Sulfuric acid tail gas desulphurization device and method

A sulfuric acid tail gas and desulfurization device technology, applied in the direction of separation methods, ammonium sulfate, chemical instruments and methods, etc., can solve the problems affecting the production of compound fertilizers, sulfur dioxide emissions, insufficient stability, etc., to reduce the solution circulation and system High power consumption, high desulfurization efficiency, and large operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with embodiment the present invention is further described.

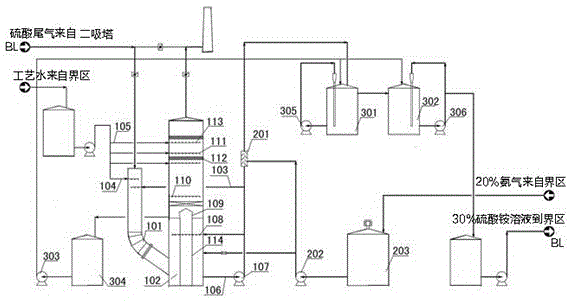

[0032] A process flow of sulfuric acid tail gas desulfurization method, sulfuric acid tail gas main pipe 101 is connected with ammonium sulfite solution inlet pipe 103 and water inlet pipe 104, the bottom of desulfurization tower 102 is connected with sulfuric acid tail gas main pipe 101, and desulfurization tower 102 is connected with water inlet pipe 105, The bottom of the desulfurization tower 102 is connected to the outlet pipe 106 and connected to the circulation pump 107, the circulation pump 107 is connected to the mixer 201 through the pipeline, the ammonia water pump 202 is connected to the mixer 201 through the pipeline and connected to the ammonia water tank 203, and the ammonia water pump 201 Connected to the bottom of the desulfurization tower 102; the mixer 201 is connected to the primary oxidation tank 301 and the secondary oxidation tank 302 through the pipeline, and the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com