Multifunctional drying device

A drying device and multi-functional technology, which is applied in the direction of drying gas arrangement, combined device, drying solid materials, etc., can solve the problems of uneven experience of the staff, affecting the service life of mechanical equipment, and harming the health of operators, so as to achieve reasonable design, The effect of maintaining integrity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

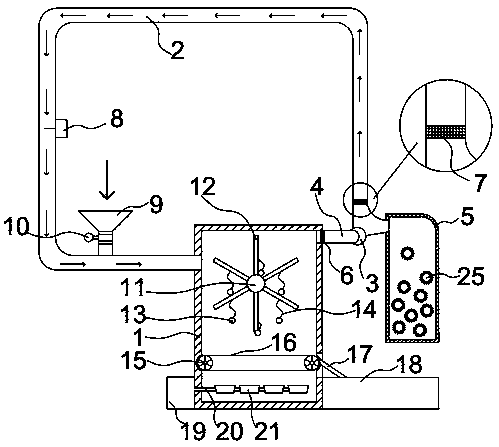

[0023] Such as figure 1 As shown, the multifunctional drying device includes a drying chamber 1, which is connected with a circulating air duct 2, and the upper feeding port of one side of the drying chamber 1 is connected with the air outlet of the circulating air duct 2, and the other side The upper part is connected with the circulation fan 3 through the branch pipe 4, the circulation air pipe 2 is provided with a feed hopper 9, the interior of the drying chamber 1 is provided with a rotating body and a transport device from top to bottom, and a discharge plate 17 is provided under the end of the transport device , the discharge plate 17 is fixedly connected to the bottom of the material collection box 18, the side wall of the connection between the circulating air duct 2 and the circulating fan 3 is provided with a dust removal chamber 5, and the interior of the dust removal chamber 5 is provided with an adsorption ball 25, and the material surface is cleaned by circulating...

Embodiment 2

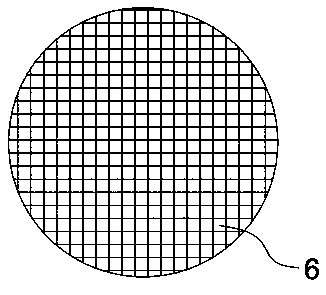

[0025] Such as Figure 1-2 As shown, the optimization scheme of this embodiment on the basis of Embodiment 1 is: a pressure sensor 8 is provided in the circulating air duct 2, and the pressure sensor 8 is in the circulating air duct 2 far away from the feed hopper 9 and the drying chamber 1, The friction and collision of the material on the pressure sensor 8 can be avoided. The speed of the circulating fan 3 can be dynamically controlled according to the feedback data of the pressure sensor 8. The connection between the branch pipe 4 and the drying chamber 1 is provided with a slag filtering net 6, and the slag filtering net 6 is preferred. The mesh size of the slag filter 6 can effectively prevent materials from entering the branch pipe 4, while smaller broken materials and dust can penetrate the slag filter 6 and be blown into the branch pipe 4. The dust removal chamber 5 and the circulating air duct 2 There is a dust filtering net 7 at the connection of the dust filtering n...

Embodiment 3

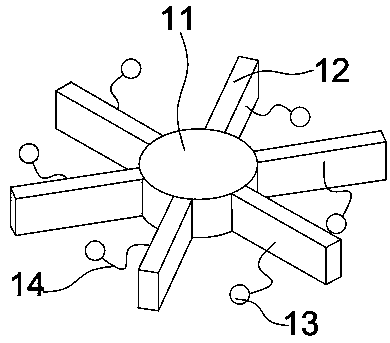

[0027] Such as Figure 3-4As shown, the optimization scheme of this embodiment on the basis of Embodiment 1 is: the rotating body includes a rotating shaft 11 and a rotating plate 12, an elastic rope 14 is connected to the rotating plate 12, and the elastic rope 14 is located at the center of the surface of the rotating plate 12 position, the longest distance of the stretched elastic cord 14 is no more than the distance between the centers of the two rotating plates 12, preventing the elastic cord 14 from becoming a mess due to the excessive length of the elastic cord 14, the end of the elastic cord 14 The rubber ball 13 is connected, and the rotating plate 12 is driven to rotate with the air circulation of the circulating air pipe 2, so that the materials entering the drying chamber 1 are stirred, and the uniformity of material drying is improved. The material of the rotating plate 12 is iron, and the rotating plate 12 The elastic rope 14 on the plate is pulled by the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com