Patents

Literature

35results about How to "Tight shape" patented technology

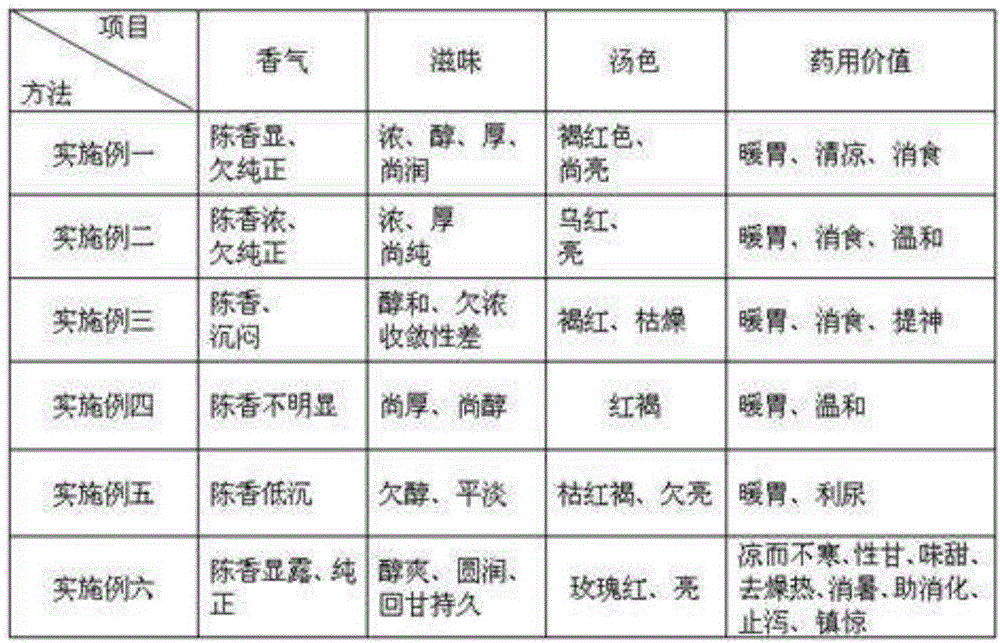

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

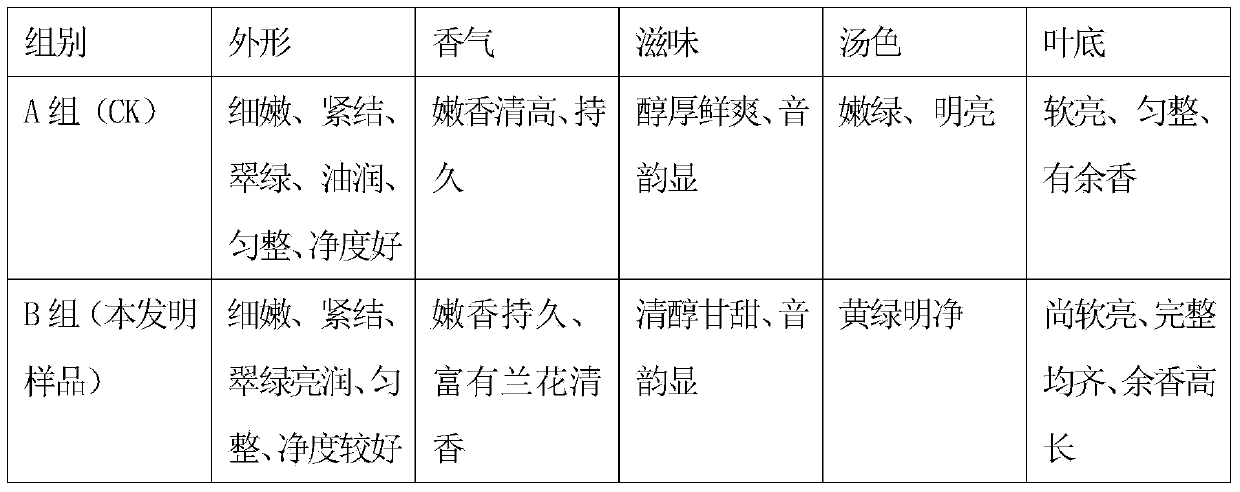

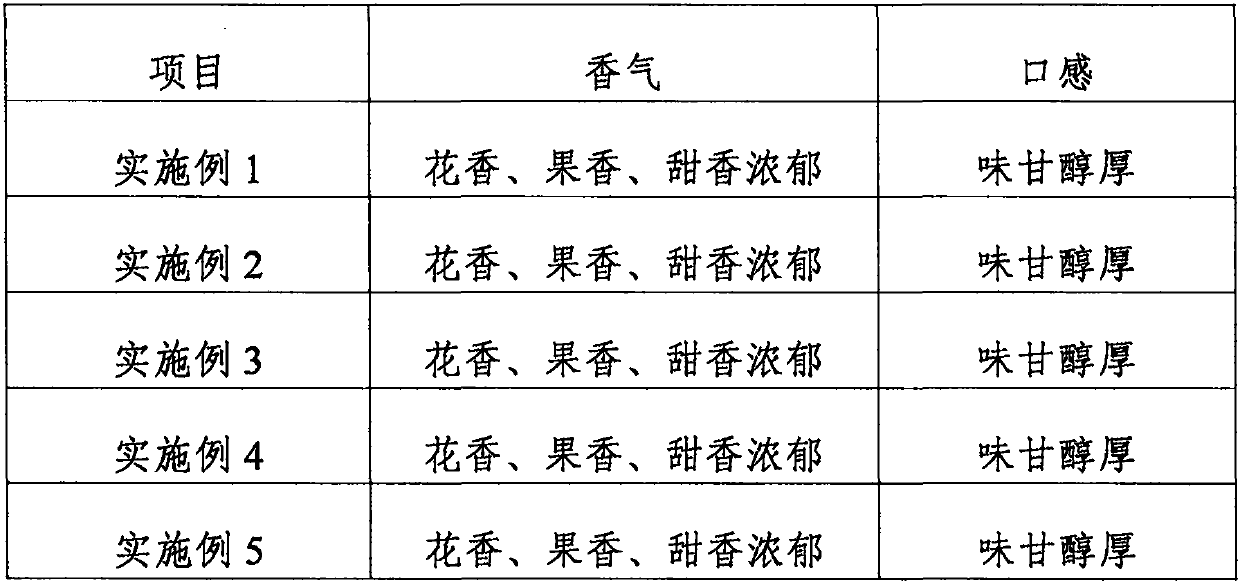

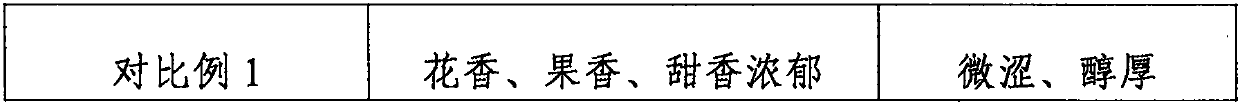

Method for preparing Hongluochun tea

InactiveCN101731377ATight shapeImprove the technical problems that cannot be vacuum packedPre-extraction tea treatmentVacuum packBlack tea

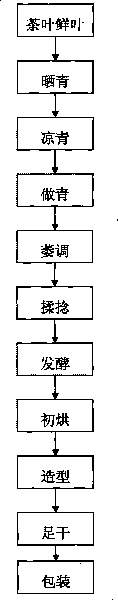

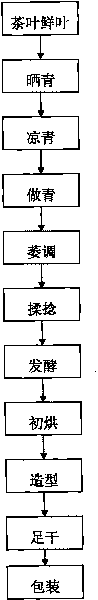

The invention discloses a method for preparing Hongluochun tea. Fresh leaves of black tea varieties or oolong varieties are taken as raw materials, and are subjected to green drying, green curing, fixing, withering, kneading, fermenting, primary drying, modeling and sufficient drying to prepare the required Hongluochun tea. The preparation process combines processing technology for black tea, green tea and oolong, so that the prepared Hongluochun tea has the characteristics of having the liquor color of the black tea, appearance of the green tea, flower fragrance of the oolong and the like. The spiral form of the Hongluochun tea solves the technical problem that the conventional strip black tea cannot be vacuum-packed so as to effectively solve the problems of fresh keeping and quality keeping of the black tea; and the Hongluochun tea fills up a blank that flower fragrance black tea does not exist in the market. The fresh leaves of black tea varieties or oolong varieties are taken as raw materials and are prepared into the flower fragrance Hongluochun tea by optimizing the processing technology. The fresh leaves in summer time are processed into the Hongluochun tea, so a problem that summer tea is thick bitter can be effectively solved, the quality of the summer tea can be improved, and the economic benefit of the summer tea can be increased.

