Patents

Literature

131results about How to "Fresh aroma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Peony flower tea and preparation method thereof

ActiveCN103190509AFresh aromaSoup color is clear and transparentPre-extraction tea treatmentTea substituesChinese hawthornChrysanthemum Flower

The invention relates to a peony flower tea and a preparation method thereof. The peony flower tea is prepared from the following materials according to parts by weight: 5.0-9.0 parts of chrysanthemum flower, 5.0-10.0 parts of Lycium chinense, 4.0-8.0 parts of red date, 2.0-4.0 parts of lemon, 4.0-6.0 parts of Chinese hawthorn, 6.0-15.0 parts of rose, 10.0-40.0 parts of peony flower and / or 10.0-30.0 parts of peony leaves. The preparation method comprises the steps of: 1) weighing chrysanthemum flower, Lycium chinense, lemon and Chinese hawthorn, respectively boiling out with water after being soaked with water for 12 hours, boiling out three times for every material, then merging decoction liquid, and storing at the temperature of 0 to -20 DEG C after concentrating till the amount of material in the solution is 0.1-0.2 g / ml; 2) picking fresh peony flower and / or peony leaves in the squaring stage, putting into cold water for cleaning and then draining water for 2-4 hours; and 3) putting the peony flower or leaves after processing into the decoction liquid after being unfrozen for soaking so as to completely absorb water and then taking out after reaching a saturation state, draining water till no water is on the surface, and air-drying at low temperature till the water content is lower than 5%. The peony flower tea contains active ingredients capable of inhibiting oral bacteria so as to achieve the effects of cleaning oral cavity and preventing dental caries.

Owner:安徽古禾记生物科技有限公司

Method for refining and concentrating citrus essential oil

InactiveCN102559386AProtect heat sensitive ingredientsReduce lossesEssential-oils/perfumesDistillationHeat sensitive

The invention discloses a method for refining and concentrating citrus essential oil, which belongs to the technical field of natural plant essential oil refining and includes 1 preparation of crude essential oil; 2 degassification of the crude essential oil; 3 molecular distillation of the crude essential oil; 4 quality inspection of concentrated essential oil and other steps. The molecular distillation technology is used for refining and concentrating the citrus essential oil, heat-sensitive components in the essential oil can be protected effectively, no additive is added, and solvent is free of residue. The method achieves efficient separation of terpene compounds and terpene oxides in the citrus essential oil, enables relative content of residual oxides after distillation to be increased to 5-20 times of that of original oxides, and remarkably improves aroma value of the essential oil. Product aroma is strong and fresh, and characteristic aroma is remarkable. The method can be popularized and applied in citrus production places and related enterprises.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

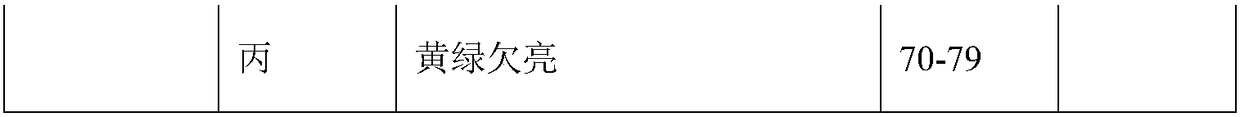

Preparation method for green tea

The invention relates to a preparation method for green tea. The preparation method comprises the following steps: leaf selection, fresh leaf withering, preliminary fixation, cooling, secondary fixation, rolling, baking for fragrance enhancement, refining, packaging and storage. The green tea cannot be fermented, so that due to the characteristic, more natural substances in the fresh leaves can be retained; by baking for fragrance enhancement, the fragrance of the green tea overflows, and the green tea tastes extremely delicious and is mild and soft; the tea leaves can be subjected to villuse removal, so that the tea leaves look shining and attractive; most importantly, tea water brewed by the tea leaves does not contain fragments; the flower fragrance of the green tea smells refreshing and tastes pure, so that most organic matters in the tea leaves can be stored; the tea leaves can be brewed for multiple times, and a comfortable flavor is brought to a tea taster, so that the quality of the tea leaves is further guaranteed.

