Patents

Literature

150results about How to "Pure quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

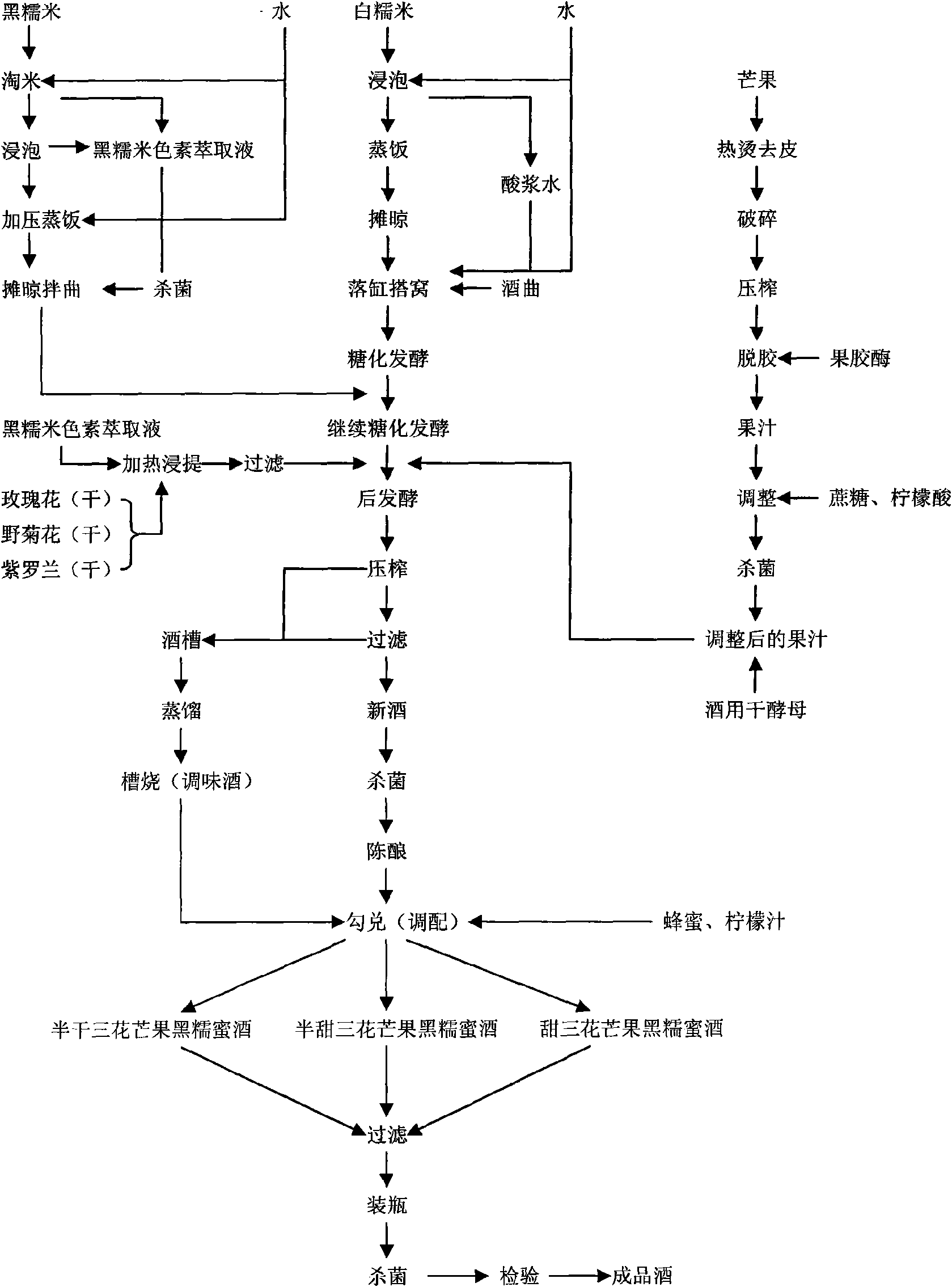

Flower fruit/vegetable honey wine and preparation method thereof

InactiveCN101649276AEnhance and exert medicinal valueHigh nutritional valueMicroorganism based processesAlcoholic beverage preparationFruit wineYeast

The invention discloses a flower fruit / vegetable honey wine and a preparation method thereof. The preparation method has the technique scheme that: taking advantages of nutritive characteristics and the like of a plurality of raw materials and auxiliary materials such as edible flowers, fruits (vegetables), black glutinous rice white glutinous rice and the like; using a pure saccharifying fermenting agent and an active dry yeast to carry out the compound fermentation with a plurality of raw materials and auxiliary materials; and using edible flower leaching liquor and cool fruit (vegetable) juice instead of brewing water so as to reduce the alcoholic strength of the yellow wine, increase the content of the dry extractive, increase the nutrients and the content of the yellow wine, enhance the health-care functions for beautifying and maintaining the face and improve the mouth feel. The honey wine tastes elegant, pure, sweet and thick, has peculiar flavor and has the characteristics of both yellow wines and fruit wines. The honey wine is a clear yellow wine having the advantages of elegant taste and health care, is suitable to drink in all seasons, and is especially suitable for women to drink.

