hand is installed at the middle portion of the upper end face of the upper platform through screws. By the adoption of the automatic building wall plastering device, the 6-SPS parallel mechanism is composed of the lower platform serving as a fixed platform, the six SPS parallel branch chains and the upper platform serving as a movable platform, the 6-SPS parallel mechanism has six freedom degrees and has the beneficial effects of being good in dynamic response, high in rigidity, large in bearing capacity, good in stability, high in motion accuracy and the like, and six first hydraulic cylinders on the six parallel branch chains move at the same time to drive the plastering mechanical hand on the upper platform to achieve the stable lifting and automatic plastering function. By the adoption of the automatic building wall plastering device, the stable lifting and automatic plastering function can be achieved, and a new way for mechanically and automatically plastering a wall face is provided.

Owner:武汉市银翰艺术工程有限公司

Rapid prototyping device for special-shaped sheet metal parts

PendingCN107377777AReduce labor intensitySolve the labor-intensiveShaping toolsEngineeringRapid prototyping

The invention discloses a rapid prototyping device for special-shaped sheet metal parts, and relates to rapid prototyping equipment for sheet metal parts. The rapid prototyping device comprises an upper die base, a concave die which is clamped inside the upper die base, a lower die base, a forming support terrace die which is fixed on the lower die base and matched with the concave die, the concave die is a concave die with a semi-closed cavity, a rubber plate is arranged inside the concave die with the semi-closed cavity, the thickness of the rubber plate is less than the depth of the semi-closed cavity, a forming workpiece feta membrane for supporting a workpiece to be machined is fixedly arranged on the forming support terrace die, and a pressure elevating mechanism is connected to the upper die base. According to the rapid prototyping device for special-shaped sheet metal parts, the surfaces of the obtained parts are smooth and flat, and the defects of indentation, scratches and convex-concave shapes appearing on the surfaces of the parts when the traditional methods are used for forming the parts are resolved.

Owner:郑州郑飞机电技术有限责任公司

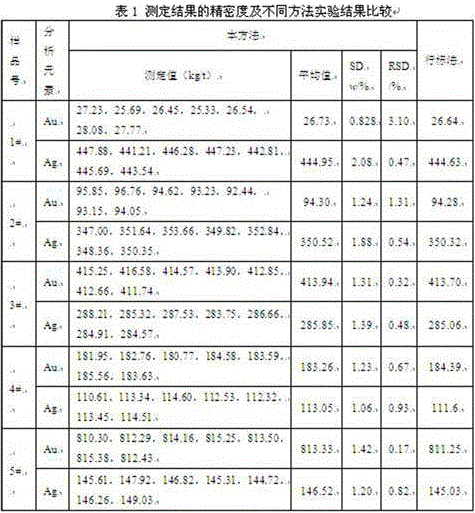

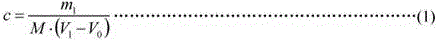

Rapid analysis method for gold and silver in silver anode slime

ActiveCN105842102AAvoid pollutionApplicable analytical testingChemical analysis using titrationMaterial weighingElectrolysisPotassium thiocyanate

The invention discloses a rapid analysis method for gold and silver in silver anode slime. The method comprises the steps: a silver anode slime sample is subjected to wet-process sample dissolving treatment, then, part of coexisting elements in the sample enter a solution, filtrating is carried out, then, precipitates are dissolved with nitric acid and sulfuric acid, filtrating is carried out to separate the gold from the silver, the gold is insoluble to the nitric acid and the sulfuric acid and enters the precipitates, and the silver enters the filtrate; the content of the gold is determined by a gravimetric method, Ag<+> has higher affinity to SCN<-> than Fe<3+> in the sulfuric acid medium, the Fe<3+> and the SCN<-> are combined to produce an apricot-red ferric thiocyanate complex after the Ag<+> is precipitated completely, then, the reaction ends, and the content of the silver can be figured out according to the volume of a standard potassium thiocyanate solution consumed. The method involves experimental conditions, sample treatment, a coexisting element interference test and an accuracy experiment for confirming experiment results. The method disclosed by the invention is simple and convenient in operation, low in test cost and stable and reliable in test result, thereby being applicable to the analysis and detection on samples in an electrolysis process.

