Truck coordinated mine removal subsection drilling stage room mining method

A stage mine method and truck technology, applied in surface mining, underground mining, special mining, etc., can solve the problems of destructive bottom structure, low mining efficiency, large amount of mining and cutting engineering, etc. The effect of increased strength and simplified bottom structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

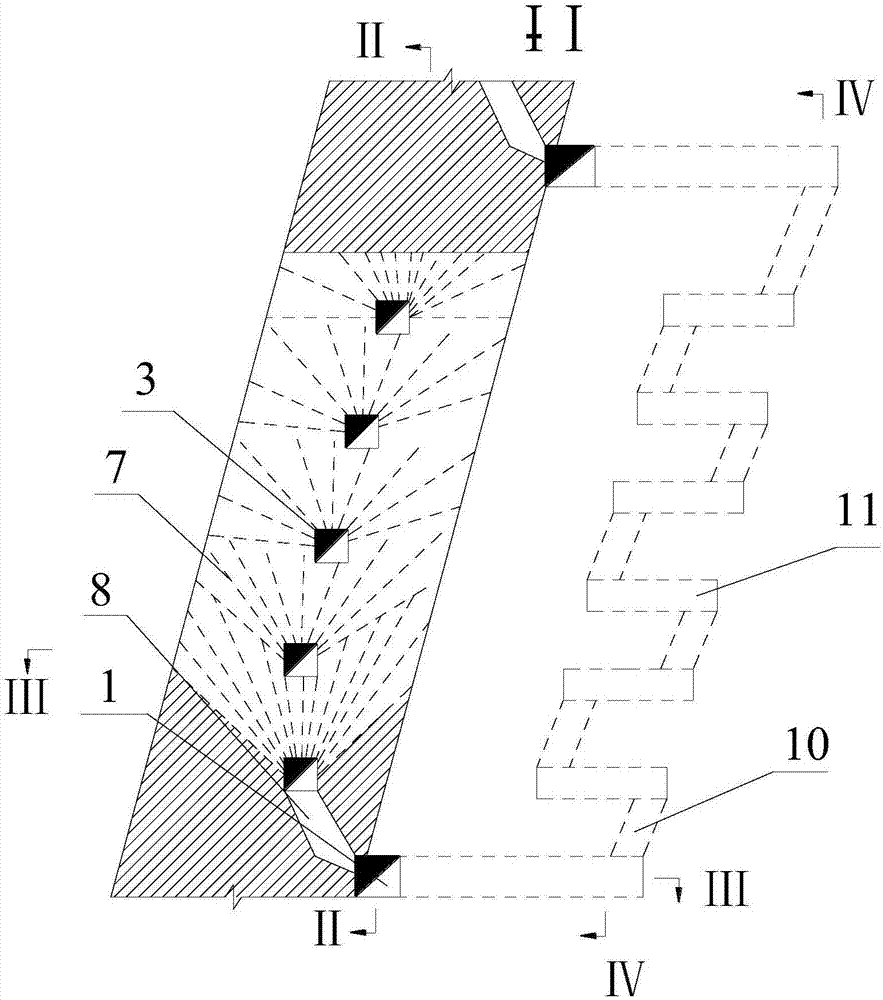

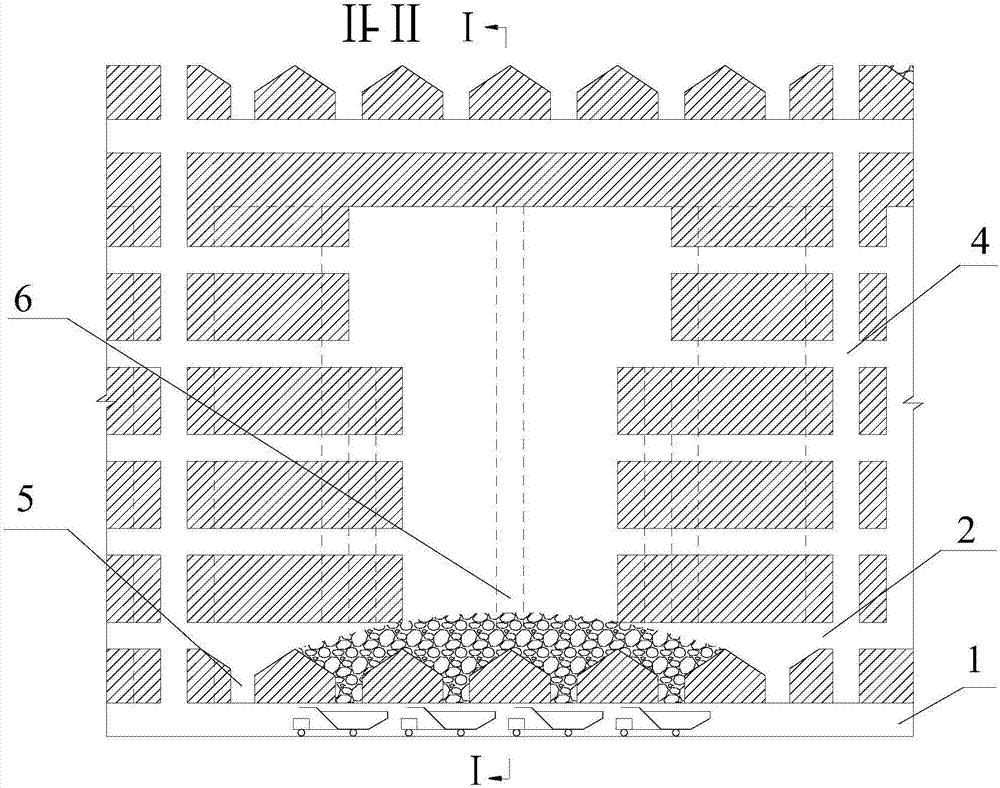

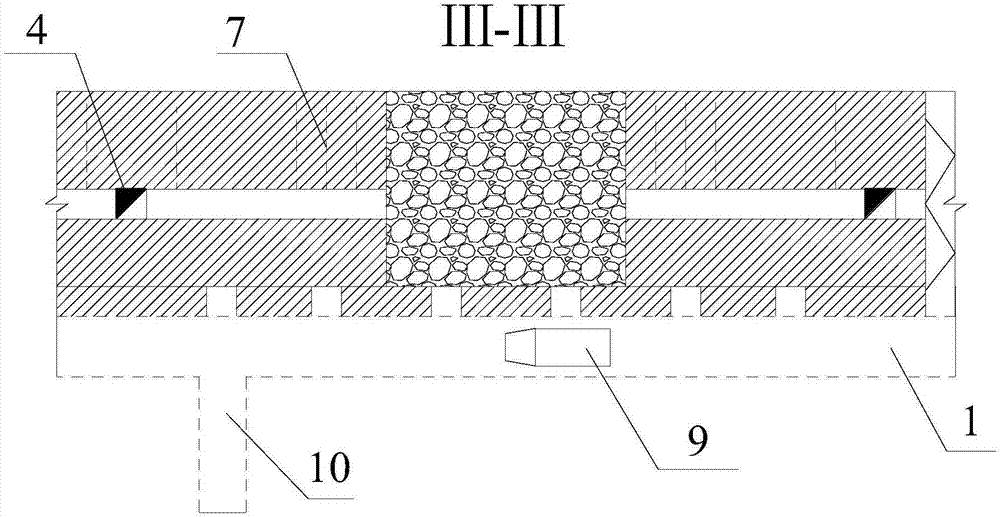

[0025] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

[0026] Such as Figure 1 to Figure 4 As shown, the mine house method of the truck in the present invention in cooperation with the ore-out segmented rock drilling stage comprises the following steps:

[0027] (1) Divide the stable thick and extremely thick steeply inclined ore bodies or the thin vein belts composed of steeply inclined parallel extremely thin veins into stages, divide the ore blocks into stages, and divide the ore blocks into ore houses and ore pillars, and the stage height is 50 ~60m, divided into several sections along the height of the mine house, the section height is 10-12m, the length of the mine house is 30-50m, the width of the inter-column is 8-10m, and the thickness of the top column is 5-6m.

[0028] (2) Before mining in the mine house, a 3m×2m short chute 8 is dug with a 4m×3.5m transportation roadway 1, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com