Owner:刘名汉

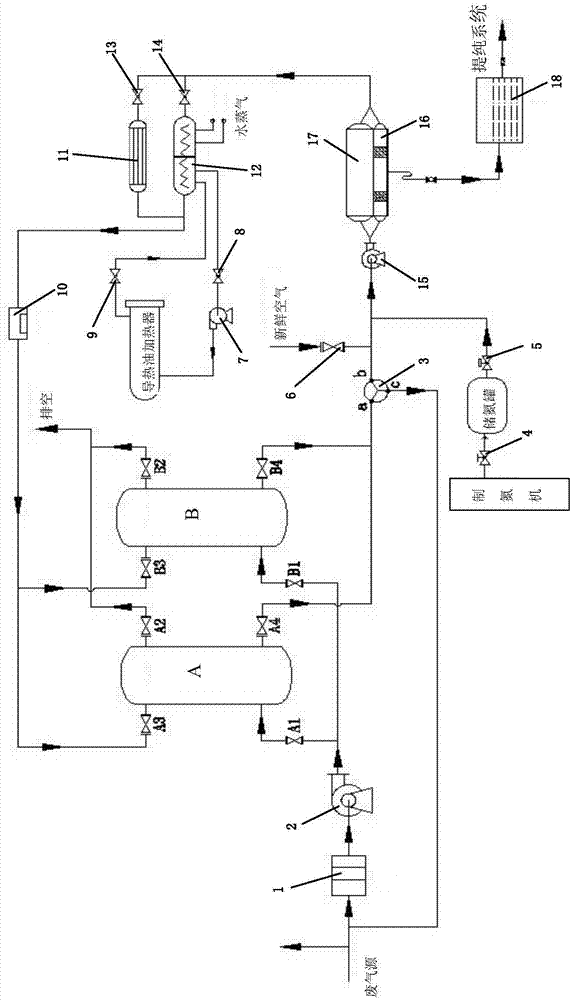

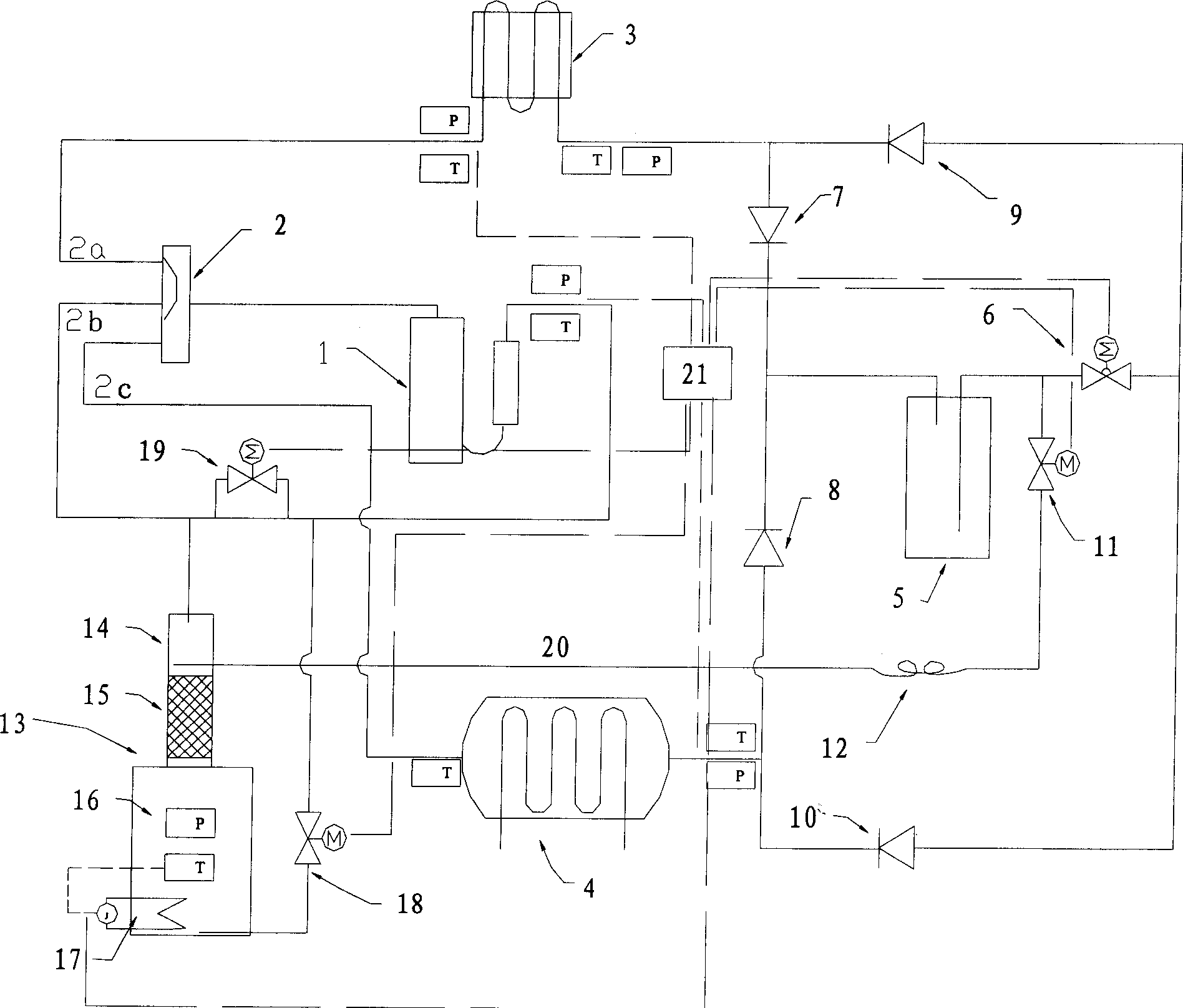

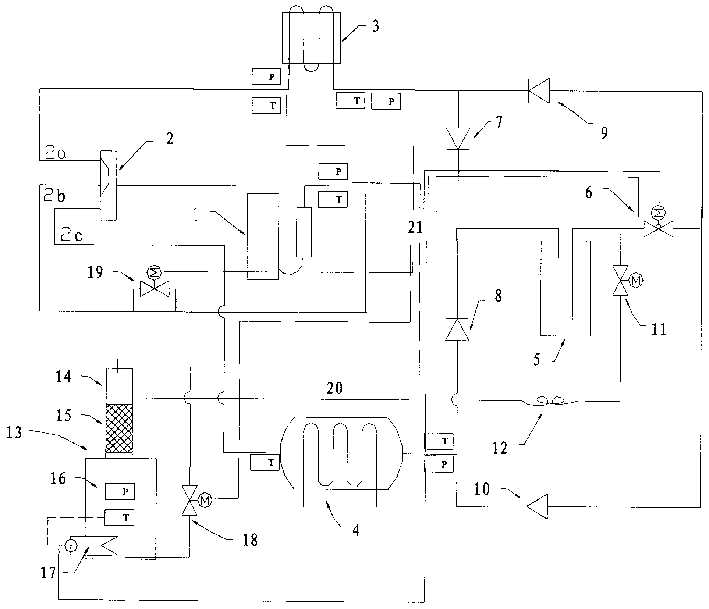

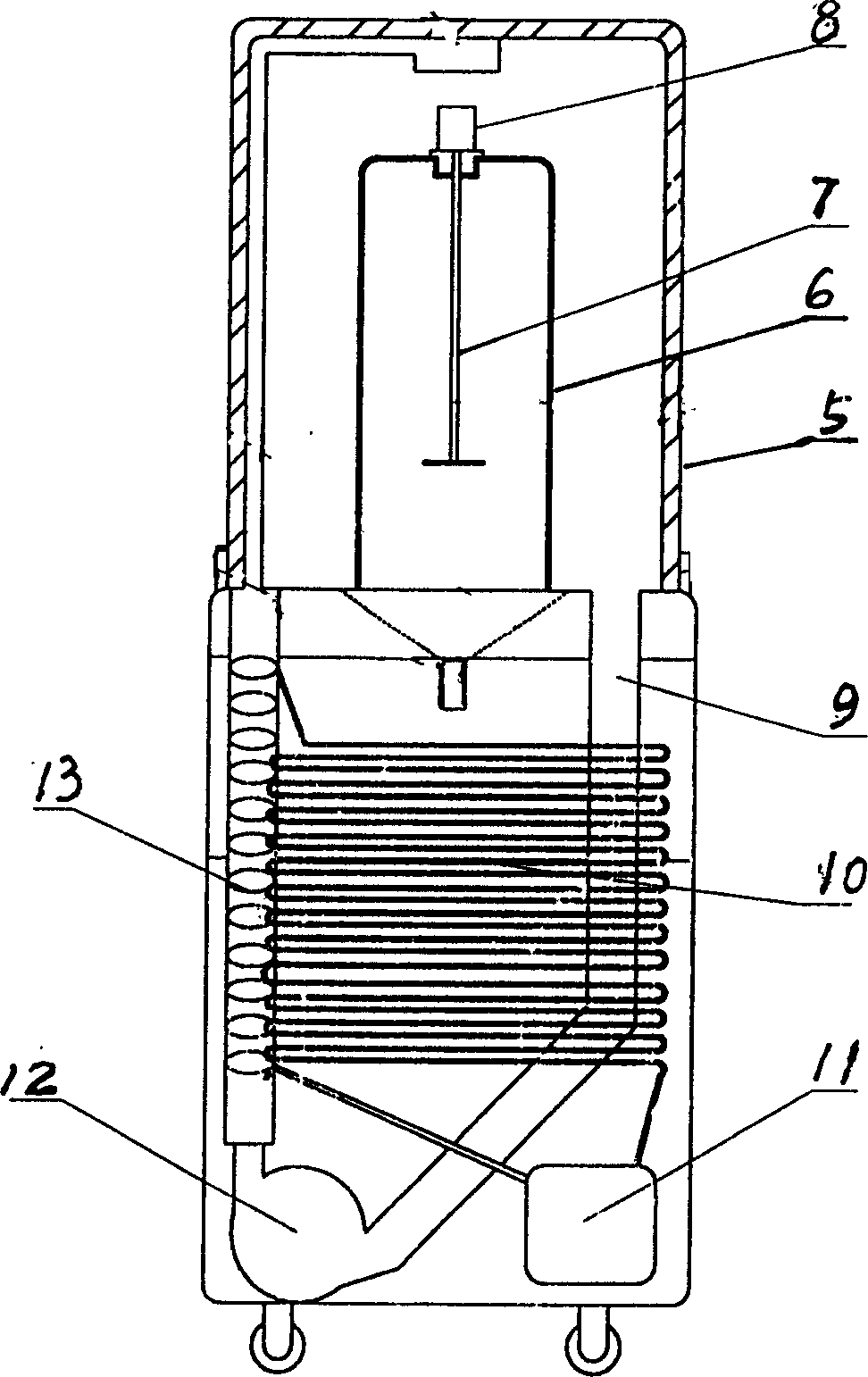

Technology for recovering and processing organic exhaust gas by activated carbon adsorption and N2 desorption

ActiveCN103585854AOvercome the limitations of large investmentPure qualityDispersed particle filtrationActivated carbonOrganic solvent

The invention provides a technology for recovering and processing organic exhaust gas by activated carbon adsorption and N2 desorption. The technology comprises the following steps: organic exhaust gas is pretreated by a coil-cooling filter; the organic exhaust gas which has been pretreated is then sent into a first activated carbon adsorption tank for adsorption; after adsorption of the first activated carbon adsorption tank, the system enters a desorption stage, and a second activated carbon adsorption tank enters an adsorption stage; the desorbed organic exhaust gas is condensed and then recovered, and after desorption of the system, the first activated carbon adsorption tank is cooled to a certain temperature, and back-purging is conducted on the first activated carbon adsorption tank, and the temperature drops to normal temperature after back-purging so as to use the exhaust gas in the next circulation; and the first activated carbon adsorption tank and the second activated carbon adsorption tank recycle and alternate the above steps. By the adoption of the technology, secondary pollution will not be caused; energy consumption is low; and the quality of recovered organic solvents is pure.

Owner:GARDEN ENVIRONMENTAL PROTECTION

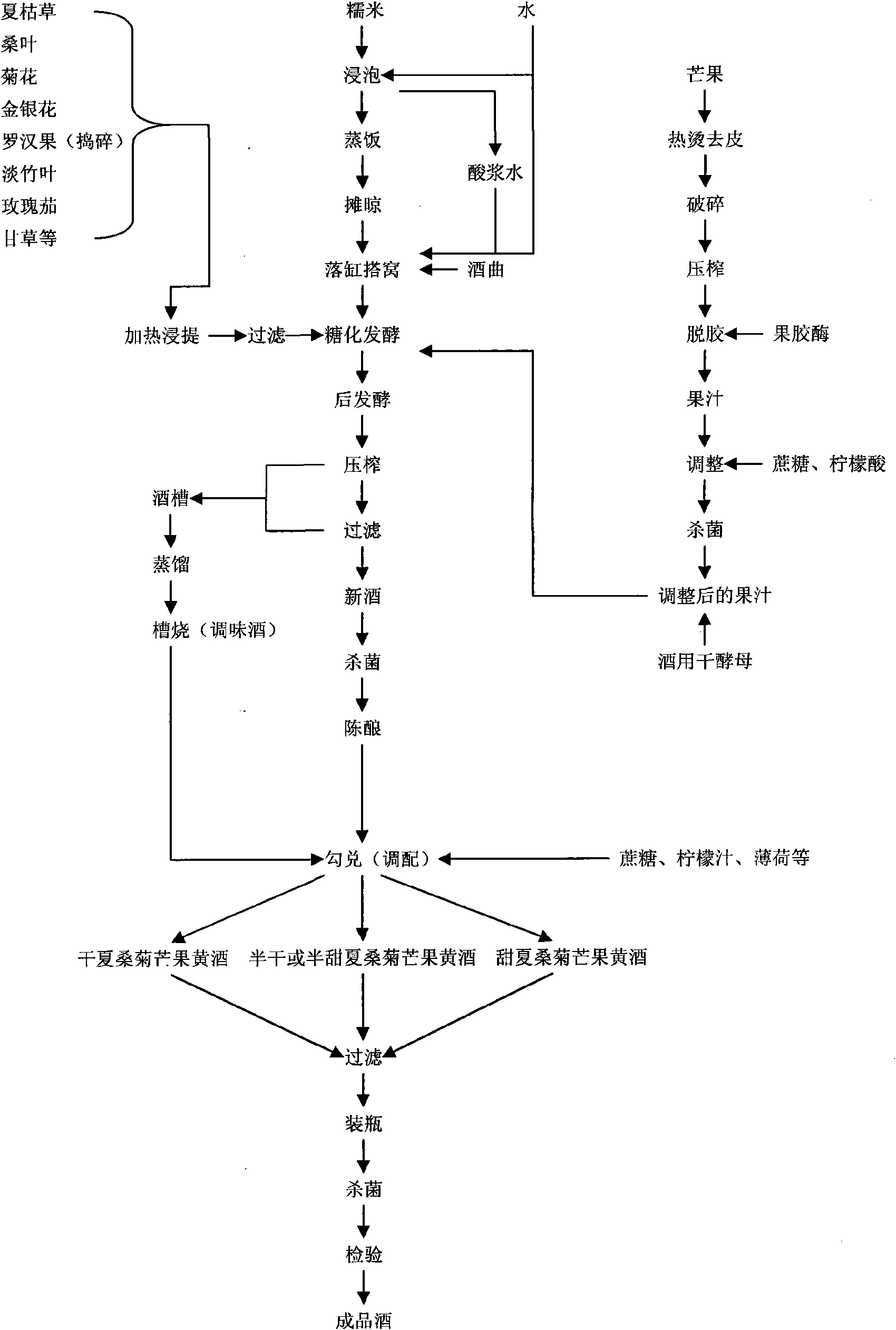

Herb-tea fruit/vegetable yellow wine and preparation method thereof

InactiveCN101649275AHigh nutritional valueEnhance heat-clearing and heat-relieving health functionAlcoholic beverage preparationMicroorganism based processesBiotechnologyMedicinal herbs

The invention discloses a herb-tea fruit / vegetable yellow wine and a preparation method thereof. Aiming at the problems of high alcoholic strength, strong flavor, high heat productivity, inadaptability to summer drink and the like of the common yellow wine, the method employs the technical proposal that: utilizing a plurality of raw and auxiliary materials having the advantages of nutritive characteristics and the like, such as Chinese medicinal herbs for herb tea, cool fruits (vegetables), glutinous rice and the like; using a pure saccharifying fermenting agent and an active dry yeast to carry out the compound fermentation with a plurality of raw and auxiliary materials; and using Chinese medicinal herb leaching liquor for herb tea and cool fruit (vegetable) juice instead of brewing waterso as to reduce the alcoholic strength and the heat value of the yellow wine, increase the content of the dry extractive, increase the nutrients and the content of the yellow wine, enhance the health-care functions for clearing away the heat and relieving the summer heat and improve the mouth feel. The yellow wine tastes, elegant, pure, sweet and thick, has peculiar flavor and has the characteristics of both yellow wines and fruit wines.

Owner:刘名汉

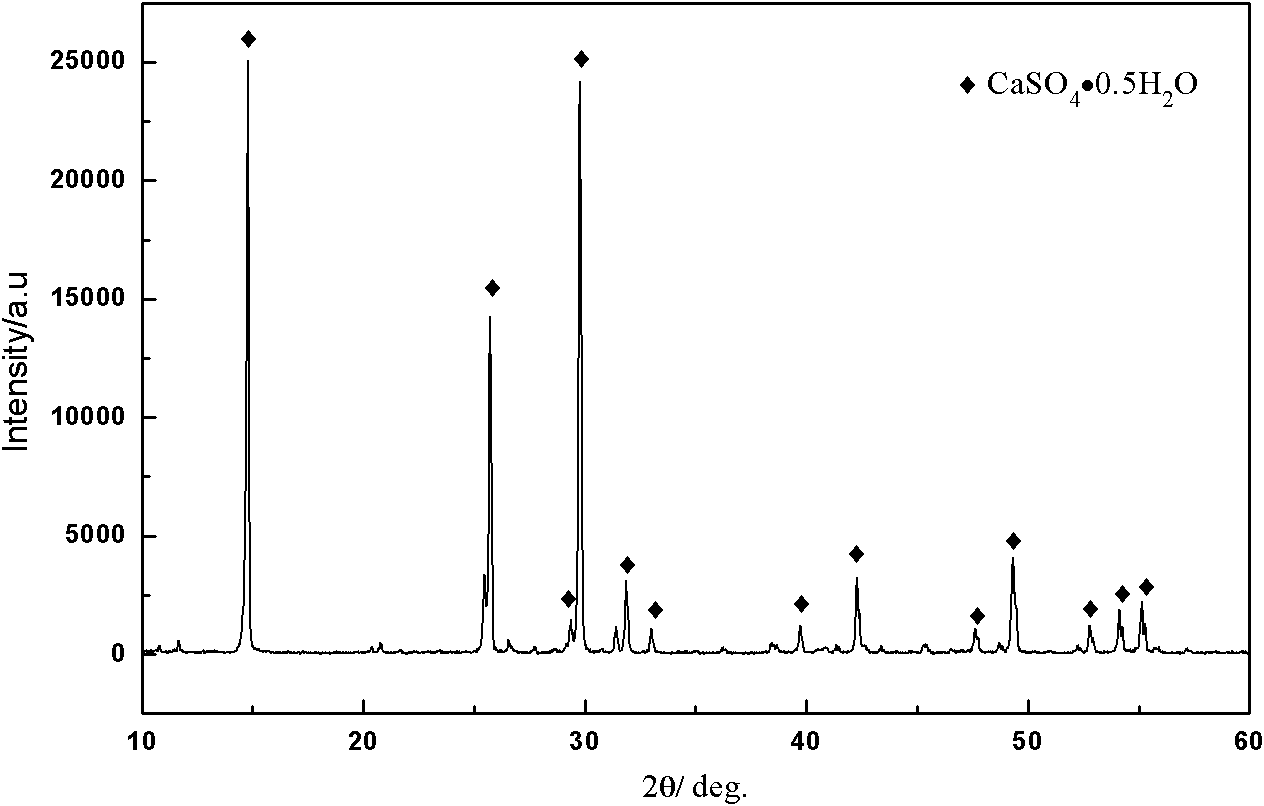

Method for extracting tungsten from scheelite and producing high-quality calcined gypsum

ActiveCN102021329AReduce lossesLow costCalcium/strontium/barium sulfatesProcess efficiency improvementPhosphoric acidSeed crystal

The invention provides a method for extracting tungsten from scheelite and producing high-quality calcined gypsum, comprising the following steps: adding a mixed acid of phosphoric acid and sulphuric acid to decompose scheelite; and after decomposition, adding hydrated gypsum seed crystals to finish the dewatering conversion process of dihydrate gypsum to obtain hydrated gypsum with good properties. The invention has the following advantages: the efficient atmospheric pressure leaching of scheelite is realized, the resource and energy consumption is saved, and the decomposition rate of scheelite can reach over 98%; the serious problems of Cl<-> corrosion and HCl volatilization in the traditional acid decomposition process can be overcome; the recycling of phosphoric acid is basically realized, and the leaching cost and the wastewater discharge are greatly reduced; the leaching device is simple, the operation is convenient and industrialization is easy to realize; the obtained byproduct gypsum has pure quality and can be used to produce gypsum boards, and can be used in retarder, plaster and the like produced by using cement; and due to the recrystallization process, the P2O5 content in gypsum is further reduced to below 0.5%.