Owner:TEA RES INST GUANGDONG ACAD OF AGRI SCI

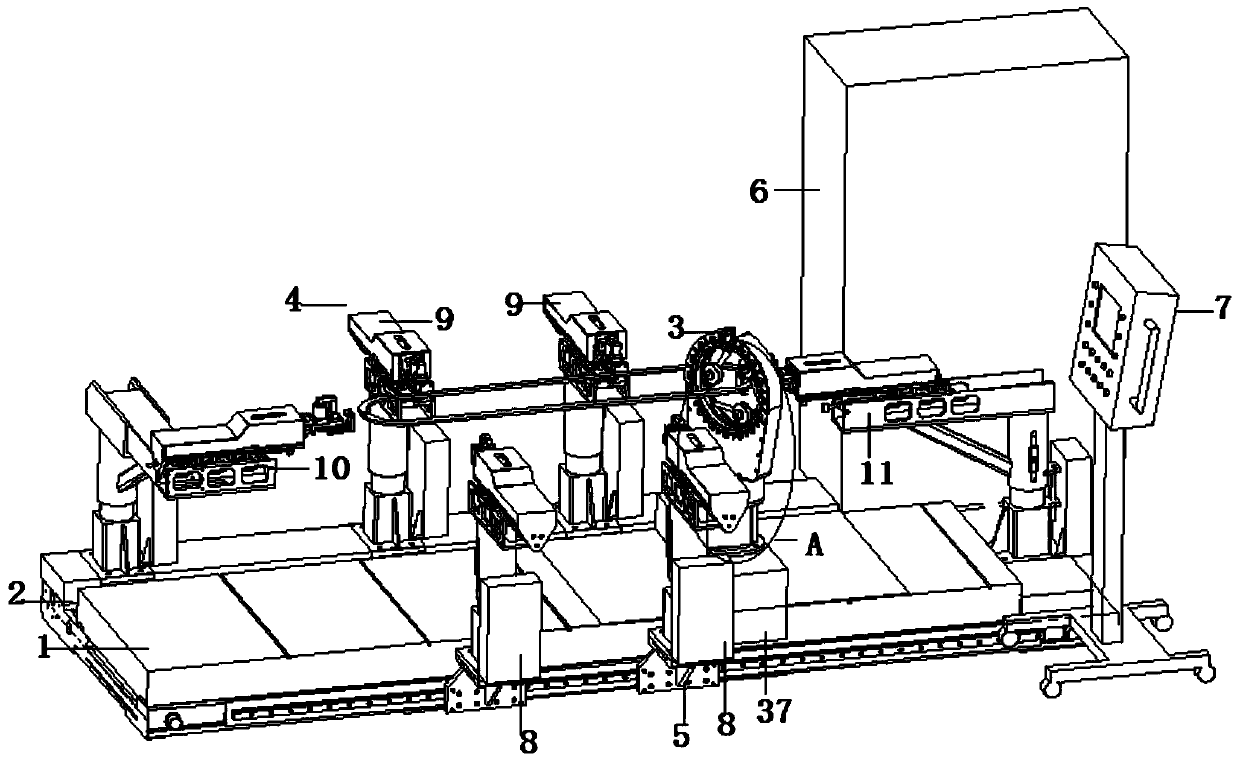

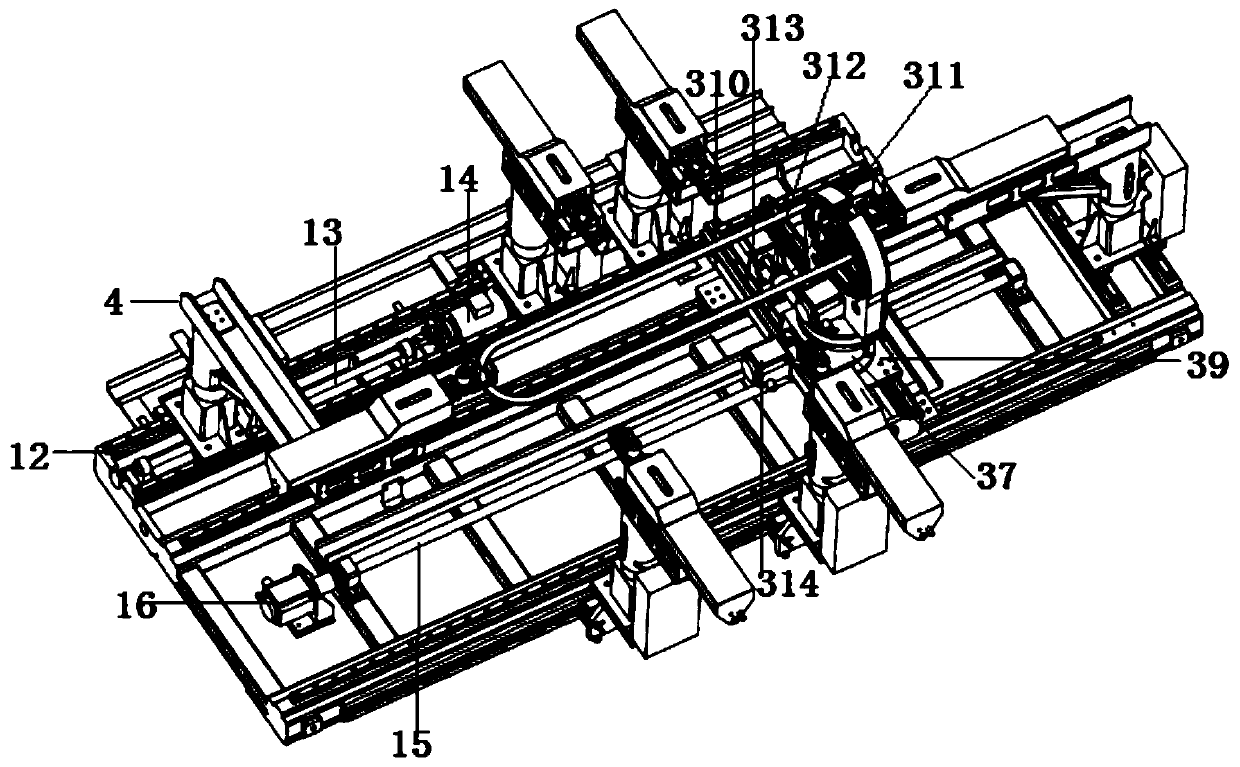

Continuous processing production line and processing method of pan-fired green tea

InactiveCN105104600AImprove tea aromaIncrease aromaPre-extraction tea treatmentProduction linePulp and paper industry

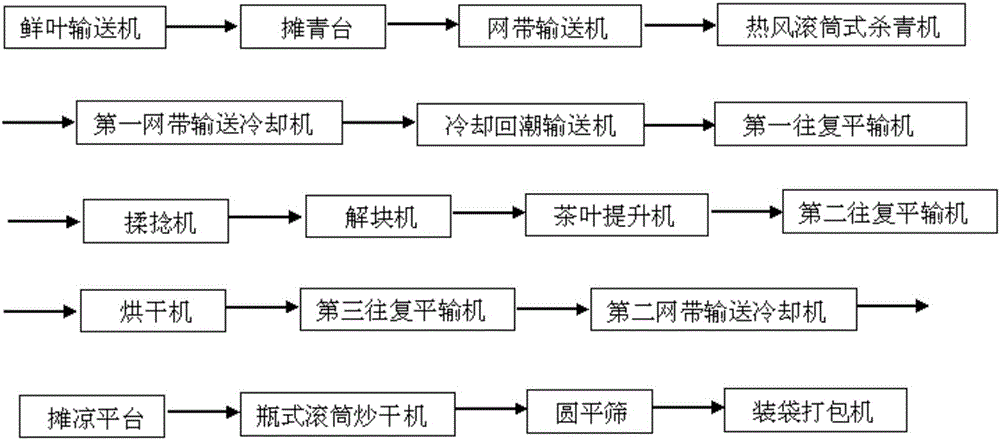

The invention provides a continuous processing production line and processing method of pan-fired green tea, and relates to the technical field of tea processing. The production line is connected with the following equipment in sequence: a fresh leaf conveyer, a spreading table, a mesh belt conveyor, a hot air cylinder-type de-enzyming machine, a first mesh belt conveying cooling machine, a cooling dampening conveyer, a first reciprocating flat conveying machine, a rolling machine, a deblocking machine, a tea leaf lifting machine, a second reciprocating flat conveying machine, a dryer, a third reciprocating flat conveying machine, a second mesh belt conveying cooling machine, a spreading cooling platform, a bottle-shaped cylinder type pan-firing machine, a round flat screen and a bagging packer. According to the continuous processing production line and processing method of pan-fired green tea, the purpose of clean and continuous production of pan-fired green tea is achieved, the production line has the characteristics of being high in yield, low in cost and high in production efficiency, and the pan-fired green tea prepared through cooperating with the standardized technology provided by the invention has the following characteristics: the appearance is compact, the color and luster are green, silver and glossy, the endosarc aroma is strong, the soup color is yellow green and bright, the taste is mellow, and the infused leaves are yellow green and bright.

Owner:柳城县国营伏虎华侨农场茶厂

Processing method of Congou black tea

InactiveCN104430993AStrong tendernessRich in endoplasmPre-extraction tea treatmentOrange FlavorBlack tea

The invention discloses a processing method of Congou black tea. Common fresh tea leaves are taken as raw materials and the processing method comprises the following steps of cold air withering, hot air withering, spreading, rolling, fermenting and drying. According to the invention, the original technology of Congou black tea is inherited, improved and innovated, so that the problems of low efficiency and high quality fluctuation of Congou black tea in the production process are solved effectively; the prepared Congou black tea is thin and fine, shows peak seedlings, is smooth in color, has bright red and yellow soup color, is mellow in taste, has heavy sweet orange flavor, is bright red in leaf bottom, and lays a good foundation for occupying the tea leaf market for the Congou black tea.

