Chain suspension type hydraulic support

A hydraulic support and chain suspension technology, which is used in pillars/supports, mining equipment, earth-moving drilling, etc., can solve the problems of poor adaptability of uneven roofs, high price, affecting production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

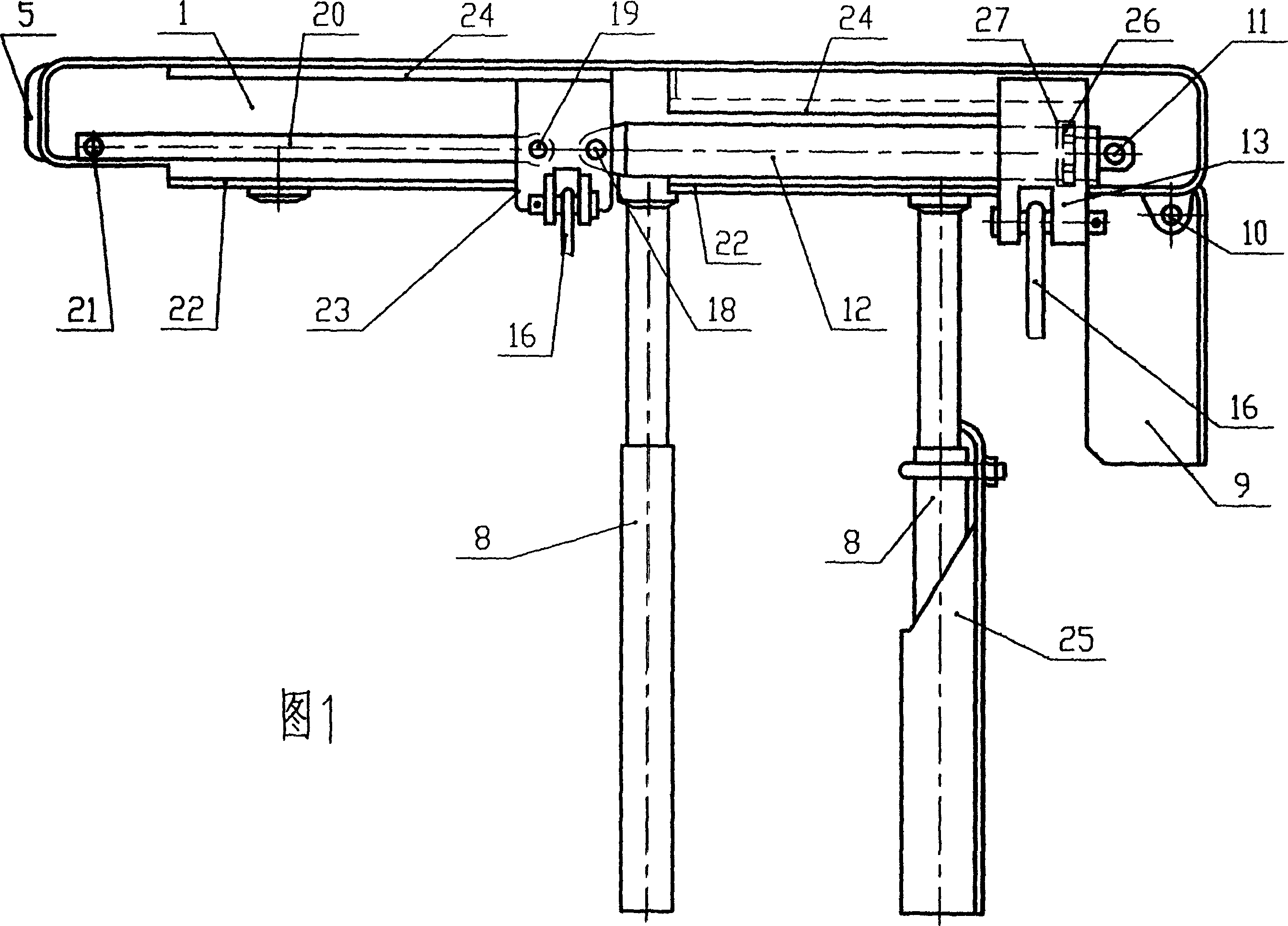

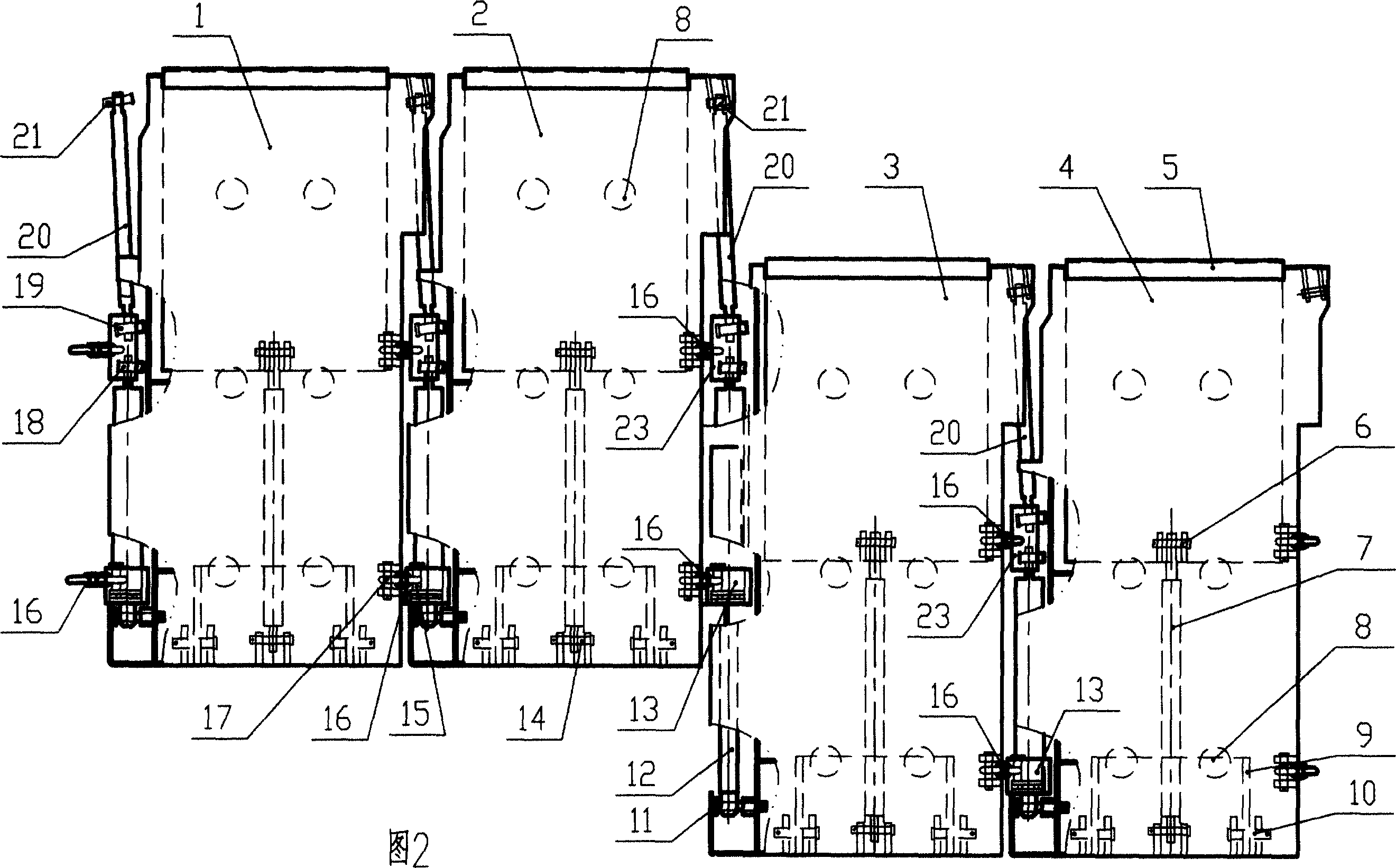

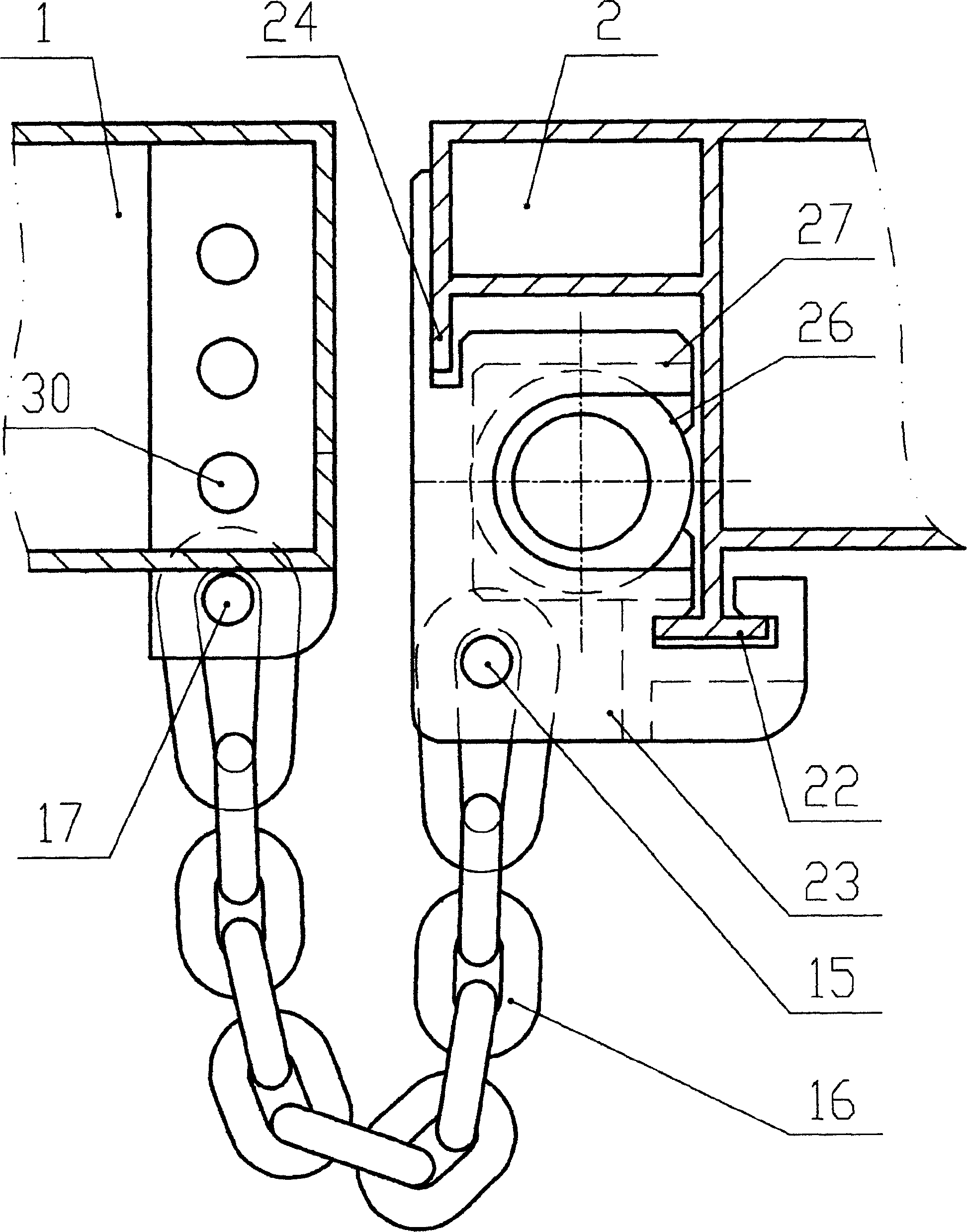

[0016] Combining Figure 1 and image 3 , the first embodiment of the chain-suspended hydraulic support of the present invention includes an integral top beam 1; a slide 13 and a slide 23 that can slide along the lower guide rail 22 and the upper guide rail 24 on the top beam 1; one end is connected with the pin 17 The top beam is hinged, and the other end is respectively hinged with the slider 13 and the slider 23 on the top beam through the pin 15; the hydraulic prop 8 vertically downward from the top beam; the piston rod passes through the pin 11 and the top beam 3 One end of the cylinder is hinged, one end of the cylinder is hinged with the slide 23 through the pin 18, and the other end of the cylinder is connected to the push cylinder 12 with the slide 13 with the corresponding groove 27 through the flange 26 which is integrated with the cylinder; The pin 19 is hinged with the slider 23, and the other end is hinged with the force transmission member 20 at the front end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com