Owner:CENT SOUTH UNIV

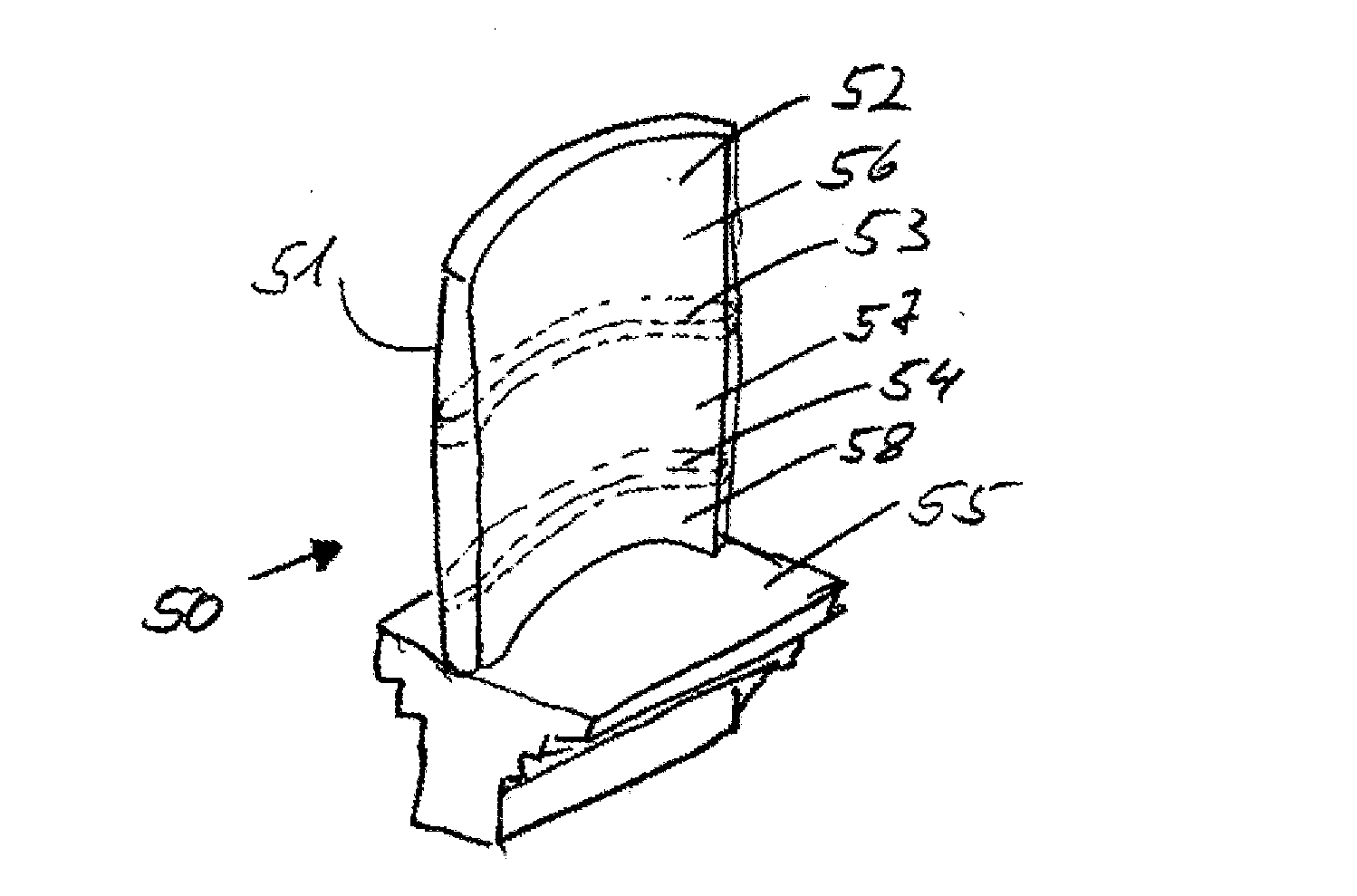

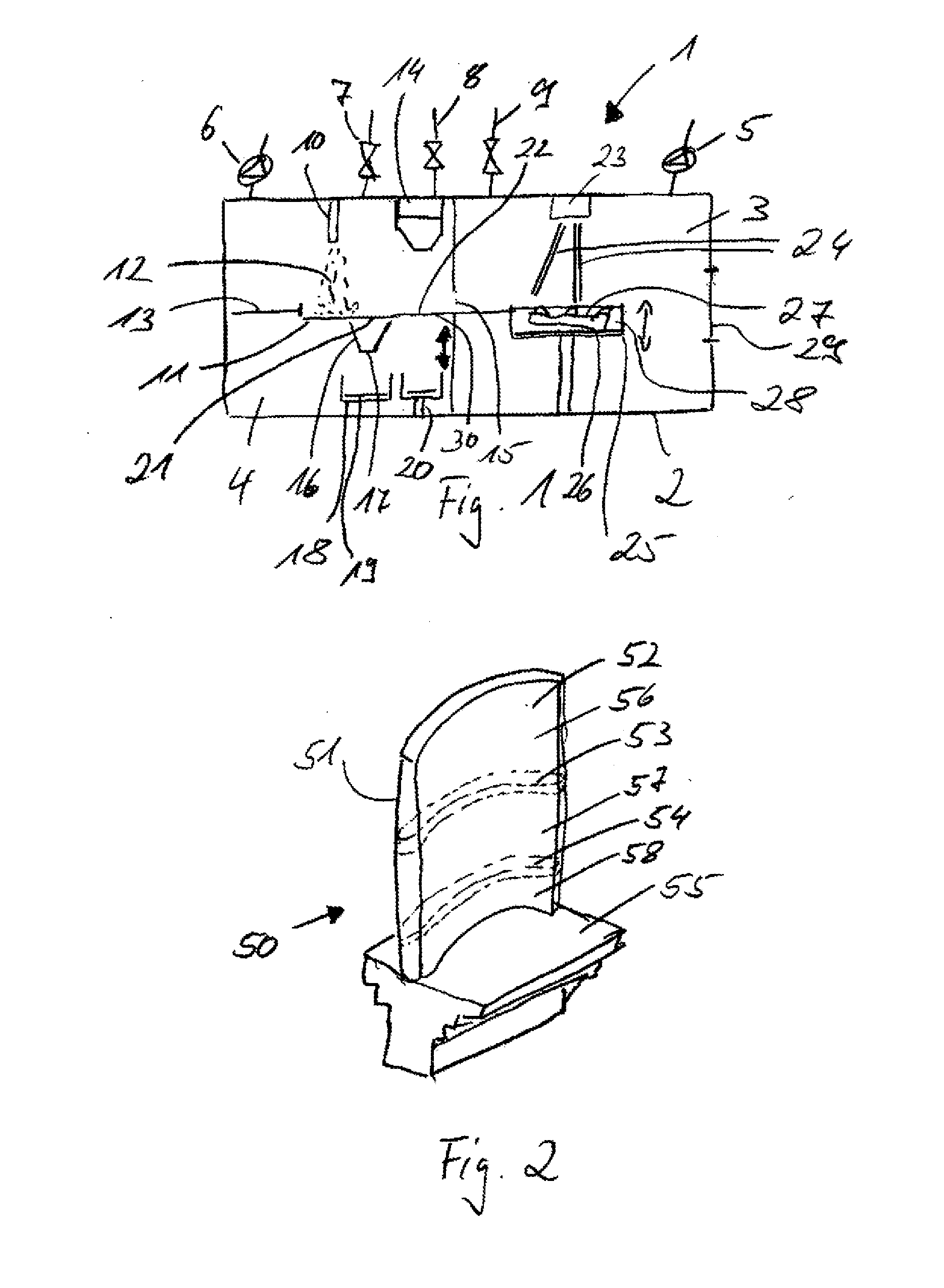

Generatively produced turbine blade and device and method for producing same

The present invention relates to a method for producing gas turbine components, in particular aircraft turbine components, preferably low-pressure turbine blades, from a powder which is sintered selectively in layers by locally limited introduction of radiant energy, wherein the sintering is carried out in a closed first housing (2), so that a defined atmosphere can be set, wherein the powder or at least a part of the powder is generated in the same first housing (2) or in a second housing connected to the first housing in a gas-tight manner. The invention further relates to a corresponding apparatus and to a gas turbine blade produced thereby.

Owner:MTU AERO ENGINES GMBH

Preparation method of high-purity cerium hydroxide

InactiveCN101633516AGood clarificationGood filtration performanceRare earth metal compoundsSal ammoniacChemistry

The invention discloses a preparation method of high-purity cerium hydroxide, comprising the following steps: taking liquid cerium nitrate as a raw material, hydrogen peroxide as oxidant and ammonia water as neutralizer, oxidizing trivalent cerium into tetravalent cerium in cerium nitrate solution in a weak acidic medium with the PH value being equal to 5 to 6 so as to form precipitate, then carrying out thermal decomposition, washing pressure filtration and drying on the precipitate to obtain high-purity cerium hydroxide product. The high-purity cerium hydroxide product prepared by the invention has high purification, wherein, the Ce ratio CeO / TREO is greater than or equal to 99.9%, the oxidation rate CeO<4+> / sigma Ce is greater than or equal to 97.0%, non-rare earth impurity magnesium oxide MgO is less than or equal to 2.5PPm, and the solubility of nitric acid is good. The process flow is short, the operation is convenient, and scale production is easy to be realized. The obtained Ce(OH)4 nitric acid is dissolved clearly, the oxidation rate of cerium is high, the content of non-rare earth impurities is low, thereby meeting the requirement of clients on quality of Ce(OH)4 products.