Owner:YIBIN CHUANHONG TEA IND GRP

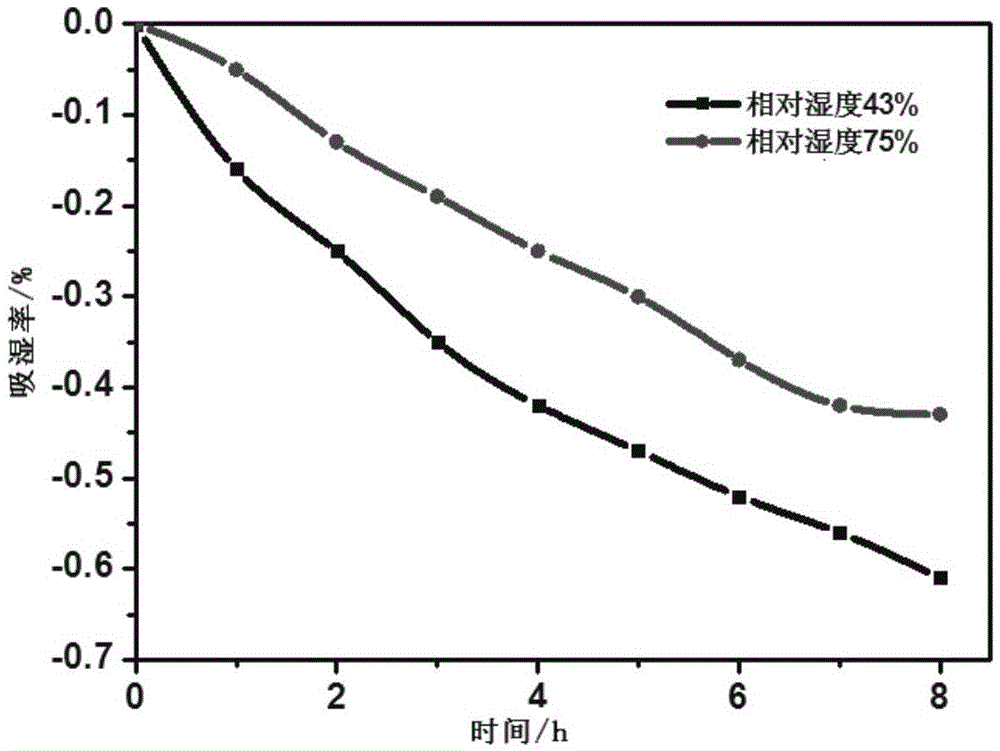

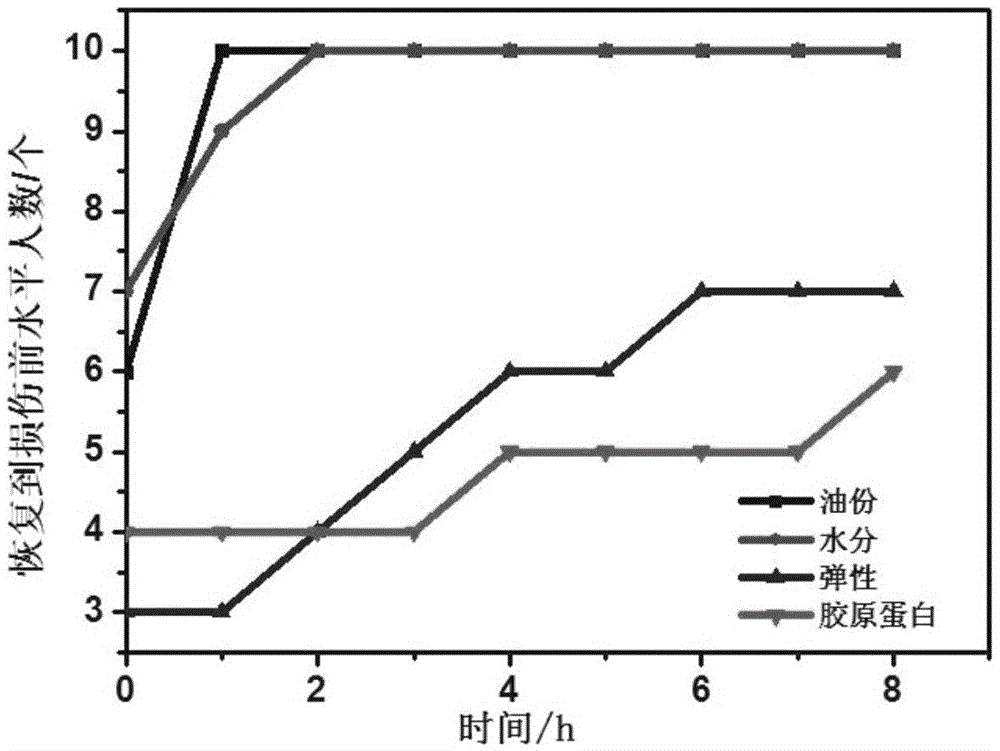

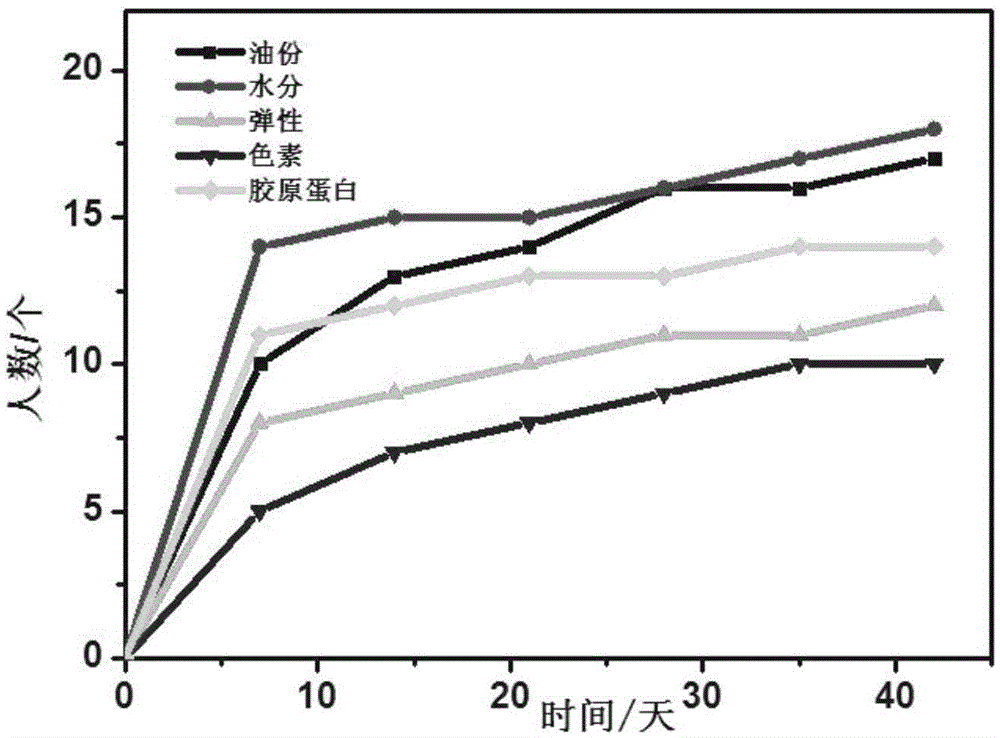

Essence with functions of activating and tightening skin and preparation method thereof

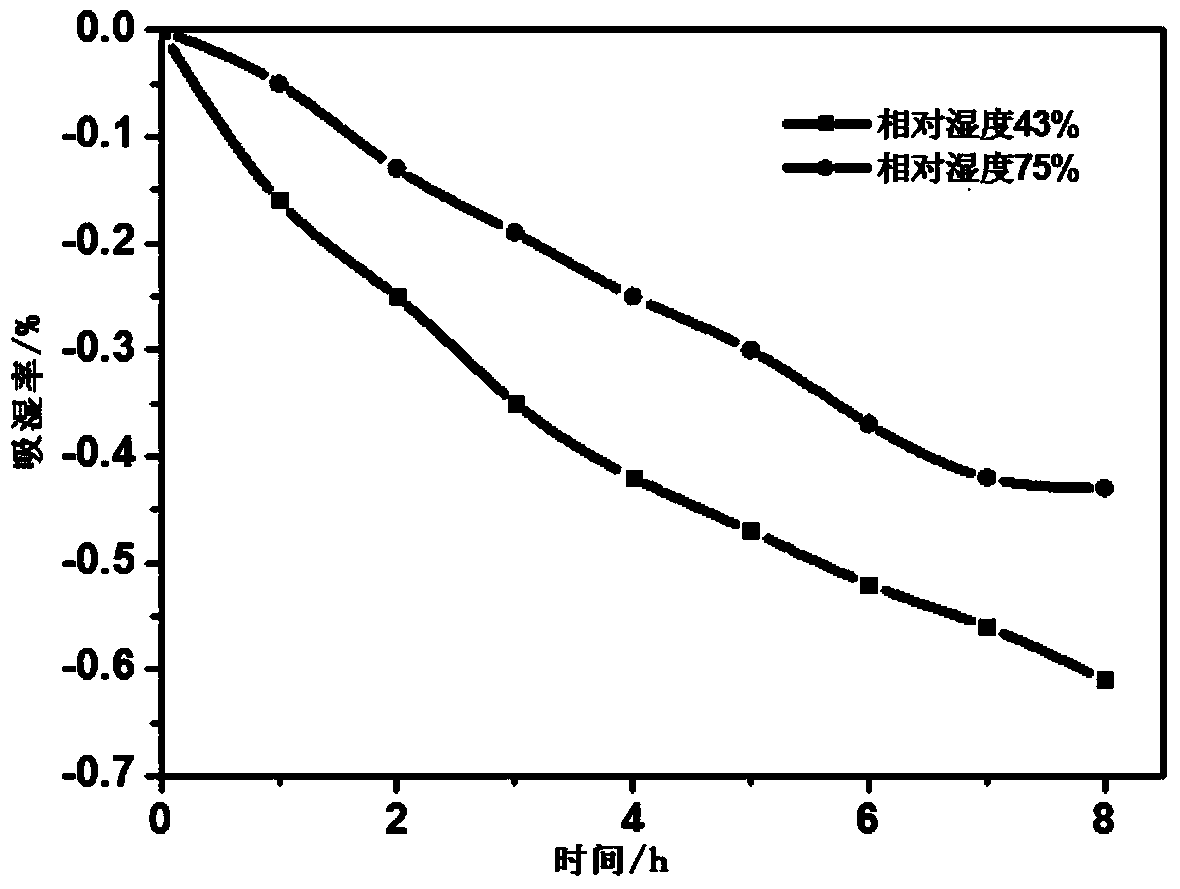

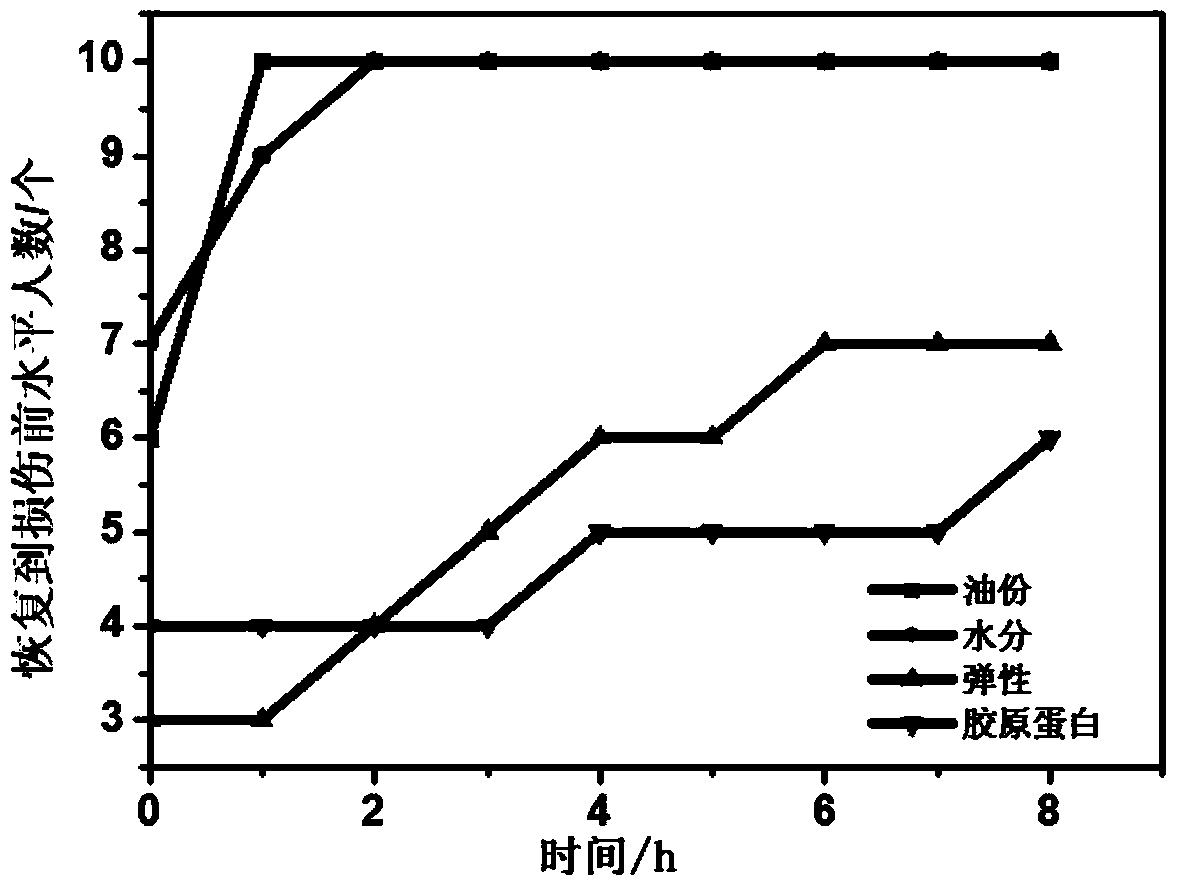

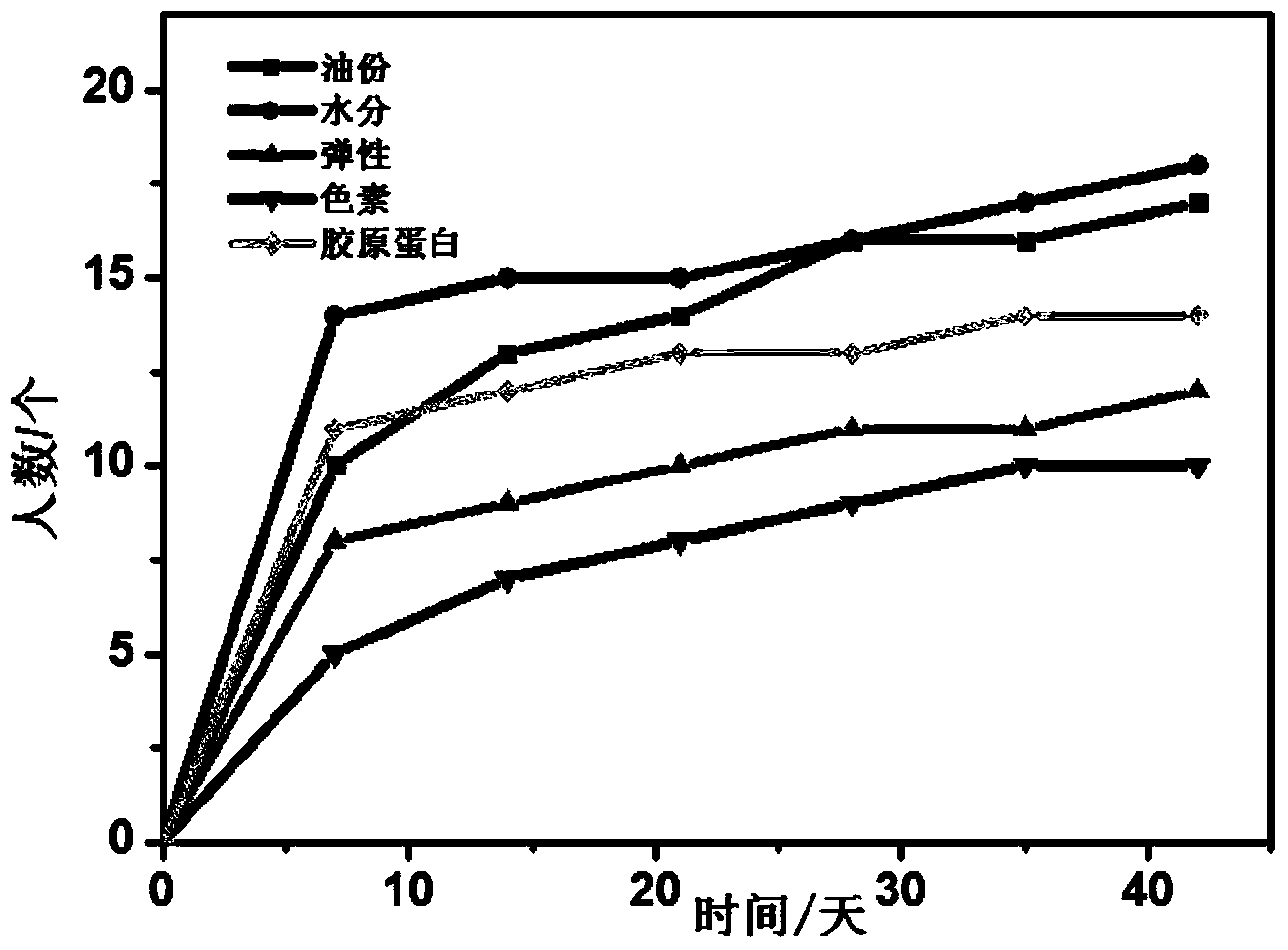

ActiveCN103585096ATo promote metabolismIncrease elasticityCosmetic preparationsToilet preparationsContinuous useAdditive ingredient

The invention discloses an emulsion type essence with functions of activating and tightening skin. On the basis of an antioxidant network system, active ingredients such as a polysaccharide skin-tightening agent, oat beta-glucan, hyaluronic acid and the like are added, various Chinese herbal medicine extracts such as rhodiola rosea, ganoderma and the like are compounded, so that the essence has higher efficacy of oxidation resistance, instant tightening and long-acting moisture preservation as well as good repairing effect on skin barrier injury; and with continuous application of the essence, wrinkles become less obvious, and the skin becomes smooth, tight, soft, tender and white.

