Solid dye-sensitized nanocrystal/microcrystal silicon composite film solar cell and preparation method thereof

A dye-sensitized and composite thin film technology is applied in the field of solid-state dye-sensitized nanocrystalline microcrystalline silicon composite thin film solar cells and their preparation, and can solve the problems of low preparation rate, poor liquid stability and high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

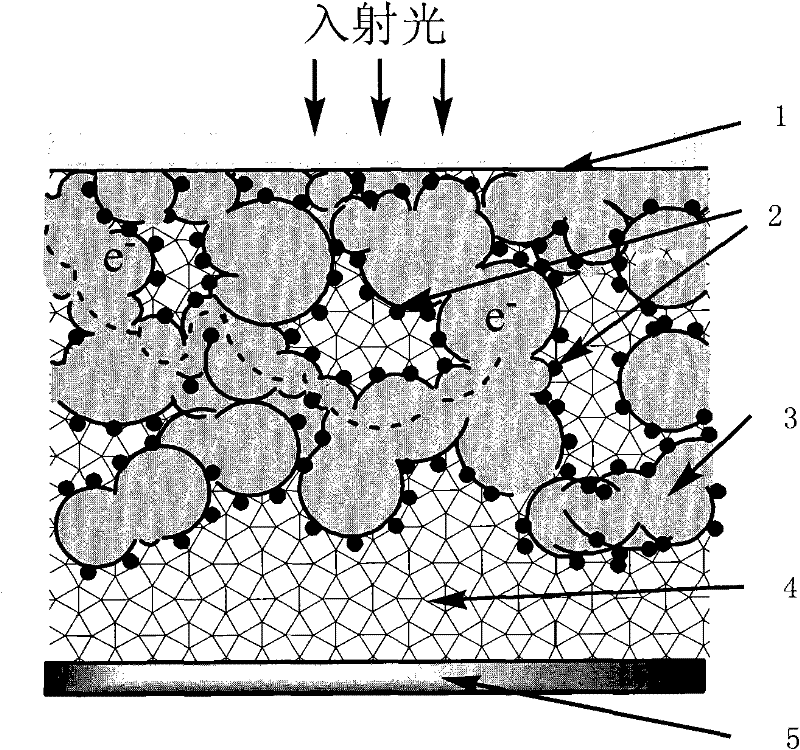

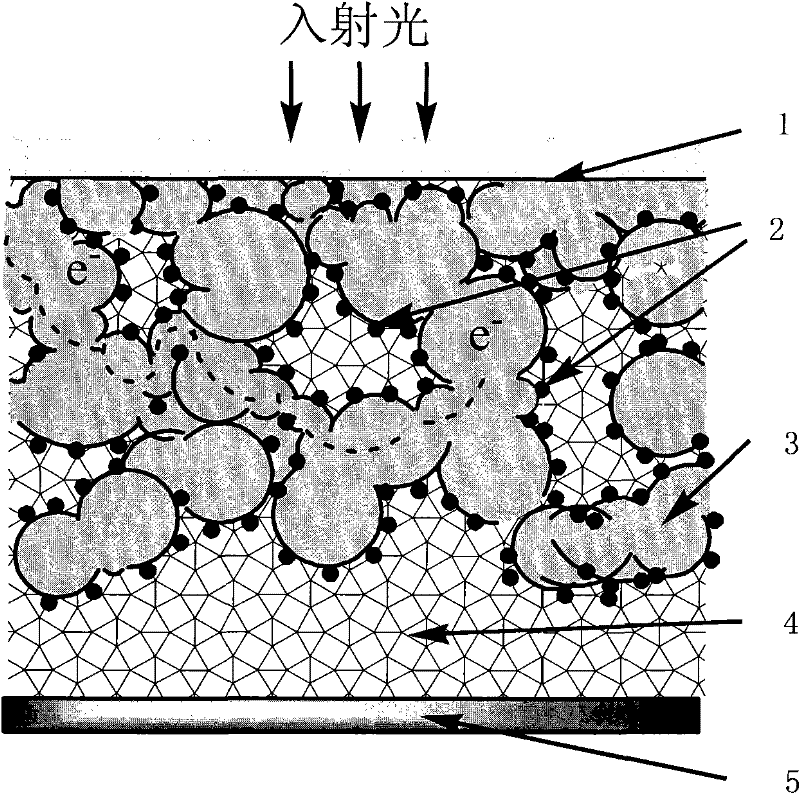

[0074] Solid blackdye dye-sensitized TiO 2 Nanocrystalline microcrystalline silicon composite thin film solar cells made of SnO doped with fluorine 2 Transparent conductive glass substrate, blackdye dye-sensitized TiO 2 Nanocrystalline porous membrane, microcrystalline silicon hole transport layer and aluminum back electrode, the blackdye dye-sensitized TiO 2 Nanocrystalline porous membranes were coated on fluorine-doped SnO 2 On a transparent conductive glass substrate, a microcrystalline silicon hole transport layer is deposited on blackdye dye-sensitized TiO 2 Formation of solid-state blackdye dye-sensitized TiO on nanocrystalline porous membranes 2 Nanocrystalline microcrystalline silicon composite films, films composed of aluminum were coated on solid blackdye dye-sensitized TiO 2 A back electrode is formed on the nanocrystalline microcrystalline silicon composite film.

[0075] The above solid blackdye dye sensitized TiO 2 Nanocrystalline microcrystalline silicon c...

Embodiment 2

[0093] Solid state RuL 2 (NCS) 2 Dye-sensitized TiO 2 Nanocrystalline microcrystalline silicon composite thin film solar cells made of SnO doped with fluorine 2 Transparent conductive glass substrate, RuL 2 (NCS) 2 Dye-sensitized TiO 2 Nanocrystalline porous membrane, microcrystalline silicon hole transport layer and copper back electrode, the RuL 2 (NCS) 2 Dye-sensitized TiO 2 Nanocrystalline porous membranes were coated on fluorine-doped SnO 2 On a transparent conductive glass substrate, a microcrystalline silicon hole transport layer was deposited on RuL 2 (NCS) 2 Dye-sensitized TiO 2 Formation of solid-state RuL on nanocrystalline porous membranes 2 (NCS) 2 Dye-sensitized TiO 2 nanocrystalline microcrystalline silicon composite film, the film composed of copper is plated on solid RuL 2 (NCS) 2 Dye-sensitized TiO 2 A back electrode is formed on the nanocrystalline microcrystalline silicon composite film.

[0094] The above solid RuL 2 (NCS) 2 Dye-sensitiz...

Embodiment 3

[0112] Solid blackdye dye-sensitized TiO 2 Nanocrystalline microcrystalline silicon composite thin film solar cells, made of In doped with Sn 2 o 3 Conductive polyethylene terephthalate substrate for conductive layer, blackdye dye-sensitized TiO 2 Nanocrystalline porous membrane, microcrystalline silicon hole transport layer and aluminum back electrode, the blackdye dye-sensitized TiO 2 Nanocrystalline porous membranes were coated on In doped with Sn 2 o 3 For the conductive layer on a conductive polyethylene terephthalate substrate, a microcrystalline silicon hole transport layer was deposited on blackdye dye-sensitized TiO 2 Formation of solid-state blackdye dye-sensitized TiO on nanocrystalline porous membranes 2 Nanocrystalline microcrystalline silicon composite films, films composed of aluminum were coated on solid blackdye dye-sensitized TiO 2 A back electrode is formed on the nanocrystalline microcrystalline silicon composite film.

[0113] The above solid blackd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com