Annular heating furnace with rotary furnace bottom

A ring-shaped heating furnace, rotary technology, applied in lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of high safety hazards, high labor intensity of operators, and high energy consumption per unit output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

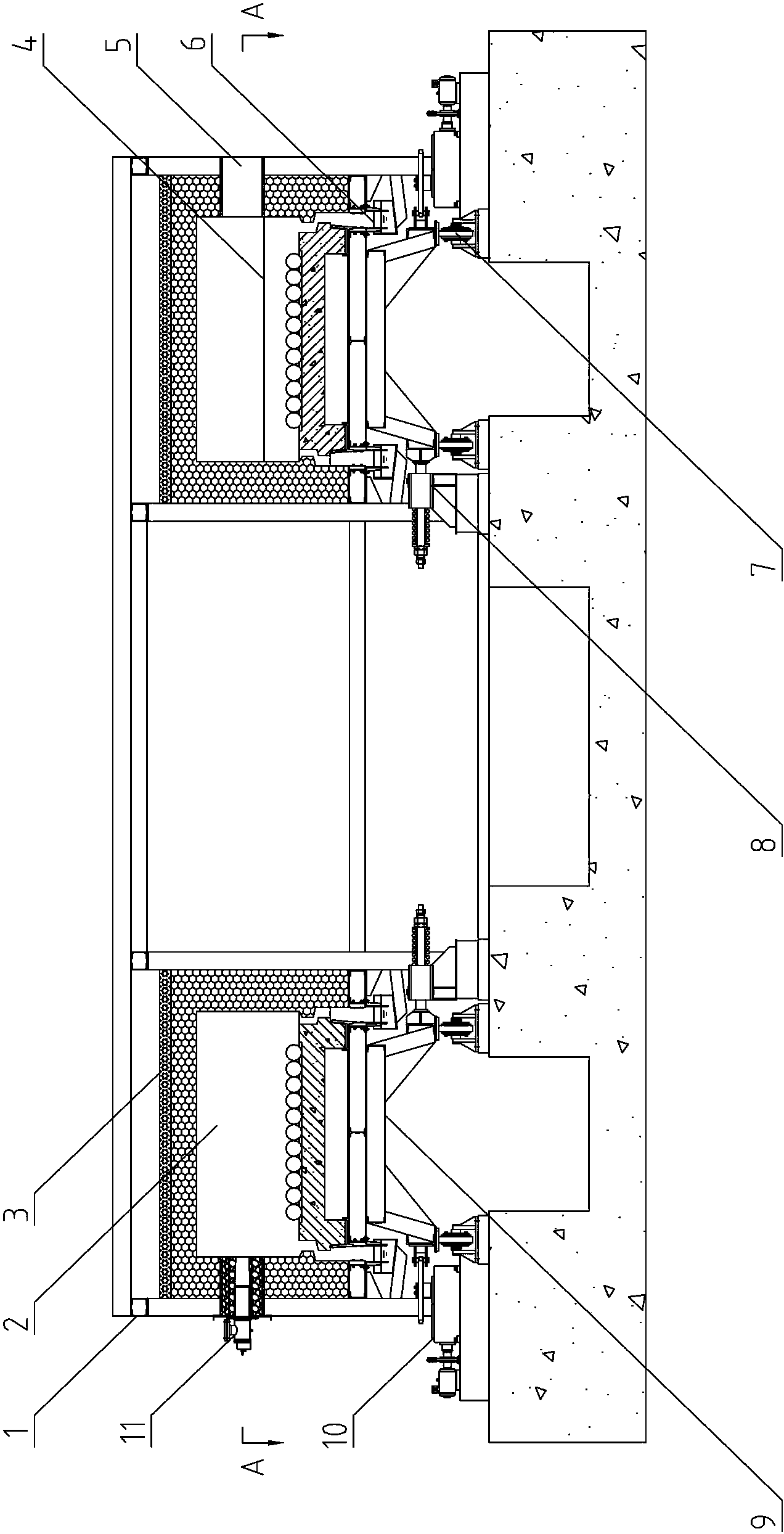

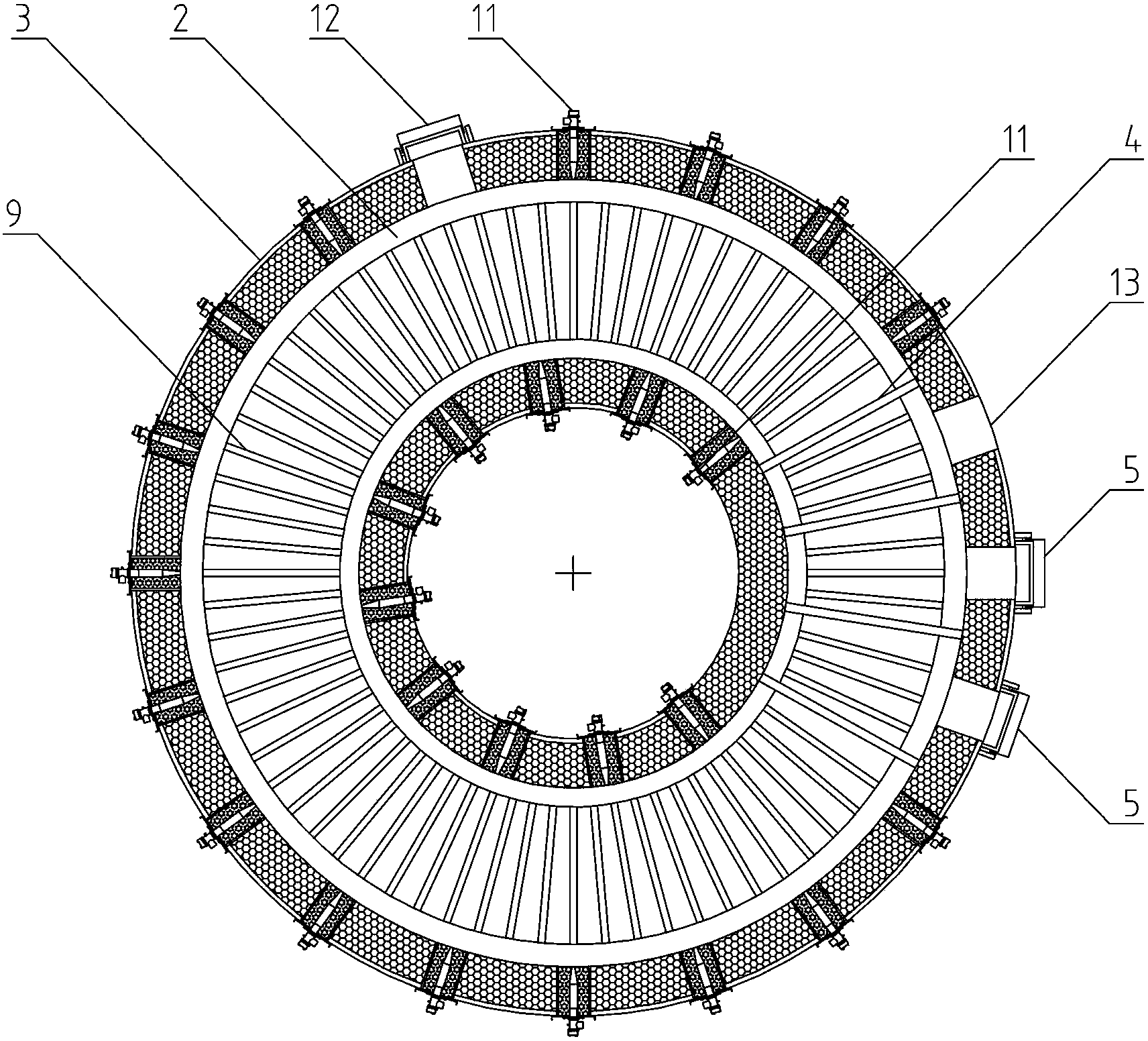

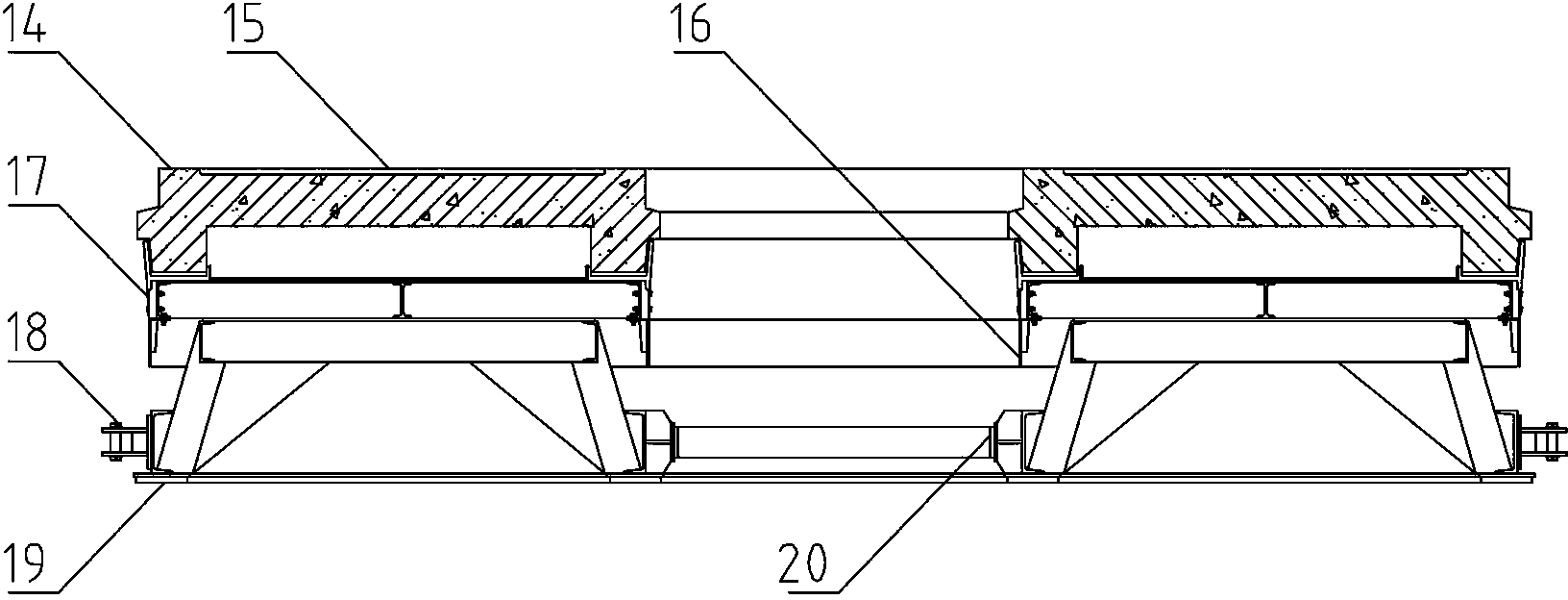

[0014] see figure 1 : A kind of rotary furnace bottom annular heating furnace, it is provided with furnace body steel frame 1 and furnace body 3, furnace body 3 is provided with furnace 2, the bottom of furnace 2 is provided with furnace bottom 9, on the side wall of furnace body 3 There are respectively inlet and outlet ports 5, burners 11, overhaul furnace doors 12 and smoke outlets 13; especially: a rotary drive mechanism 10, a lateral positioning mechanism 8 and two channels are respectively installed on the bottom of the furnace body 3. The inner and outer annular support raceways 7; the furnace 2 is in an annular structure (see figure 2 ), the furnace 2 is provided with a fire baffle 4, and the inner and outer annular side walls of the bottom of the furnace 2 are respectively provided with two annular water seal grooves 6; the furnace bottom 9 is composed of a heat insulation panel 14, a skirt seal 16. Composed of structural support 17, ring gear 18, annular rail surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com