Owner:鸯兰国际贸易(上海)有限公司

Preparation method of natural pine pollen Liupu tea

InactiveCN105613835AThe taste is mellow and sweetImprove immunityPre-extraction tea treatmentTea flavoringPine pollenToxic material

The invention relates to a preparation method of tea and in particular to a preparation method of natural pine pollen Liupu tea. The method comprises the following steps: picking tea leaves, removing moisture from the tea leaves, primarily rolling, heaping for fermentation, rolling secondarily, drying, blending and piling for fermentation, steaming and pressing, and ageing. According to the preparation method of the natural pine pollen Liupu tea, due to addition of natural pine pollen powder in the preparation process of the the natural pine pollen Liupu tea, the prepared natural pine pollen Liupu tea has the functions of resisting fatigue, strengthening the brain, adjusting the intestines and stomach and improving the autoimmunity of a human body in addition to having the intrinsic functions of relieving summer heat, eliminating dampness, tonifying the spleen, appetizing and aiding digestion, and the natural pine pollen Liupu tea has mellow and refreshing taste, is smooth and delicious, and has the beneficial effects of beautifying, clearing away heat and toxic materials, adjusting the intestines and stomach, warming the stomach, invigorating the stomach to attain mental tranquility, improving the autoimmunity of the human body, and losing weight for fitness after long-term drinking.

Owner:刘翰锦 +1

Gongfu oolong tea preparation method and products thereof

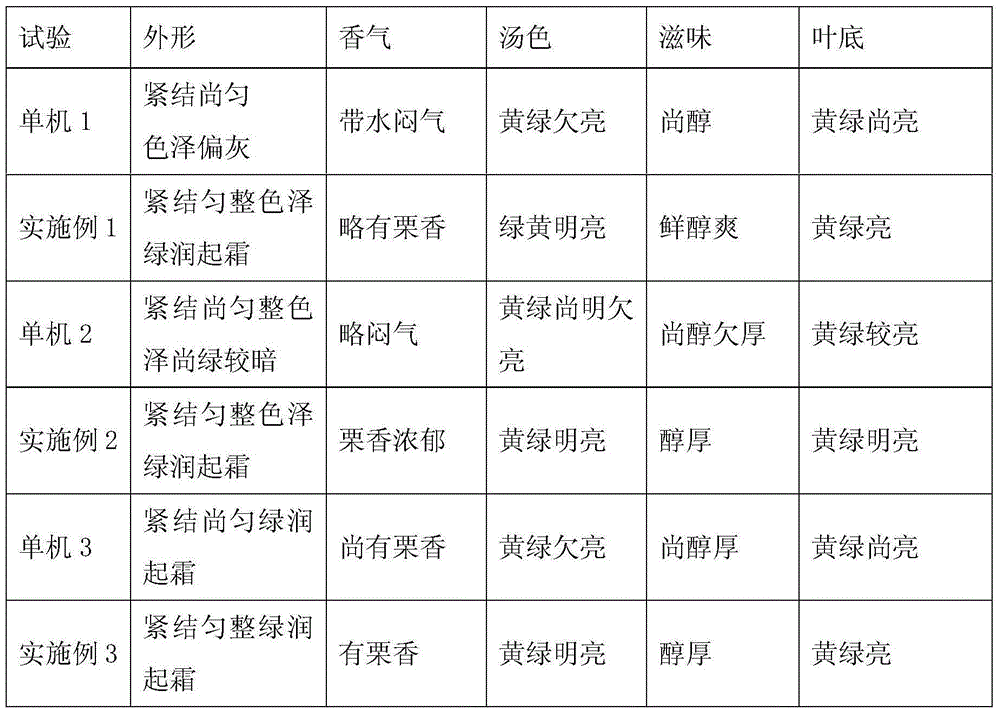

InactiveCN105580920AImprove qualityTight and even shapePre-extraction tea treatmentClimate change adaptationBiotechnologyFermentation

The present invention discloses a gongfu oolong tea preparation method and products thereof. The gongfu oolong tea preparation method provided by the invention comprises the following steps: Jinxuan and Cuiyu tea tree fresh leaf taking, withering, sun drying, leaf cooling, fine manipulating, rolling, fermenting, first firing, full firing, aging, fragrance improving and finished product obtaining. The traditional gongfu black tea preparation method and the variety resources of the Jinxuan and Cuiyu are combined, a scientific collecting and processing technology is combined, and the ''sun drying'' and ''fine manipulating'' processing technologies of the oolong tea are combined with the black tea full fermentation process, so that the prepared gongfu oolong (red oolong) tea is tight and compact in appearance, black and smooth, gold in soup color, has a flower flavor and a mountain charm, is mellow and fresh in taste, and is red and bright in leaf bottom. The preparation method puts forward for the first time that in the processing technology of the gongfu oolong (red oolong) tea and after the drying of raw tea, air conditioner temperature control aging (after-aging) is used and then the fragrance improving technology is also used, so that the tea products are more fragrant and the tastes are mellow and fresh.

Owner:GUANGXI STATE FARMS TEAS GRP

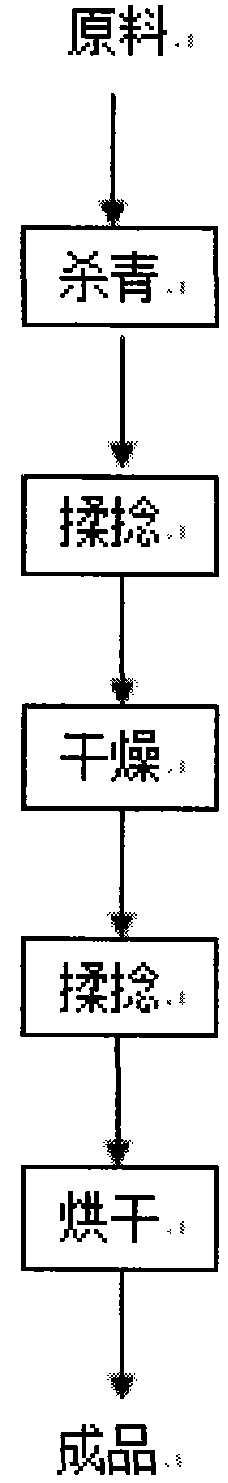

Hand-made process of little cymbidium tea

The invention discloses a hand-made process of little cymbidium tea. The hand-made process of little cymbidium tea comprises the following steps: picking fresh leaves, classifying, spreading and airing, carrying out fixation, primarily kneading, primarily drying, kneading again, tipping and drying and the like. The little cymbidium tea produced by the hand-made process is compact and solid in appearance, emerald and bright in color and luster, obvious in silver pekoe, good in product shape, durable in tender flavor and rich in cymbidium fragrance; the brewed tea is excellent in color, aroma and taste, tenderly green and clear in liquor color, full and durable in aroma, and has a unique charm; the tea quality of the little cymbidium tea is greatly improved.

Owner:舒城县南港茶叶专业合作社

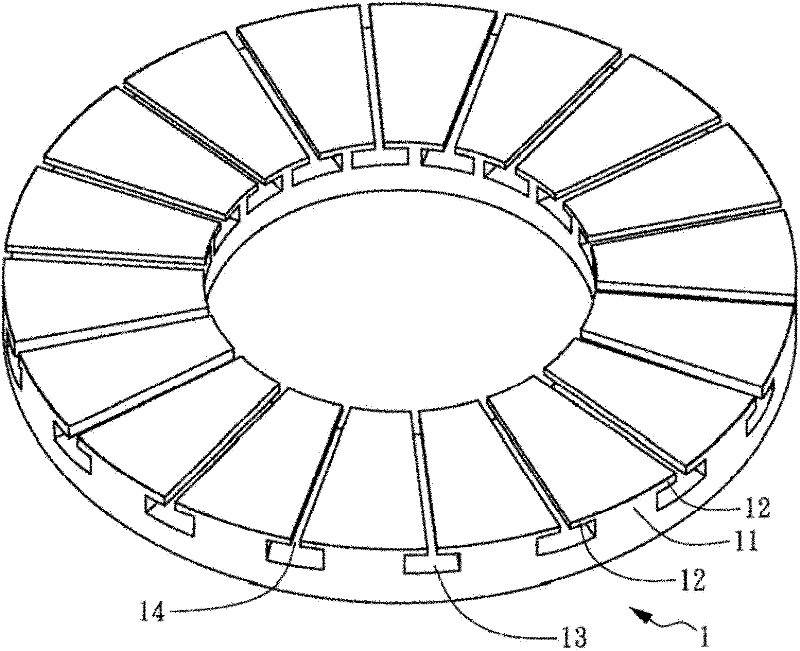

Novel black tea processing technology

ActiveCN105325584ASimplify processing stepsTight shapePre-extraction tea treatmentMicrowaveBlack tea

The invention discloses a novel black tea processing technology. The technology includes the first step of picking, the second step of spread cooling, the third step of microwave withering, the fourth step of deep withering, the fifth step of primary kneading, the sixth step of secondary kneading, the seventh step of tertiary kneading, the eighth step of fourth-time kneading, the ninth step of fifth-time kneading, the tenth step of primary fermenting, the eleventh step of secondary fermenting, the twelveth step of baking, the thirteenth step of packaging and the like. Through the technical means, the technology has the technical advantages that the technology is simple in step, easy and convenient to operate and suitable for application and popularization; made black tea is thin and tight in appearance, good in seedling tips and jet black and glossy in color and luster; after being brewed, the tea is red and bright in soup color, strong in fragrance, slight in sugar fragrance, mellow in taste, sweet after taste, and uniformly red, fine and soft in leaf bottom; the organic substance keeping rate is high, and the nutritional value of black tea is effectively improved.

Owner:贵州省凤冈县浪竹有机茶业有限公司

Method for processing green tea

The invention provides a method for processing green tea. The method includes particular steps of (1) picking, (2) withering, (3) enzyme deactivating, (4) cooling, (5) rolling, (6) strip sorting, (7) primary baking, (8) secondary baking and (9) refining and classifying. The method has the advantages that the quality of the green tea can be guaranteed, and the yield and output value of the high-grade green tea can be increased; green tea products manufactured by the aid of the method are purely natural, comprise uniform strips and obvious tips and have dark green, clear, glossy and bright liquor colors, fragrant, strong, delicate and durable aroma, mellow taste, fresh and brisk after-taste, light green and bright leaf bases and intact bud leaves; the shortcoming of slight bitter sense when people drink existing green tea liquor can be overcome; the green tea can be stored at the normal temperature for five years without deterioration, and effects of clearing heat, inducing diuresis, eliminating phlegm and moistening dryness can be realized by the green tea.

