Online chamfering device for wood pallets

A wooden pallet and angle cutting technology, which is applied in the direction of feeding devices, sawing components, sawing equipment, etc., can solve the problems of high labor intensity, labor intensity of employees, and large area occupied by the angle cutting machine, so as to reduce equipment The site occupies a large area, the environment is improved, and the effect of dust flying around is solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

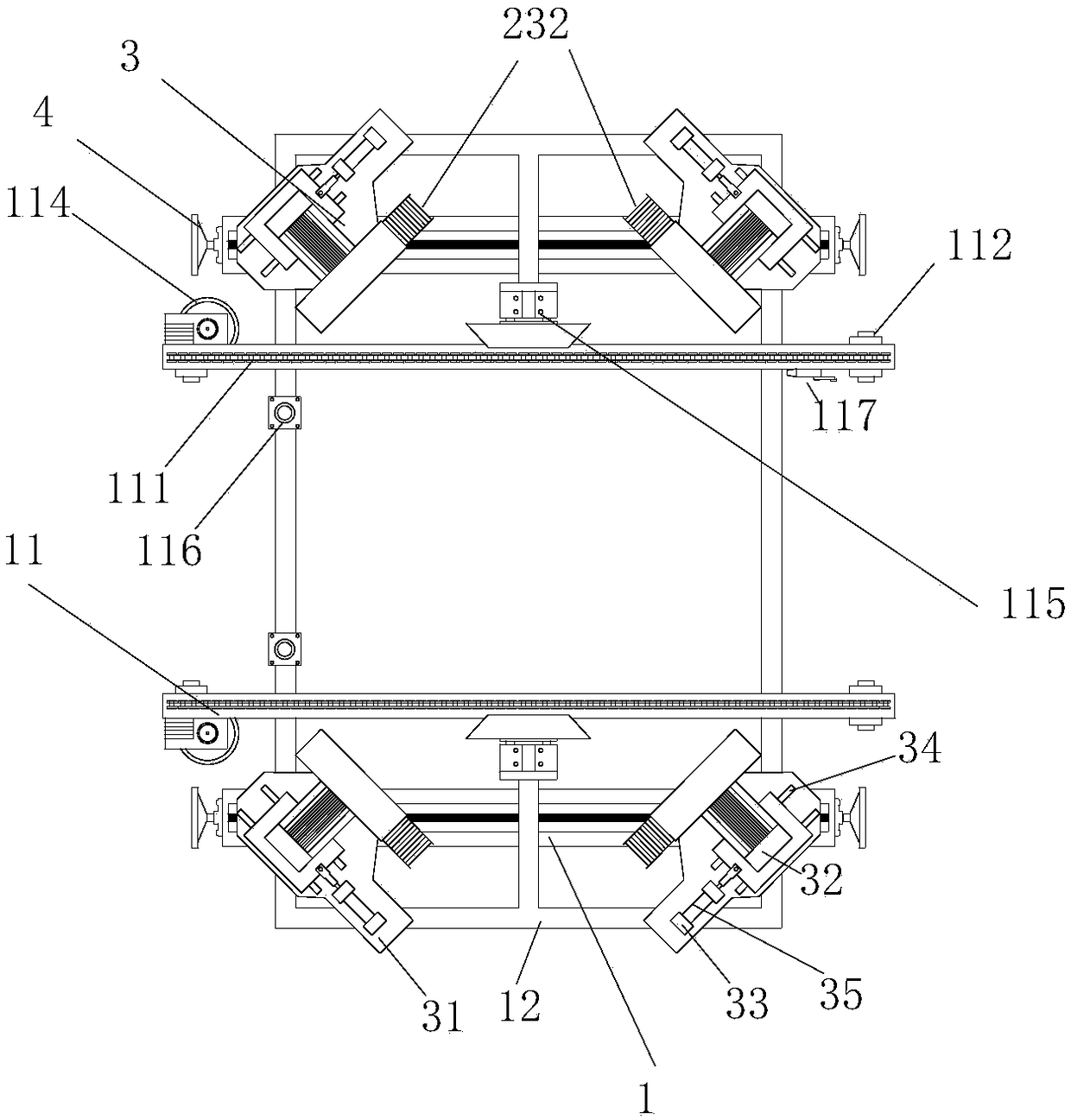