Owner:甘肃稀土新材料股份有限公司

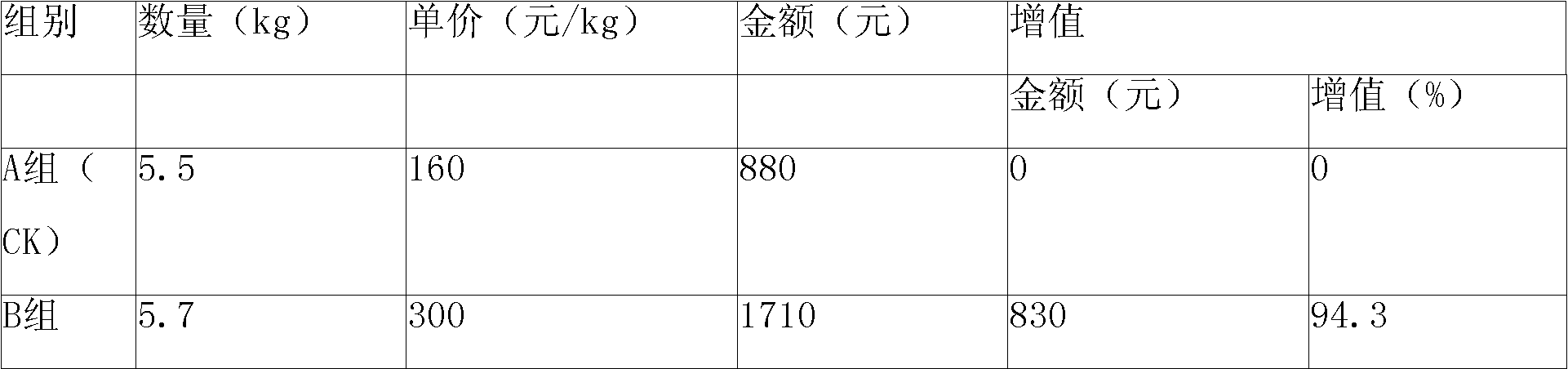

Compression production process for fresh aromatic Tie Guanyin tea and product thereof

InactiveCN101978842AEasy to makeReduce productionPre-extraction tea treatmentClimate change adaptationMoistureChemistry

The invention discloses a compression production process for fresh aromatic Tie Guanyin tea and a product thereof. The process comprises the picking of fresh tea leaves, sun drying, fine manipulation, pan frying, kneading, picking and choosing, compression forming, packaging, drying and the like. The process comprises the following steps of: performing the fine manipulation at the temperature of between 18 and 21 DEG C and the humidity of between 75 and 85 percent, and performing rotating and spreading for 2 to 4 times respectively and alternately; after the pan frying is performed, kneading the tea leaves in a tea kneading machine; picking the leaves of which the quality meets the standard out after the kneading; compressing the picked tea leaves to form baled Tie Guanyin tea of which the thickness or the diameter is not more than 0.8 centimeter, and packaging the baled Tie Guanyin tea for forming; performing the kneading, the picking and choosing, the compression forming and the packaging at the temperature of between 16 and 22 DEG C and the humidity of between 30 and 50 percent; and drying immediately after the packaging, namely baking for the first time until the moisture content is between 10 and 14 percent, and baking for the second time until the tea leaves are dried completely to form a finished product. The process is reasonable and unique, has high feasibility, so that the product has the unique fresh aromatic taste, is mellow, delicious and fresh, has high and lasting fragrance and attractive appearance, and improves the integral quality of the tea leaves.

Owner:陈荣发

Process for production of ultra-fine wool worsted face fabric

The invention relates to a manufacturing method for superfine wool worsted fabric. It selects superfine wool with the diameter of 14.5um and produces superfine wool worsted fabric by stripe dyeing, spinning, weaving and after-treatment. Merits of the invention are that the high quality of superfine wool worsted fabric is outstanding; the fabric is provided with good quality, exquisite handle feeling and good spring-back; it is also provided with high-grade quality, high added value and it has higher social and economical benefits.

Owner:杨毅方

Method for producing pure pashm worsted plus material

The invention relates to a producing method for a pure wool spinning lining by using wool as raw material, comprising steps of top dyeing, spinning, weaving and finishing. The advantages of the invention are that the produced lining has good quality, delicate hand feeling, good flexibility, high added value and is provided with good social benefit and economic effectiveness.

Owner:杨毅方

Preparation of liquid barley green and application thereof in preparation of beverage

The invention provides a liquid highland barley green and process for preparing beverage containing rich highland barley green, wherein the beverage is prepared from non-contaminated highland barley sprouts in Tibetan plateau as raw material through the steps of cutting, cleaning, extracting, filtering, homogenizing, charging carbon dioxide, loading and sterilizing.

Owner:TIBET TIANMAILI HEALTH PROD CO LTD

Foundation-free section honey production method of Apis ceranas

The invention relates to a foundation-free section honey production method of Apis ceranas, which replaces section honey lattices by special section honey frames, replaces queen separation plates by separation plates and replaces purpose-made shallow boxes by standard boxes. The section honey production method of the Apis ceranas comprises the flowing steps of: manufacture of the special section honey frames and the separation plates, obtaining of non-husks natural spleen bases, fixation of spleen bases, fixation of the section honey frames, production of the section honey of the Apis ceranas, section honey cutting and section honey package. The production method is simple and practical, reduces the production cost and has low cost. The section honey has better quality and richer fragrance. The honey yield can be increased because no queen plate is adopted. The production method changes complexity into simplicity, reduces the labor intensity, has low technical requirements, is easy to learn and master by beekeepers and has low labor intensity in the production process. Strong colony is easy to maintain because the space of honey boxes is increased. The nest insect harm is reduced.

