Nonreciprocal circuit device and its mounting structure

A technology of circuit devices and circuit boards, applied in the direction of circuits, electrical components, waveguide devices, etc., can solve the problems of miniaturization and weight reduction, difficulty in miniaturization of devices, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

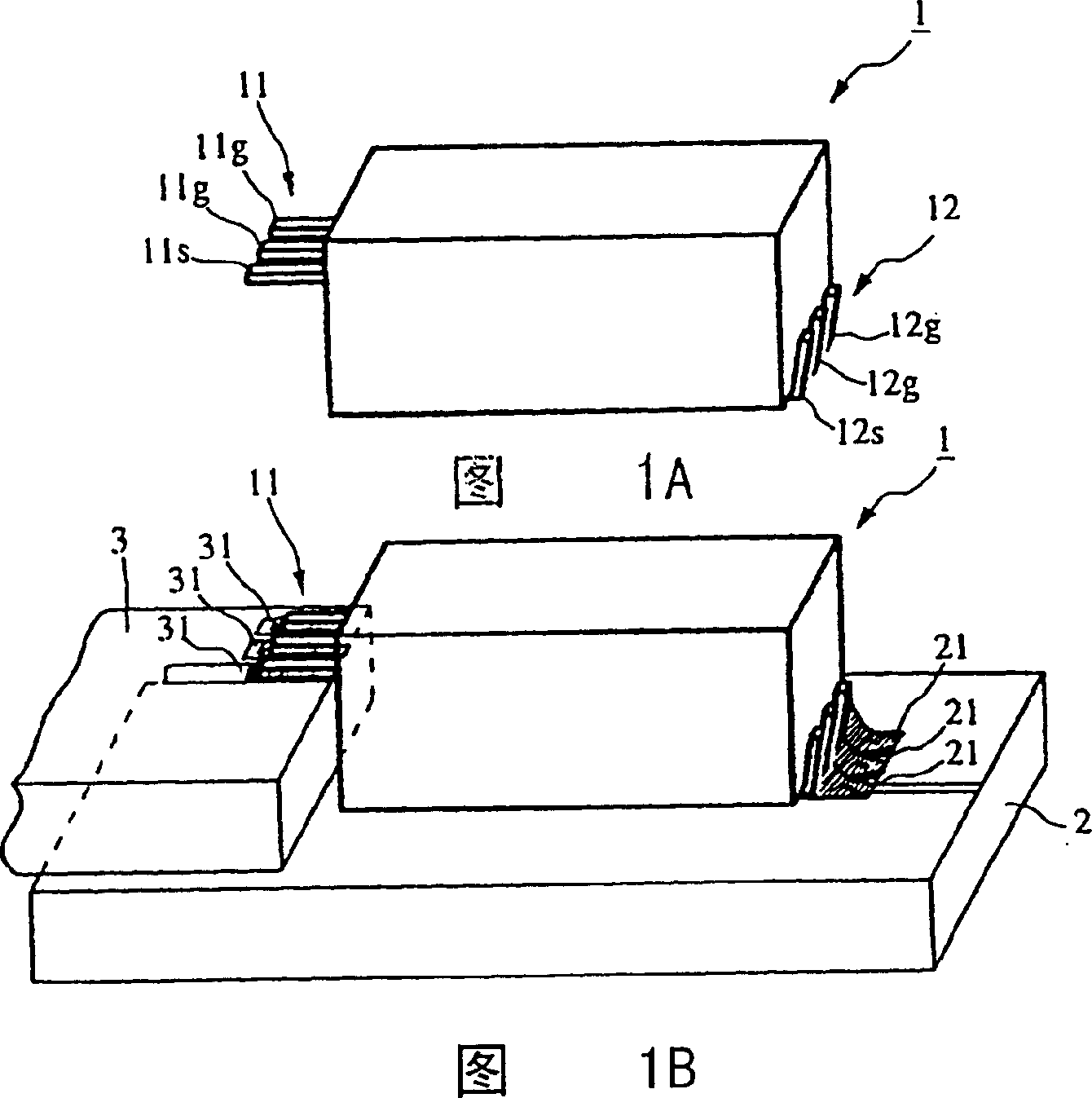

[0044] 1A to 5B, the isolator and its mounting structure according to the first embodiment will be described.