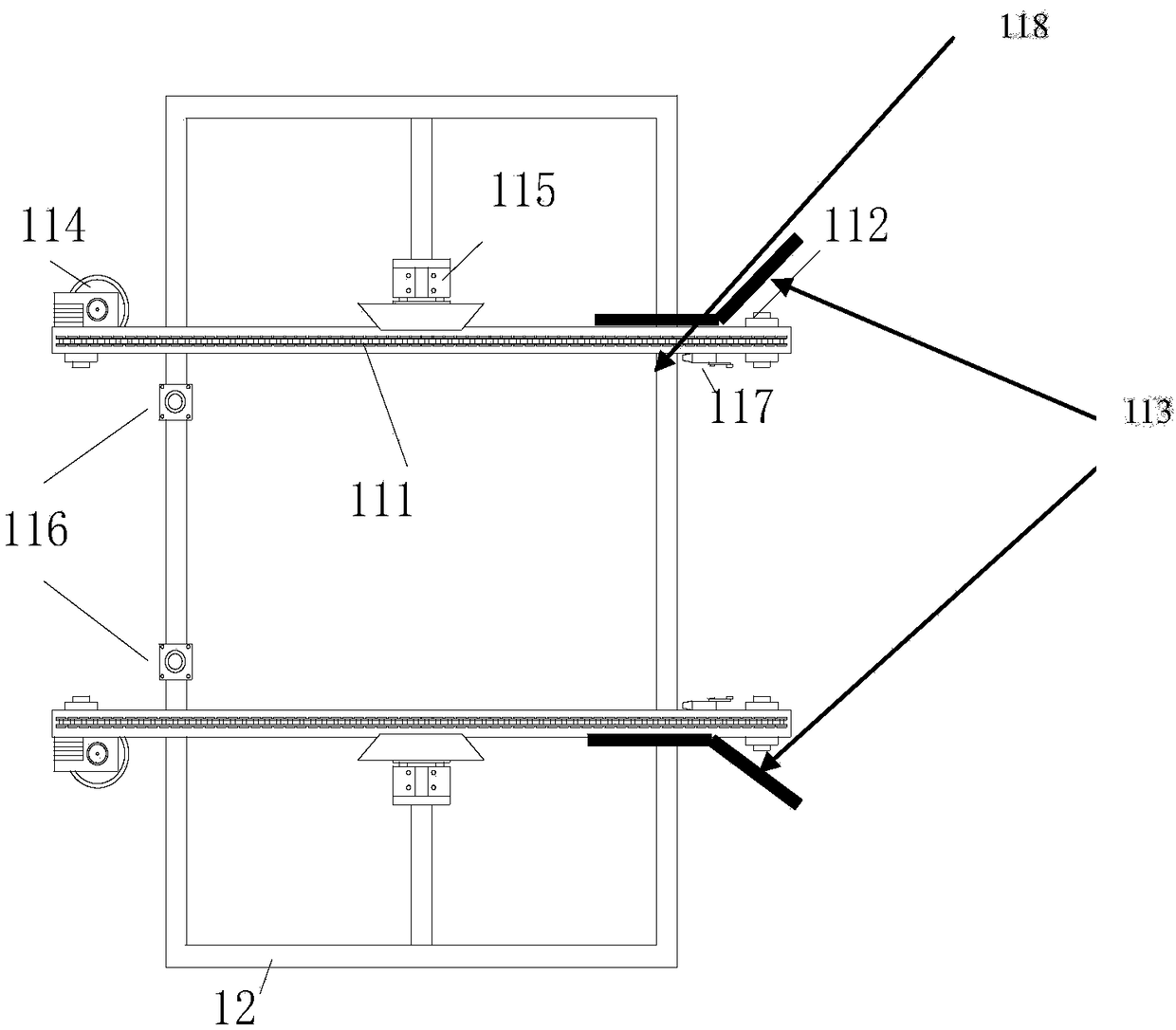

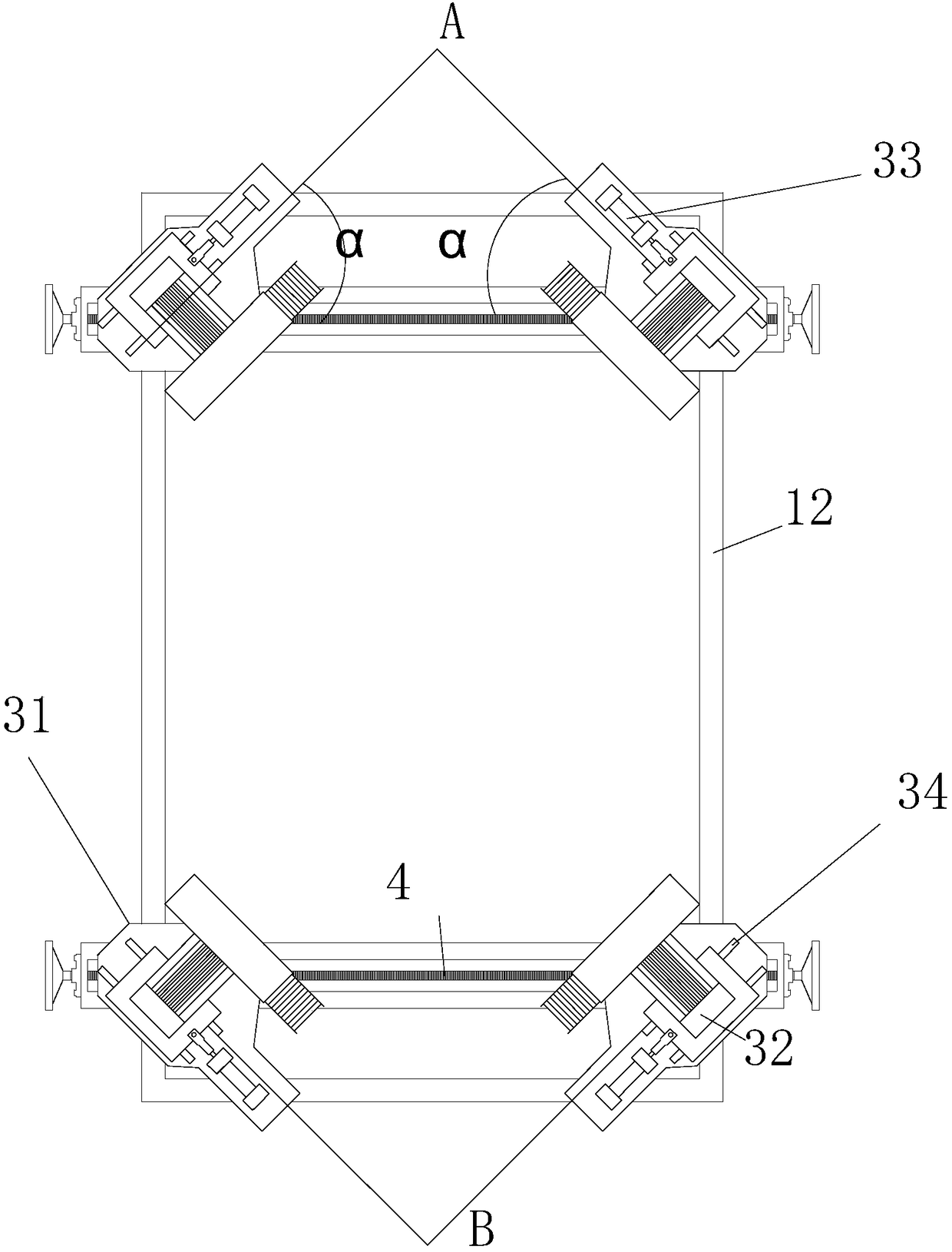

[0024] Embodiment 1 An online corner cutting device for wooden pallets according to the present invention includes a pallet conveying mechanism 1 for conveying the pallets to the dust collection area of the dust suction mechanism, a dust suction mechanism 2 for cleaning the waste on the surface of the pallet, and a The corner cutting mechanism 3 for cutting the corners of wooden pallets, the adjusting screw 4 for adjusting the position of the corner cutting mechanism 3 and the controller for controlling the operation of the entire cleaning device, one end of the pallet conveying mechanism 1 as the pallet placement end , the other end passes through the cutting area directly below the corner cutting mechanism 3 and is transported to the next station. The corner cutting mechanism 3 is installed on the adjusting screw 4 to realize the locking connection between the corner cutting mechanism 3 and the pallet conveying mechanism 1 The control end of the tray conveying mechanism 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com