Preparation method of agilawood oolong tea

A technology of oolong tea and agarwood, which is applied in the field of tea processing, can solve the problems of agarwood oolong tea lacking the fresh and refreshing aroma of agarwood oolong, and achieve the effects of inhibiting decomposition and loss, thick leaf quality and excellent leaf bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

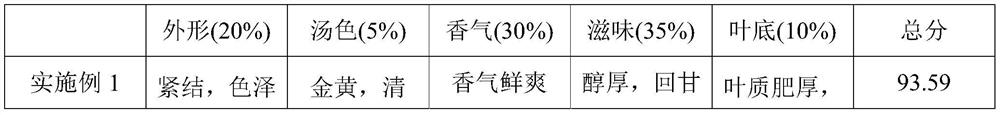

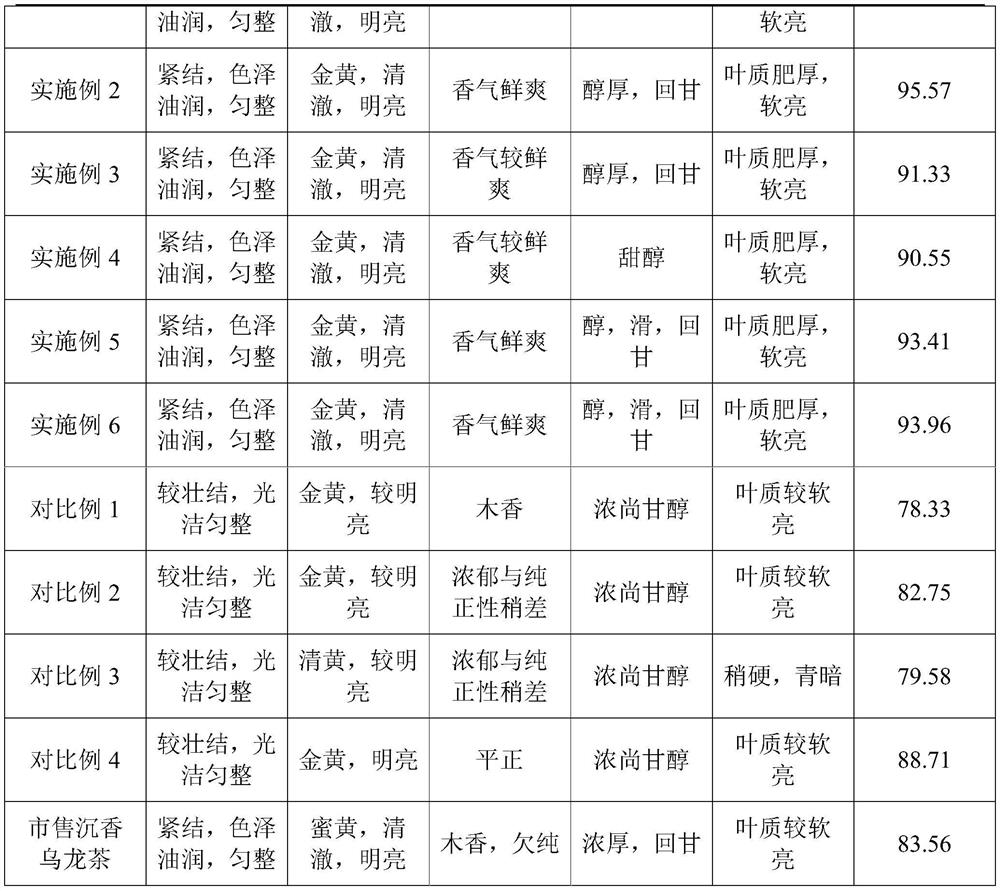

Examples

Embodiment 1

[0027] A preparation method of agarwood oolong tea, comprising the following steps:

[0028] (1) Withering: collect the mature leaves of the Agarwood tree, and wither for 2 hours under the conditions of relative humidity of 70%, wind temperature of 35°C, wind speed of 3.4m / s, and leaf thickness of 3cm;

[0029] (2) Shake green: at 25 ℃, under the condition of 50% relative humidity, adopt shake machine to carry out shake green, shake green machine rotating speed is 25rpm, shake green 4 times, shake green time 1h each time, after shaking green green each time, spread out The leaf thickness is 3cm, the wind temperature is 20°C, and the wind speed is 3.4m / s, and it is left to stand for 0.5h;

[0030] (3) Finishing: Finish at 200°C for 15 minutes, then immediately spread the leaves for 1 hour under the conditions of wind temperature 25°C, wind speed 1.5m / s, and spread leaf thickness 3cm;

[0031] (4) Kneading: use a kneading machine (6CR-55 type) to knead twice, high-speed light p...

Embodiment 2

[0034] A preparation method of agarwood oolong tea, comprising the following steps:

[0035] (1) Withering: collect the mature leaves of the Agarwood tree, and wither for 2 hours under the conditions of relative humidity of 50%, wind temperature of 35°C, wind speed of 5.4m / s, and leaf thickness of 3cm;

[0036] (2) Shake green: at 28 ℃, adopt shake green machine to carry out shake green under the condition of 40% relative humidity, shake green machine rotating speed is 30rpm, shake green 4 times, shake green time 0.5h each time, shake green after each time The thickness of the spreading leaves is 3cm, the wind temperature is 20°C, and the wind speed is 5.4m / s, and it is left to stand for 1h;

[0037] (3) Finishing: Finish at 230°C for 10 minutes, then immediately spread the leaves for 0.5h under the conditions of wind temperature 25°C, wind speed 1.5m / s, and spread leaf thickness 3cm;

[0038] (4) Kneading: use a kneading machine (6CR-55 type) to knead twice, high-speed light...

Embodiment 3

[0041] A preparation method of agarwood oolong tea, comprising the following steps:

[0042] (1) Withering: collect the mature leaves of the Agarwood tree, and wither for 1 hour at a relative humidity of 70%, a wind temperature of 40°C, a wind speed of 5.4m / s, and a leaf thickness of 3cm;

[0043] (2) Shake green: at 28 ℃, under the condition of 50% relative humidity, adopt shake machine to carry out shake green, the speed of shake green machine is 30rpm, shake green 3 times, shake green time 1h each time, after shaking green green each time, spread out The leaf thickness is 3cm, the wind temperature is 15°C, and the wind speed is 5.4m / s, and it is left to stand for 0.5h;

[0044] (3) Finishing: Finish at 230°C for 15 minutes, then immediately spread the leaves for 1 hour under the conditions of wind temperature 20°C, wind speed 0.3m / s, and spread leaf thickness 3cm;

[0045] (4) Kneading: use a kneading machine (6CR-55 type) to knead twice, high-speed light pressure and low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com