Automatic conveying and stacking device for material boxes

An automatic conveying and stacking device technology, which is applied in the field of transportation or storage, can solve the problems of unfavorable impact on production rhythm, low work efficiency, and high labor intensity of operators, and achieve low workpiece conveying efficiency, strong practicability, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

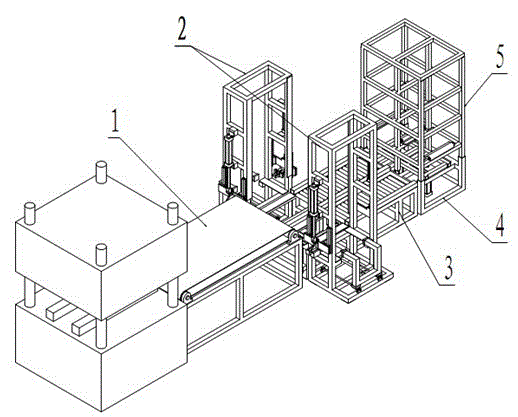

[0025] Referring to Fig. 1, the present invention includes an empty box replacement mechanism 2, a full box delivery mechanism 3, a full box stacking mechanism 4 and a full box material rack 5, and the empty box replacement mechanism 2 is arranged on a small punching machine delivery platform 1 and a full box Between the conveying mechanisms 3, the full-container conveying mechanism 3 is located in front of the full-container stacking mechanism 4, and the full-container stacking mechanism 4 is equipped with a full-container material rack 5, and the full-container material rack 5 is arranged on the full-container Above the stacking mechanism 4.

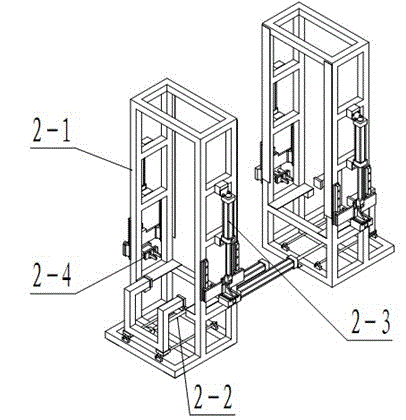

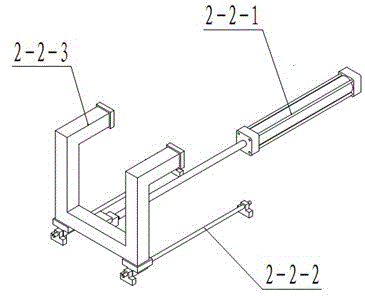

[0026] see figure 2 , The empty box replacement mechanism 2 of the present invention is made up of empty box storage frame 2-1, empty box horizontal movement assembly 2-2, empty box up and down movement assembly 2-3, empty box positioning assembly 2-4. Among them, the main function of the empty box storage frame 2-1 is to place the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com