Owner:ZUNYI NORMAL COLLEGE

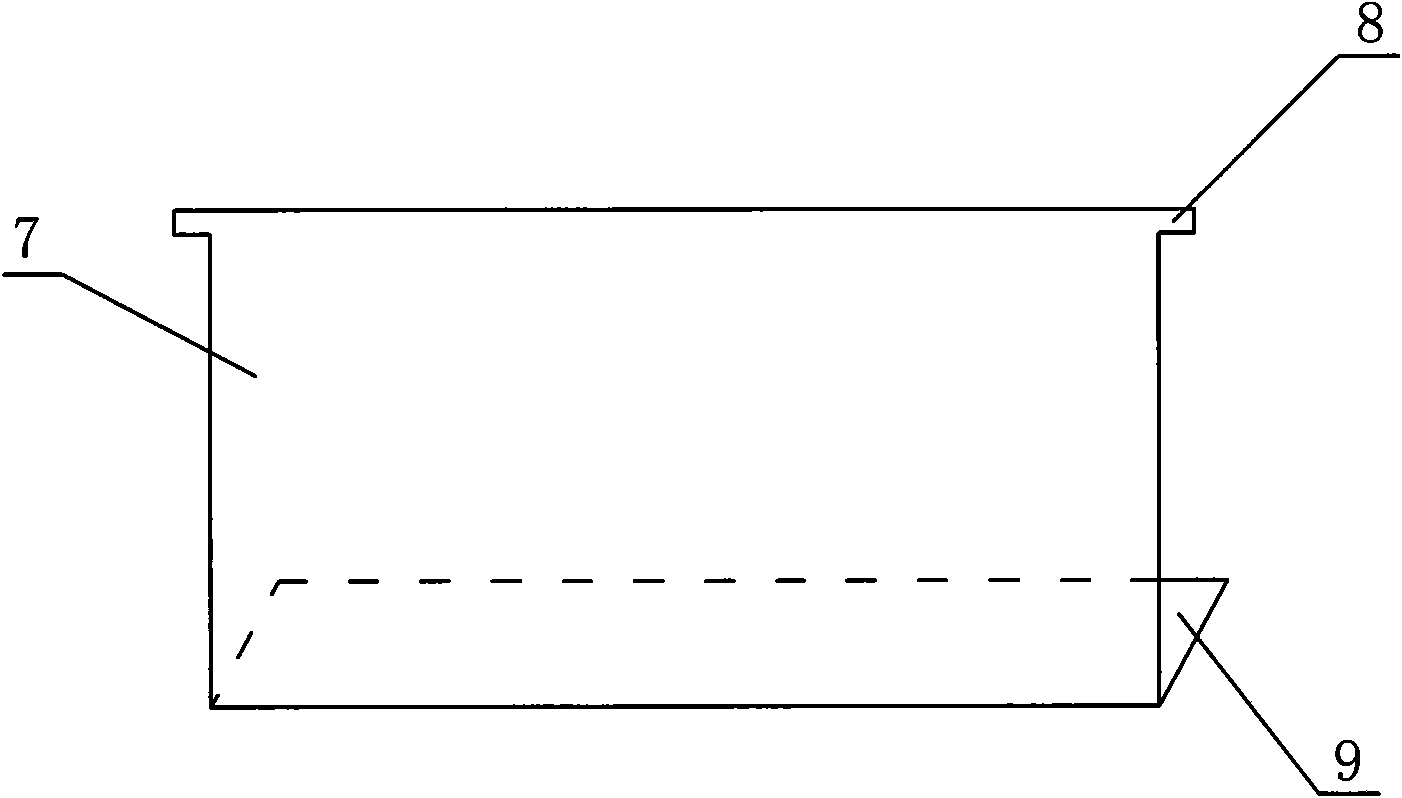

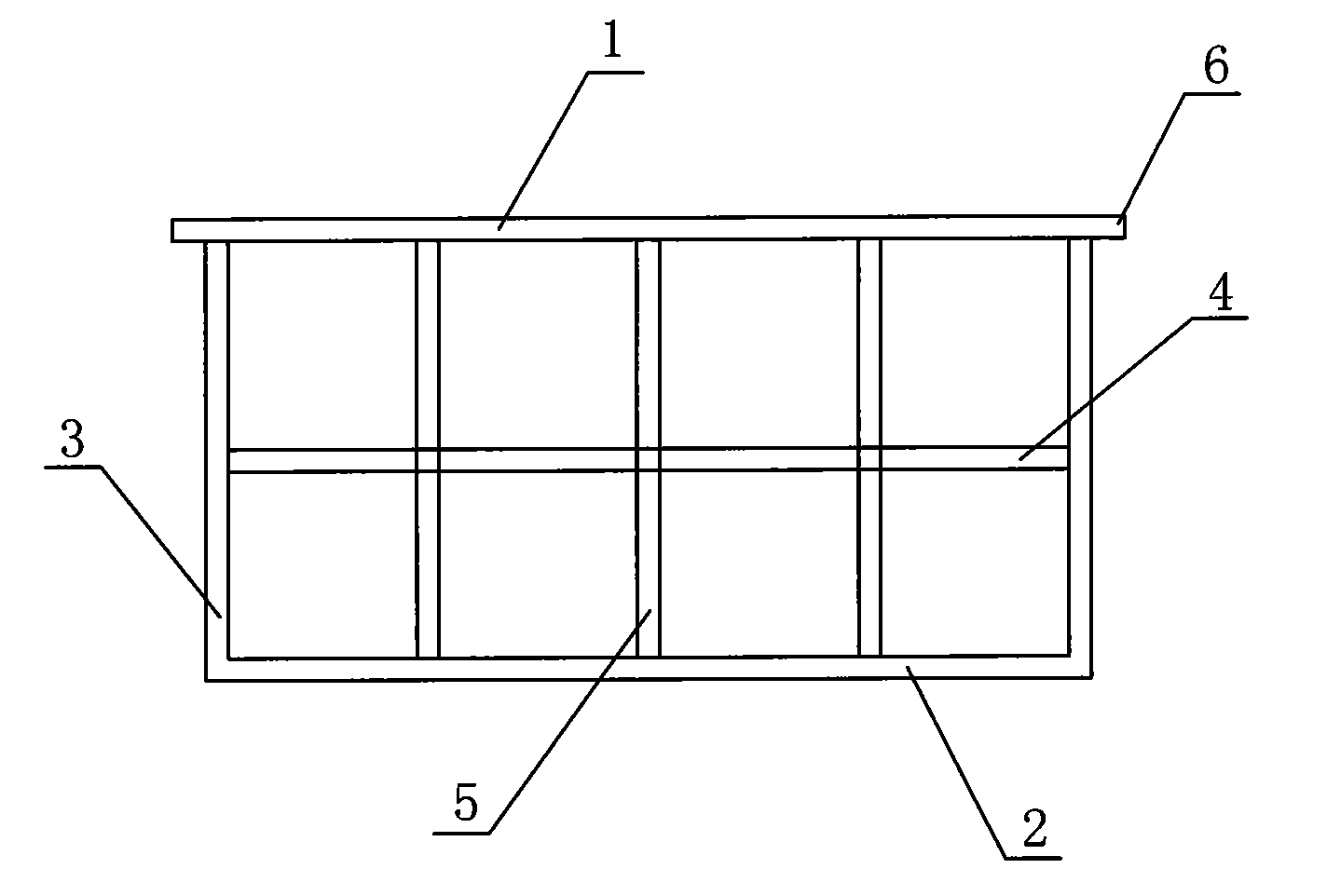

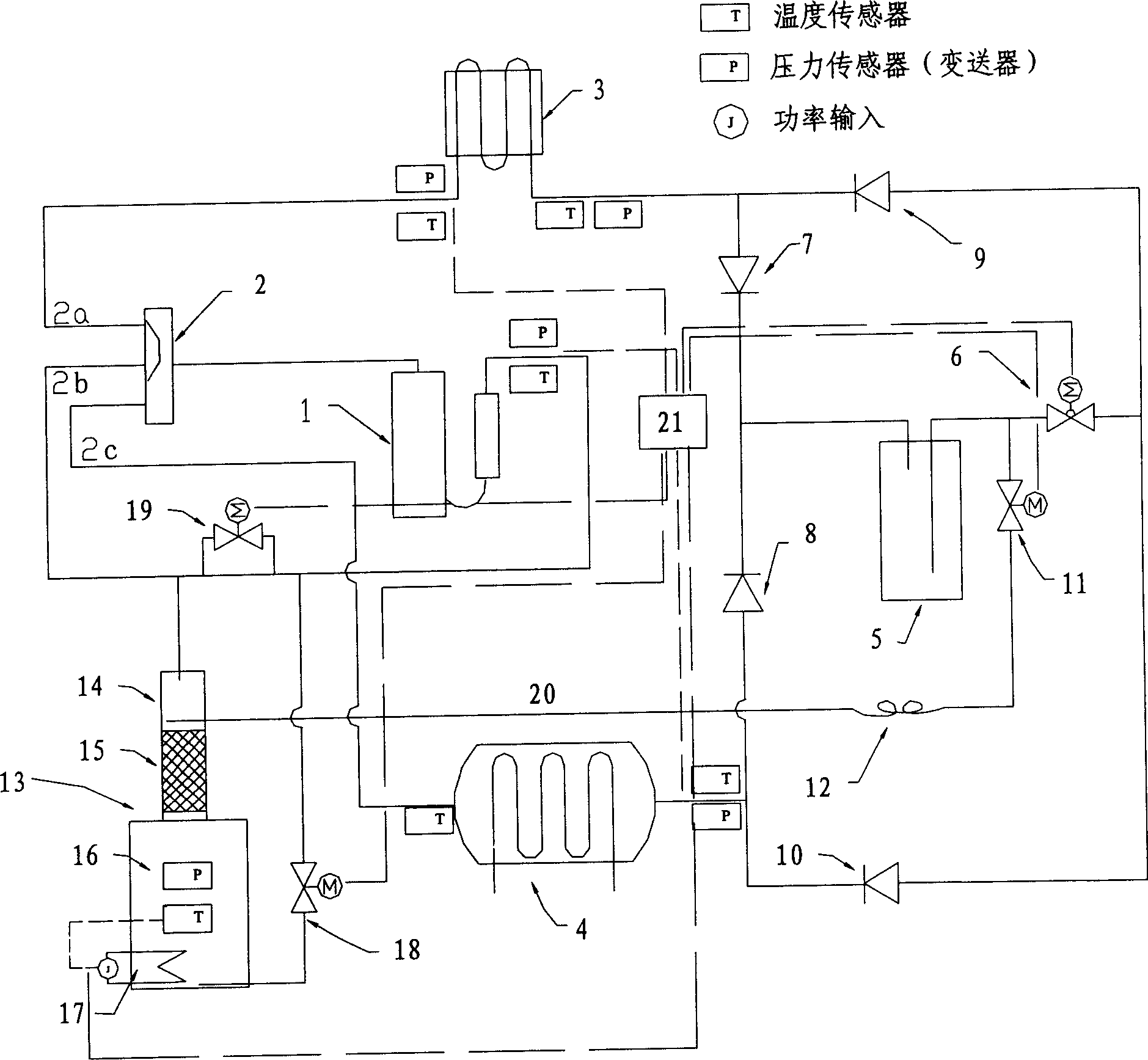

Low temperature heat source heat pump system and its capacity regulating method

InactiveCN1514193AMeet heating load requirementsImprove performanceHeat pumpsHigh concentrationBoiling point

The method applies refrigerant mixed by two or above compositions to change circulating media concentration through a separation unit; when load is increased at heat pump operation system separates composition of high boiling point through separation unit to raise concentration of low boiling point media in circulation for enhancing ability of heating at low temperature environment; when load is decreased high boiling point composition of high concentration stored in low pressure liquid storage tank at bottom part of separation unit is absorbed systematically through heating means to decrease heat generating amount of system.

Owner:ZHEJIANG UNIV

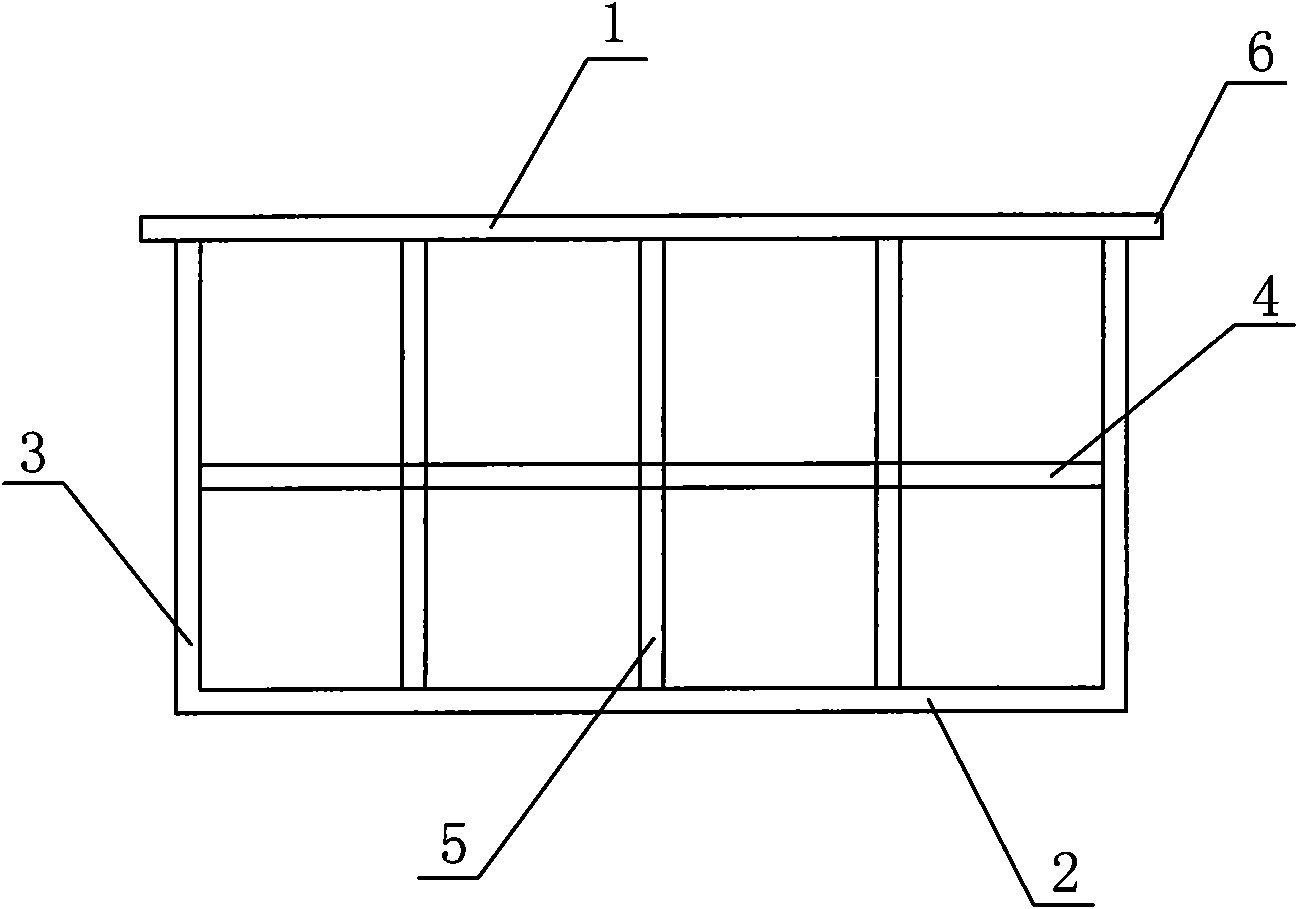

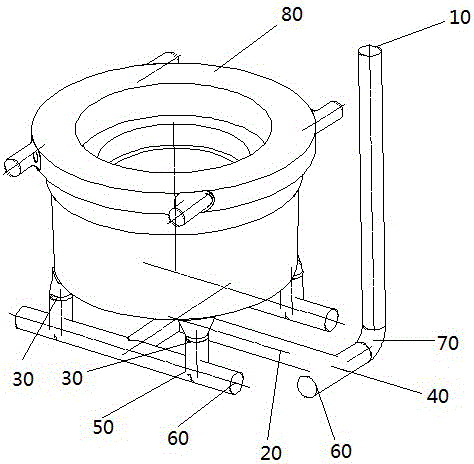

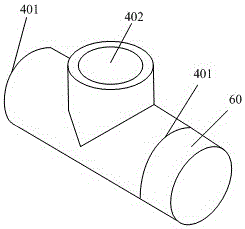

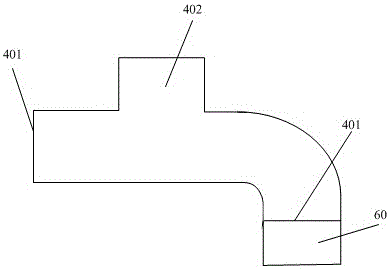

Bottom gating system and paving method thereof

ActiveCN105108065ASolve the shortcomings of poor qualityPure qualityFoundry mouldsFoundry coresBottom gateEngineering

The invention discloses a bottom gating system. The bottom gating system comprises a straight pouring gate, a transverse pouring gate and an inner pouring gate, wherein the inlet end of the straight pouring gate is connected with the outlet end of the transverse pouring gate through a first T-shaped pouring gate. The first T-shaped pouring gate adopted by the bottom gating system is similar to a conventional three-way porcelain tube; one transverse end is sealed by a metal plugging plate; the function of the metal plugging plate is characterized in that a first strand of molten steel mixed with a large quantity of impurities enters the T-shaped porcelain tube and can be quickly chilled and coagulated to form a shell when being in contact with the metal plugging plate, so that the impurities are fixed to one side with the metal plugging plate of the T-shaped pouring gate, thereby ensuring that the subsequent clean molten steel is incapable of carrying the impurities into the cavity during flowing; the defects of low quality of the first strand of molten steel and the impurities generated by flushing of the molten steel in the gating system can be effectively solved; the purity of the molten steel flowing into the cavity is ensured, so that the quality of castings is improved. The invention also provides a paving method of the bottom gating system.

Owner:KOCEL STEEL

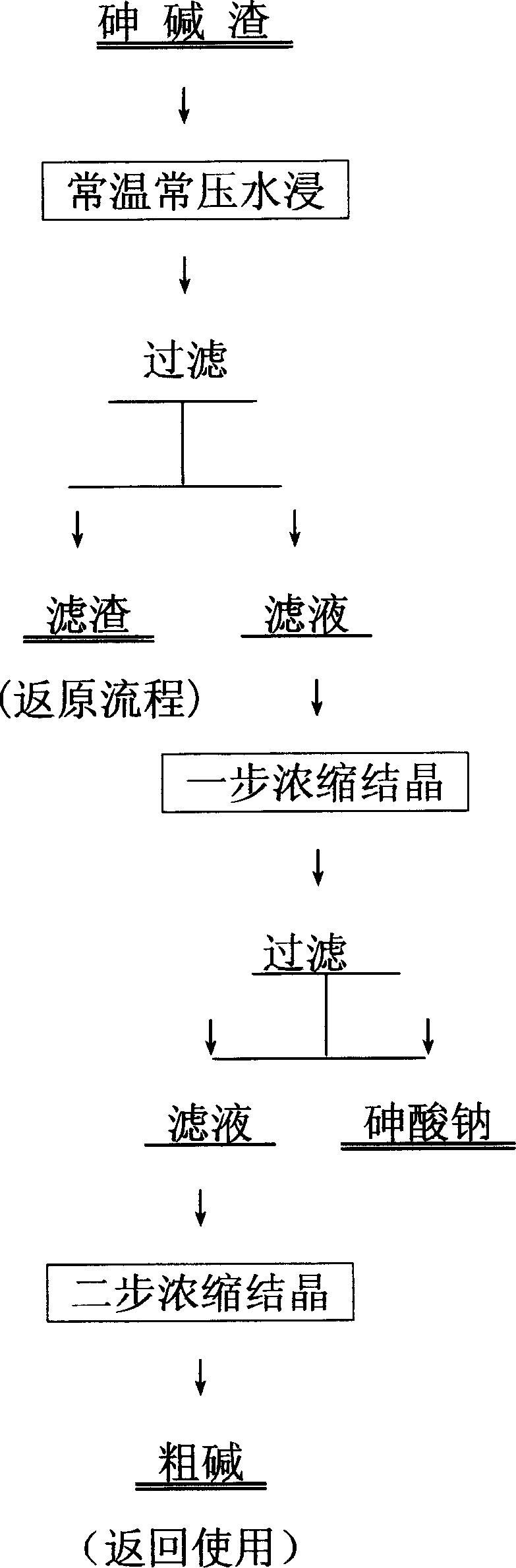

Method for separating and recovering sodium arsenate and alkali by fractional crystallization method

InactiveCN1594090AIncrease Concentration Energy ConsumptionShort processArsenites/arsenatesSodium/potassium compoundsChemistryMother liquor

The invention provides a method for separating and recovering sodium arsenate and alkali by fractional crystallization method which consists of, condensing the arsenic alkaline residue infusion, cooling down to below room temperature, stewing for 2 hrs, filtering to obtain sodium arsenate, concentrating the crystallization mother liquor, and calcining the crystallized product.