Owner:YUQING COUNTY YULONG TEA

Production method of Japan allspice flower tea

InactiveCN101336663APromote structural adjustmentConducive to commercial productionPre-extraction tea treatmentFlavorWax

The invention belongs to the field of tea technology, which relates to a new preparation method of calyx canthus flower tea. The invention has the characters of plucking the fresh sprouts or leaves of tea tree, drying to premiere green tea, processing the tea with the two-scenting technology, aromatizing, scenting, drying and flowers-removing. The calyx canthus flower tea, which is the product of this invention, has the typical smell of calyx canthus flower, can keep fresh for a long time, the tea liquor has the color of light yellow and green with fresh flavor, the tea leaves bottom has the color of light yellow and green. The calyx canthus flower tea not only has the beautiful shape of good tea, but also has the light scent of calyx canthus flower, a novel flower tea is provided for customers.

Owner:HUAZHONG AGRI UNIV

Preparation methods for blueberry scent green tea and blueberry black tea

ActiveCN103609769ADoes not affect the fragranceReduce absorptionPre-extraction tea treatmentAmber colorResource utilization

The invention relates to preparation methods for blueberry scent green tea and blueberry black tea. The preparation method of the blueberry scent green tea comprises the following steps of (1) tea base treatment; (2) blueberry leaf treatment; (3) scenting; (4) heat dissipation; (5) re-heaping up and scenting; (6) holding-out of scented flowers; (7) baking; (8) flower lifting; and (9) holding-out of scented flowers. The preparation method of the blueberry black tea comprises the following steps of (1) rolling, (2) fermentation and (3) baking. The preparation methods are characterized in that the blueberry leaf treatment is treated through a shaking technology; leaves are taken as flowers and are used as scenting raw materials for the blueberry scent green tea; in the scenting stage, tea leaves are covered with a tea bag, so that heat dissipation and holding-out of the scented flowers are facilitated; due to a one-scenting and one-lifting technology, the technology is simple and feasible; the blueberry leaves for scenting and lifting can be prepared into blueberry black tea, so that the utilization rate of a resource is increased. The blueberry scent green tea prepared from baked green tea and the fresh blueberry leaves has fresh blueberry scent; the tea liquor is brightly olivine; a person drinking the blueberry scent green tea can feel the flower scent, and the blueberry scent green tea tastes delicious. The finished blueberry black tea product is amber, and the tea liquor is brightly red; the blueberry black tea has the blueberry fruit flavor and tastes sour, sweet and refreshing.

Owner:QINGDAO AGRI UNIV +1

Manual manufacture method of Maojian tea

The invention discloses a manual manufacture method of Maojian tea, which comprises the manufacture steps of 1. water removal (fresh tea leaves with the putting amount of 0.8 to 1.5 Jin are put into a pot during the water removal when the pot temperature is 120 to 130 DEG C), 2. twisting (the pot temperature for stir-frying the Maojian tea is maintained between 100 and 110 DEG C, and shaking is used as the major measure at first for volatilizing moisture), 3. ball kneading (the pot temperature is maintained between 80 and 90 DEG C, and tea balls are kneaded and rolled in the center of hands in a clockwise direction), 4. fuzz extraction (fuzz extraction is carried out on the tea balls from large size to small size, and the pot temperature is maintained between 70 and 80 DEG C), and 5. baking (when tea strips are tight, fine and curved, and white fuzz appears, the baking is started, and a thin layer of tea is spread at the pot temperature of 60 to 70 DEG C to obtain the Maojian tea). The temperature for processing the Maojian tea in the invention is gradually reduced from the high temperature, so the manufactured Maojian tea has fresh green color, tight, fine and cured appearance, allover white fuzz, tip existence, fragrant and fresh incense, mellow flavor, sweet aftertaste, tender, uniform and bright leaf bottom, strong bud and good quality.