Owner:兴业县山心云雾茶厂

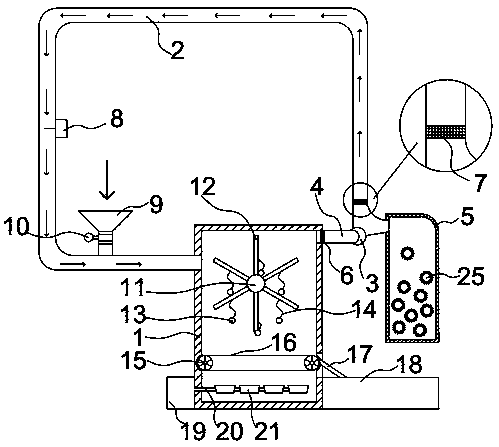

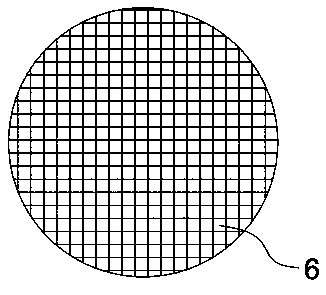

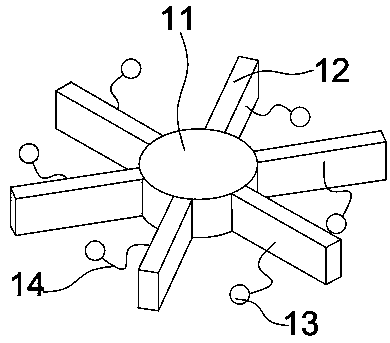

Multifunctional drying device

ActiveCN108662887AReduce breakageIntegrity guaranteedCombination devicesDrying gas arrangementsWaste managementAirflow

The invention provides a multifunctional drying device. The multifunctional drying device comprises a drying room, wherein the drying room is connected with a circulating air tube; a charge hole in the upper part of one side of the drying room communicates with an air outlet of the circulating air tube; the upper part of the other side of the drying room is connected with a circulating fan througha supporting tube; a charge hopper is arranged on the circulating air tube; a rotary body and a transport device are arranged inside the drying room from top to bottom; a discharge plate is arrangedbelow the end part of the transport device; the discharge plate is fixedly connected with the bottom of a material collecting box; a dust removal room is arranged on the side wall of a joint of the circulating air tube and the circulating fan; and an adsorbing ball is arranged inside the dust removal room. A circulating air flow way is adopted for preliminarily drying water on the surfaces of materials, and the materials uniformly diffuse and move under action of air flow, are directly blown into the drying room, and are not in contact with the inner wall of the circulating air tube, so that material breakage is reduced, and integrity of the materials is kept. The device does not need manual intervention throughout the process, and uniformly heat the materials, so that a material breakingrate can be reduced, and the quality guarantee period of the materials is prolonged, and therefore, the multifunctional drying device is suitable for large-scale popularization.

