Mining method for stoping inclined extremely-thin mineral veins

A mining method and ultra-thin ore technology, which is applied in ground mining, mining equipment, underground mining, etc., can solve problems such as slipping and falling of workers, large amount of mining and cutting, and poor safety of working faces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

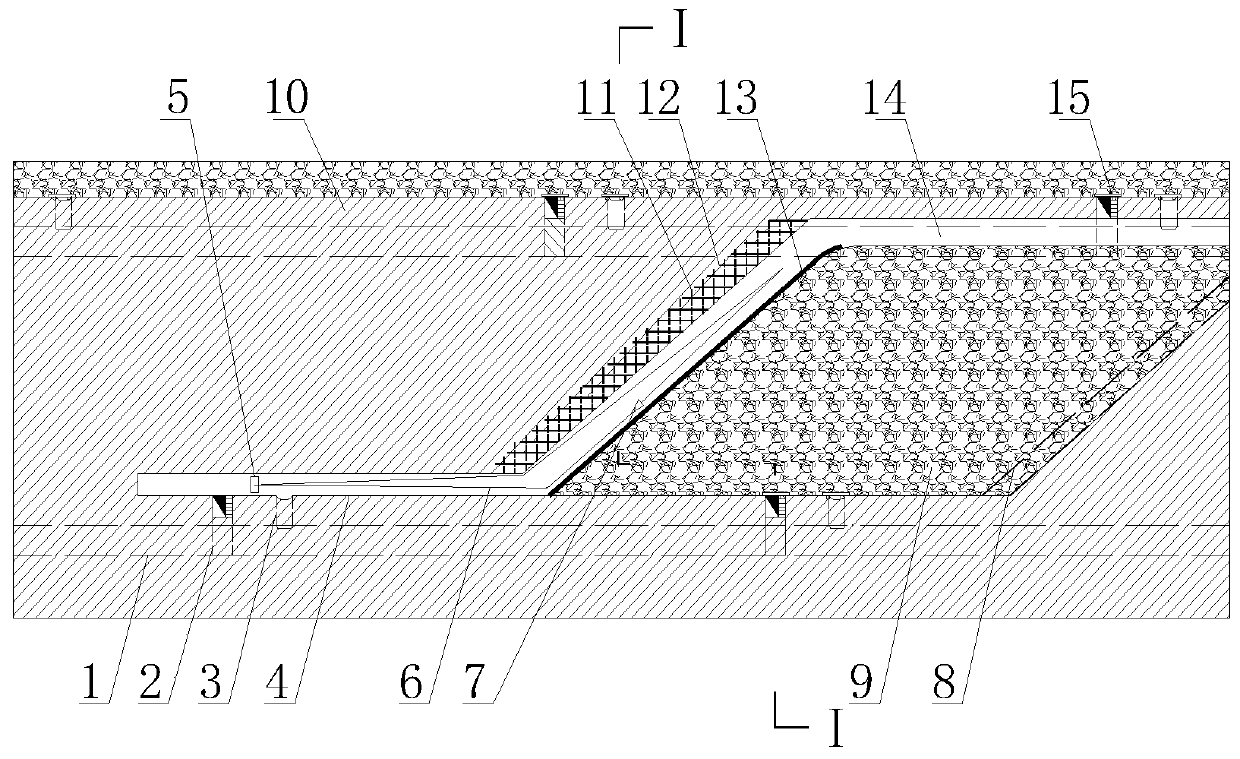

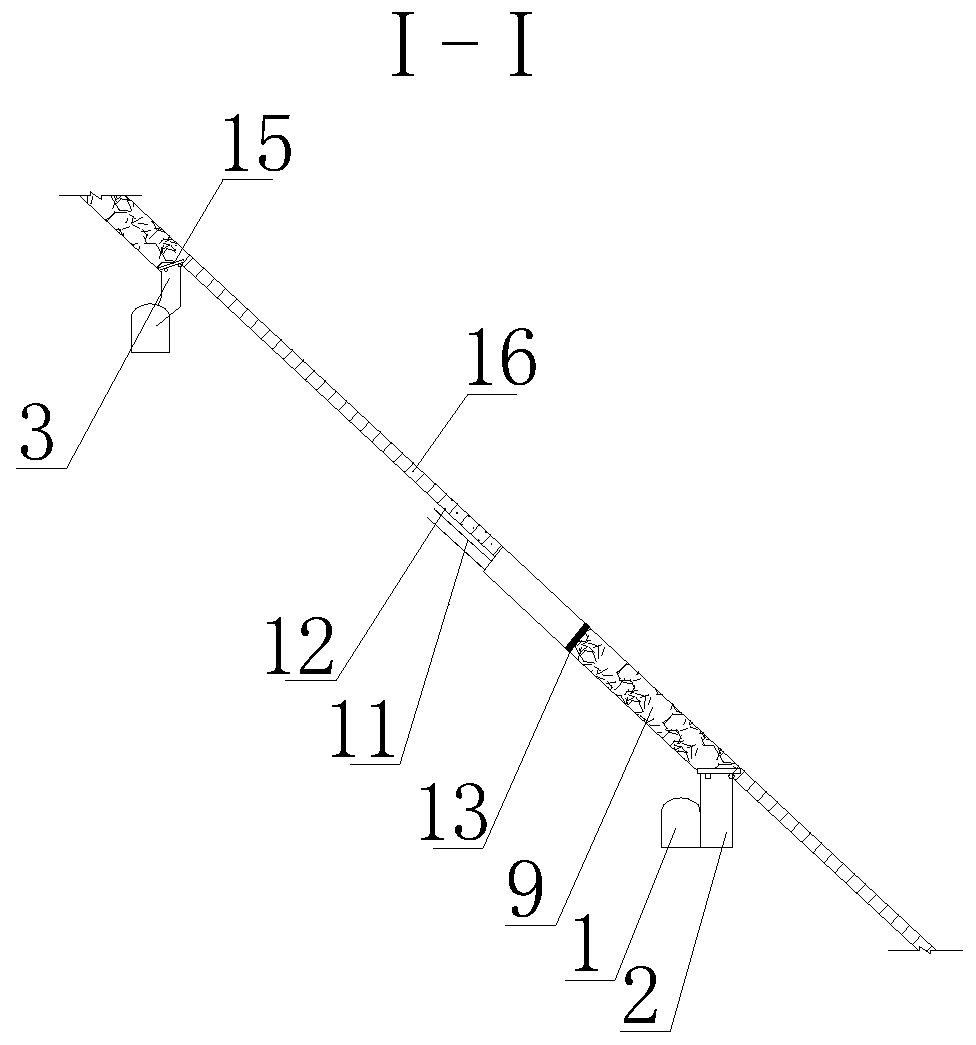

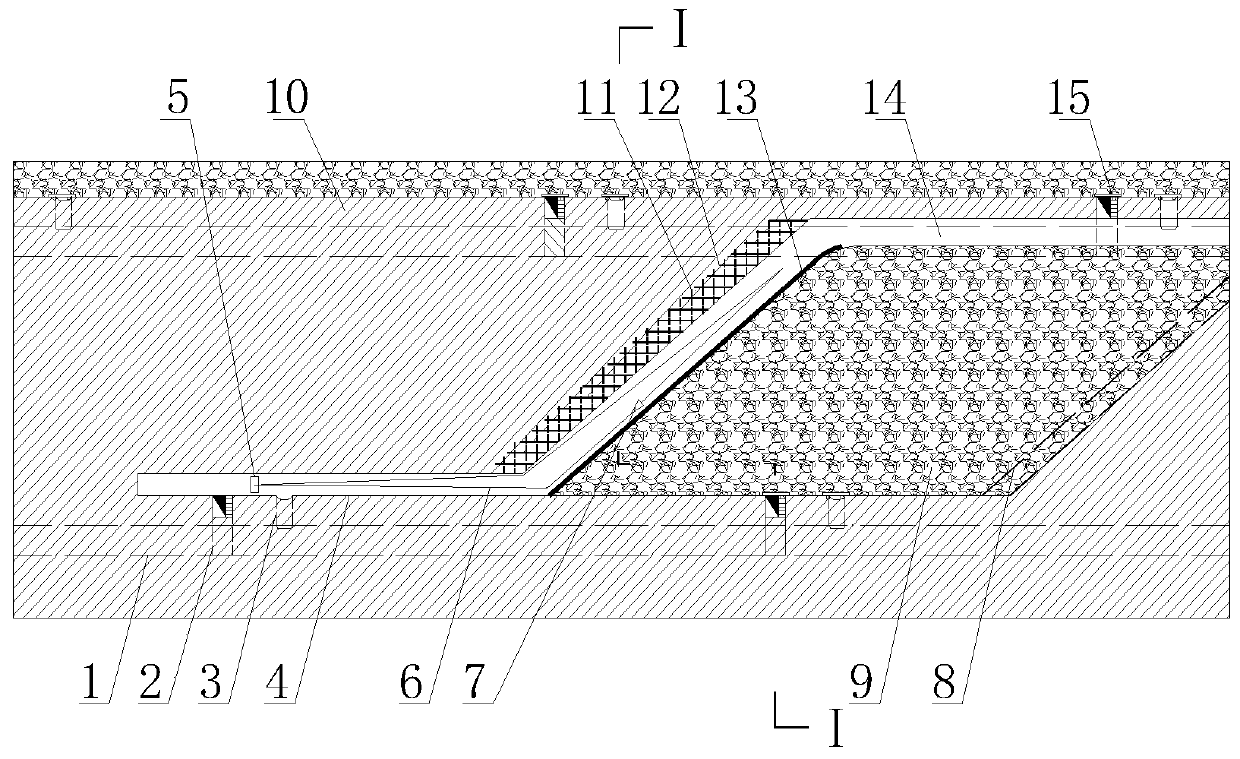

[0030] like figure 1 , figure 2 As shown, in the mining method for mining inclined extremely thin veins described in this embodiment, the ore body dip angle is 40°, the thickness is 0.6m, and the hanging wall rock is above medium and stable. Adopt mining method provided by the invention to mine, its main technology is as follows:

[0031] Mining area setting: along the strike of the ore body, every 500m is divided into a mining area, and the mining area is mined from one end to the other along the strike. The height of the middle section is 25m, and the transport level roadway 1 in the middle section is excavated outside the orebody lower plate vein, 3m away from the orebody floor, and the pedestrian shaft 2 is used to communicate with the mining area every 50m along the orebody direction. A middle ore pillar 10 with a thickness of 3m is left between the middle sections.

[0032] Mining and cutting: from the middle section of the transport level roadway 1, along the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com