Owner:黔南州茶叶产业化发展管理办公室

Tartary buckwheat tea and preparation technology thereof

InactiveCN102934710AExact health benefitsThe composition of the formula is reasonablePre-extraction tea treatmentBiotechnologyGreen teas

The invention discloses a tartary buckwheat tea and a preparation technology thereof. The tartary buckwheat tea is composed of 500 parts to 800 parts of tartary buckwheat cortex powder, 50 parts to 100 parts of tartary buckwheat extractives and 50 parts to 80 parts of green tea powder. The preparation technology of the tartary buckwheat tea includes steps of powder mixing, molding, drying and fragrance improving, the tartary buckwheat cortex powder, the tartary buckwheat extractives and the green tea powder are mixed uniformly until the color is uniform, and the mixture is stood for 20 minutes; uniformly mixed green tea is taken, 25% to 30% of water is added, the mixture is mixed uniformly by a pressurization molding machine and subjected to 30 meshes to be granulated; molded tartary buckwheat granules are placed in a plate and then in a hot air drying box, the granules are dried at a temperature ranging from 50 DEG C to 55 DEG C until the water content is less than 8%, then the dried granules are placed in a far infrared oven to be baked at a temperature ranging from 200 DEG C to 220 DEG C for 2 to 3 minutes and then cooled naturally; and the cooled tartary buckwheat tea is placed in a roller drying oven to be baked at a temperature ranging from 110 DEG C to 145 DEG C until the water content is no more than 5%.

Owner:太原市素有苦荞食品有限公司

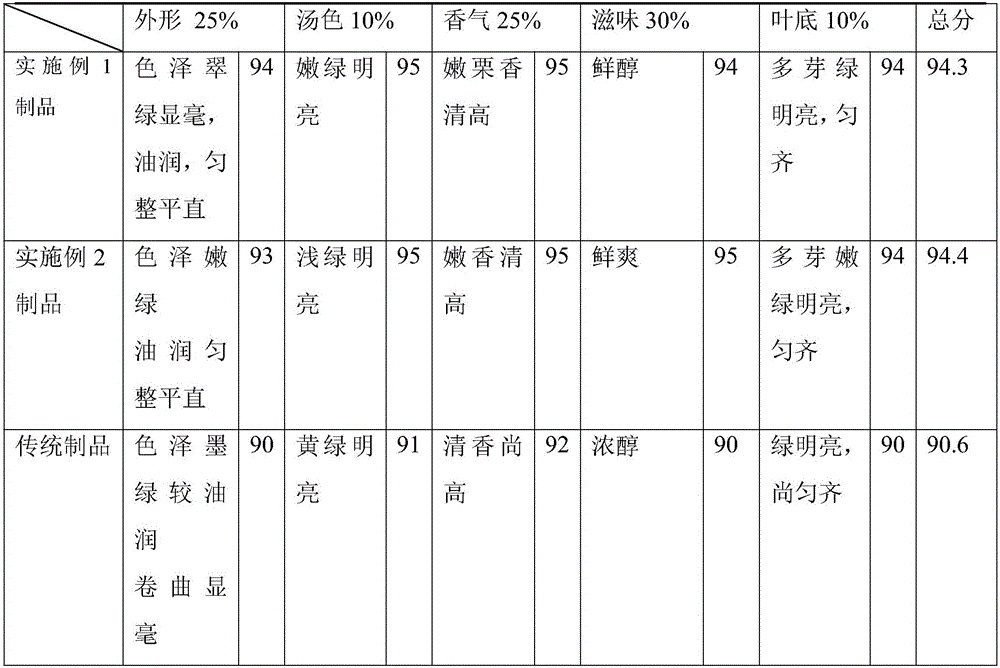

Granular green tea processing method through combination of microwave drying of first-step roasting leaves and double-pot tea curling machine shaping

The invention relates to a granular green tea processing method through the combination of microwave drying of first-step roasting leaves and double-pot tea curling machine shaping, and belongs to the technical field of tea processing. The granular green tea processing method comprises the following processing steps: spreading of fresh tea leaves; deactivation; spreading for cooling; rolling; drying of first-step roasting leaves; shaping; spreading for cooling; drying; fragrance extraction. According to the granular green tea processing method through the combination of microwave drying of the first-step roasting leaves and double-pot tea curling machine shaping, the design is reasonable, and a good foundation is provided for the subsequent steps of drying of the first-step roasting leaves and shaping by reasonably restricting the conditions of spreading, deactivating, spreading for cooling and rolling; microwave heating is utilized for completing the working procedure of drying of the first-step roasting leaves, so that the water content of first-step roasting leaves is easily adjusted and controlled, the color is relatively green, and cooling treatment is not needed, so that the shaping can be directly performed; a double-pot tea curling machine is utilized for shaping, so that the shaping time is short, and the quality of a final tea product is excellent. Experiment results show that leaves collected by machines are suitable for being processed into granular green tea by adopting the granular green tea processing method provided by the invention, and the granular green tea is attractive in appearance, fresh in fragrance and pure in mouthfeel, and is popular among green tea consumers.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

