Tipping bucket barrel plating machine

A tipping bucket and tipping device technology, which is applied in the field of tipping bucket barrel plating machines, can solve problems such as low efficiency, high labor intensity of workers, complex mechanical lifting equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

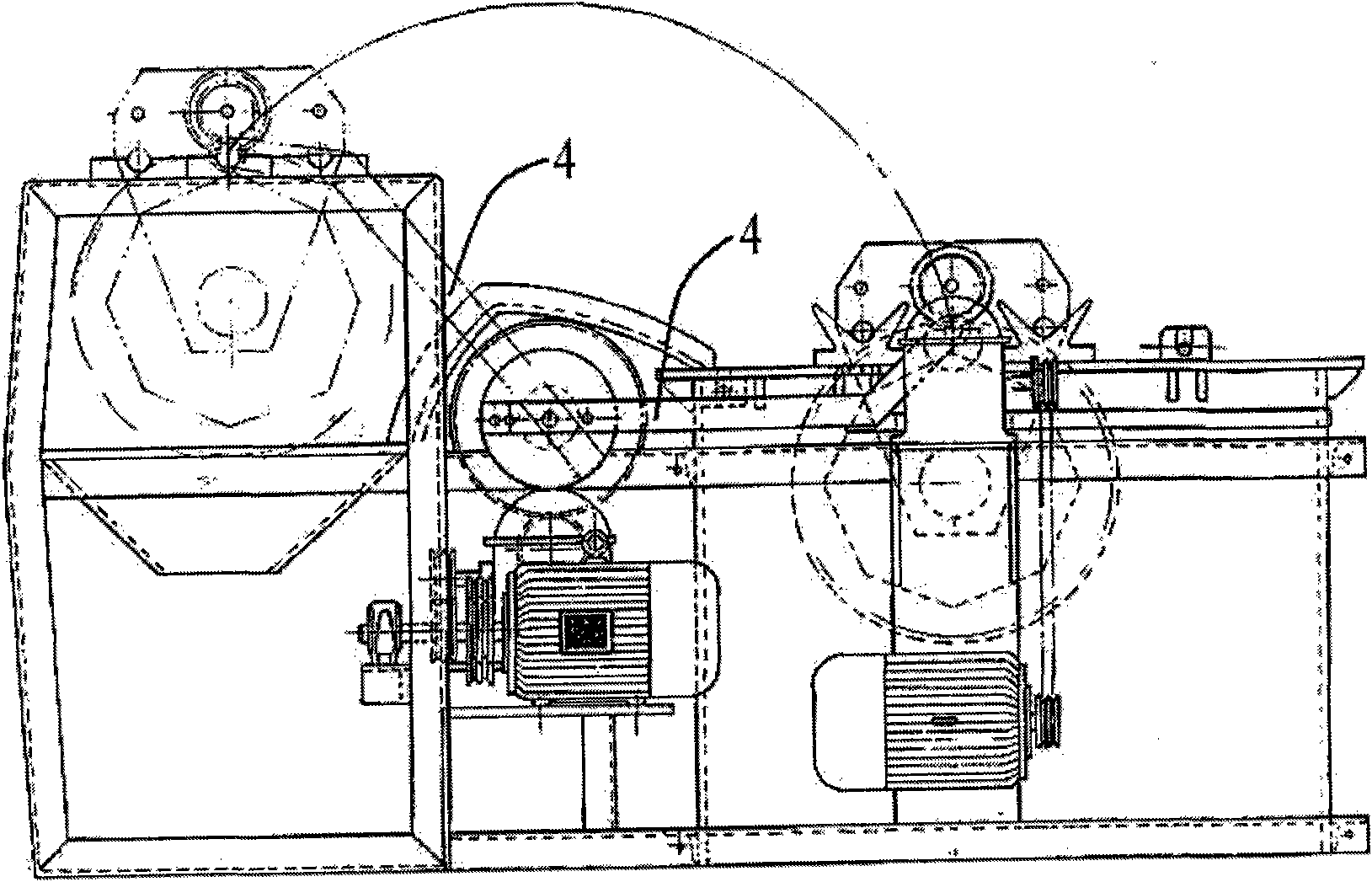

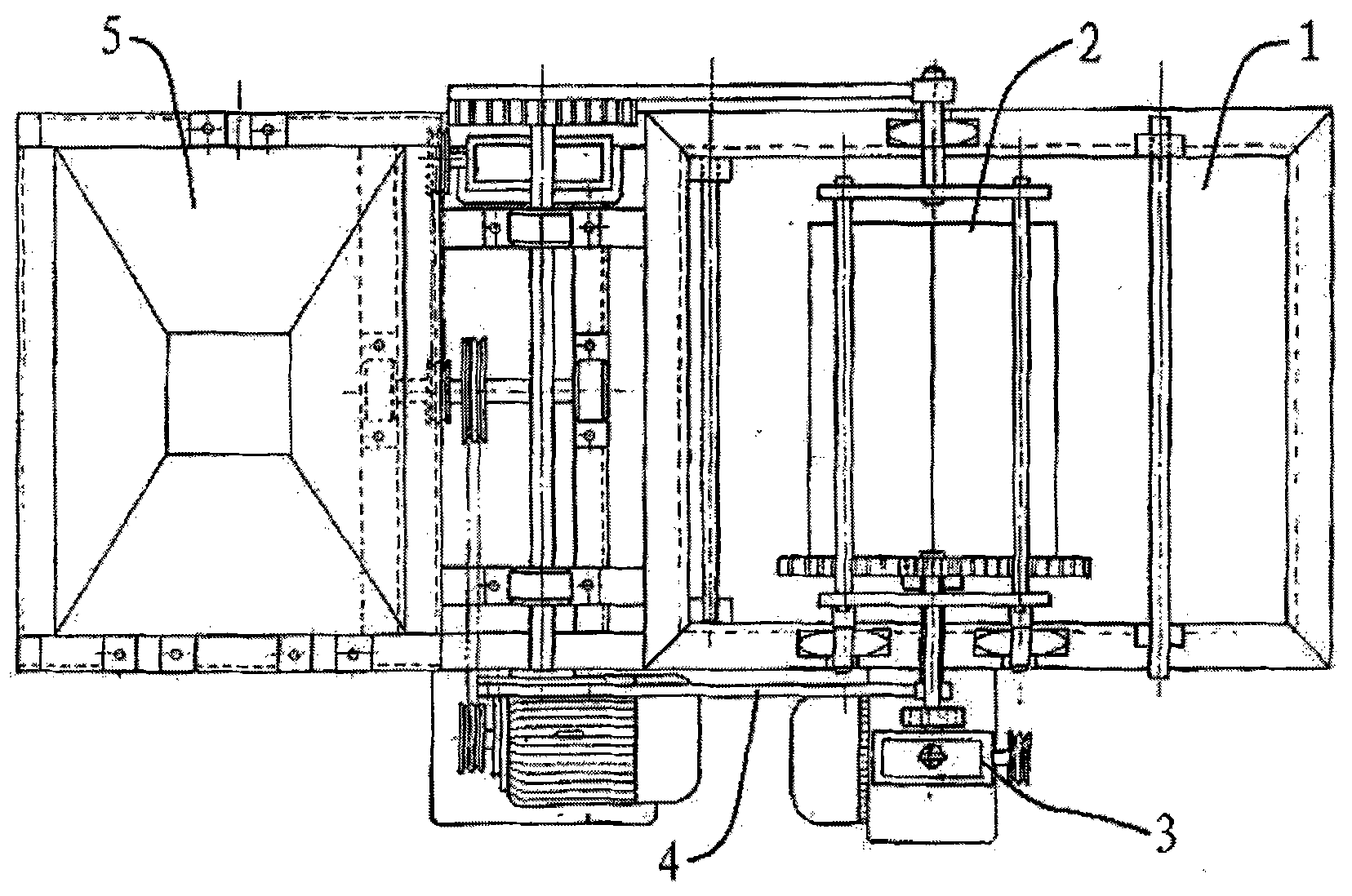

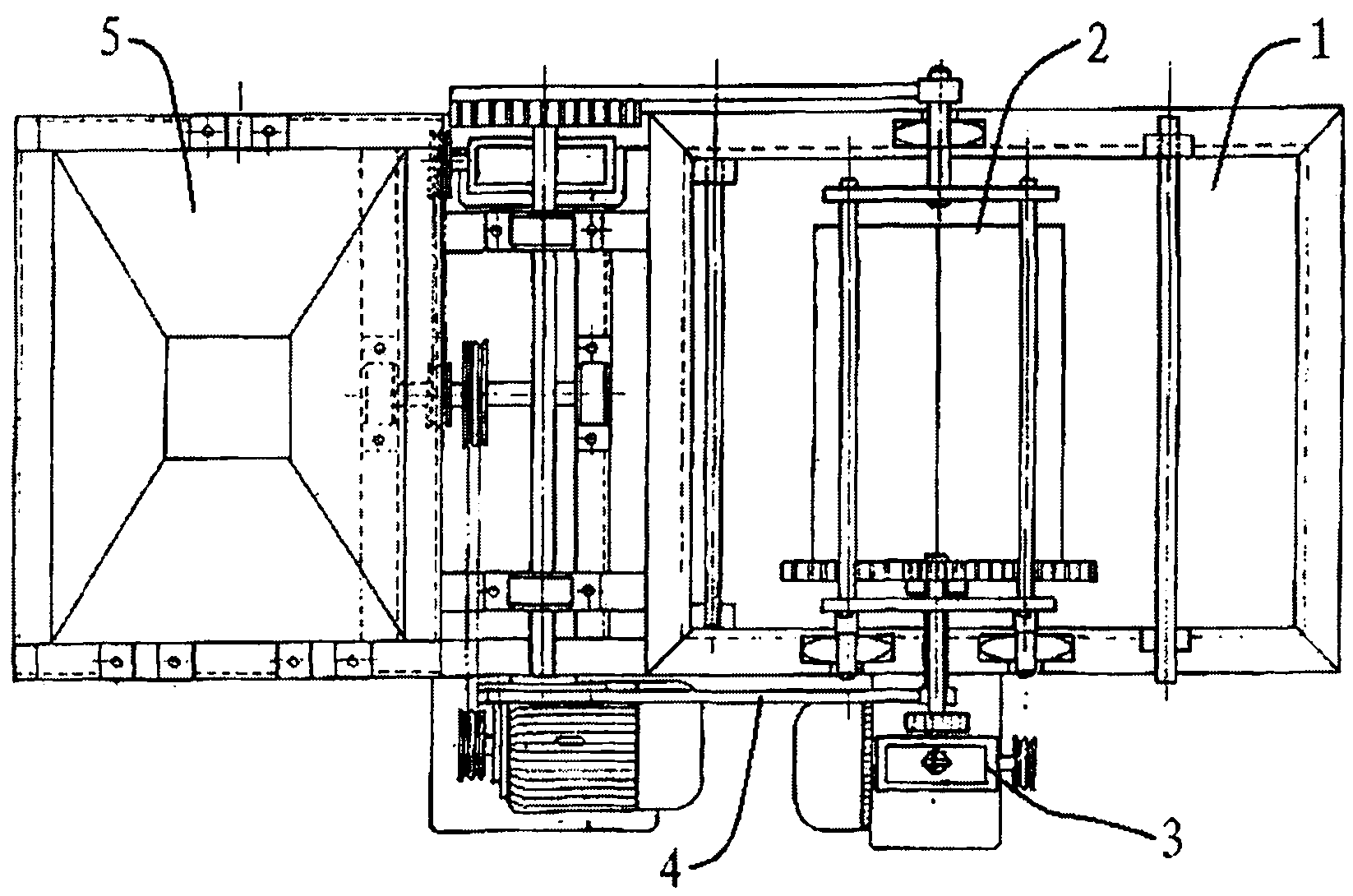

[0017] Such as Figure 1-2 As shown, the tipping bucket type barrel plating machine is mainly composed of plating tank 1, drum 2, drum transmission device 3, tipping bucket device 4, discharge rack 5, tank surface conductive equipment and electrical control equipment, and drum 2 is located in plating tank 1. In addition, tank surface conductive equipment is provided on both sides of the plating tank 1. A drum transmission device 3 is connected to the plating tank 1. The drum transmission device 3 controls the operation of the drum 2 itself. The bucket device 4 is driven by a motor to turn the boom over. Furthermore, the drum 2 is driven by the boom to turn over between the discharging rack 5 and the plating tank 1. When in use, only the power supply and the anode and cathode are connected, and the plating solution can be used.

[0018] Electroplating drum: It is the main component of the tipping bucket barrel plating machine. The material is generally hard polyvinyl chloride. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com