Hydraulic fracturing comprehensive mechanized continuous mining method for gently inclined hard rocks

A comprehensive mechanized and hydraulic fracturing technology, applied in mining equipment, discharge machinery, mining equipment, etc., can solve the problems of fast pick wear, large undulation of ore body floor, short replacement cycle, etc., to reduce ore loss rate, The effect of reducing the amount of mining and cutting work and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

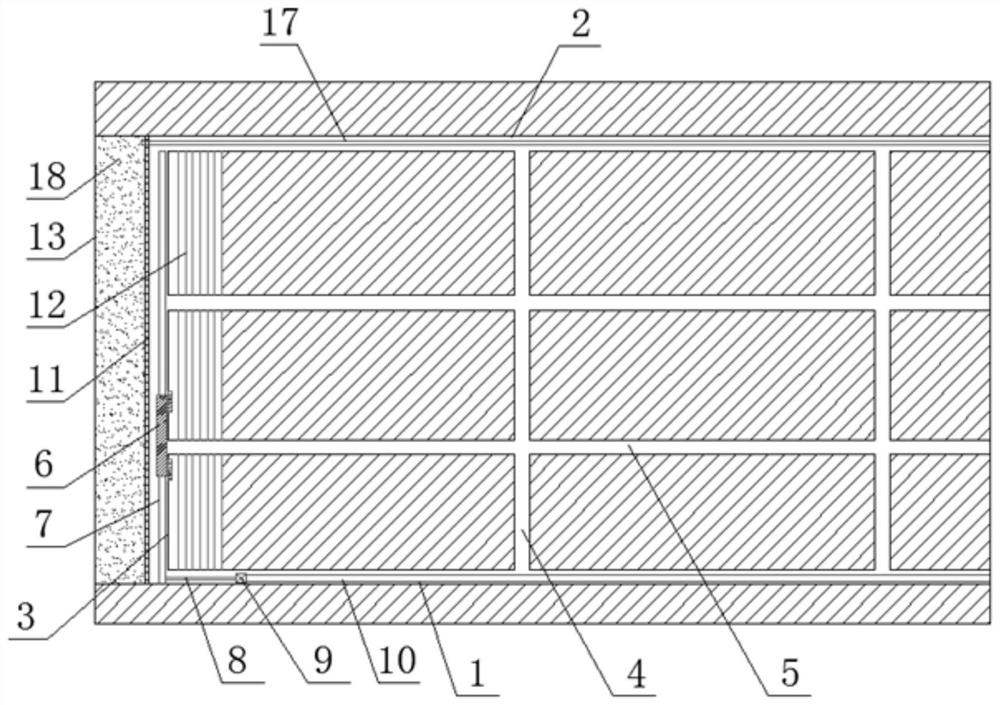

[0043] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