Owner:岳阳市屈原管理区屈原茶业有限公司

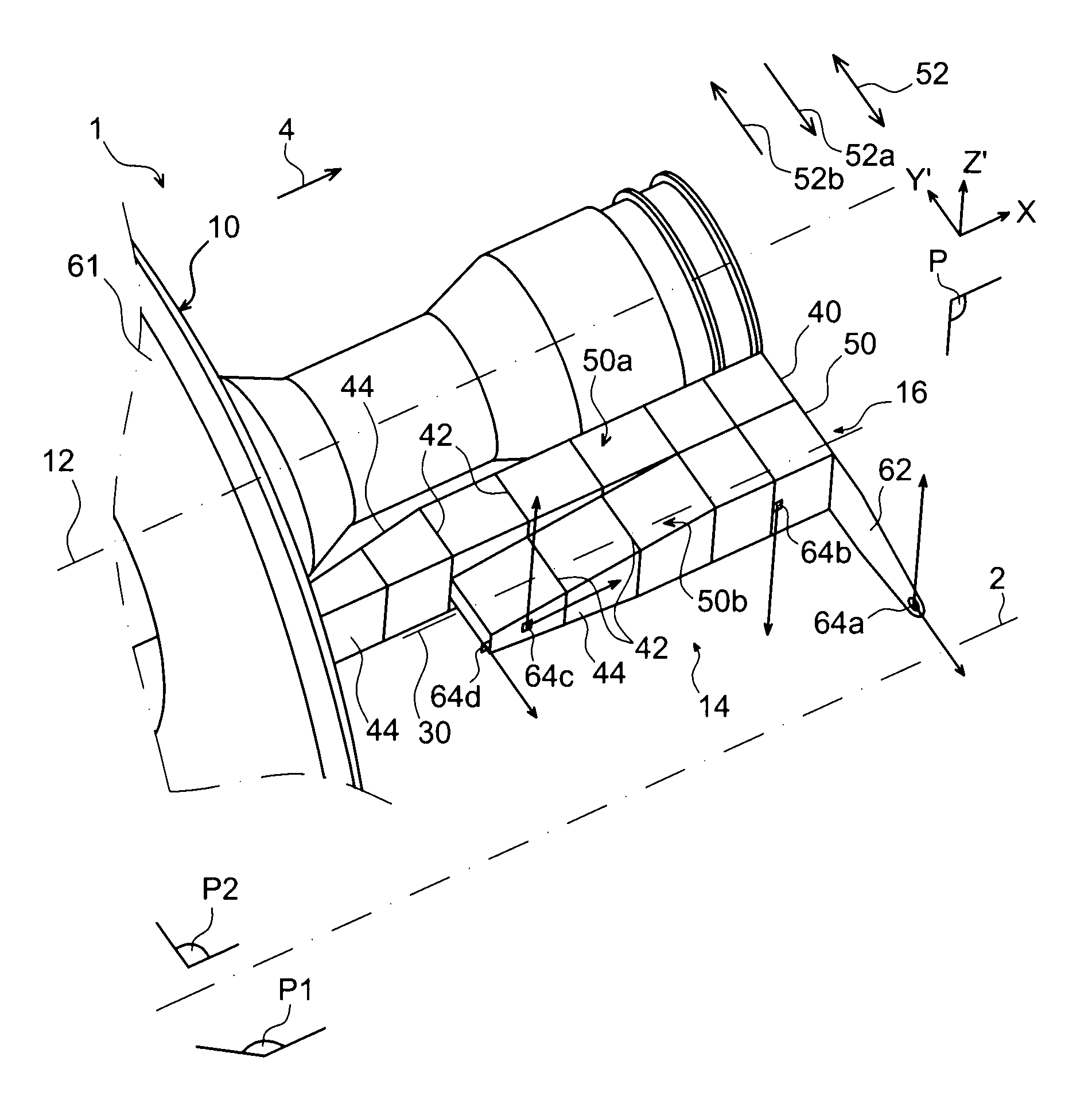

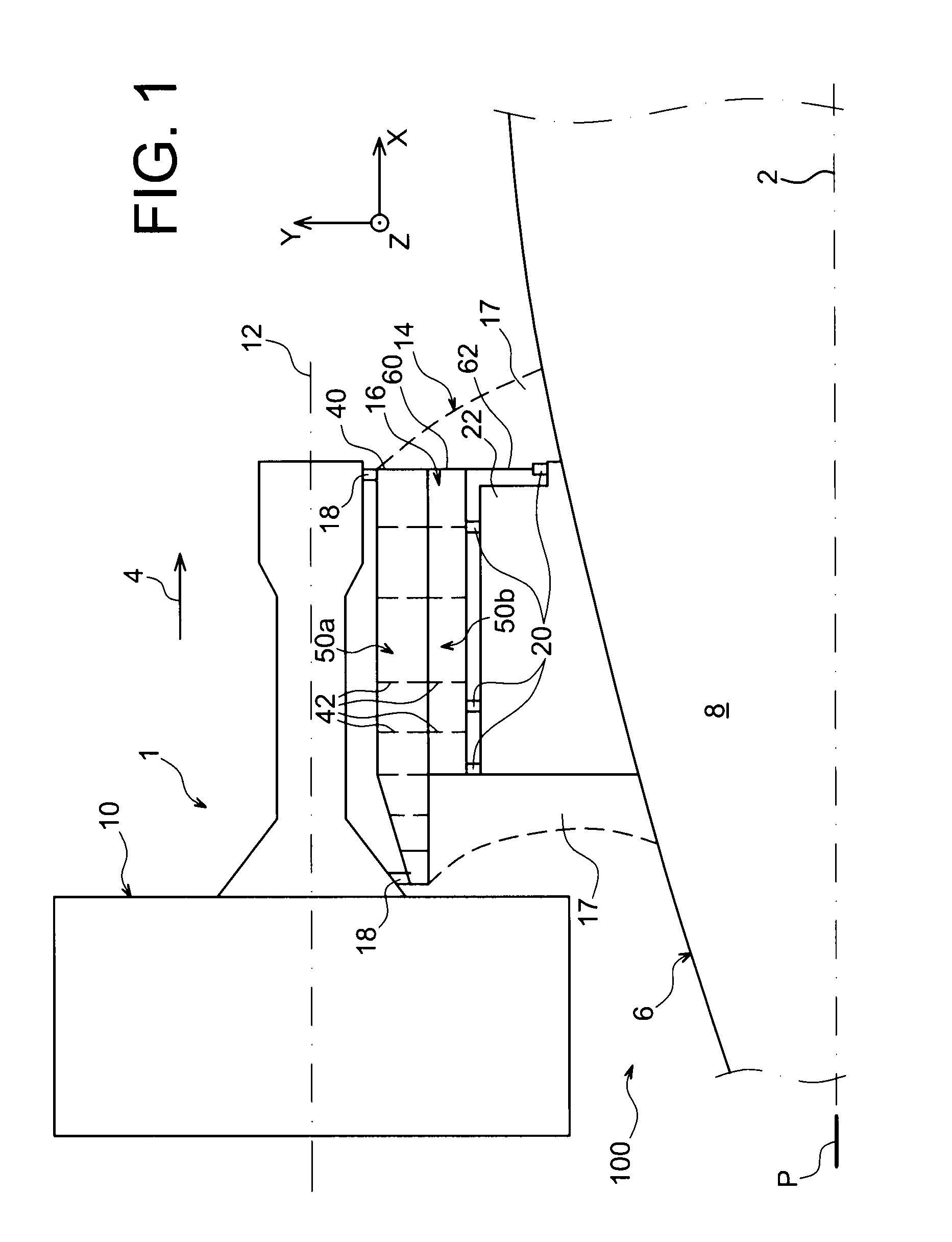

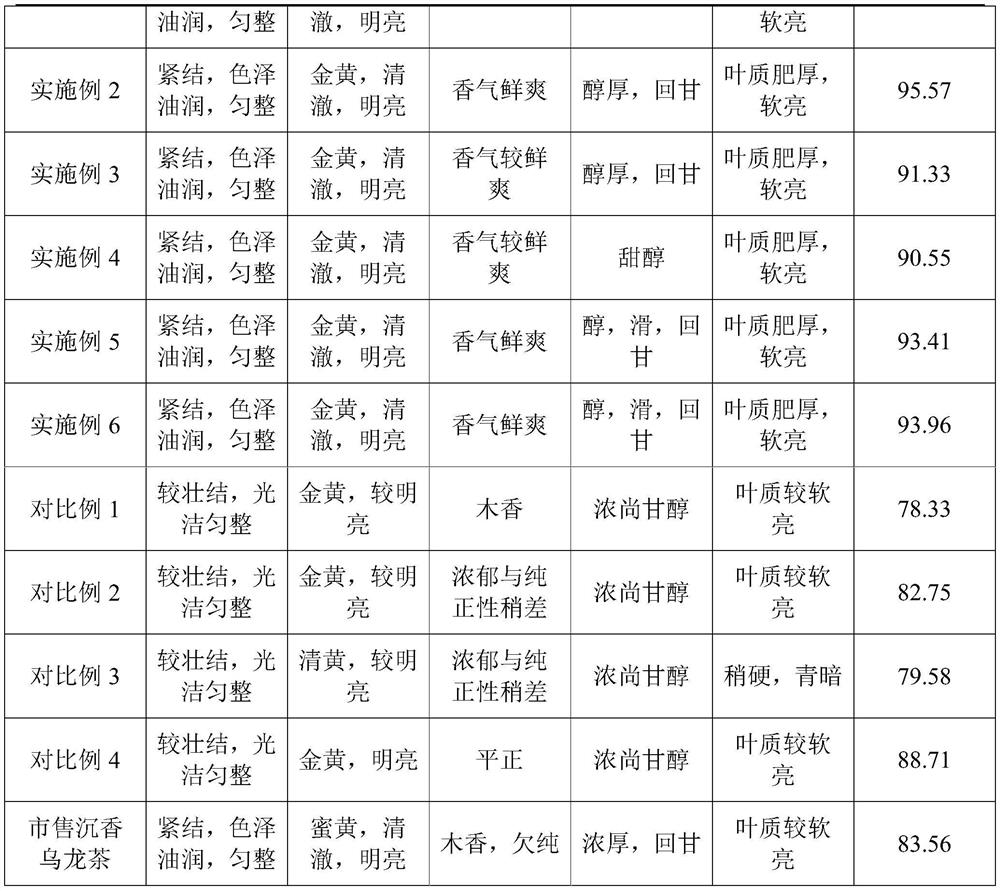

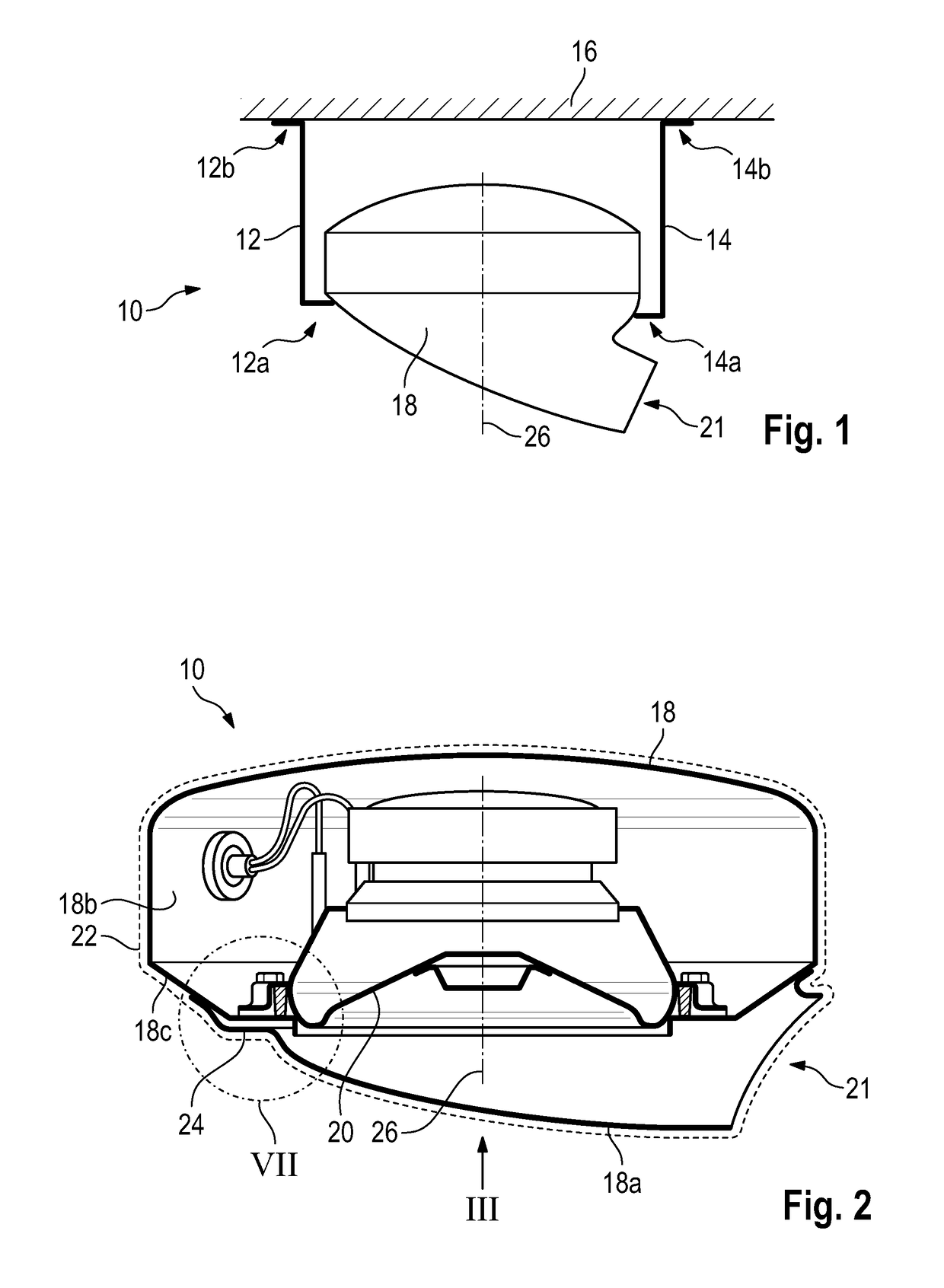

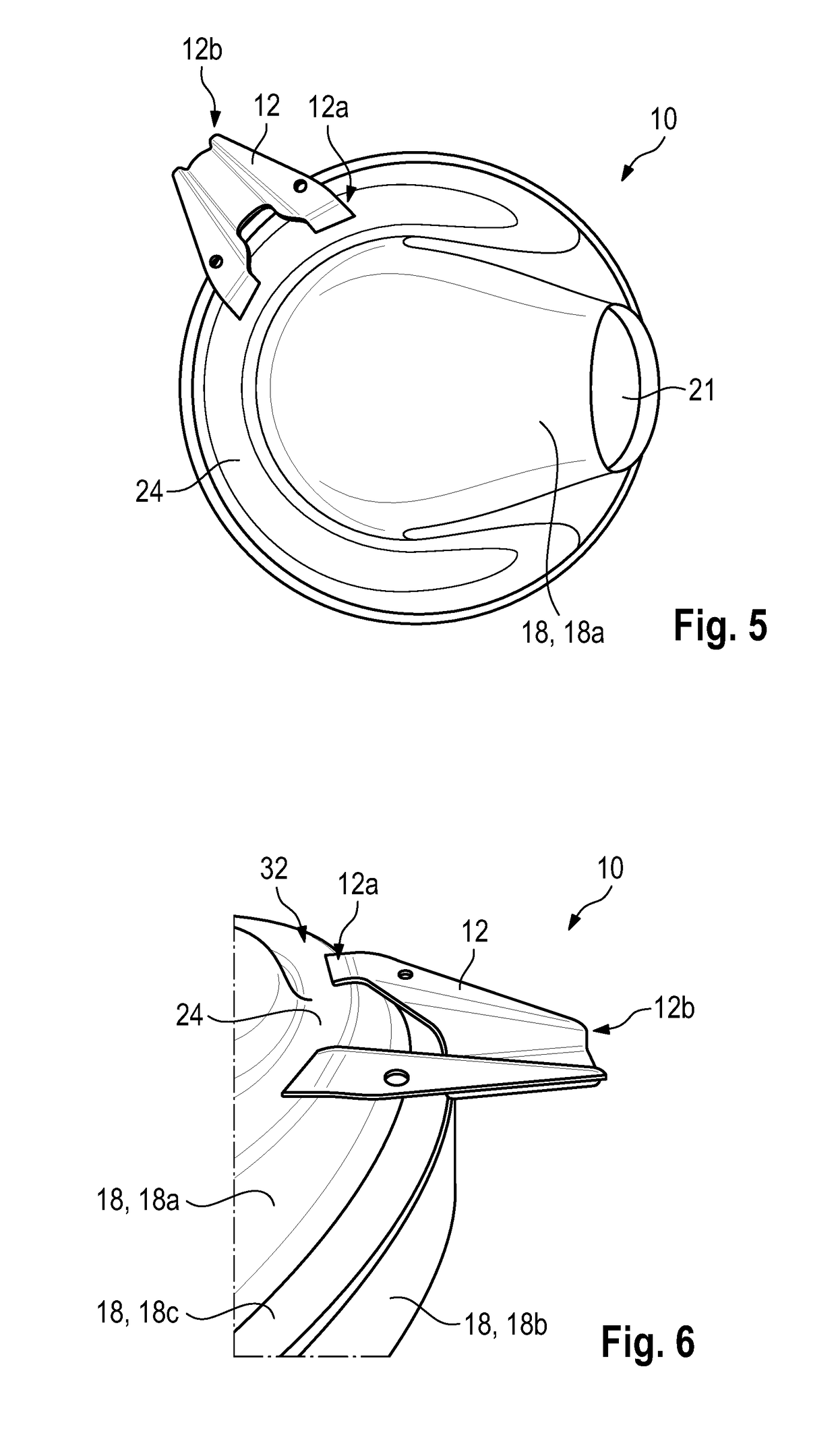

Rigid aircraft pylon fitted with a rib extension for taking up the moment in the lengthways direction

ActiveUS8864066B2Large separationReasonable overall massPower plant constructionGas turbine type power plantsAirplaneRib cage

An engine assembly for an aircraft, including a rigid structure including a box rib extension protruding from a box of the structure, in a line of separation, towards a fuselage of the aircraft. The extension supports a first attachment in a position separating it from a second attachment in the line of separation. The first and second attachments enable the moment being exerted in a lengthways direction of the turbine engine to be transmitted jointly.

Owner:AIRBUS OPERATIONS SAS

Preparation process for white tea

InactiveCN104757149AImprove the richness and mellowness of the tastePromote formationPre-extraction tea treatmentWater contentFood science

The invention discloses a preparation process for white tea. The preparation process comprises the steps of a picking step, a withering step, a rolling step and a drying step. The preparation process is characterized in that the withering step is a warm withering step which is specifically characterized in that fresh tea leaves are uniformly spread in a withering trough for withering, the thickness is 1-1.5 centimeters, the withering temperature is controlled at 30 DEG C-36 DEG C, the withering time is 4-6 hours, the tea leaves are withered until the leaves are shrunk, the leave texture is soft, and stalks are not broken when bent, faint fragrance is generated, and the water content is 65-70%. According to the white tea, the trabes are tight in appearance, the color is silvery, the pekoe is revealed, the liquor color is yellow and bright, the fragrance is strong and durable, the taste is strong, fresh and mellow, and infused leaves are tender, even and bright.

Owner:成都市碧涛茶业有限公司

Making method of black tea cakes

The invention provides a making method of black tea cakes, and belongs to the technical field of black tea making methods. The making method of the black tea cakes adopts fresh tea tree leaves suitable for making black tea as a raw material comprises the following steps: picking fresh leaves, wilting, rolling, fermenting, passing through a red pan, pressing to form cakes, drying, storing, and re-drying to make finished black tea cakes. The making method provided by the invention overcomes the defects of light taste, low and bored smell, dark soup color, insufficient concentration, poor convergence and unfavorable quality stability after long-time storage of traditional technologies, all the steps are technologically improved, and all the steps are accurately grasped and mutually cooperate, so uniform fermentation, bronzed leaf bottom, mellow and fresh taste, strong and lasting fragrance, red and bright soup color and strong convergence of the Tongbai black tea cakes made in the invention are effectively guaranteed, and the quality of the Tongbai black tea cakes is obviously improved.

