Manufacturing process of mild aromatic Tieguanyin tea

A production process, the technology of Tieguanyin, which is applied in the new production process of "One Leaf Avalokitesvara" and the production process of fragrant Tieguanyin tea. The quality of the finished tea is easy to control the rolling strength and baking temperature, the taste is clear and mellow, and it is conducive to product standardization.

Inactive Publication Date: 2010-08-25

福建省安溪县长和茶业有限公司

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the raw tea after kneading and drying has become dry and hard, it will inevitably damage the raw tea in the process of picking and removing impurities. The most common occurrence is that the tea leaves are broken, and the broken tea and powder exceed the standard. Destroying the raw tea aggregates and overall shape, resulting in an imbalance in the proportion of the upper, middle, and lower teas, "out of gear", and reducing the quality of the tea; in addition, repeated operations in the process of picking and removing impurities make the tea absorb odors and miscellaneous flavors and regain moisture, it must be refired and dried to prevent the possibility of aging and mildew; the most deadly is the difference in tea size, length, thickness, tenderness, elasticity, and whole brokenness, and there are differences between old and young, buds and leaves, and leaves and stems. , from the content of tea leaves, there are differences in the quantity and quality of various ingredients. These buds and leaves are mixed together for packaging and drying, which makes it difficult to control the rolling strength and baking temperature, and it is easy to appear loose or broken. , The heat is either too light or too heavy, or even scorched fire, carbonization and other ills, which directly affect the quality of the finished tea, and the mixing of thick and old stems, leaves and impurities is easy to bring rough taste, miscellaneous taste, and peculiar smell to the tea, which also affects the quality of tea. quality of tea

