Coil holder for receiving field winding of rotor, and motor having such coil holder

A technology of coil support and excitation winding, which is applied in the direction of winding, electrical components, electromechanical devices, etc. It can solve the problems that the coil support is not fixed, the filling resin does not reach the excitation winding sufficiently, and achieve the effect of improving insulation and preventing fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

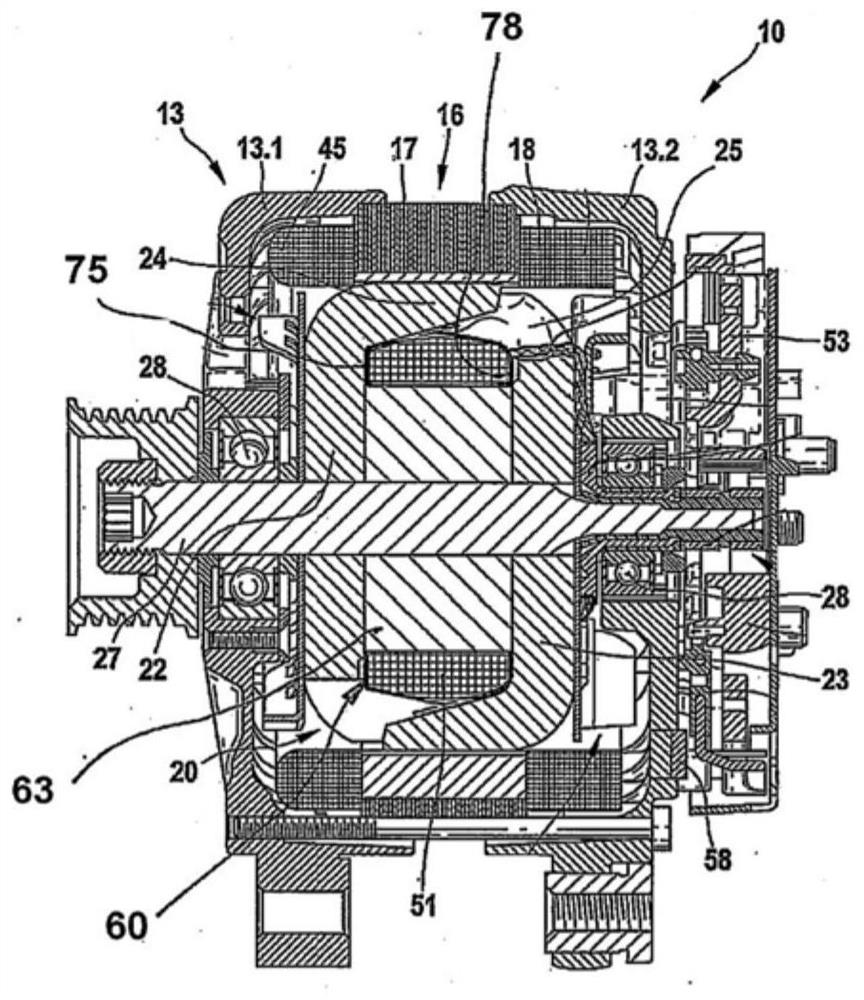

[0025] exist figure 1 A cross-section of an electric machine 10 , which in this embodiment is a generator or a three-phase alternator for a motor vehicle, is shown in . The electric machine 10 also has a two-part housing 13, which is formed from a first end shield 13.1 and a second end shield 13.2. The end shield 13.1 and the end shield 13.2 are accommodated in a so-called stator 16, which on the one hand consists of a substantially annular stator core 17 and in its radially inwardly directed, axial Stator windings 18 are embedded in ground-extending grooves.

[0026] The annular stator 16 surrounds, with its radially inwardly directed slotted surface, a rotor 20 , which is a claw-pole rotor. The rotor 20 also includes two claw-shaped pole plates 22 and 23, on the outer circumference of which claw-shaped pole pins 24 and 25 extending in the axial direction are respectively arranged. The two claw pole plates 22 and 23 are arranged in the rotor 20 such that their claw pole pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com