Owner:桐柏县鑫茗农业有限公司 +2

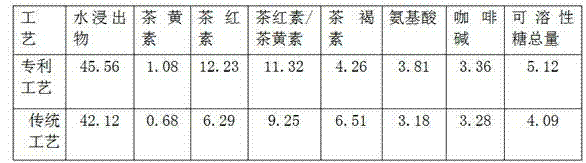

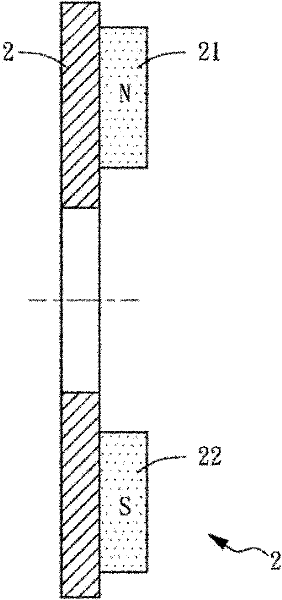

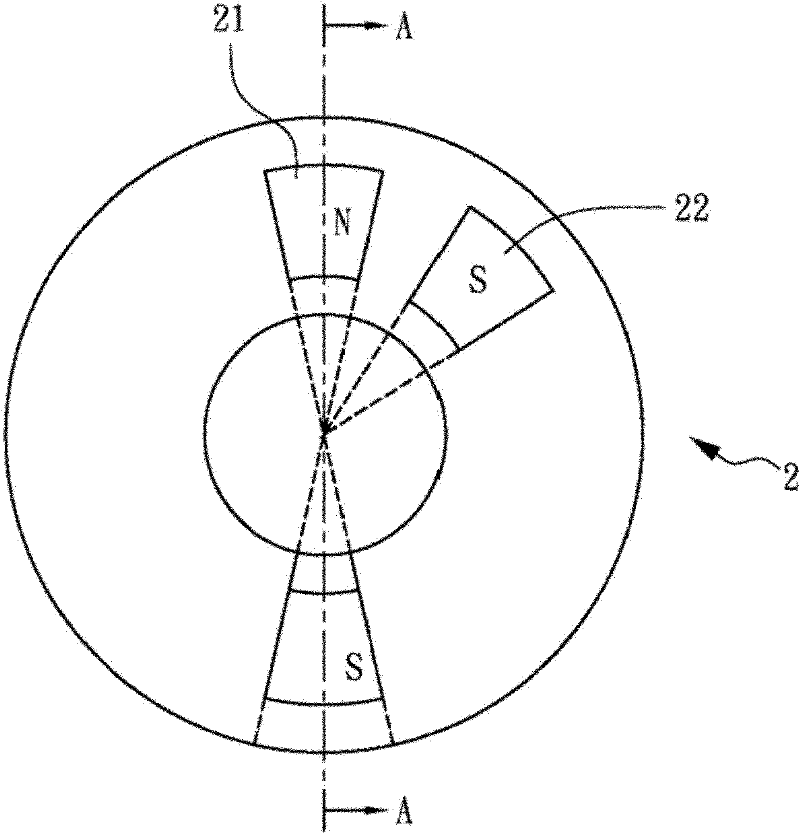

Axial-flux thin-plate motor

InactiveCN102480176AIncrease the slot rateTight shapeWindingsMagnetic circuit stationary partsCircular discEngineering

Owner:IND TECH RES INST

Compressed small-cake-shaped herb tea processing method

InactiveCN104522255AQuality assuranceReduce labor intensityPre-extraction tea treatmentTea substituesEngineeringMoisture

The invention discloses a compressed small-cake-shaped herb tea processing method. A processing process characterized by physical modes of material mixing, moisture regaining, compression, shaping and the like is adopted, drying is avoided, the process is simplified, no binding agent is needed, direct compression and forming are achieved, safety and sanitation are achieved, energy consumption is lowered, efficiency is improved, the quality and the characteristics of color, aroma and taste of original herb tea are maintained, particles are made into cakes in a low basis weight and small specification mode, and the tea can be stored for a long time and convenient to carry and use. The invention further provides a formula of common herb tea and proper basis weight specification.

Owner:GUANGXI POLYTECHNIC

Manufacturing method of orange black tea

InactiveCN110892929AStrong tendernessRich in endoplasmPre-extraction tea treatmentTea flavoringBiotechnologySugar

The invention belongs to the field of tea processing, and specifically relates to a manufacturing method of orange black tea. The orange black tea is composed of the following components in parts by weight: 3-8 parts of tangerine, and 10-17 parts of black tea. According to the present invention, by inheriting, improving and innovating the process of black tea preparation, the problems of low efficiency and large quality fluctuation in the production process of black tea are effectively solved; and the prepared orange black tea has a compact appearance, a fine peak seedling, an oily color, a bright red and yellow soup, a sweet and mellow taste, a strong aroma of orange sugar, and a bright and red leaf bottom, and the method lays a good foundation for the development of the orange black teamarket.

Owner:贵州省黎平县蝉之声农业发展有限公司

Honeysuckle stem type broadleaf holly leaf tea

A honeysuckle stem type broadleaf holly leaf tea is prepared through deactivating enzymes, rolling, drying, rolling and drying. The honeysuckle stem type broadleaf holly leaf tea is characterized in that the honeysuckle stem type broadleaf holly leaf tea is formed by processing honeysuckle stem, has the mouthfeel of broadleaf holly leaf, and also has the healthcare functions of honeysuckle stem. The dried honeysuckle stem type broadleaf holly leaf tea has a curled profile, is compact and heavy, has a delicate fragrance and a bitter and then sweet-cool taste after the dried tea is boiled by boiled water, and has a water extract content of 30% or more, a chlorogenic acid content of 1.5% or more and a total ash content of 6% or less.

Owner:XINYANG AGRI & FORESTRY UNIV

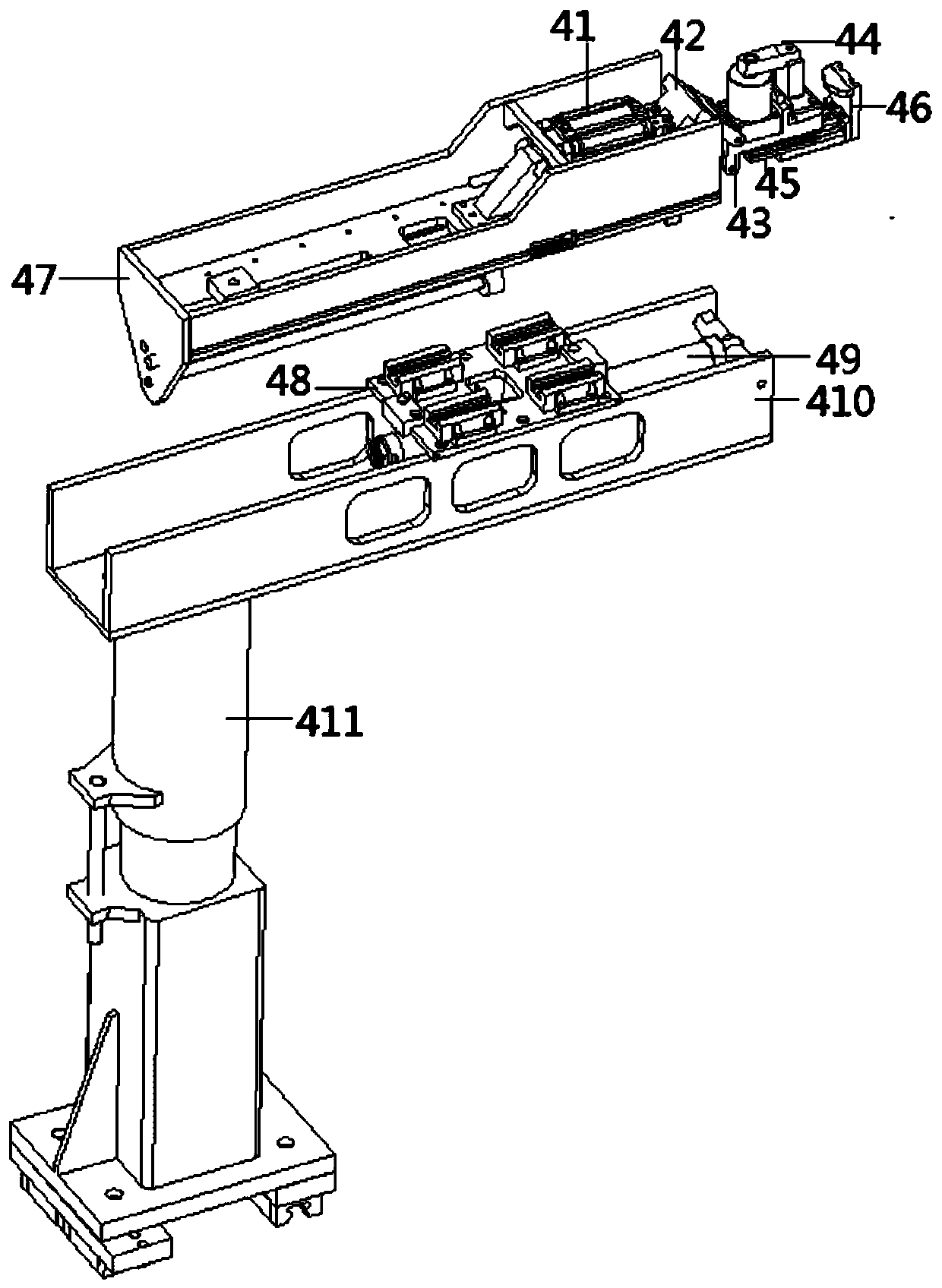

Runway type coil numerical control taping machine

PendingCN110611408AHigh degree of automationEasy to operateApplying solid insulationElectrical and Electronics engineeringTape head

The invention discloses a runway type coil numerical control taping machine which comprises a base, a telescopic platform is arranged on the base along the periphery, a taping head is mounted on the telescopic platform, the taping head can move along the telescopic platform, an air cylinder clamping device is arranged on the periphery of the telescopic platform, the air cylinder clamping device isfixed to the base through an air cylinder locking handle, an electrical cabinet and an operation box are arranged on two sides of the base, the electrical cabinet is electrically connected with the operation box, the operation box is electrically connected with the air cylinder clamping device, and the taping head is electrically connected with the electrical cabinet and the operation box. The runway type coil numerical control taping machine has the advantages of a high automation degree of a taping mode, simple operation, tight tape shape, uniform binding tightness, accurate lapping, attractive appearance and good practicability.

Owner:上海闵行机械工程技术研究所有限公司

Processing technology of tea leaves rich in calcium

InactiveCN104920681ACarry forward the cultural spiritTight shapePre-extraction tea treatmentCalcium contentPsychological health

The invention discloses a processing method of tea leaves rich in calcium. The tea leaves rich in calcium is prepared through methods of selection, fixation, withering, shaking, rolling, fermentation, drying, stalk sorting, packing and the like. The produced tea leaves are compact and uniform in appearance, orange and bright in brewed tea color, lasting in fragrance, and strong and mellow in taste. The processing method is simple, and the production cost is low. The produced tea leaves have the efficacy of clearing heat, resolving thirst, moistening spleen and refreshing taste, as well as utility of tasting and viewing, are perfect in color, fragrance and taste, and are beneficial for physical and psychological health. With the adoption of the tea leaves disclosed in the invention, the calcium content is ensured, and need of consumers in body and spirit is satisfied.

Owner:柳州市侗天湖农业生态旅游投资有限责任公司

Health reed tea

InactiveCN103999976AOvercome the bland tasteFresh and long lastingTea substituesTraditional medicineEssential oil

The invention discloses a health reed tea. The health reed tea is composed of reed roots and additives, and the additives contain asparagus and wild chrysanthemum flower essential oil. The health reed tea does not change the medicinal and health efficacies of the reed roots, and the addition of the asparagus and wild chrysanthemum flower essential oil and the stir-frying of the obtained mixture effectively overcome the light astringent mouthfeel of the reed roots, so the health reed tea has a unique flavor and refreshing and lasting mouthfeel, has a tight profile, is convenient to package, and can be actively popularized.

