Bulk packing yoghourt processing method and its processing device

A technology for yogurt and yogurt machine, which is applied in the fields of milk preparations, dairy products, and applications, can solve the problems of long storage time, high oxygen, affecting the taste and quality of yogurt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

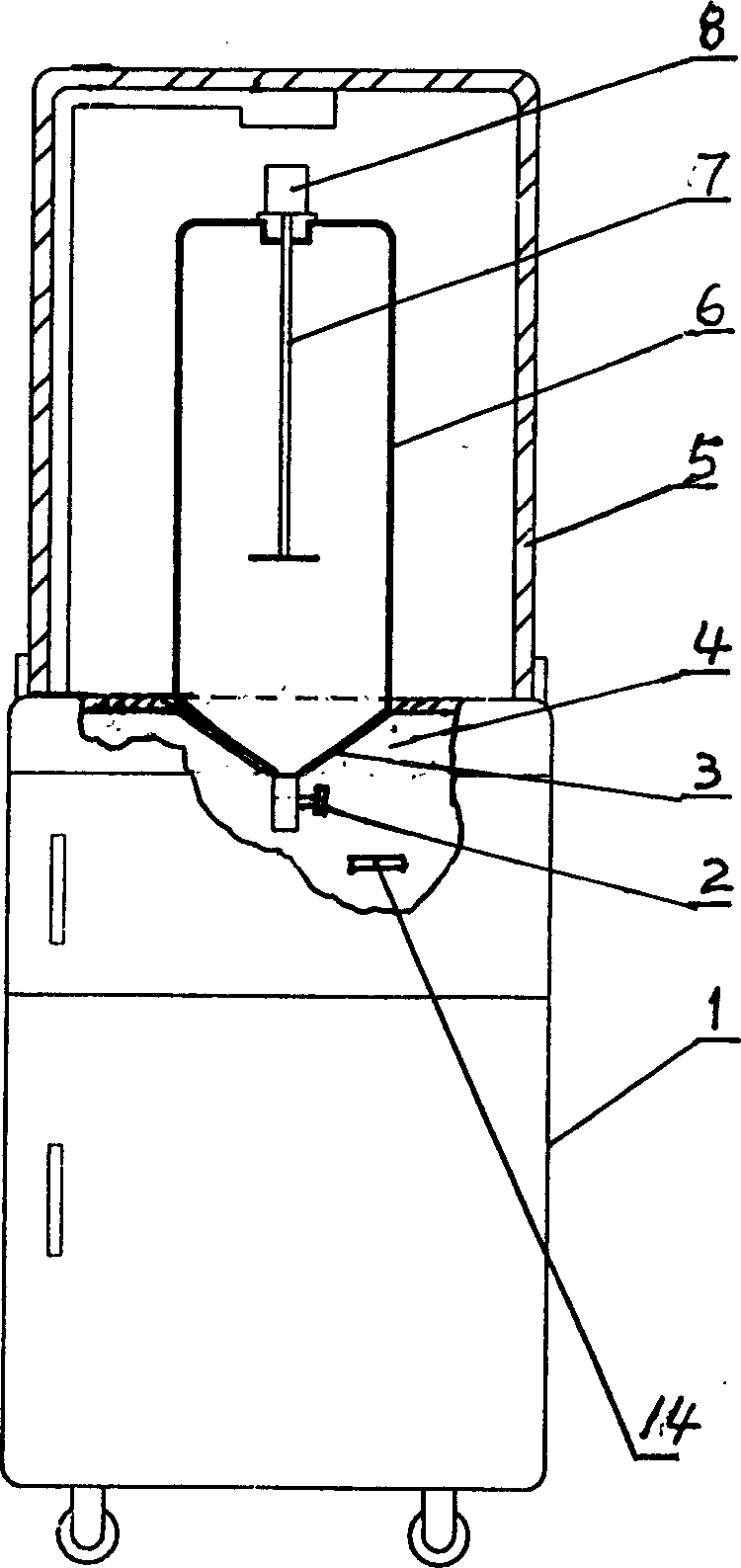

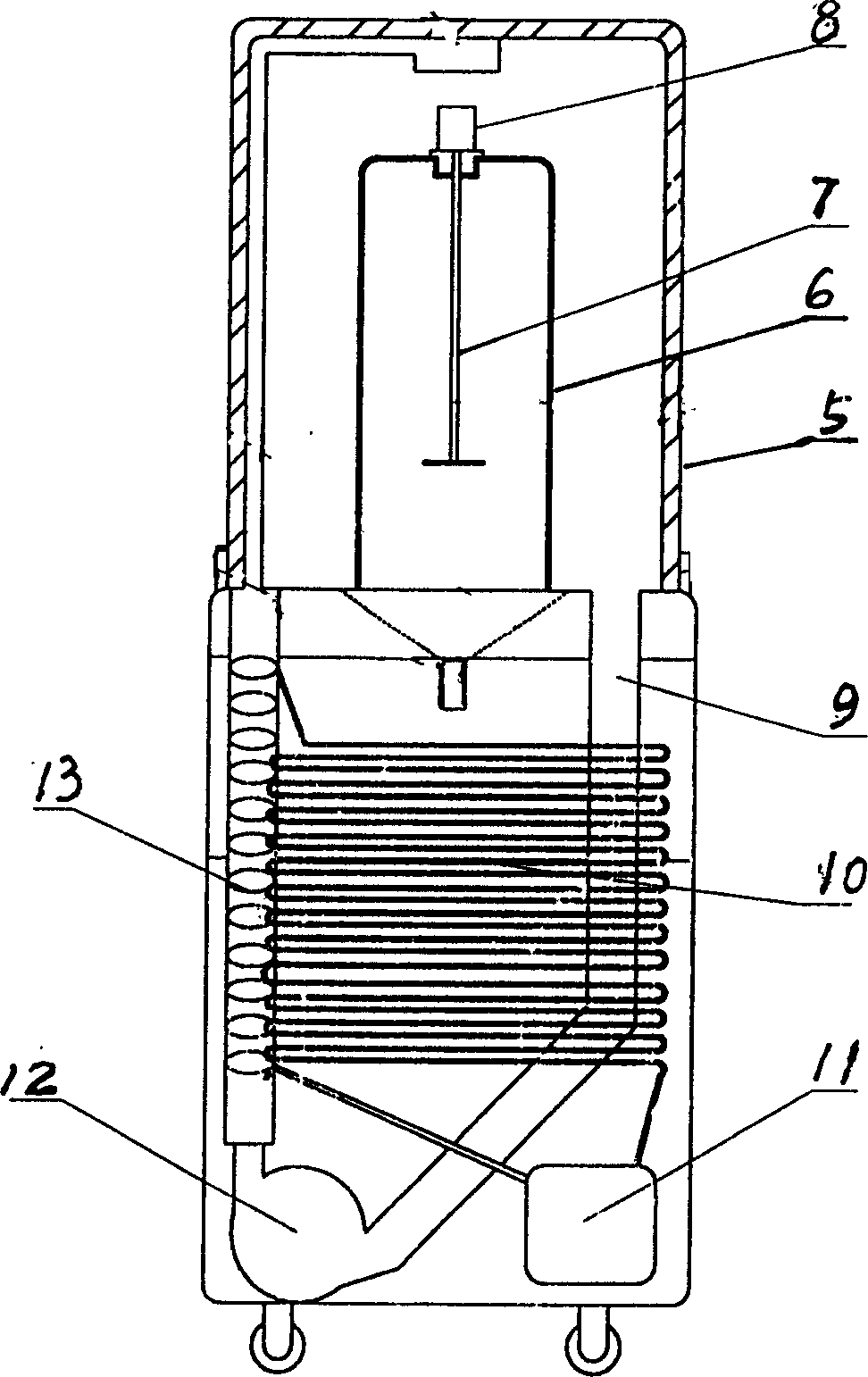

Embodiment Construction

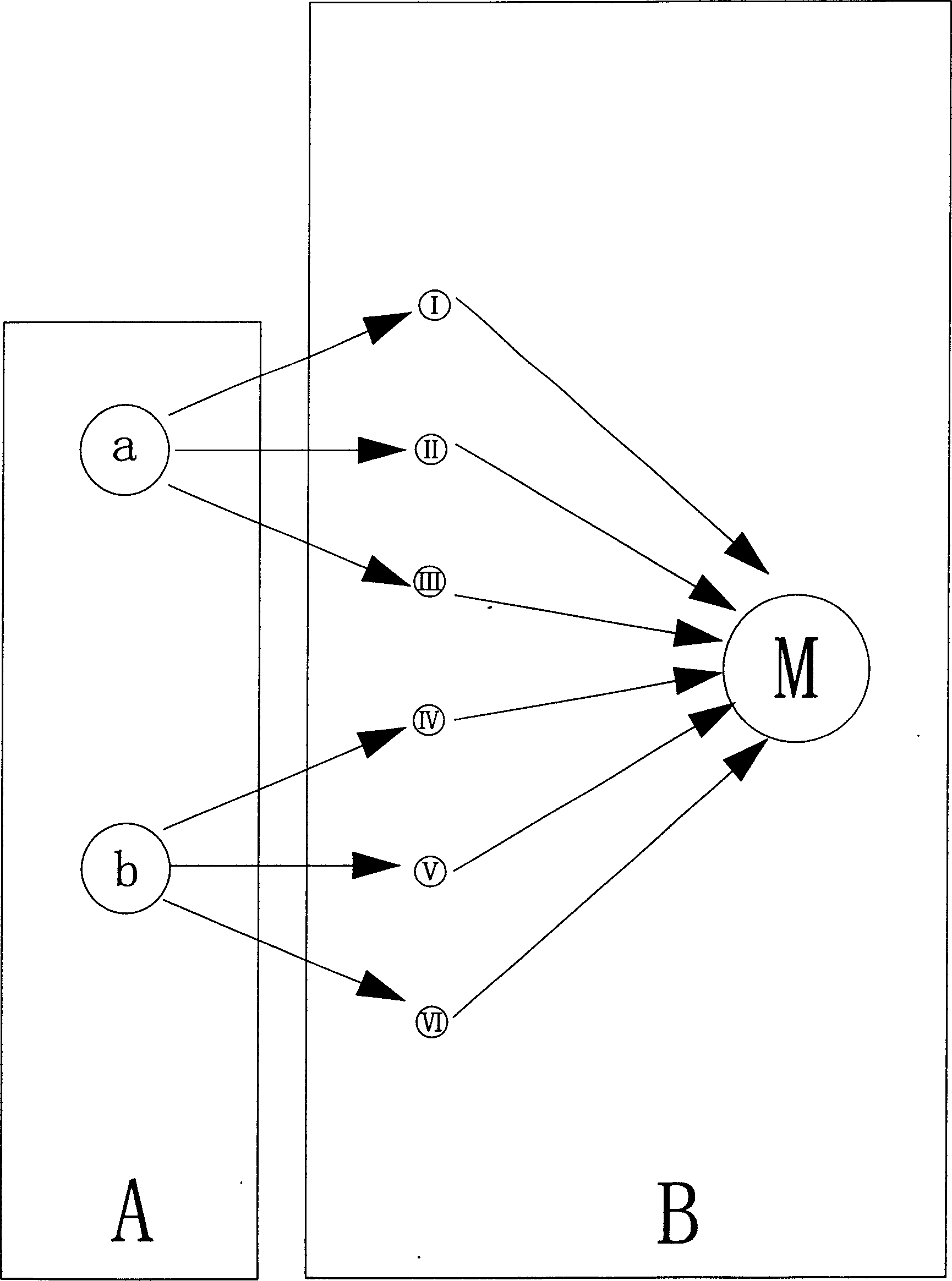

[0036] The present invention is further described as follows with reference to the accompanying drawings in conjunction with specific embodiments: the processing method of bulk yogurt, that is, unpackaged yogurt, is: it is composed of two parts: processing at the hole product factory A and processing at the edible consumption site B, see the appendix figure 1 , M in the figure is the user.

[0037] 1. Firstly, process procedure a or procedure b in dairy factory A. Processing procedure a is: raw milk disinfection, homogenization, inoculation, filling, sealing and fermentation. Processing procedure b is: raw milk disinfection, homogenization, filling, sealing or raw milk disinfection, homogenization, inoculation, filling and sealing.

[0038] 2. Further processing into yogurt in eating unit B:

[0039] I. Use an electric tower stirring yogurt machine to process it into bulk yogurt after stirring

[0040] II. Use a manual tower stirring yogurt machine to process it into bulk yo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com