Flexible automatic welding production line for electric four-wheel vehicle frame

An electric four-wheel vehicle and automatic welding technology, which is applied to welding equipment, welding equipment, auxiliary welding equipment, etc., to achieve the effects of small footprint, high utilization rate, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

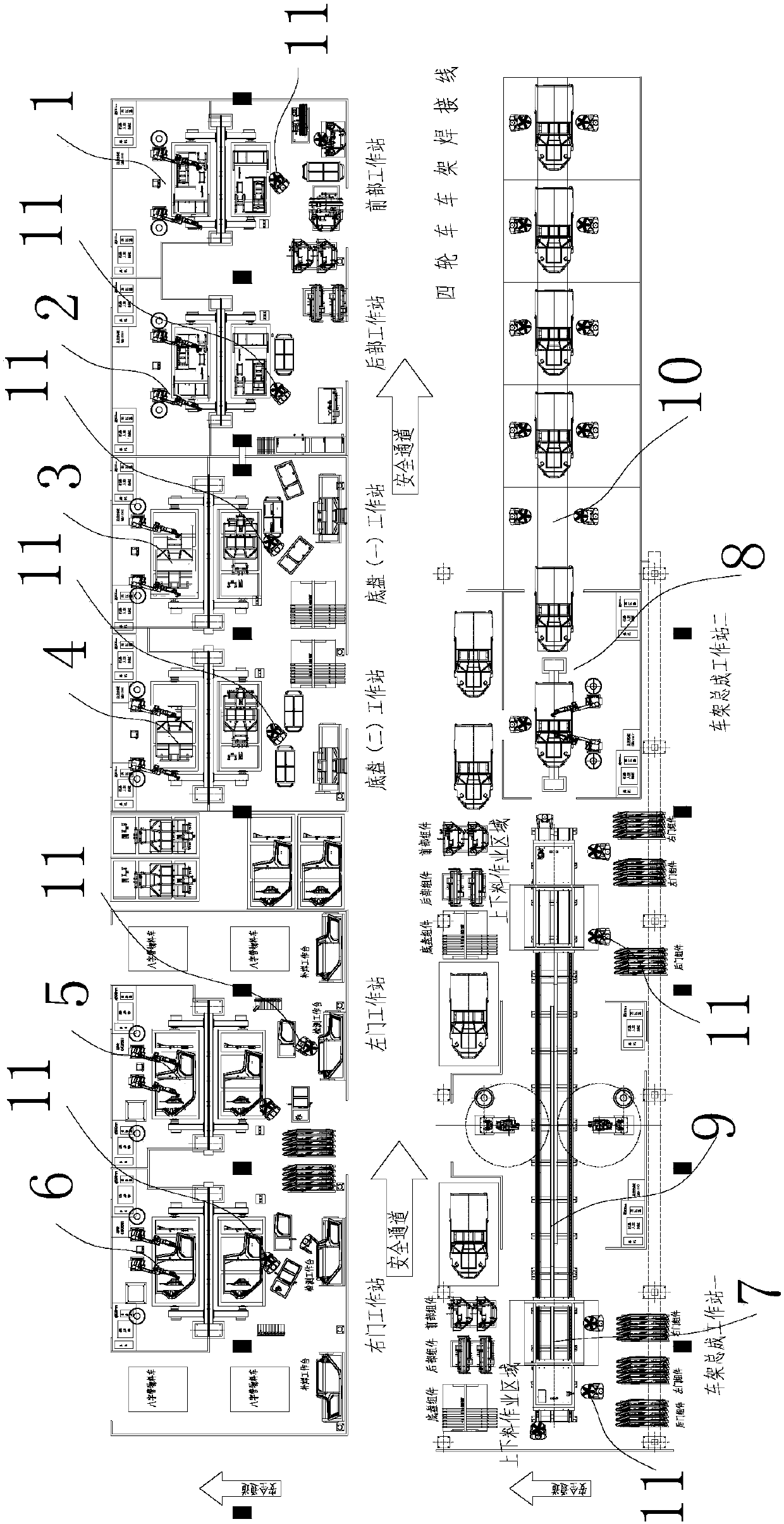

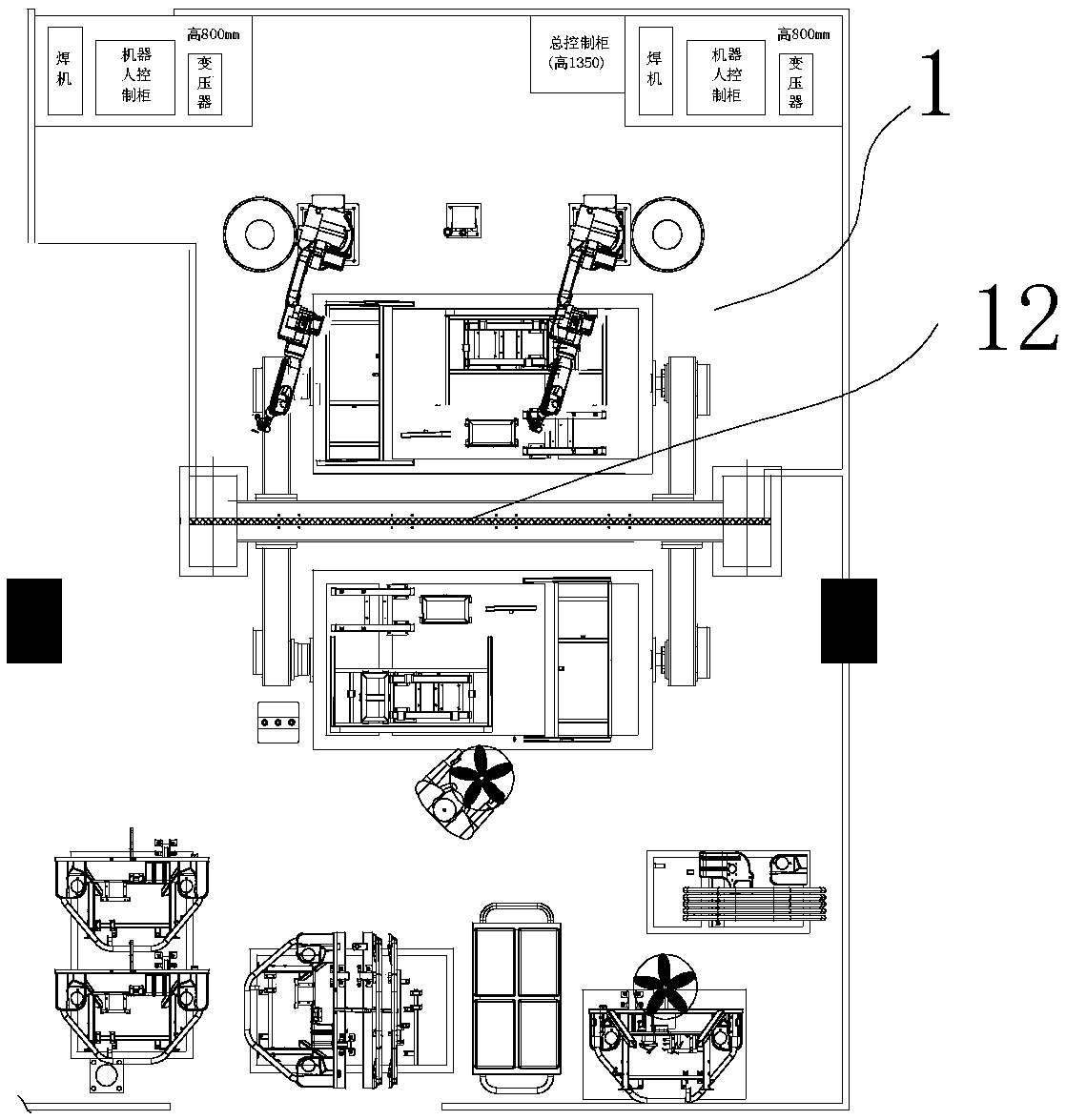

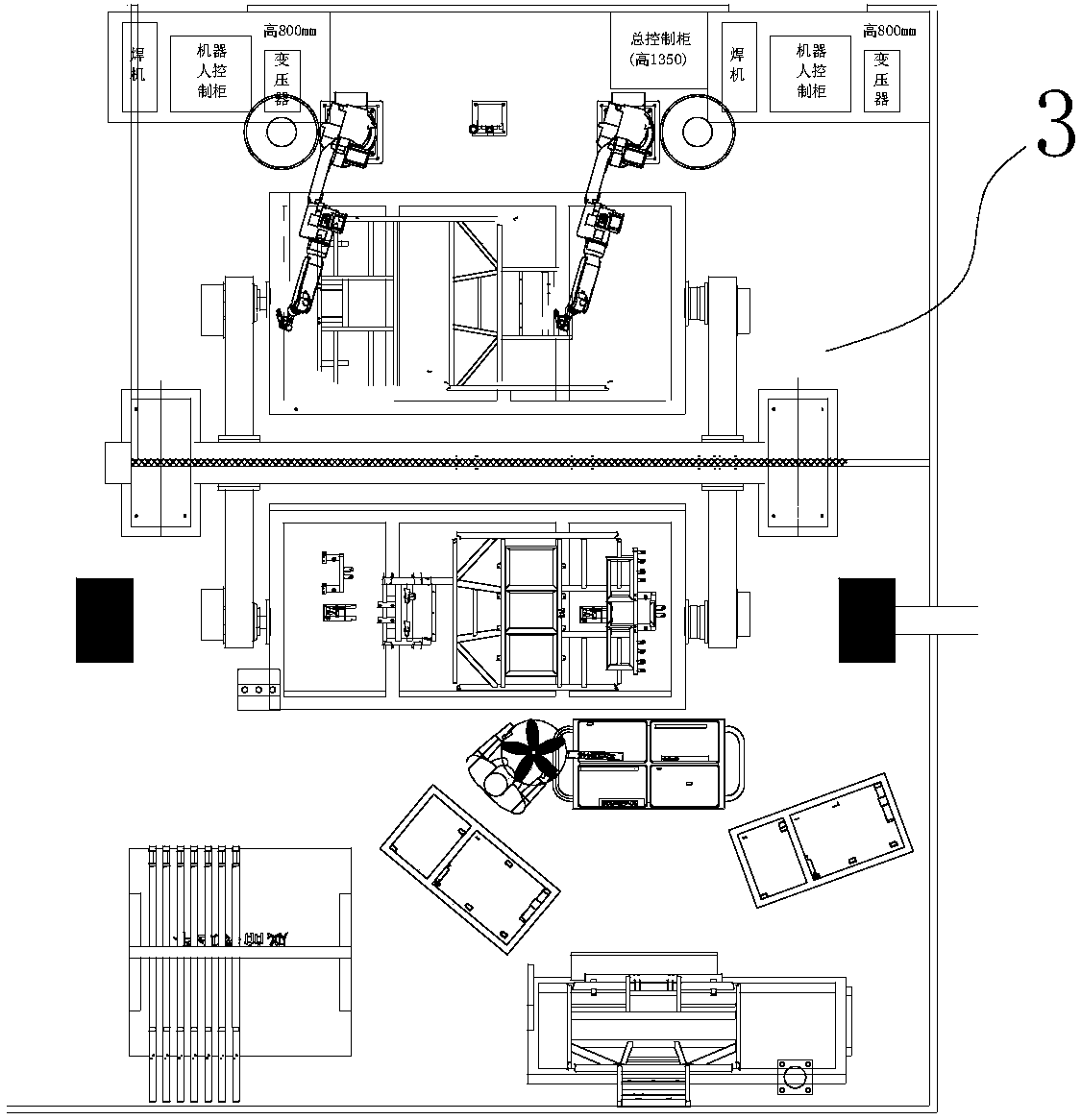

[0029] Electric four-wheel vehicle frame flexible automatic welding production line, such as Figure 1 to Figure 8 As shown, it includes front workstation 1 for electric quadricycle frame welding of front components, rear workstation 2 for rear component welding of electric quadricycle frame, for electric quadricycle frame Chassis one workstation 3 and chassis two workstation 4 for chassis welding, left door workstation 5 for welding the left door assembly of the electric four-wheel vehicle frame, right door workstation for welding the right door assembly of the electric four-wheel vehicle frame 6, and the front assembly, rear assembly, chassis assembly, left door assembly, right door assembly, and the rear door assembly sent together with the finished products are delivered to the loading and unloading operation area to complete the overall assembly of the frame assembly. Workstation one 7 and frame assembly workstation two 8; the front workstation 1, rear workstation 2, chas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com