Gently inclined-inclined medium-thick orebody mining method

A mining method and technology of thick ore body, which are applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of large mining accurate cutting volume, diluting ore drawing loss, low ore value, etc., and reach the mining and cutting engineering volume. Less, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the drawings and specific embodiments.

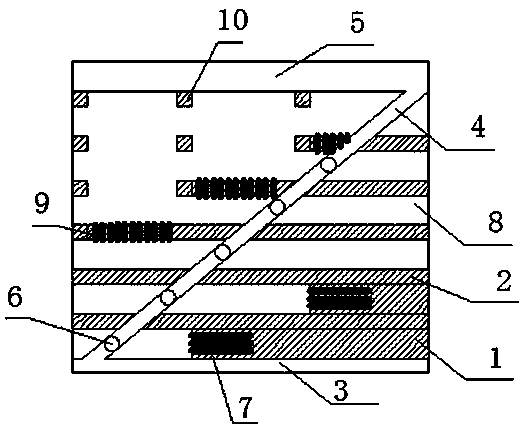

[0016] Such as figure 1 As shown, a gently inclined-inclined medium-thick ore body mining method includes the following steps:

[0017] 1) Divide the structure parameters: divide the ore body into ore blocks, the vertical height of the ore block is 30-40m, and the width of the ore block is 80-100m; and the ore block is divided into sections, and each section is divided into a sectioned ore house and a sectioned top pillar 2. The thickness of sectioned mine room 1 is 5-8m, and the thickness of sectioned top pillar 2 is 3-5m.

[0018] 2) Quasi-mining engineering: from stage transportation lane 3 excavating the diagonal ramp 4 in the vein to the previous stage transportation lane 5 to form the pedestrian, driving and ventilation system in the ore block, and the diagonal ramp 4 in the vein is at the opening of each section Layout chute 6.

[0019] 3) Stopping work in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com