Runway type coil numerical control taping machine

A wrapping machine and track-type technology, which is applied in the field of track-type coil numerical control tape wrapping machines, can solve the problems of low degree of automation, low wrapping efficiency, and unguaranteed wrapping quality, and achieves high degree of automation and good practicability. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

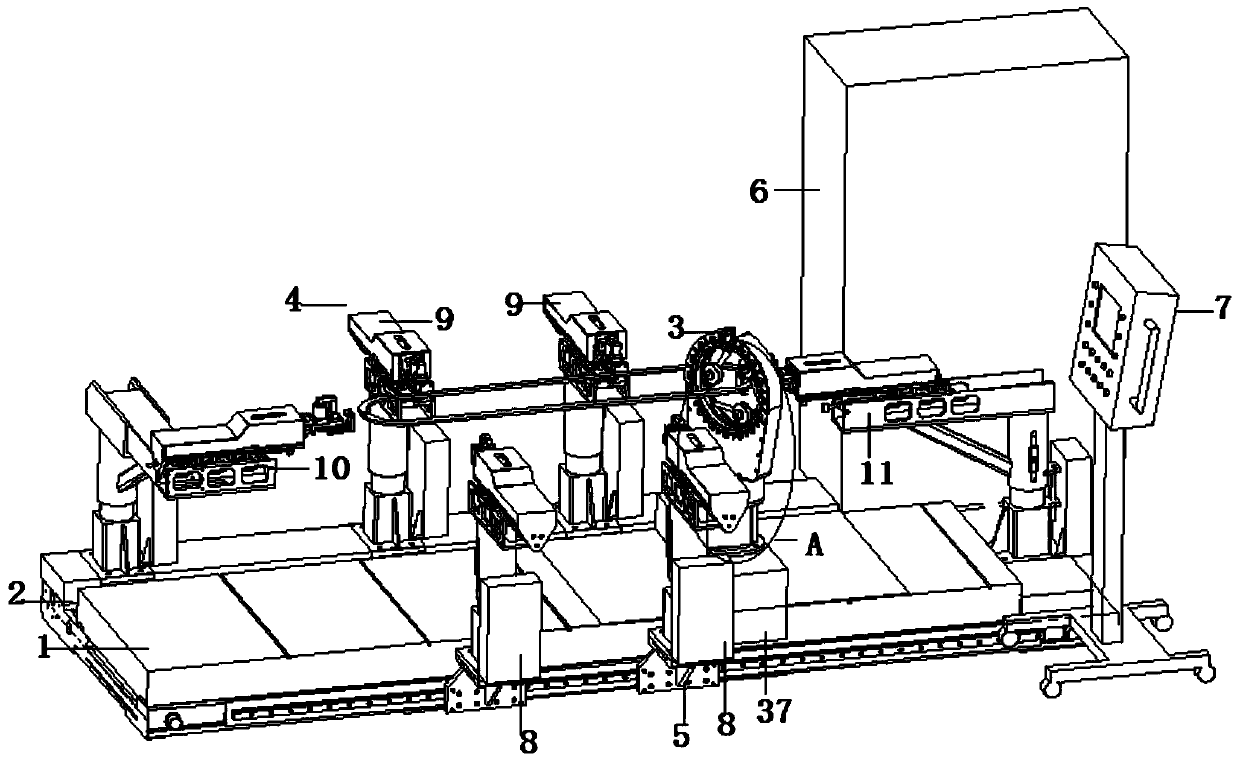

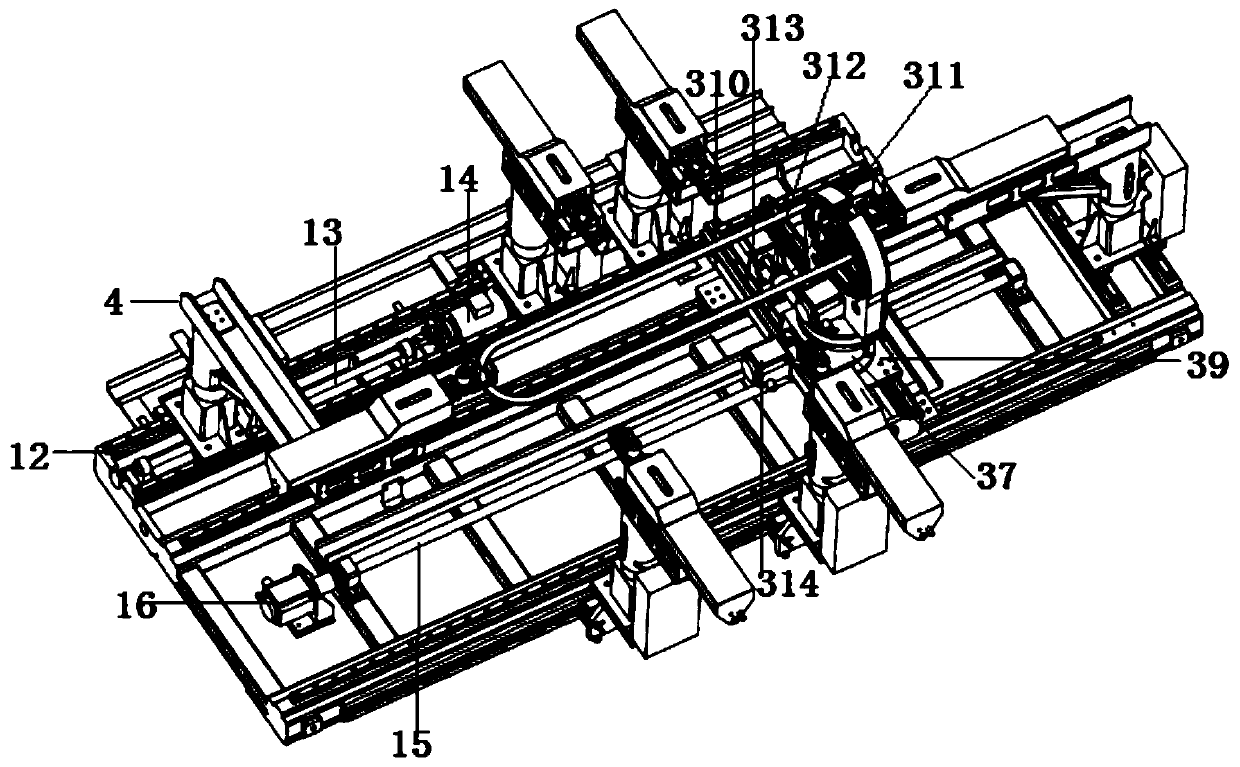

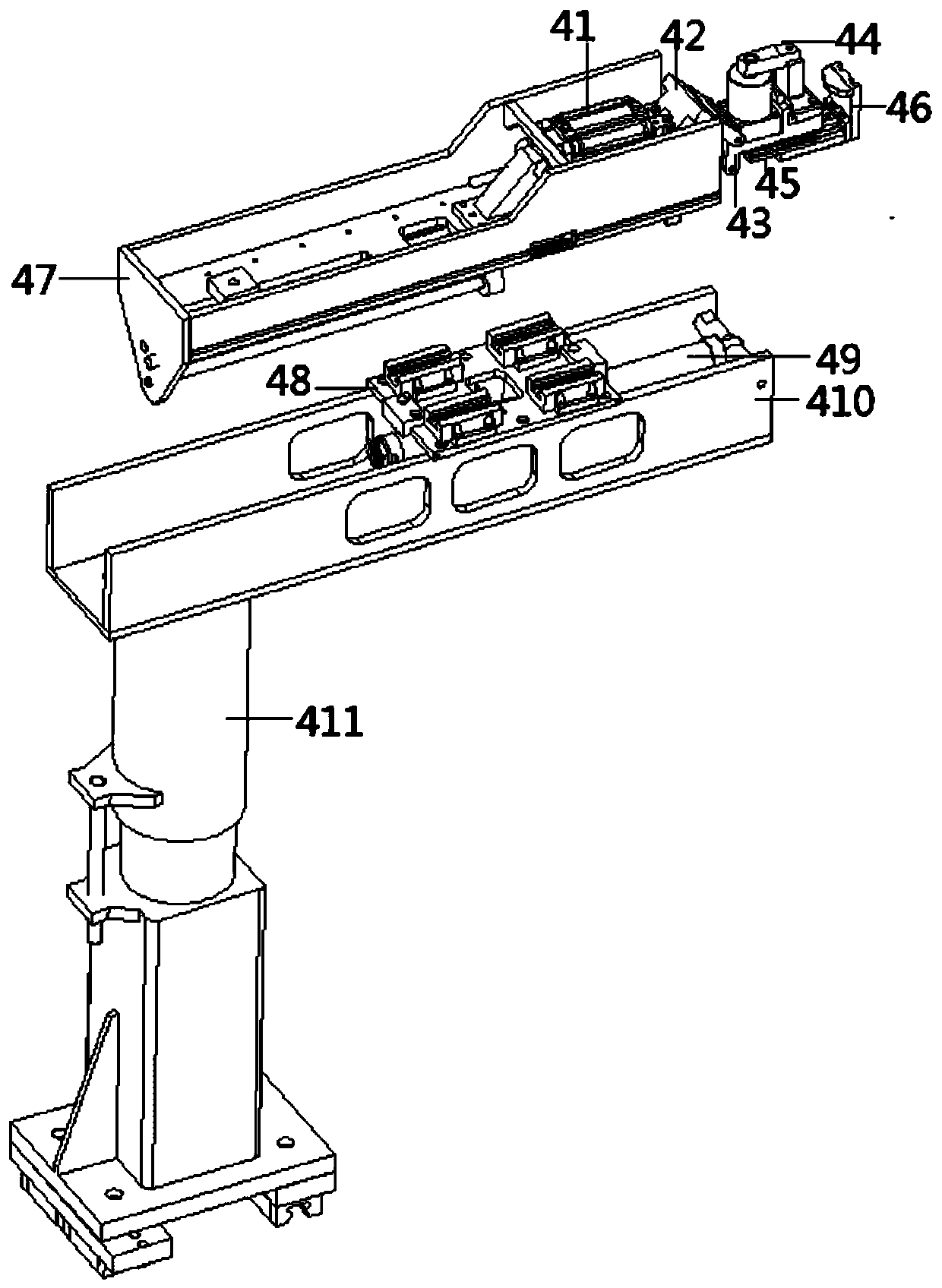

[0017] Such as Figure 1~Figure 3 A kind of runway type coil numerical control taping machine shown, comprises base 1, and described base 1 is provided with telescopic platform 2 along the periphery, and taping head 3 is installed on described telescopic platform 2, and described taping head 3 can be stretched along