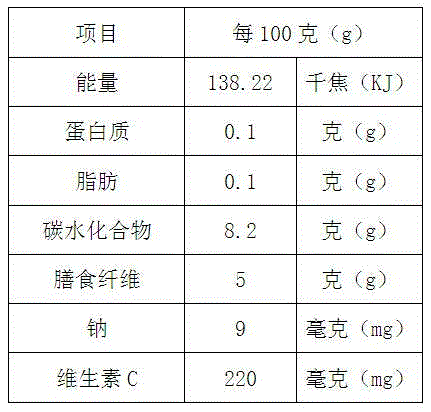

Preparation method of freeze-dried honey lemon slice

InactiveCN104605286AMaintain Bioactive NutrientsGuaranteed food safetyFood ingredient functionsFood preparationBiotechnologyDietary fiber

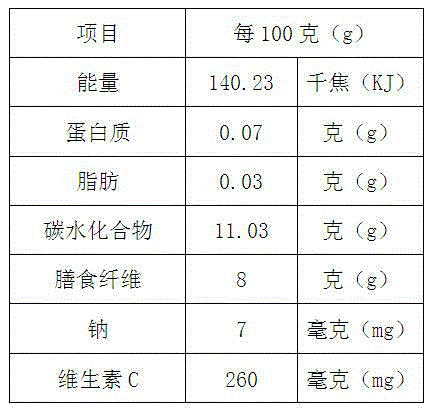

The invention provides a preparation method of a freeze-dried honey lemon slice. The freeze-dried honey lemon slice prepared by the method is rich in vitamins, has the effects of whitening and spot banishing, refreshing and restoring consciousness and appetizing, has the inherent color of lemon, is free of other adverse colors and visible impurities and high in transparency, remains the general taste and flavor of lemon and honey, is fresh in flavor, high in plumpness, proper in sour and sweet and coordinative in flavor, tastes a little bitter of lemon, remains the special color, flavor, taste, appearance and various bioactive nutritional components of fresh lemon, and has the same flavor with the new cut fresh lemon. The freeze-dried honey lemon slice contains 130.77KJ of energy, 0.065g of protein, 0.07g of fat, 10.03g of carbohydrate, 7g of dietary fiber, 8gm of sodium and 250mg of vitamin C. The preparation method has an obvious effect; freezing is performed at three times; the product can be further sterilized, so that the safety of the food can be ensured.

Owner:福建欧瑞园食品有限公司

Preparation method of osmanthus fragrans flower green tea

InactiveCN105410236ASilver bud beautyFresh aromaPre-extraction tea treatmentGreen teasEpigallo-catechin gallate

The present invention discloses a preparation method of osmanthus fragrans flower green tea, which comprises the following steps: step 1: tea base processing; step 2: fresh osmanthus fragrans flower conserving; step 3: tea base and osmanthus fragrans flower blending for scenting; step 4: spreading the blended tea base and osmanthus fragrans flowers for heat dissipation; step 4: osmanthus fragrans flower pickling from the tea base; step 5: steaming, pressing and shaping; and step 6: drying. The prepared osmanthus fragrans flower green tea finished product is tightly rolled into strip types, tender, green, oily and moisture, beautiful in silver sprouts, revealed in white fine hair, fresh and clean in aroma, mellow and refreshing in taste, slight yellow and green in soup color, and tender green and even in leaf bottom.