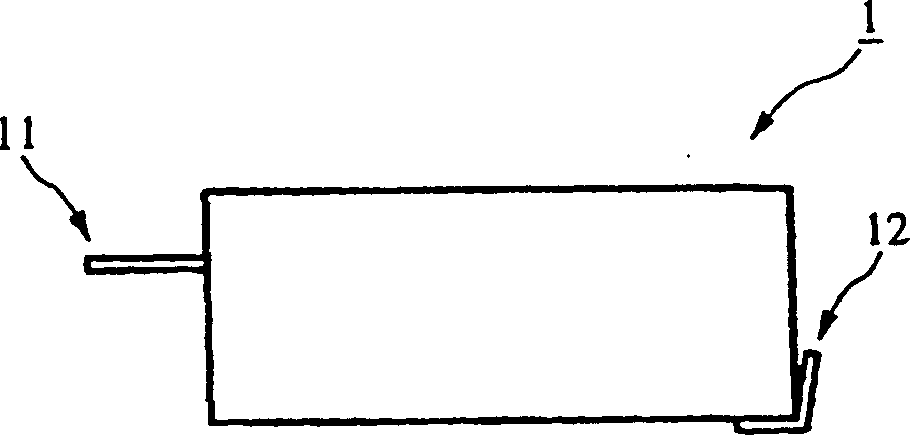

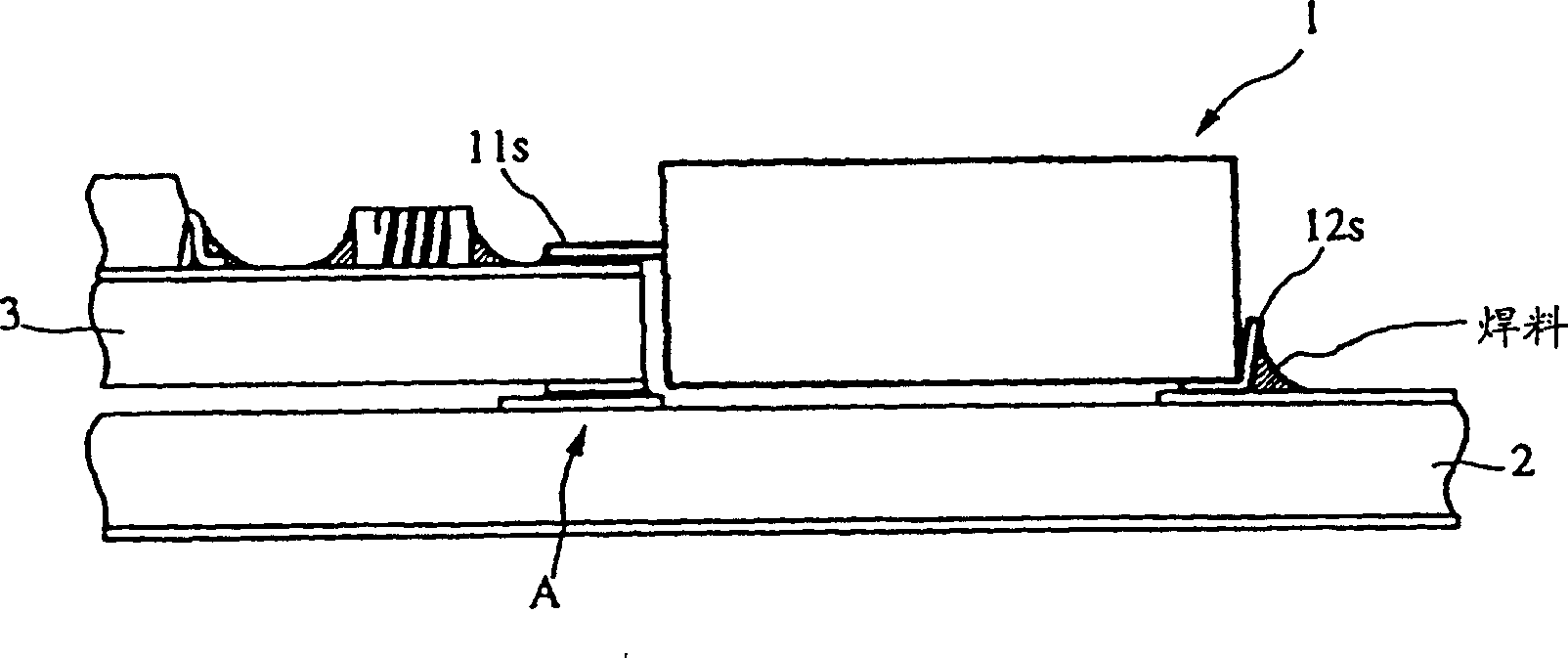

[0045] Fig. 1A is a perspective view of an isolator; Fig. 1B is a perspective view of the isolator in an installed state. The bottom surface of the isolator 1 seen in the figure is a mounting surface; the input terminals 11 are arranged in parallel on the first side of the mounting surface and are at a predetermined height; the output terminals 12 are arranged in parallel on the installation opposite to the first side. The second side of the surface. The input terminal 11 is formed by a hot (voltage) terminal 11s and two ground terminals 11g; the output terminal 12 is formed by a hot terminal 12s and two ground terminals 12g.

[0046] In FIG. 1B, a module circuit board 3 and an isolator 1 are mounted on the top surface of a printed circuit board 2, which forms most of the circuits of the communication device. On the module circuit board 3, for example, a power amplifier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com