Automatic brush plate machine of zinc electrolysis cathode plate

A cathode plate and automatic brushing technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of high labor intensity, insufficiency, low work efficiency, etc., and achieve high brushing efficiency. , Simple and compact structure, easy to maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings of the description.

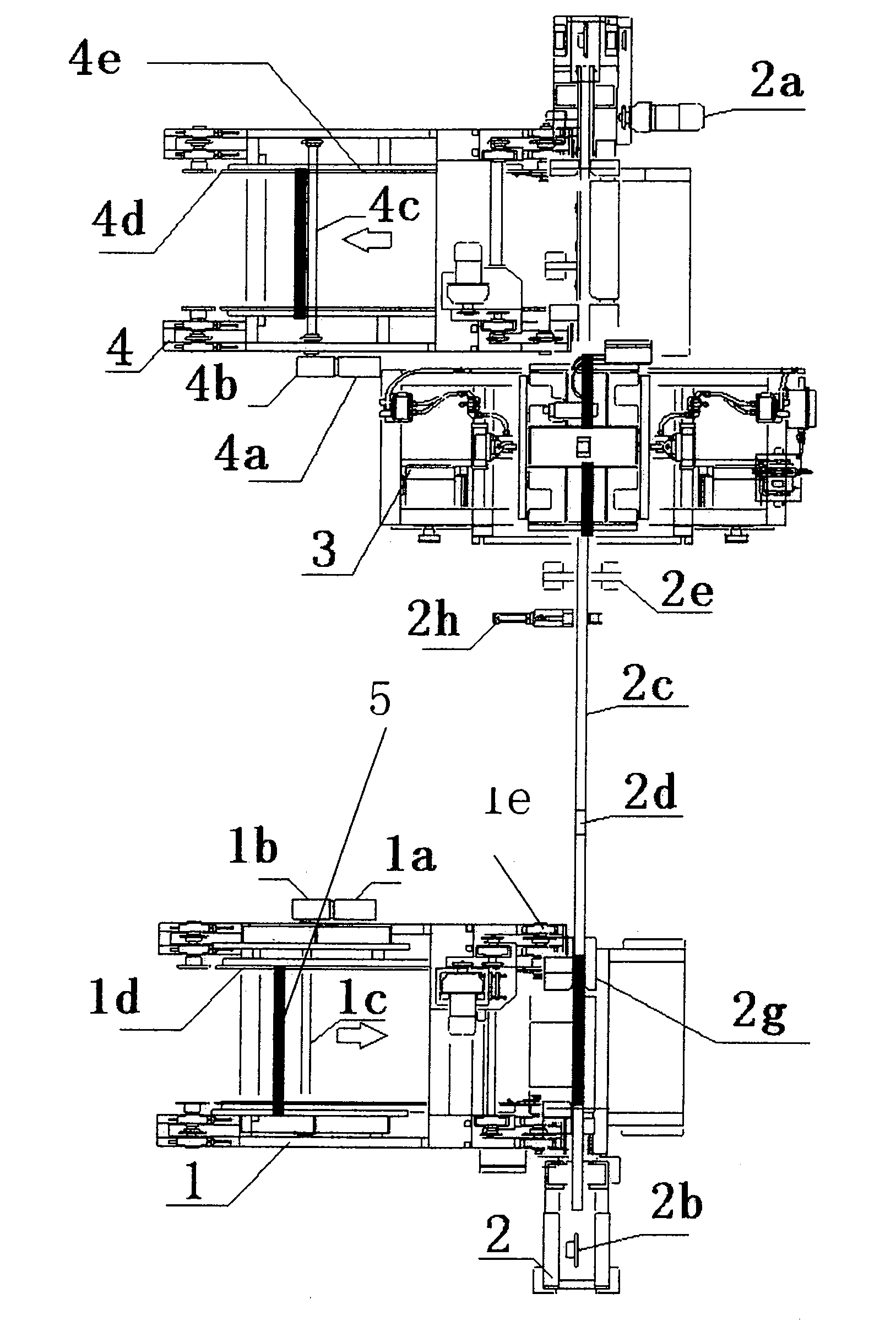

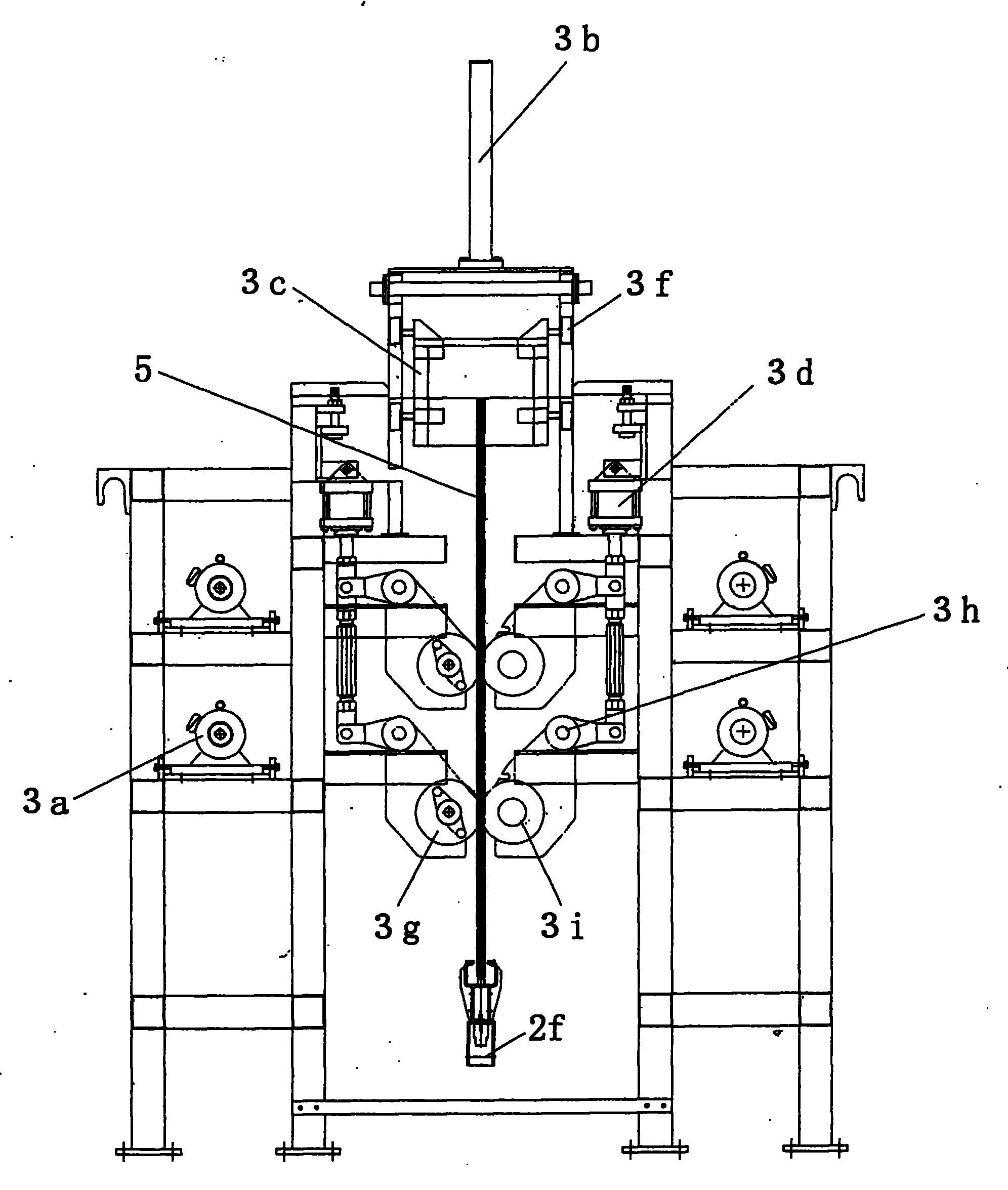