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

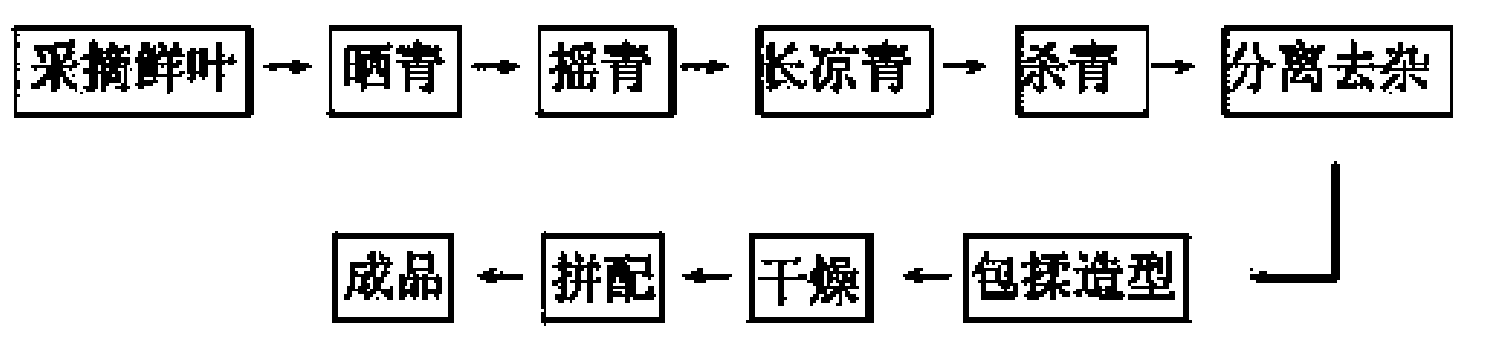

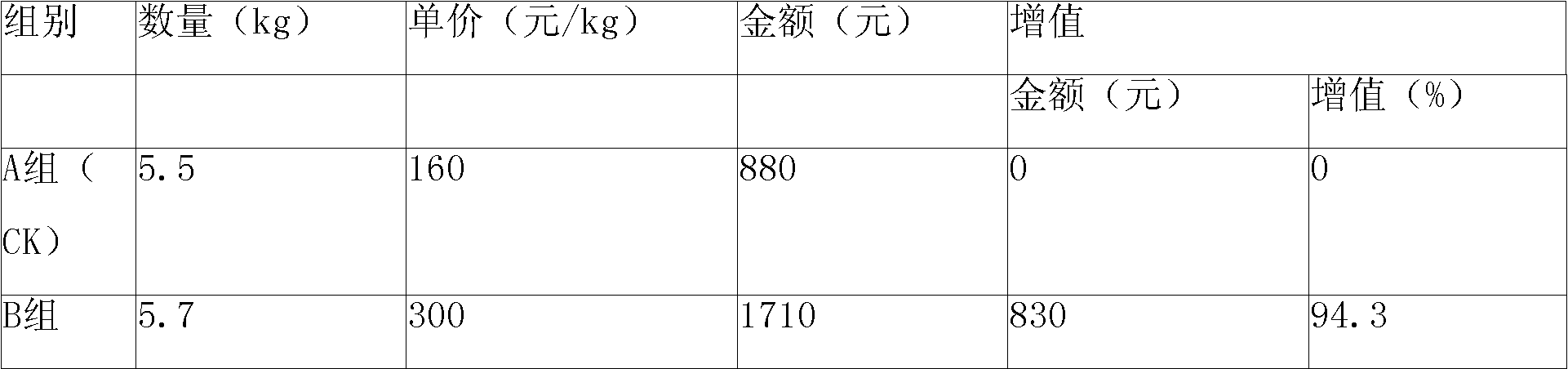

The invention relates to a manufacturing process of mild aromatic Tieguanyin tea, which is characterized by comprising the following steps: picking fresh leaves, sun drying, rocking, cooling for a long time, removing water, separating and removing impurities, kneading and shaping, drying and matching to obtain a finished product. Because the process of separating and removing impurities is carried out in advance, the manufactured finished product of the mild aromatic Tieguanyin tea of the invention has a tight, jade green, neat and well-spaced and clean shape, pure and strong aroma for a long time, fresh, mellow and sweet flavor, obvious rhyme, golden yellow, clear and bright soup color, soft and bright leaf base, obvious red edge, integral and uniform leaf base, and long-time after-taste. Compared with the traditional process, the process of the invention reduces parts of the processes, greatly improves the tea quality, reduces the cost, and has obvious economic benefit.

Description

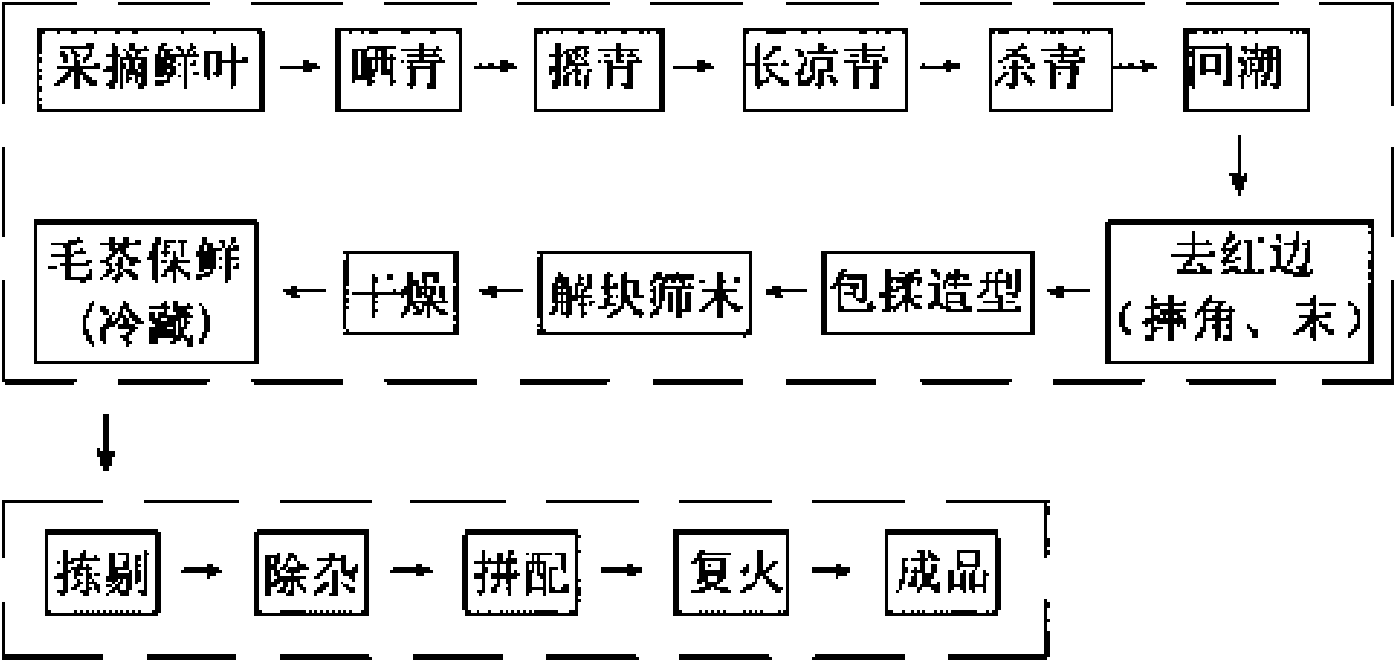

technical field The invention relates to a processing method of oolong tea, in particular to a process for producing a light-flavored Tieguanyin tea, also known as a new technique for producing "One Leaf Guanyin". Background technique The processing of traditional Fen-flavor Tieguanyin tea leaves is roughly divided into two parts: initial production and refined production, with a total of sixteen processing procedures: The initial production process includes: picking fresh leaves → drying greens → shaking greens → long-green greens → killing greens → regaining moisture → removing red edges (wrestling, powder) → kneading and shaping → deblocking and sieving → drying → cold storage of raw tea (preservation); The refining process includes: raw tea → sorting → sieving → impurity removal → blending → refiring (drying of fine tea) → finished product. From the above, it can be seen that the process of removing red edges in the primary production process of traditional Fen-flavo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23F3/08

Inventor 张木林

Owner 福建省安溪县长和茶业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com