Vertical hydraulic turbine set shaft system adjusting method

A hydraulic turbine shaft and unit technology, which is applied in the direction of hydroelectric power generation, mechanical equipment, engine components, etc., can solve the problems of low safety and stability, excessive shaft swing, high labor intensity, etc., to solve the problem of excessive shaft swing, Ensure installation accuracy and improve installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

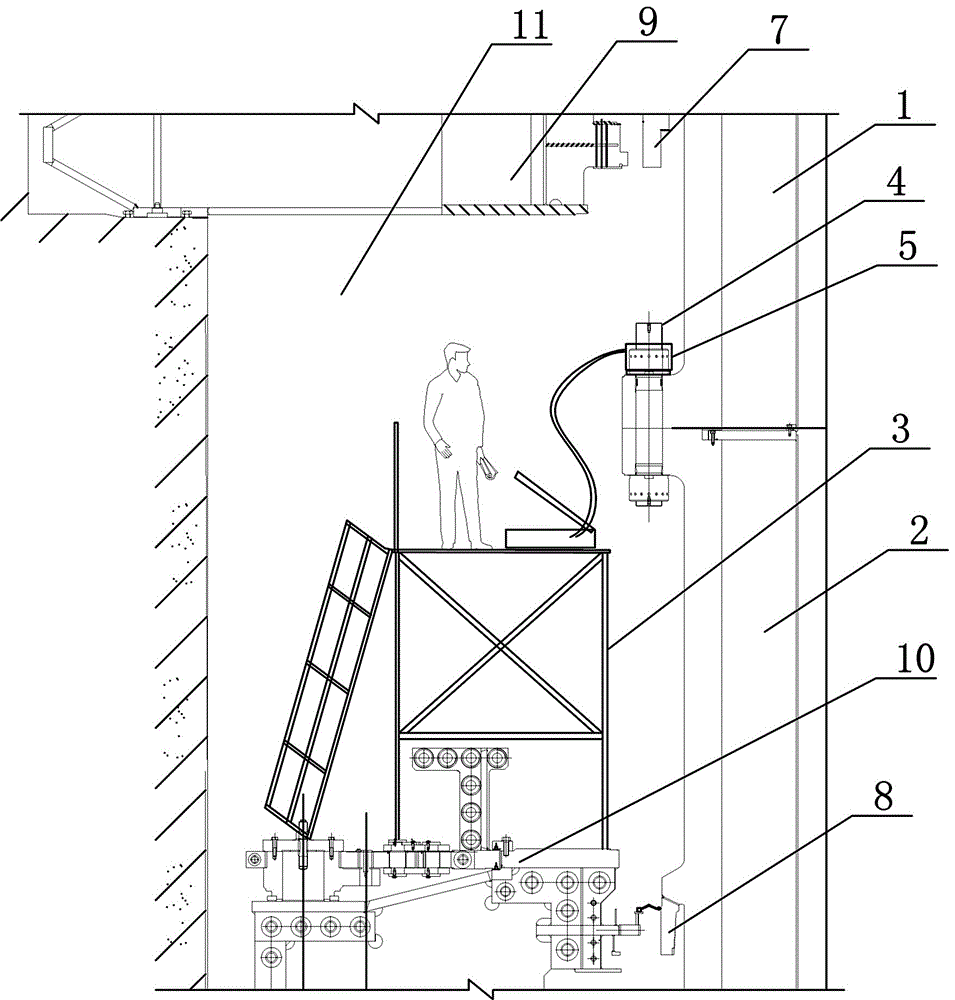

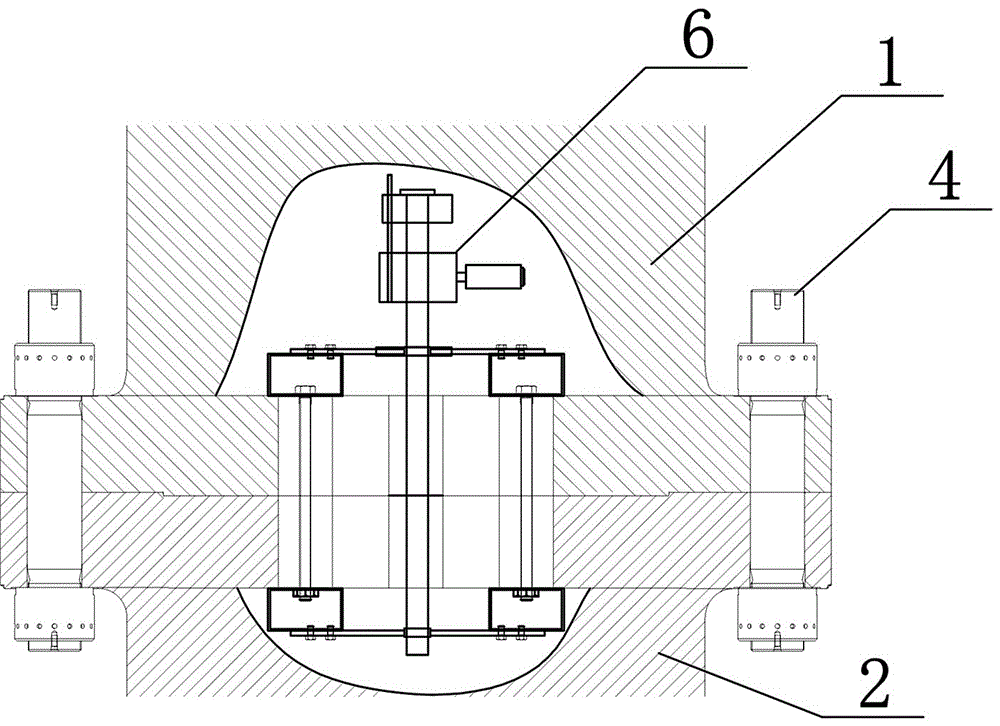

[0023] Such as figure 1 and 2 As shown, a method for adjusting the shafting of a vertical water turbine unit, the method includes the following steps:

[0024] Step 1: Lift the turbine shaft 2 of the vertical turbine unit into the machine pit to connect with the runner, hoist the generator shaft 1 and the turbine shaft 2, pre-tighten all the connecting bolts according to the drawings, and hoist the lower frame 9 and the rotor , the thrust bearing installation is completed, the braking system and the high-pressure oil system have been put into use, the connection between the rotor and the generator shaft is completed, the force conversion of the rotating part is completed, and the center of the rotating part has been pushed to the center of the unit, that is, the unit is ready for cranking;

[0025] After the cranking of the unit meets the conditions, carry out the first cranking to check the shafting swing. If it is qualified, the follow-up work of the unit assembly will be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com