Owner:JINLING INST OF TECH

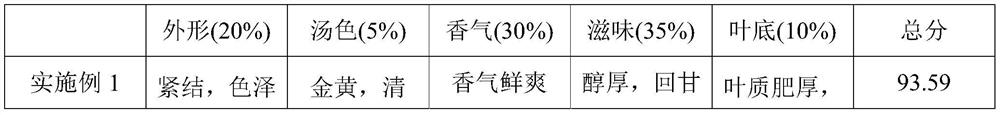

Preparation method of agilawood oolong tea

The invention relates to a preparation method of agilawood oolong tea, which comprises the following steps: (1) withering: collecting mature leaves of agilawood trees, and withering for 1-2 hours under the conditions that the relative humidity is 50-70%, the wind temperature is 35-40 DEG C and the wind speed is 3.4-5.4 m / s; (2) rocking of green leaves; (3) fixation: performing fixation at 200-230 DEG C for 10-15 minutes, and then immediately spreading the leaves under the conditions that the wind temperature is 20-25 DEG C and the air speed is 0.3-1.5 m / s; (4) rolling, wherein the first rolling pressure is 100-130 N, the rotating speed is 20-30 rpm, the second rolling pressure is 300-350 N, and the rotating speed is 5-8 rpm; and (5) drying: primarily drying at 100-130 DEG C for 1-2 hours, after spreading for cooling, re-drying under the re-drying condition that the temperature is raised to 90-95 DEG C at the rate of 5-7 DEG C from 60-65 DEG C, and preserving heat for 0.5-1 hour. The agilawood oolong tea prepared by the method disclosed by the invention is tight in appearance, oily and uniform in color and luster, golden, clear and bright in soup color, fresh and refreshing in fragrance, mellow in taste, sweet in aftertaste and fleshy, soft and bright in leaf quality, and the sensory score reaches 90 points or above. Compared with other samples, the agilawood oolong tea has fresh and cool brand-new fragrance and is excellent in appearance, color, luster, taste and leaf bottom.

Owner:海南林鹏茶业有限公司

Sound generating assembly for an exhaust system

InactiveUS20190072021A1Reliable and durable mountingIncreased durabilityLoudspeaker casing supportsSilencing apparatusEngineeringInternal combustion engine

A sound generating assembly for an exhaust system of an internal combustion engine of a motor vehicle includes a sound generator arranged within a sound generator housing. Furthermore, an outer contour of the sound generator housing has a connecting surface configured to be attached to a motor vehicle structure. The connecting surface is set off from a remaining surface of the outer contour.

Owner:FAURECIA EMISSIONS CONTROL TECH GERMANY

Processing method of green tea

InactiveCN107439712AShort killing timeLeaves intactPre-extraction tea treatmentEnzymeEpigallo-catechin gallate

The invention relates to a processing method of green tea. The processing method comprises the following steps of (1) tedding fresh leaves; (2) performing fixation; (3) performing resurgence; (4) performing twisting; (5) performing shaping; (6) performing cooling; (7) performing drying; (8) performing cooling once again, and performing drying; and (9) performing careful selection and performing packaging. According to the processing method disclosed by the invention, a fixation manner combining infrared rays and microwave waves is adopted, so that the fixation time is short and uniform, leaves are complete, and little chlorophyll is lost; and besides, the problems that according to a conventional green tea processing technology, leaves and leaf stems are not uniform in fixation, little chlorophyll is lost and enzyme sterilization is not thorough can be solved. According to the processing method disclosed by the invention, a special fixation manner is adopted, and technological steps of performing later-stage resurgence, performing shaping, performing drying twice, performing drying twice and the like are combined, so that the produced green tea is compact in shape strips, green and moistening in color, high and refreshing in internal fragrance, rich, mellow, fresh and brisk in taste, clean in tea soup color, fine, tender, thick and soft in leaf bases, and excellent in product.

Owner:李本宏

How to make black tea cake

The invention provides a making method of black tea cakes, and belongs to the technical field of black tea making methods. The making method of the black tea cakes adopts fresh tea tree leaves suitable for making black tea as a raw material comprises the following steps: picking fresh leaves, wilting, rolling, fermenting, passing through a red pan, pressing to form cakes, drying, storing, and re-drying to make finished black tea cakes. The making method provided by the invention overcomes the defects of light taste, low and bored smell, dark soup color, insufficient concentration, poor convergence and unfavorable quality stability after long-time storage of traditional technologies, all the steps are technologically improved, and all the steps are accurately grasped and mutually cooperate, so uniform fermentation, bronzed leaf bottom, mellow and fresh taste, strong and lasting fragrance, red and bright soup color and strong convergence of the Tongbai black tea cakes made in the invention are effectively guaranteed, and the quality of the Tongbai black tea cakes is obviously improved.

Owner:桐柏县鑫茗农业有限公司 +2

A kind of revitalizing and firming essence and preparation method thereof

ActiveCN103585096BImprove solubilityEasy transferCosmetic preparationsToilet preparationsWrinkle skinContinuous use

Owner:鸯兰国际贸易(上海)有限公司

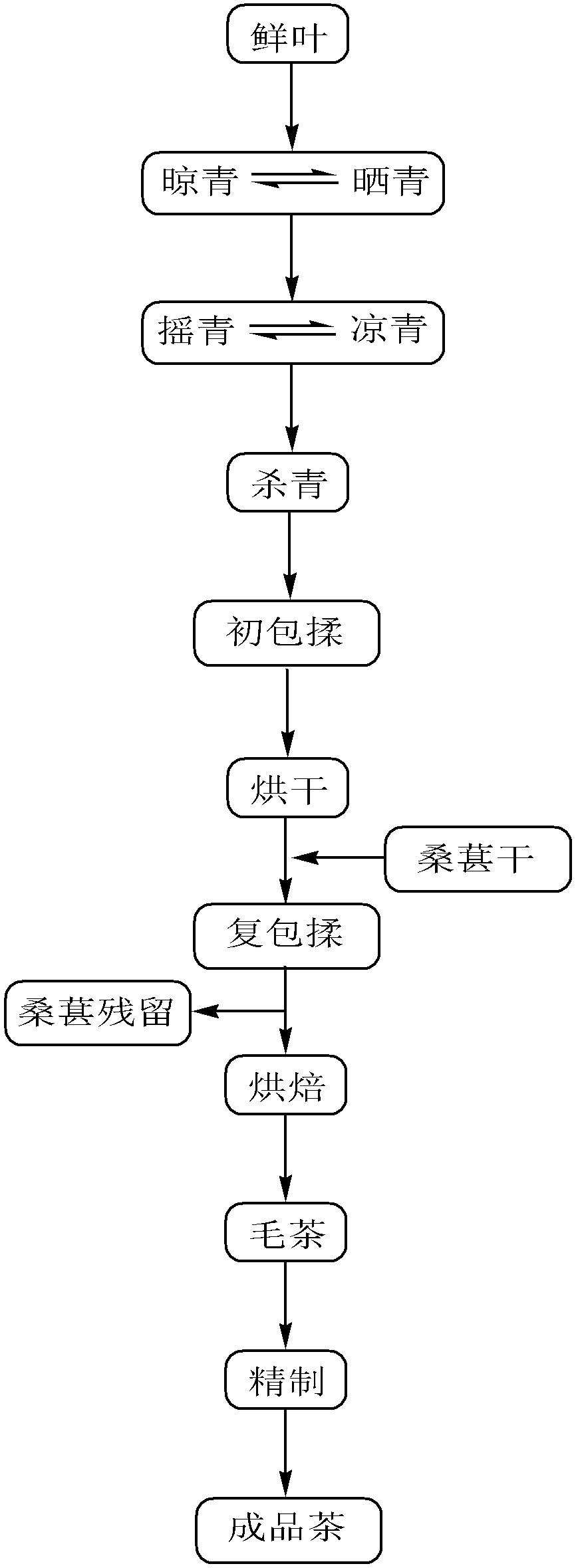

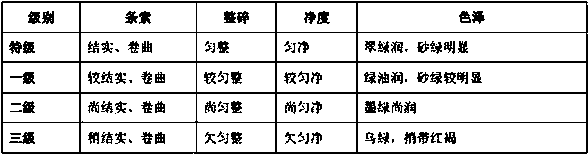

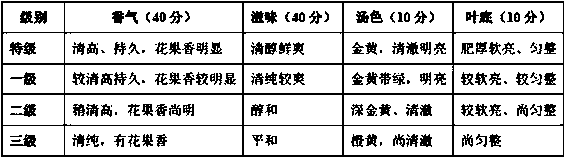

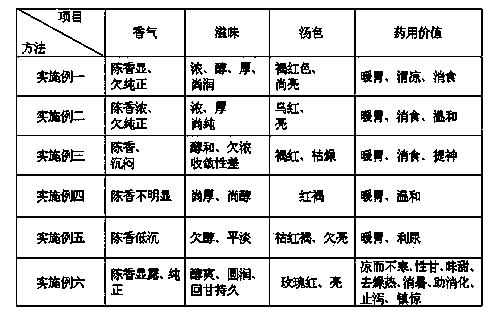

Preparation method of faint scent-type oolong tea

InactiveCN110037141ALow costIncrease added valuePre-extraction tea treatmentClimate change adaptationCooking & bakingTea leaf

The invention provides a preparation method of faint scent-type oolong tea. The method comprises the following steps: alternately carrying out cooling and sunning on tea leaves, and then alternately carrying out rocking and cooling on the tea leaves; performing primary wrapping rolling after fixation, adding dried mulberries, and performing wrapping rolling again until the appearance is compact and round; performing sieving to remove mulberry residues, and performing baking; and spreading and airing the baked tea leaves, performing drying to obtain crude tea, and performing refining and grading to obtain finished tea. The method adopts fresh tea leaves in Shandong region and a mode of adding dried mulberries, so that the tea leaves in the area can produce the faint scent-type oolong tea. The oolong tea has the advantages of round and solid appearance, sand green color and clear and pure dry tea fragrance; after brewing, the flower and fruit fragrance is rich, and the fragrance is strong and lasting; the soup color is golden yellow, bright and clear, the taste is pure and thick, and the sweet after taste is obvious; and the leaf bases are soft, fat, thick and smooth, and are completely spread. The method utilizes rich mulberry resources in the region which are low in cost and high in added value, and further develops and utilizes Shandong tea leaves and mulberry resources.

Owner:山东圣源绿色食品科技有限公司 +1

Processing method of Tuling aged tea

ActiveCN104171089AReduce humidityTight shapePre-extraction tea treatmentClimate change adaptationFlavorThirst

The invention discloses a processing method of Tuling aged tea. The processing method comprises the steps of fresh leaf picking, standing, sunning, re-standing, rolling, reddening, primary roasting, spreading for drying, secondary roasting, loading in a cellar, annealing, sealing, and storing in the cellar. With the processing method, the tea processing efficiency is improved, the quality of the Tuling aged tea is improved, and the obtained Tuling aged tea is tight in appearance, oily in color and luster, obvious in stable flavor, red in soup color, mellow and fresh in taste, sweet in after taste, and cool, and is a previous tea product for relieving summer heat and quelling thirst.

Owner:泉港区雨石辉红茶行

A kind of processing method of purple bamboo shoot tea

Owner:浙江茶乾坤食品股份有限公司

A kind of production process of Tuling old tea

ActiveCN104171089BReduce humidityTight shapePre-extraction tea treatmentClimate change adaptationFlavorThirst

The invention discloses a processing method of Tuling aged tea. The processing method comprises the steps of fresh leaf picking, standing, sunning, re-standing, rolling, reddening, primary roasting, spreading for drying, secondary roasting, loading in a cellar, annealing, sealing, and storing in the cellar. With the processing method, the tea processing efficiency is improved, the quality of the Tuling aged tea is improved, and the obtained Tuling aged tea is tight in appearance, oily in color and luster, obvious in stable flavor, red in soup color, mellow and fresh in taste, sweet in after taste, and cool, and is a previous tea product for relieving summer heat and quelling thirst.

Owner:泉港区雨石辉红茶行

Processing method of floral-type agilawood granulated tea

The invention belongs to the technical field of tea processing, and particularly relates to a processing method of floral-type agilawood granulated tea. The method comprises the following steps: (1) fresh leaf picking; (2) sunshine withering; (3) cooling; (4) fine manipulation / rocking; (5) fixation; (6) shaping; (7) drying; (8) picking; and (9) re-firing and boxing. The method has the beneficialeffects that the agilawood granulated tea prepared by the method is strong in orchid fragrance, sweet and mellow in taste and good in mouth feel and quality.

Owner:TEA RES INST GUANGDONG ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com