Owner:广西华锡集团股份有限公司

Rapid cultivation method for high-quality meat lucid ganoderma

InactiveCN102113448AFast growthGood lookingOrganic fertilisersHorticultureBiotechnologyApocynum venetum

The invention discloses a rapid cultivation method for high-quality meat lucid ganoderma, and relates to a meat lucid ganoderma strain and health care product cultivation technology thereof. Culture solution is prepared from the following raw materials: apocynum venetum, scindapsus aureus, lucid ganoderma, Chinese wolfberry, snow lotus herb, rhodiola, astragalus, saffron and mineral water; and the preparation comprises the following steps of: soaking the raw materials in the mineral water for 12 to 24 hours, boiling for 10 to 30 minutes, and filtering residues to obtain the meat lucid ganoderma culture solution. The meat lucid ganoderma prepared by the method has the advantages that: 1, the meat lucid ganoderma has high growth rate and can be grown by more than 1 to 1.5 times in one month, and meat lucid ganoderma nutrient solution can be prepared in 30 to 60 days; 2, the meat lucid ganoderma has good appearance, good color and luster, is red, bright and attractive, and can be hardened and shaped in one month; 3, the meat lucid ganoderma has high quality, and the culture solution has full nutriments and high quality; and 4, the meat lucid ganoderma has low cultivation cost. The method of soaking and boiling is adopted to better facilitate the extraction and release of active ingredients of the raw materials so as to reduce the using amount of the raw materials; therefore, the cultivation cost is greatly reduced so as to facilitate popularization and application.

Owner:马兰英

Method for extracting fructus momordicae tetranuclear triterpene

A method for extracting fructus momordicae tetranuclear-triterpene is carried out by leaching flavine from fresh fructus momordicae skin by warm water, heating gelatinous protein in fruit cell, solidifying, crushing, leaching by 60-90 deg. C, de-bonding by pectase, filtering, concentrating and drying to obtain final product. Crude products containing tetranuclear-triterpene 43% 300-350g are extracted from fresh fruits 10000g. It's pure, safe, efficient, simple and cheap. It has no environmental pollution. The pumace can be made into feed.

Owner:张雨生

Edible camellia marinade and preparation method thereof

The invention relates to edible bittern and a preparation method thereof, in particular to edible oil-tea camellia bittern for rice noodles and a preparation method thereof. The edible oil-tea camellia bittern consists of sauce and oil-tea camellia in the weight ratio (1.5-2.5):1, wherein the sauce is prepared by mixing, cooking and filtering the following raw materials: water, ox vertebrae, pig ribs, pig bones, old ginger, cooking wine, fermented soya beans, salt, sugar, star anise, sand ginger, pseudo-ginseng root, cassia bark, tsaoko amomum fruit, clove, wild pepper, dried orange peel, liquoric root, common fennel, bay leaves, dahurian angelica root, clove mother, corsvenor momordica fruit, cassiabarktree fruit and vegetables; and the oil-tea camellia is prepared by mixing, cooking andfiltering the following raw materials: water, old chicken, pig bones, qingming tea, mango ginger, toasted garlic, chive, parsley and camellia-seed oil. In the method, the oil-tea camellia is preparedby frying qingmin tea with the camellia-seed oil, i.e., tea oil; tea oil does not contain any substance harmful to human bodies such as cholesterol, flavacol and the like, is a true pure natural environmentally-friendly edible oil, and can be matched with various Chinese medicinal herbs; and the edible oil-tea camellia bittern has rich nutrition, remarkable oil tea function and ideal physical therapy and body care functions.

Owner:毛本业 +1

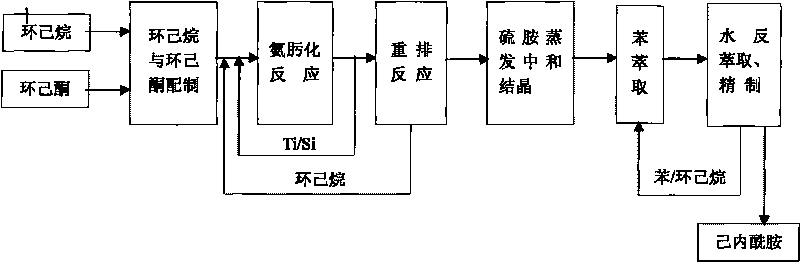

Process for preparing caprolactam

The invention discloses a process for preparing caprolactam, which comprises the following steps: after mixing cyclohexanone and cyclohexane evenly, carrying out an oxamidine reaction to obtain a cyclohexane solution of cyclohexanone oxime; enabling the cyclohexane solution of the cyclohexanone oxime and oleum to react to generate a caprolactam sulfate solution, curing the caprolactam sulfate solution, then carrying out a neutralization reaction on the cured caprolactam sulfate solution and ammonia, afterwards separating the two materials to obtain a crude product of caprolactam and then carrying out extraction and water back extraction respectively to prepare a finished product. Because of the existence of a cyclohexane inert solvent, rectification and separation do not need to be carried out after the oxamidine reaction, and only a rearrangement reaction needs to be carried out after the water phase of a catalyst is separated, thereby saving a rectification device and the steam consumption; as a result, a caprolactam enterprise with an annual yield of a hundred thousand tons can save energy worth approximately 60000000 yuan every year and can also save the one-off equipment investment totaling 60000000 yuan, the technological process of caprolactam is simplified, the procedures of water washing, extraction, distillation and the like are reduced, the production period is shortened, and the annual yield is enhanced.

Owner:河北美邦工程科技股份有限公司

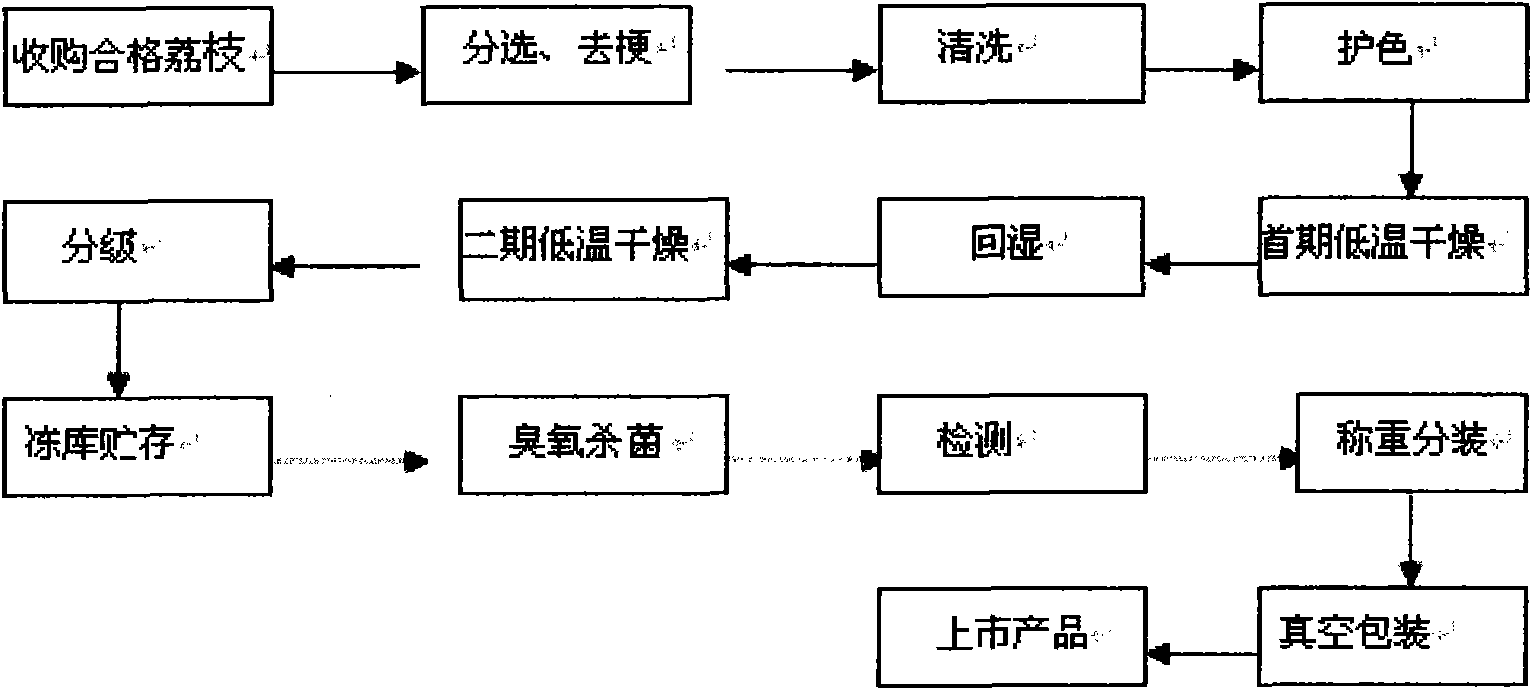

Dried lichees with original color and taste and processing method thereof

InactiveCN102100249APure qualitySolve pollutionFood processingFruits/vegetable preservation by freezing/coolingAdditive ingredientComputer science

The invention relates to dried lichees with original color and taste and a processing method thereof and also relates to a low-temperature dehydration processing technology for the dried lichees. Low-temperature dehumidification is circulated among the lichees forcibly, so that water content is gradually reduced until the lichees are dry, and color, flavor, taste, shape and nutritional ingredients of the original lichees are maintained. The technical scheme overcomes the defects of the conventional technology and solves the problems of poor quality, high cost and environmental pollution in the traditional processing method for the dried lichees in China.

Owner:HUIZHOU SIJIXIAN GREEN FOOD

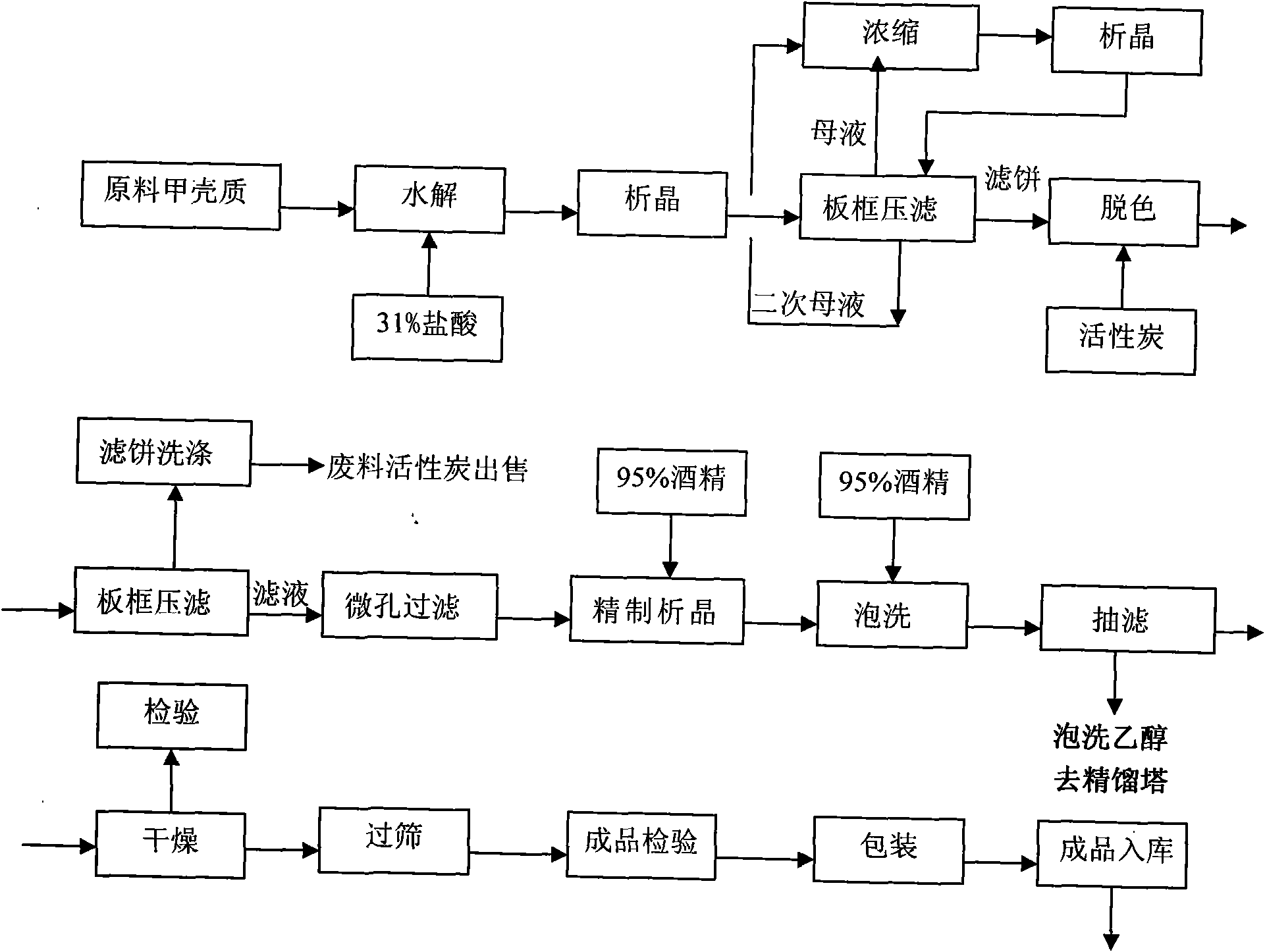

New technique for extracting D-glucosamine hydrochloride

ActiveCN101671374ANo emissionsAvoid pollutionSugar derivativesSugar derivatives preparationGeneration rateFiltration