Owner:大冶有色设计研究院有限公司

Online chamfering device for wood pallets

InactiveCN108214673ASolve the labor-intensiveSolve the problem of flying aroundGuide fencesFeeding devicesPallet

An online chamfering device for wood pallets comprises a pallet conveying mechanism, a dust collection mechanism, a chamfering mechanism, an adjusting lead screw and a controller. One end of the pallet conveying mechanism serves as a pellet holding end, and the other end of the pallet conveying mechanism penetrates a cutting region right below the chamfering mechanism to be conveyed to a next station. The chamfering mechanism is mounted on the adjusting lead screw, and locking connection between the chamfering mechanism and the pallet conveying mechanism is realized. Control ends of the palletconveying mechanism, the dust collection mechanism and the chamfering mechanism are connected with a signal output end of the controller electrically. The online chamfering device has the advantagesthat the problem of high labor intensity in manual chamfering is solved; chamfering is completed automatically by the device, so that the problem of dust scattering during cutting is solved, and on-site environment is improved; the device completes chamfering online, so that the problems of large equipment occupation space due to manual chamfering and low efficiency due to individual chamfering are reduced.

Owner:JUSHI GRP CO

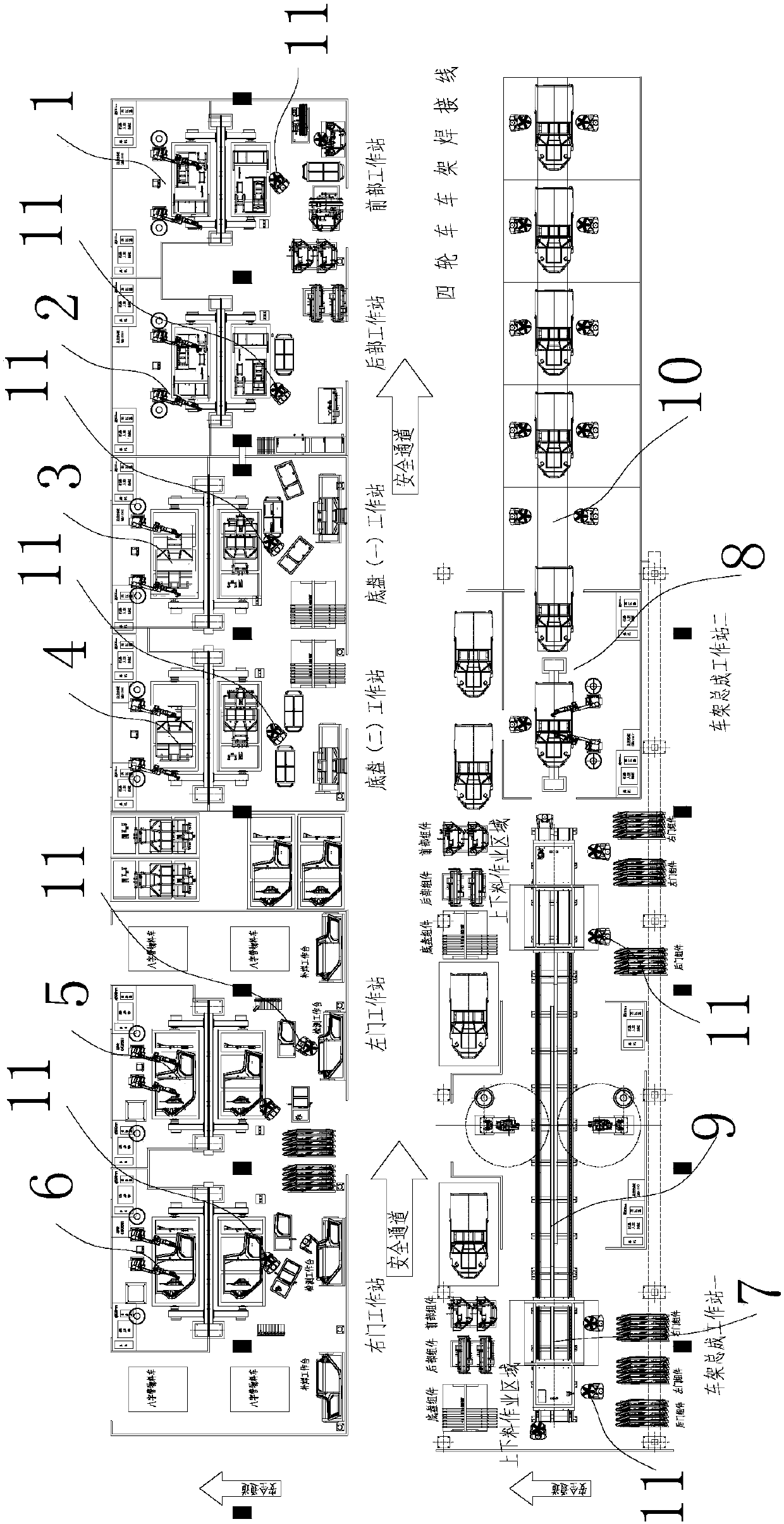

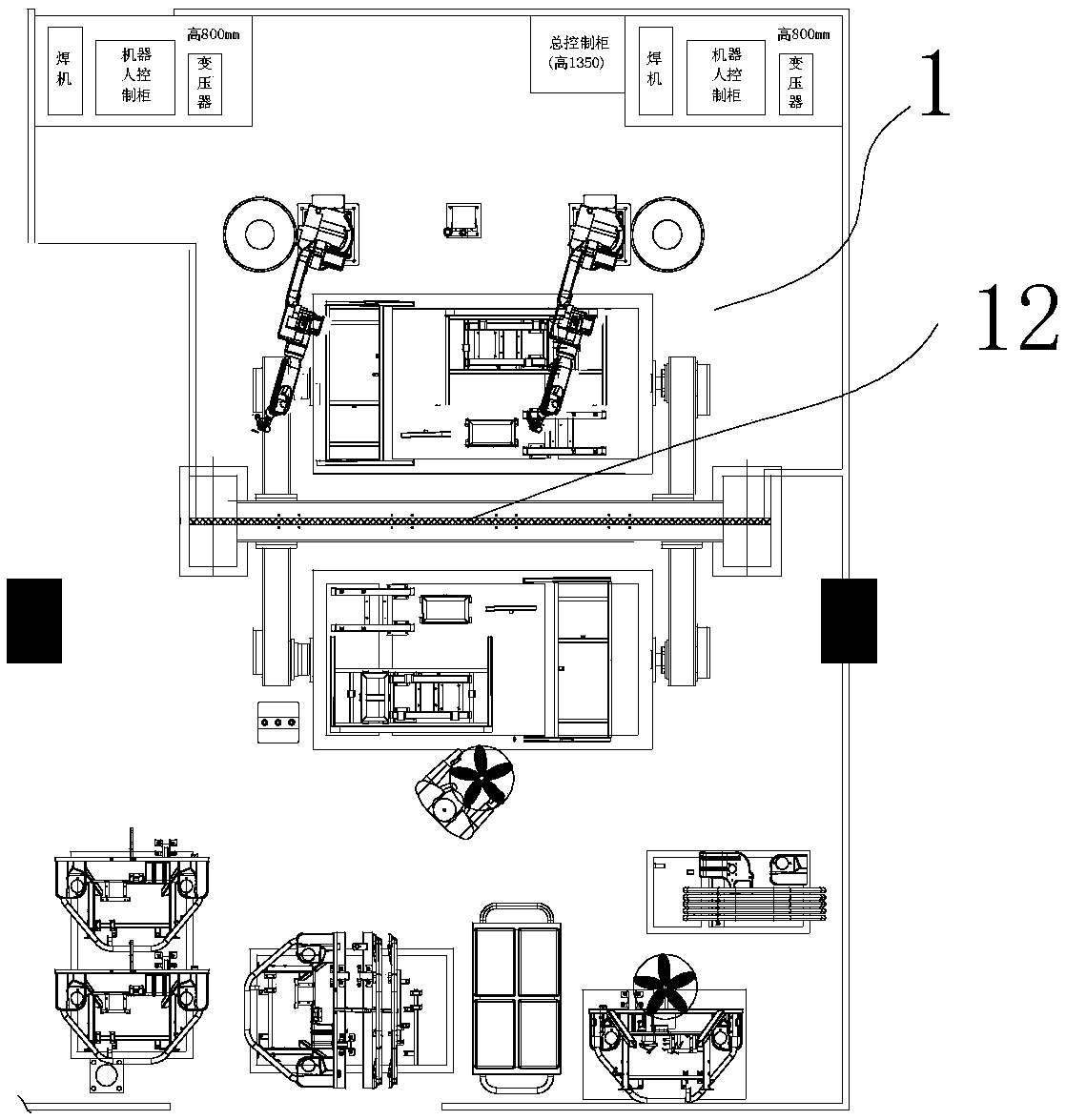

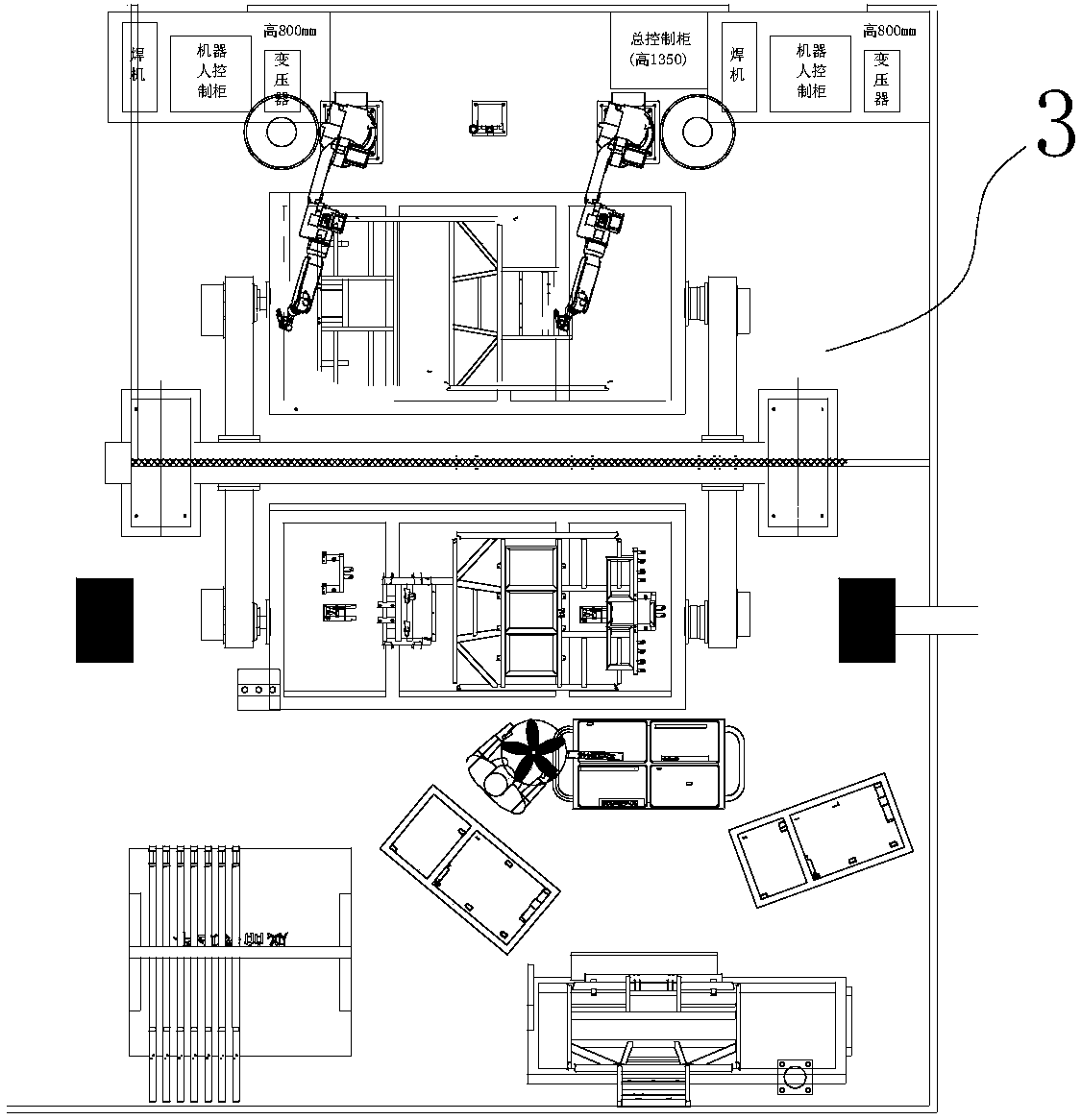

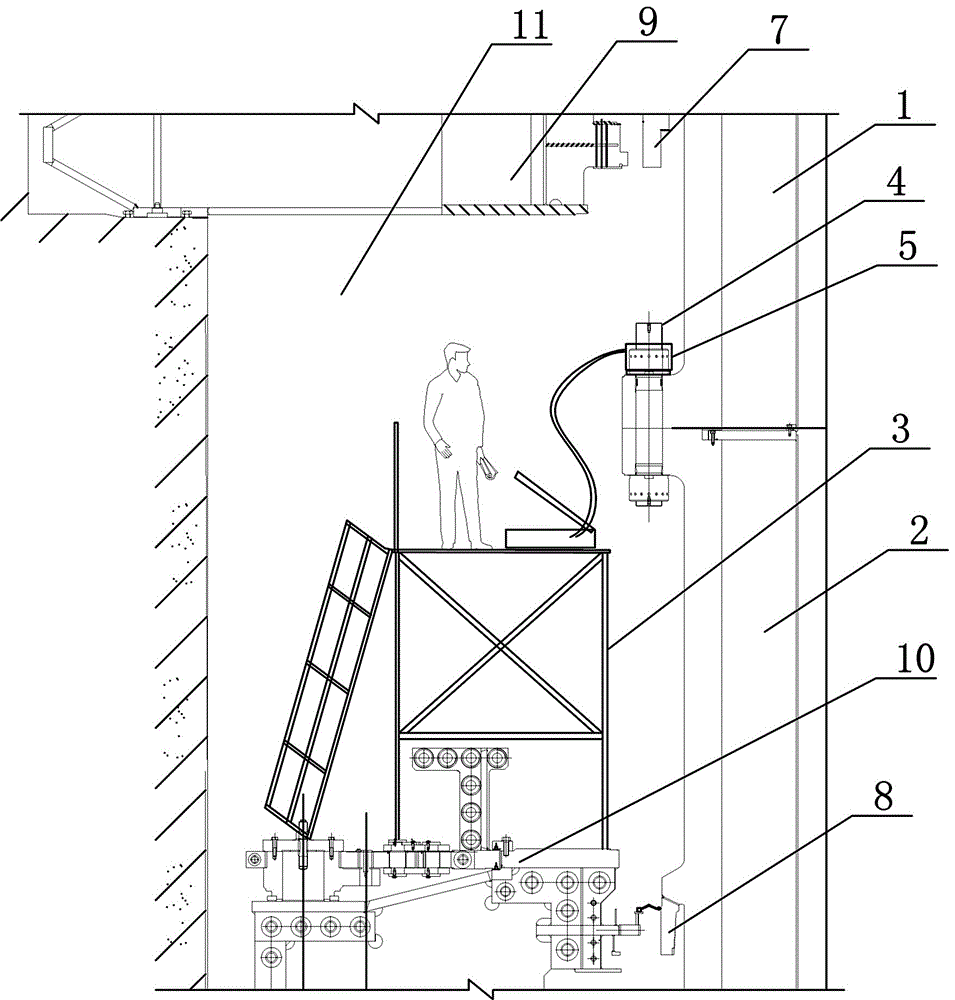

Flexible automatic welding production line for electric four-wheel vehicle frame

ActiveCN107598406ASolve the labor-intensiveSimple foundationWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameRolling chassis

The invention provides a flexible automatic welding production line for an electric four-wheel vehicle frame. The flexible automatic welding production line comprises a front workstation for welding of a front assembly of the electric four-wheel vehicle frame, a rear workstation for welding of a rear assembly of the electric four-wheel vehicle frame, a first chassis workstation, a second chassis workstation, a left door workstation, a right door workstation, a first vehicle frame assembly workstation and a second vehicle frame assembly workstation, wherein the first chassis workstation and thesecond chassis workstation are used for chassis welding of the electric four-wheel vehicle frame, the