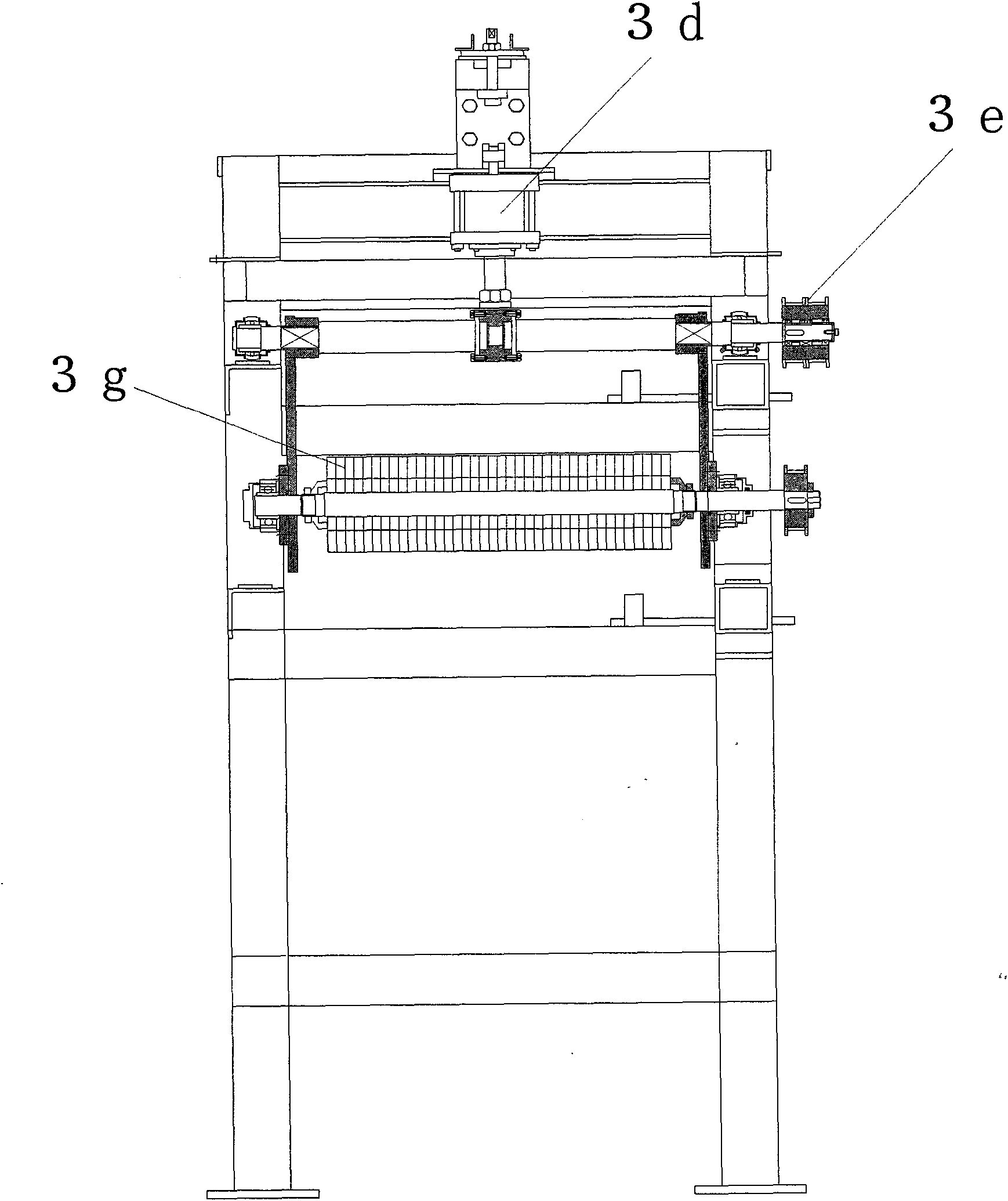

[0013] like figure 1 As shown, the present invention includes a board-feeding and spacing device 1 and a chain conveyor 2 arranged in sequence, and a roller brushing device 3 and a board unloading device 4 are sequentially arranged along the conveyor chain 2d of the chain conveyor 2, and the roller brush The plate device 3 is located below the chain conveyor device 2 .

[0014] The board feeding and spacing device 1 includes a first conveyor and a first mover 1e installed at the output end of the first conveyor, and the first mover 1e adopts a planetary gear structure. The first conveyor includes a frame and a first motor 1a, a first speed reducer 1b, a first main shaft 1c and a first conveyor chain 1d which are sequentially connected and installed.

[0015] The chain conveyor 2 includes a second motor 2a, a sequentially driven sprocket 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com