telescopic platform 2 to move back and forth, the bottom of the taping head 3 is installed on the ball screw II 15, the end of the ball screw II 15 is connected to the telescopic platform movement servo motor 16, and the telescopic platform movement servo motor 16 is fixed on the base 1, the A cylinder clamping device 4 is provided on the periphery of the telescopic platform 2, and the cylinder clamping device 4 is locked on the ball guide rail 12 through the cylinder locking handle 5. The ball guide rail 12 is fixed on the base 1, and the base 1 is provided on both sides. The electrical cabinet 6 and the control box 7, the electrical cabinet 6 and the control box ...

Embodiment 2

[0020] Such as Figure 1~Figure 4 A kind of runway type coil numerical control taping machine shown, comprises base 1, and described base 1 is provided with telescopic platform 2 along the periphery, and taping head 3 is installed on described telescopic platform 2, and described taping head 3 can be stretched along telescopic platform 2 to move back and forth, the bottom of the taping head 3 is installed on the ball screw II 15, the end of the ball screw II 15 is connected to the telescopic platform movement servo motor 16, and the telescopic platform movement servo motor 16 is fixed on the base 1, the A cylinder clamping device 4 is provided on the periphery of the telescopic platform 2, and the cylinder clamping device 4 is locked on the ball guide rail 12 through the cylinder locking handle 5. The ball guide rail 12 is fixed on the base 1, and the base 1 is provided on both sides. The electrical cabinet 6 and the control box 7, the electrical cabinet 6 and the control box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com