A new technique for extracting D-glucosamine hydrochloride comprises steps of hydrochloric acid hydrolyzation, devitrification, filtration, re-devitrification and re-filtration after concentrating thefiltrate, semi-product decoloration, destaining solution re-crystallization and refinery, and the like. The technique adopts full closed type closed loop cycle operation, discharges no waste liquid or acid mist, remarkably relieves direct harm of hydrochloric acid waste gas on operating workers, and is clean and environment-friendly. During hydrolyzation, acid solution is heated, afterwards chitosan is added in succession, the hydrolyzation adopts sectional heating method, adds a low temperature reaction stage, effectively reduces coking, and improves product yield. In the reaction process, N2 protection is adopted, the moisture during hydrolyzation is subject to steam stripping, thus avoiding incomplete reaction of hydrolyzation and low yield due to reduced hydrochloric acid concentration caused by high water content in the raw materials. N2 protection facilitates the reactions to be smooth and fast and reduces generation rate of side reaction, thus the quality of the product is morepure.

Owner:JIANGSU AOXIN BIOTECHNOLOGY CO LTD

Edible wild fungus oil

The invention relates to edible wild fungus oil. In the invention, supercritical carbon dioxide is used for extracting wild fungus essential oil, and then the wild fungus essential oil is mixed with sunflower seed oil to prepare the wild fungus oil; the extraction by the supercritical carbon dioxide can reserve unique fat soluble ingredients, vitamins, trace elements and active substances in the wild funguses, and the extraction process is carried out below 50 DEG C so as to effectively reduce the oxidation of conjugated unsaturated fatty acid oil; under high pressure, the carbon dioxide can permeate into the interior of wild fungus cells, thus the separation rate of effective ingredients is high; in the whole extraction process, entrainers are not used, so that the quality of the wild fungus essential oil is purer; through mix with the sunflower seed oil, the taste of the wild fungus oil is strong and mellow; and the wild fungus oil maintains the unique nutrient ingredients of the wild funguses and is convenient to transport and store.

Owner:香格里拉县圣宝食品进出口有限责任公司

Method for extracting pimento berry oil through subcritical normal butane fluid

ActiveCN106433989AEffectively retain the activity of ingredientsLow costEssential-oils/perfumesMobility statusButane

The invention discloses a method for extracting pimento berry oil through subcritical normal butane fluid. The method includes the following steps of (1) raw material pretreating; (2) extracting; (3) separating; (4) material residue recycling; extracting process optimizing; the extracting time is short, operating is easy and convenient, energy dissipation is small, and the cost is low. The extracting process is carried out in the vacuum low-temperature low-pressure environment, damage to fragrance and secondary pollution are avoided, the fragrant components in pimento berries can be reserved to a maximum degree, the extracted pimento berry oil and an extracting agent are thoroughly separated, the fragrance of the product is pure, and the mobility stable is good. Under the parameter condition of the method, the extracting yield of the pimento berries ranges from 4.5% to 5.2%.

Owner:郑州雪麦龙食品香料有限公司

Manufacturing technology for preparing purified water containing water-soluble silicon

ActiveCN104098169APure qualityUniform meltingScale removal and water softeningMultistage water/sewage treatmentDiseaseHigh concentration

The invention belongs to the technical field of medicine production, and particularly relates to a manufacturing technology for preparing purified water containing water-soluble silicon by adding the water-soluble silicon into the purified water. The manufacturing technology comprises the following steps: (1) selecting raw materials: selecting water-soluble silicon amorphous crystal particles or powder and purified water for later use; (2) preparing a high-concentration water-soluble silicon solution; (3) preparing a low-concentration water-soluble silicon solution; (4) filtering; (5) sterilizing; (6) storing; (7) labeling, and warehousing and storing at a cool and shady place. The water-soluble silicon solution prepared by the invention, once added into daily food and drink, has beneficial functions on growth, disease preventing, health caring and health improvement of a human body, is applicable to purified water silicon adding of families, schools, small groups and the like, and is applicable to industrial continuous production.

Owner:叶卫斌

A production process for preparing purified water containing water-soluble silicon

ActiveCN104098169BPure qualityUniform meltingScale removal and water softeningMultistage water/sewage treatmentHigh concentrationDisease

The invention belongs to the technical field of medicine production, and particularly relates to a manufacturing technology for preparing purified water containing water-soluble silicon by adding the water-soluble silicon into the purified water. The manufacturing technology comprises the following steps: (1) selecting raw materials: selecting water-soluble silicon amorphous crystal particles or powder and purified water for later use; (2) preparing a high-concentration water-soluble silicon solution; (3) preparing a low-concentration water-soluble silicon solution; (4) filtering; (5) sterilizing; (6) storing; (7) labeling, and warehousing and storing at a cool and shady place. The water-soluble silicon solution prepared by the invention, once added into daily food and drink, has beneficial functions on growth, disease preventing, health caring and health improvement of a human body, is applicable to purified water silicon adding of families, schools, small groups and the like, and is applicable to industrial continuous production.

