Combined downward mechanized filling mining method used for steeply inclined and extremely broken ore vein

A backfill mining method and extremely crushing technology, applied in underground mining, backfill, surface mining, etc., can solve the problems of high labor intensity and large amount of cutting and cutting engineering, and achieve a small amount of cutting and cutting engineering, improve recovery efficiency, and improve mining efficiency. The effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

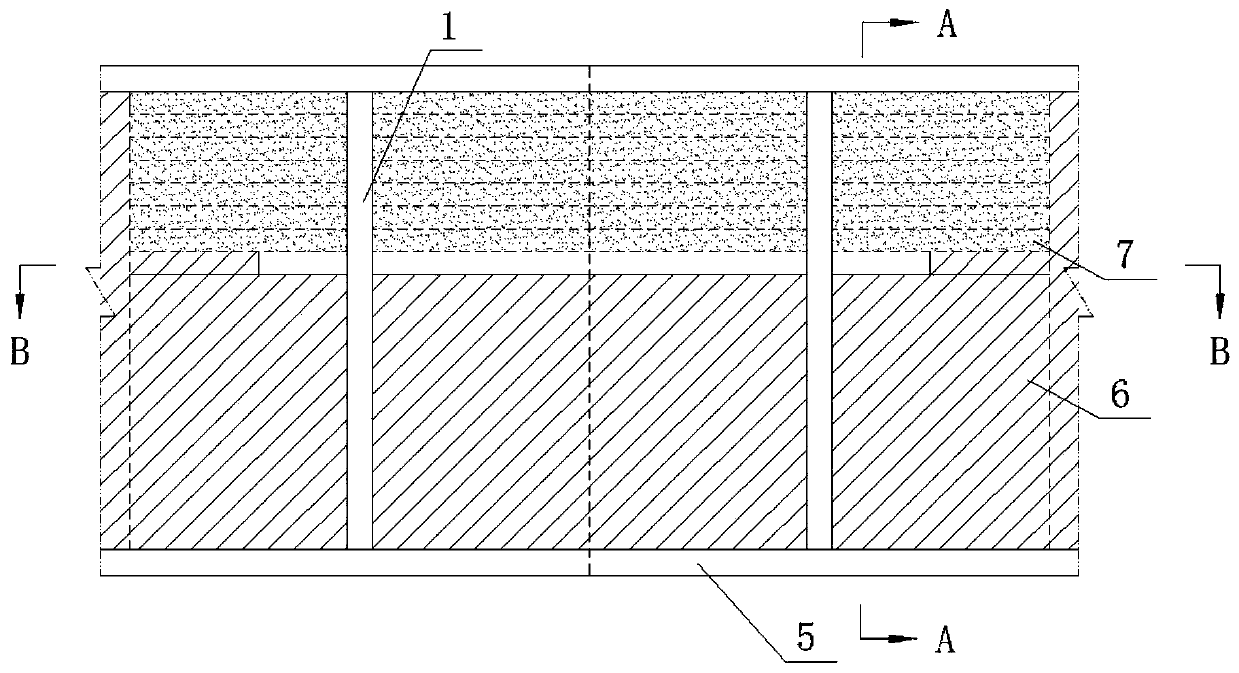

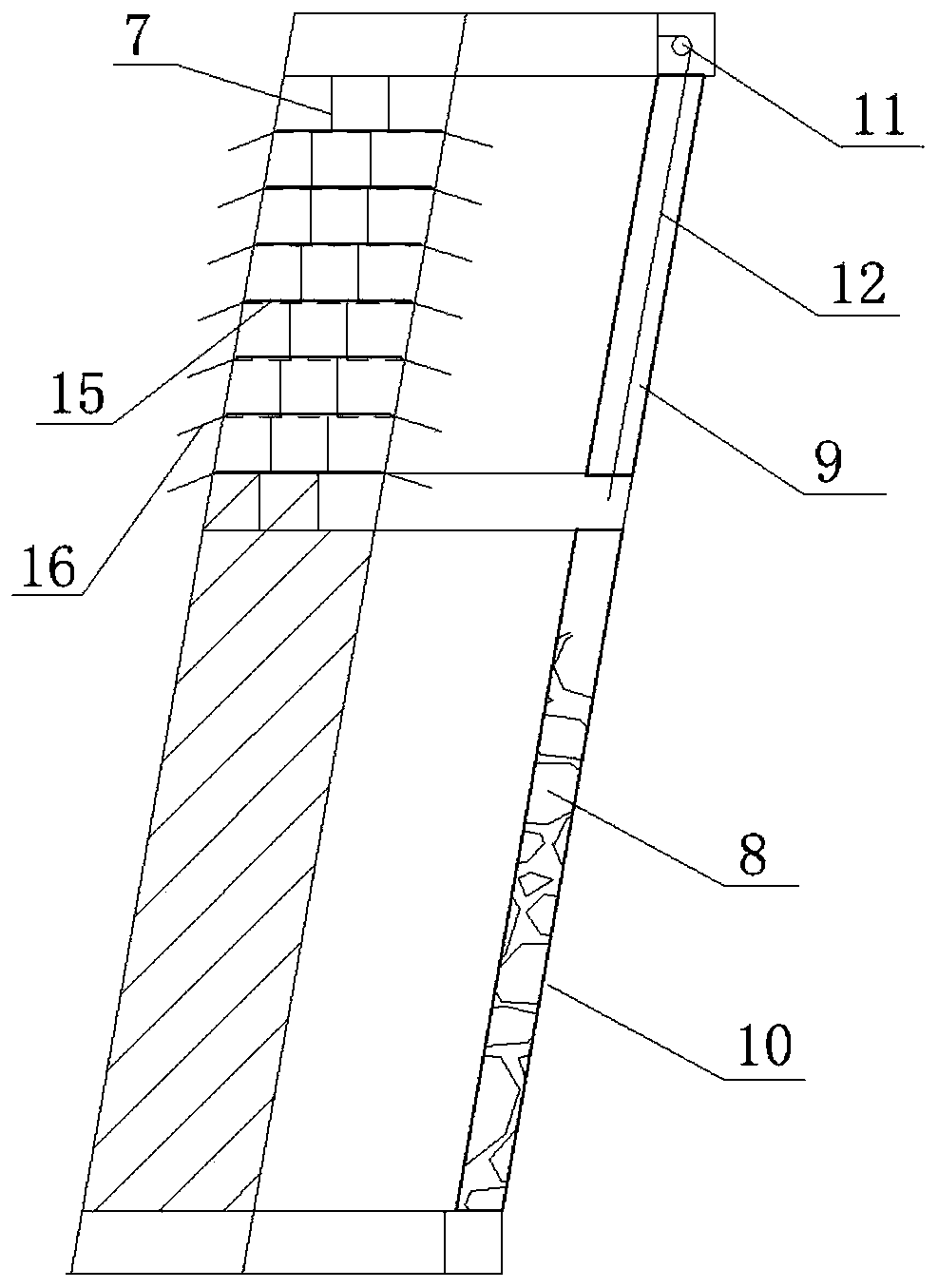

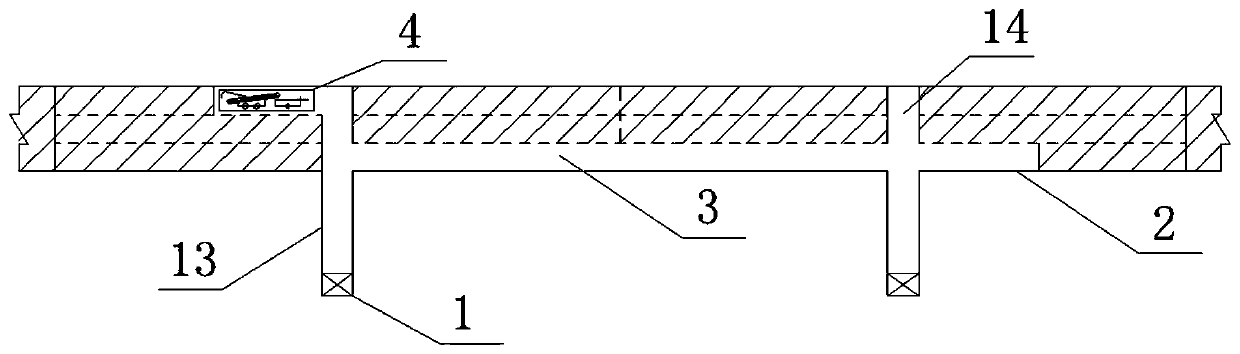

[0027] In the technical solution proposed by the present invention, the original mining standard method is adopted, that is, a raised well outside the vein is arranged in a single stope, and the vertical ore body construction connection road of the raised well outside the vein enters the stope, and then the mining is carried out to the adjacent stope along the ore body The connecting road is used as a channel connecting the two stopes, and then the approach method is used to recover the two stopes at the same time. The aforementioned problems caused by the construction method of excavating the ramp outside the vein in the prior art are avoided. The combination of miniature slag removal machine + self-propelled electric dump truck or skid-steer loader mechanization can ensure safe and efficient ore extraction.

[0028] The following describes in detail that the present invention is used for the combined downward mechanized filling mining method of steeply inclined extremely bro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com