Device and method for the in-situ production of articulating spacers

A joint spacer, in-situ technology, applied in elbow joints, knee joints, joint implants, etc., can solve the problems of air inclusion damage, harmful sliding characteristics of joint spacers, complex mold structure, etc., and achieve low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

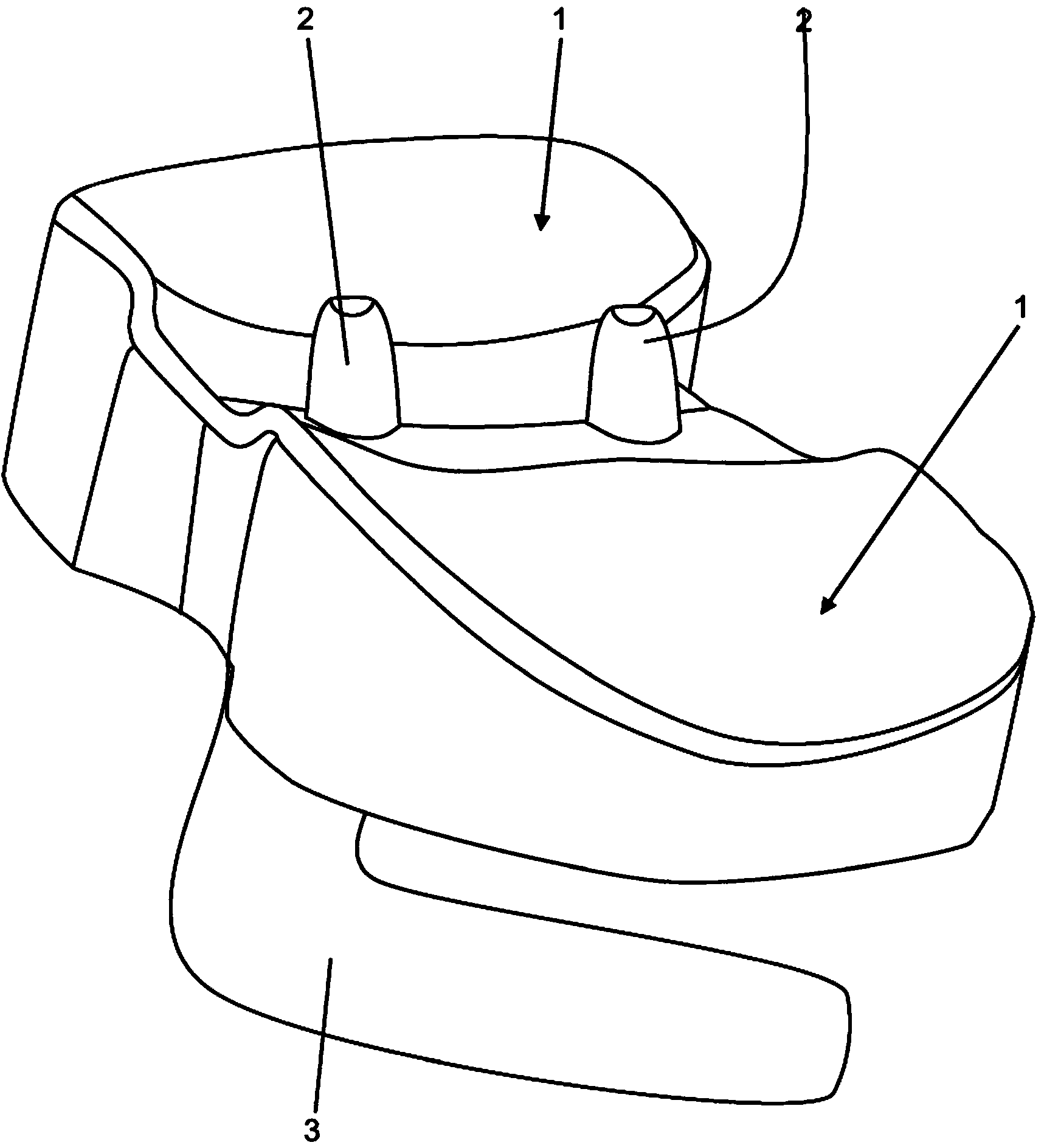

[0080] figure 1 A schematic perspective view showing a femoral die made of thermoplastic material according to the invention. exist figure 1 In the view shown, the femoral die comprises an upwardly facing die surface 1 for forming an articular surface in bone cement (not shown), thereby placing the bone cement on the prepared end of the femur. For this purpose, bone cement is attached to the contact surface on the femur. When the raw components of the bone cement react with each other, the bone cement first becomes doughy, ie more viscous. In this condition, the die surface 1 of the femoral die is pressed against the bone cement. The fully cured bone cement later forms the femoral joint spacer and replicates at least the condyles of the femur.

[0081] The thickness of the bone cement and of the spacer later formed therefrom is determined by the height of the two separators 2 arranged on the mid-plane of the femoral die. The flat end of the separator 2 serves as a contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com