left door workstation is used for welding of a left door assembly of the electric four-wheel vehicle frame, the right door workstation is used for welding of a right door assembly of the electric four-wheel vehicle frame, and welded workpieces on all the workstations and a finished rear door assembly are conveyed to the first vehicle frame assembly workstation for completing primary welding of a vehicle frame assembly, then the workpieces are transferred to the second vehicle frame assembly workstation for completing overall welding assembly, and U-shaped arrangement facilitating the operation of conveying the welded workpieces to the first vehicle frame assembly workstation and the second vehicle frame assembly workstation at the shortest distance is formed overall; and welding is divided into eight processes, a three-shaft overturning type welding positioner for workstation exchangeamong feeding, discharging and welding and autoroatation of each workstation is arranged, and the working efficiency of a welding robot is maximized.

Owner:ZHUHAI RUILING WELDING AUTOMATION CO LTD

Vertical hydraulic turbine set shaft system adjusting method

InactiveCN106762342ASolve the labor-intensiveSolve the shaft system swing exceeding the standardHydro energy generationMachines/enginesAutomotive engineeringHydraulic turbines

The invention discloses a vertical hydraulic turbine set shaft system adjusting method which includes the steps: firstly, pre-tightening all connecting bolts, firstly turning after a turbine set has turning conditions, and checking shaft system swing; secondly, building an annular working platform; thirdly, replacing and pre-tightening four tool bolts; fourthly, secondly turning; fifthly, thirdly turning, and checking whether the shaft system swing is qualified or not; sixthly, machining one set permanent connecting bolts; seventhly, installing and pre-tightening residual tool bolts; eighthly, boring; ninthly, fourthly turning to finish adjustment of a vertical hydraulic turbine set shaft system. The adjusting method can solve the problems of high labor intensity, long correction time, low safety and stability and the like and can also thoroughly solve the problem that shaft system swing exceeds standards, installing accuracy of the turbine set shaft system is effectively ensured, so that installing quality of the turbine set is improved.

Owner:CHINA GEZHOUBA GRP MECHANICAL & ELECTRICAL CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com