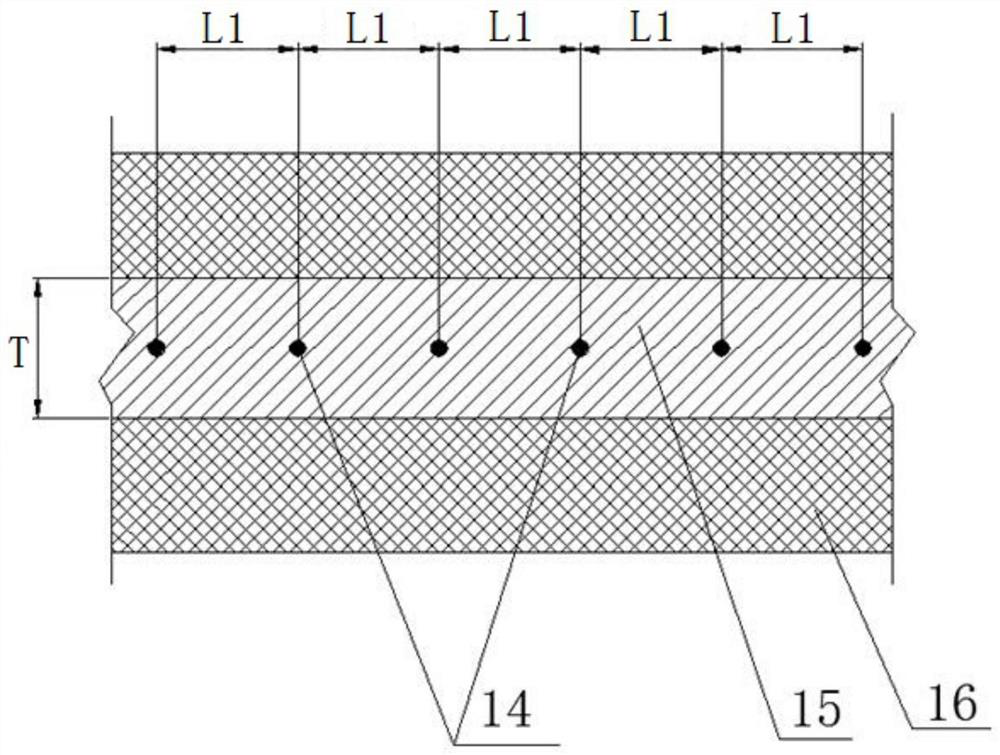

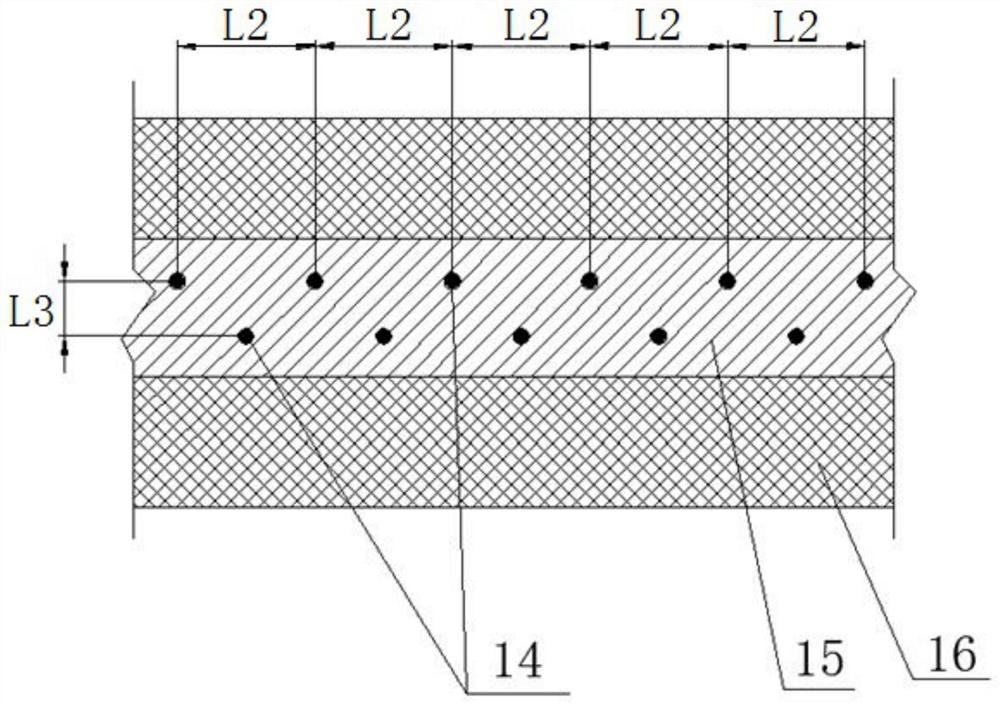

[0044]The mining scale of a certain mine is 600,000 t / a, and the underground mining method is adopted. The average dip angle of the ore body is 21°, the average thickness is 2.4m, the strike length is 2000m, and the buried depth is 500m. The ore types are mainly silicified sandstone and silicified limestone, with an average compressive strength of 72.05Mpa, and the surrounding rocks of the roof and floor are mainly limestone, with an average compressive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com