Owner:叶卫斌

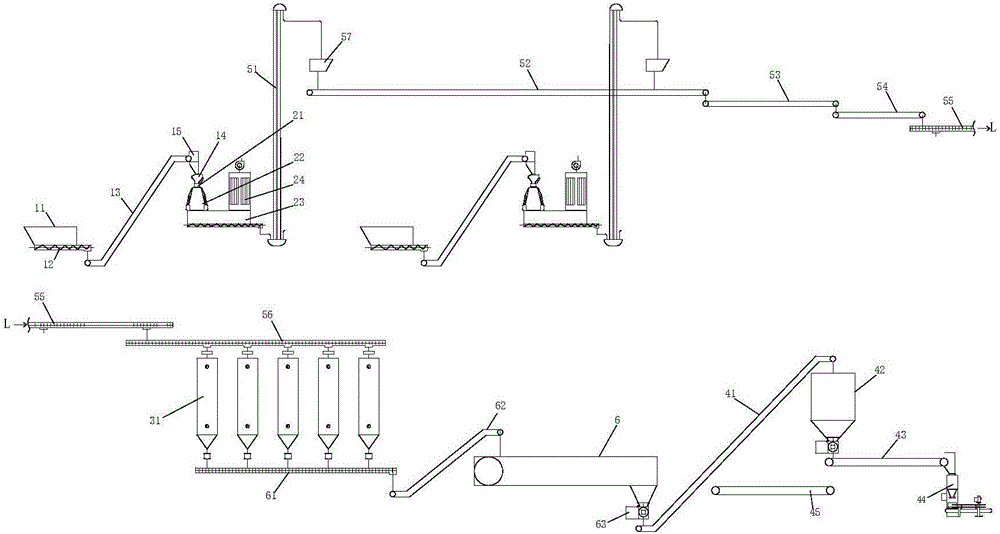

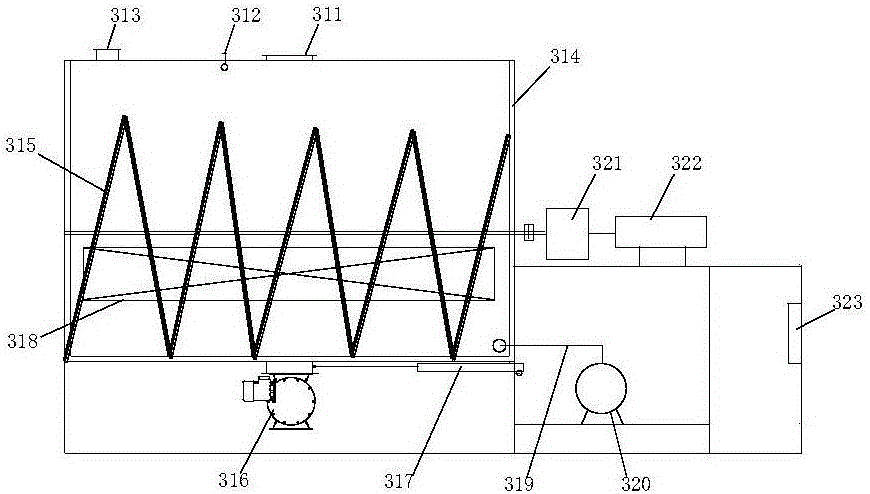

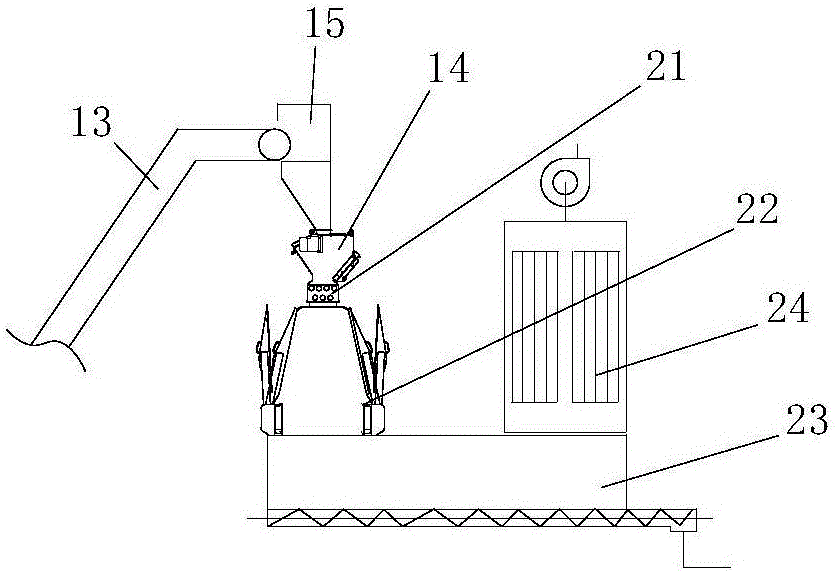

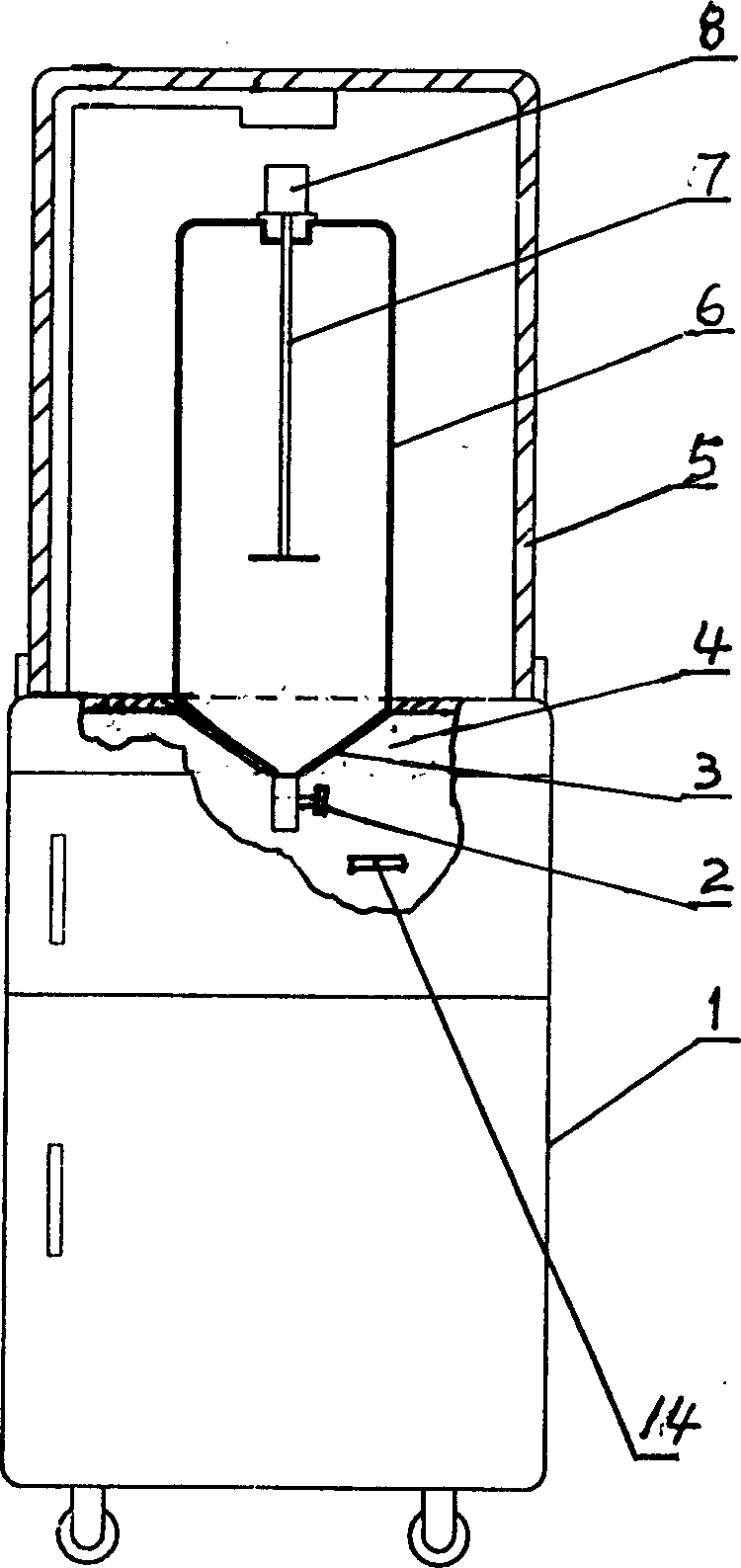

Organic fertilizer production line device and method

InactiveCN105837279ANo smellVirus freeBio-organic fraction processingFertiliser treatment controlScrew conveyorManufacturing engineering

The invention discloses an organic fertilizer production line device and method. The organic fertilizer production line device comprises a feeding device, a smashing device, a fermenting device, a pushing device and a controller for controlling the integral device to operate; the discharge end of the feeding device is connected with the feeding end of the smashing device; the smashing device is connected with the fermenting device by a conveying device; the discharge end of the fermenting device is connected with the feeding end of the pushing device; the smashing device comprises a magnetic selector, a smasher, a screw conveyor and a pulse dust collector; the integral device can accurately regulate and control each technical parameter in the production process, achieves scale production and automatic production of an organic fertilizer, and breaks the industrial bottleneck that organic fertilizer production standards are undetermined; the organic fertilizer production standards and speed are improved; moreover, production cost is reduced; labor is saved; the organic fertilizer production line device and method have no pollution to the environment in the production process.

Owner:冯书妙

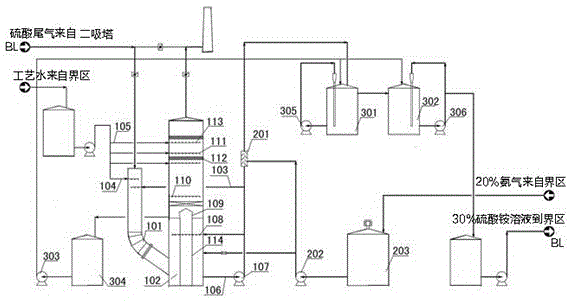

Sulfuric acid tail gas desulphurization device and method

InactiveCN104998530AImprove desulfurization efficiencyIncrease contact areaChemical industryDispersed particle separationTowerCirculating pump

The invention relates to a sulfuric acid tail gas desulphurization device and method. A multi-layer spraying, cleaning and defogging device and anti-blocking design are adopted in a desulphurization tower, and the three functions of desulphurization, cleaning and defogging are integrated by the tower. The bottom of the desulphurization tower is connected into a liquid outlet pipe and a circulating pump. The circulating pump is connected to a mixing device through a pipe. The mixing device is connected with an ammonia water pump through a pipe and connected into an ammonia water tank. Circulating solutions in the tower are ammonium sulfite and ammonium hydrogen sulfite. The higher desulphurization efficiency can be reached. The mixing device is connected into a first-level oxidation tank through a pipe and connected into a second-level oxidation tank. Secondary hydrogen peroxide oxidation outside the desulphurization tower is conducted, an ammonium sulfite solution and hydrogen peroxide fully react with each other through stirring of the air, the oxidation rate of the ammonium sulfite can reach over 98%, the quality of a by-product ammonium sulfate solution is guaranteed reliably, absorption, adjustment and oxidation are conducted on sulfuric acid tail gas, ammonium sulfate is generated, operating devices are fewer, and low power consumption and the energy-saving effect are achieved.

Owner:武汉宇青环保科技有限公司

Low-temperature thermal source heat pump capacity regulation method

InactiveCN1690596AMeet heating load requirementsImprove performanceHeat pumpsHigh concentrationWorking fluid

The invention discloses a lower-temperature source heat pump capacity regulating method. The invention adopts mixture contains two or more components as coolant and changes concentration of circulating working fluid in system via disconnecting means. When heat pump operating load increases, system separates high boiling component from fluid via disconnecting means to increases concentration of circulating lower boiling working fluid and increases heating efficiency under low temperature environment. When heat pump operating load decreases, system draws high boiling component of high concentration from low-pressure fluid tank at the bottom of debonding unit and so reduces the heat-production amount. When system processes cold-production step, it can also change proportion of ingredients to meet the need of load variation.

Owner:ZHEJIANG UNIV

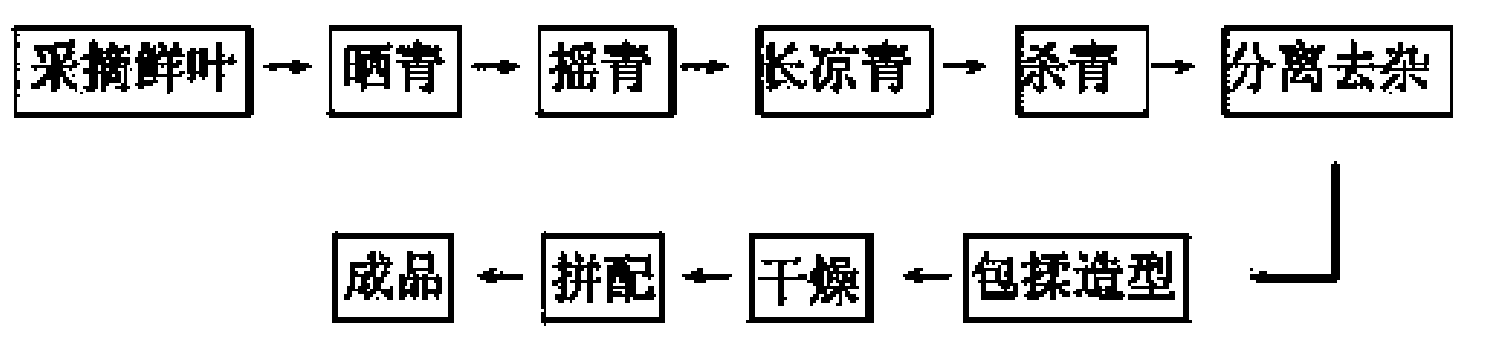

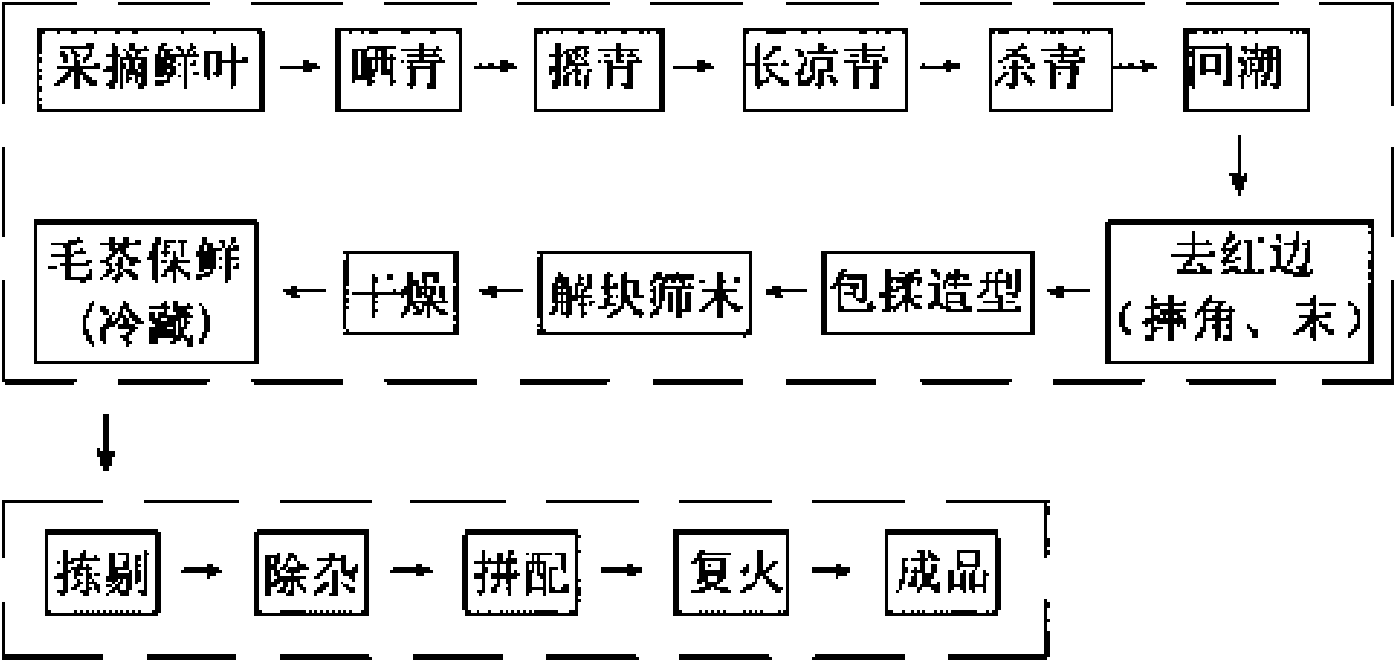

Manufacturing process of mild aromatic Tieguanyin tea

InactiveCN101810229AEasy to control the kneading strength and baking temperatureConsistent qualityPre-extraction tea treatmentChemistrySweet flavor

The invention relates to a manufacturing process of mild aromatic Tieguanyin tea, which is characterized by comprising the following steps: picking fresh leaves, sun drying, rocking, cooling for a long time, removing water, separating and removing impurities, kneading and shaping, drying and matching to obtain a finished product. Because the process of separating and removing impurities is carried out in advance, the manufactured finished product of the mild aromatic Tieguanyin tea of the invention has a tight, jade green, neat and well-spaced and clean shape, pure and strong aroma for a long time, fresh, mellow and sweet flavor, obvious rhyme, golden yellow, clear and bright soup color, soft and bright leaf base, obvious red edge, integral and uniform leaf base, and long-time after-taste. Compared with the traditional process, the process of the invention reduces parts of the processes, greatly improves the tea quality, reduces the cost, and has obvious economic benefit.

Owner:福建省安溪县长和茶业有限公司

Bulk packing yoghourt processing method and its processing device

Disclosed is a processing method of bulk packed yoghourt consisting two phases of manufacture in milk product factory and on-site processing of eating consumption, the first of which comprises original milk disinfecting, homogenizing, inoculating, loading, packing, fermenting, stirring with various bulk yoghourt machines, and freezing to obtain the bulk packed yoghourt, one or two of vaccination and fermentation processes can be conducted on the eating consumption phase.

Owner:王政期

Tobacco water leaching method for lowering its tar and toxicity

A tar-reducing and detoxicating technology for tobacco leaf features that such steps are added between flue-curing and fermenting steps as immersing tobacco leaves in water for 0.5-3 hr, drip-drying and baking at 40-50 deg.C until its water content is lower than 10%. Its advantages are high effect to remove 70% of tar, amine and alkali, and no influence to smell of tobacco.

Owner:周水平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com