Owner:朱罗伟

Green tea processing method

ActiveCN103621692ANice appearanceGuaranteed qualityPre-extraction tea treatmentGreen teaRemoving hair

The invention relates to a green tea processing method. The green tea processing method comprises the following steps: spreading for cooling, deactivation of enzymes, wetting back, shaping and screening, and further comprises a final panning step between the shaping and screening steps, wherein the final panning step is to arrange tea subjected to the wetting back process into a final panning machine for drying evenly and removing hairs. Compared with a traditional processing method, due to the adoption of the final panning step after the shaping process, the inner part and the outer part of the tea are dried evenly, moisture is taken away, and the green tea is fragrant; furthermore, the tea is subjected to the hair removing process, so that the tea is bright and good in appearance; most importantly, tea dust is removed from tea water made from the tea, the fragrance is fresh and the mouth feel is pure; in addition, through the control on the temperature in traditional processing steps and the parameters of moisture and the like in the tea, most organisms in the tea are maintained, and the quality of the tea is further guaranteed.

Owner:GUIZHOU YELUGAI TEA CO LTD

Processing method of Laoshan green tea

InactiveCN106578162ARich in amino acidsAvoid disadvantages such as damage and rednessPre-extraction tea treatmentCooking & bakingVitamin C

The invention belongs to the field of processing of tea leaves, and relates to a processing method of Laoshan green tea, and particularly relates to a processing method of clean and fresh type high-grade special Laoshan green tea capable of erecting after being brewed. The processing method comprises the following steps of picking, spreading, deactivation of enzymes, strip tidying, spreading for cooling and moistening regain, primary baking, secondary spreading for cooling and moistening regain, and re-baking to be enough dry, wherein a fresh leaf which is subjected to the deactivation of enzymes is directly subjected to the treatment of the strip tidying without being subjected to the spreading for cooling and temperature lowering; after the primary baking, the leaf is subjected to the secondary spreading for cooling and moistening regain; the re-baking to be enough dry is carried out by selecting and using a temperature which is lower than that of the primary baking. The Laoshan green tea processed through the processing method of the Laoshan green tea is tall and graceful in appearance, green and sleek in color and luster, apricot-green and transparent in liquor color, clean and fresh in fragrance, fresh and mellow in taste, and bright, complete and lobate in brewed leaf; after being brewed, the tea leaf erectly spreads in a cup and is high in viewing and admiring performance; the contents of an amino acid and a vitamin C which are beneficial to a human body are higher than those of ordinary Laoshan green tea.

Owner:QINGDAO ACAD OF AGRI SCI

Processing technology of millennial ancient black tea

InactiveCN104186743AElegant and beautiful tea typeStrands are fat and evenPre-extraction tea treatmentBrilliant RedBlack tea

The invention discloses a processing technology of millennial ancient black tea. The processing technology of the millennial ancient black tea comprises a series of complex working procedures of picking, withering, twisting, carrying out pile fermentation and drying. Tea leaves disclosed by the invention are picked from young sprout buds and leaves of primitive ancient tea trees with two or three leaves sprouting at the age of about 1000 years with cloud and mist in the whole year at the altitude of 700-1000 meters in Yunnan-Guizhou Plateau and the boundary of Guizhou and Chongqing. The prepared tea is elegant and beautiful in type, not only the phenomena of stacking and caking are avoided, but also strips of tea finished products are fat and uniform, and the problems of simple and rough selected materials, uneven modeling and the like in the production process of black tea are solved well; although the preparation technology is complex, the prepared finished products are fat in tea form, sorrel and brown in color, brilliant red in soup color, fresh in fragrance, durable in soaking and mellow in taste, and meet the individual requirements of health maintenance and relaxation for most black tea consumers at home and abroad.

Owner:TONGREN UNIV

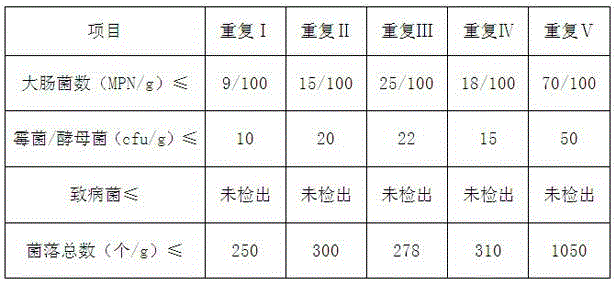

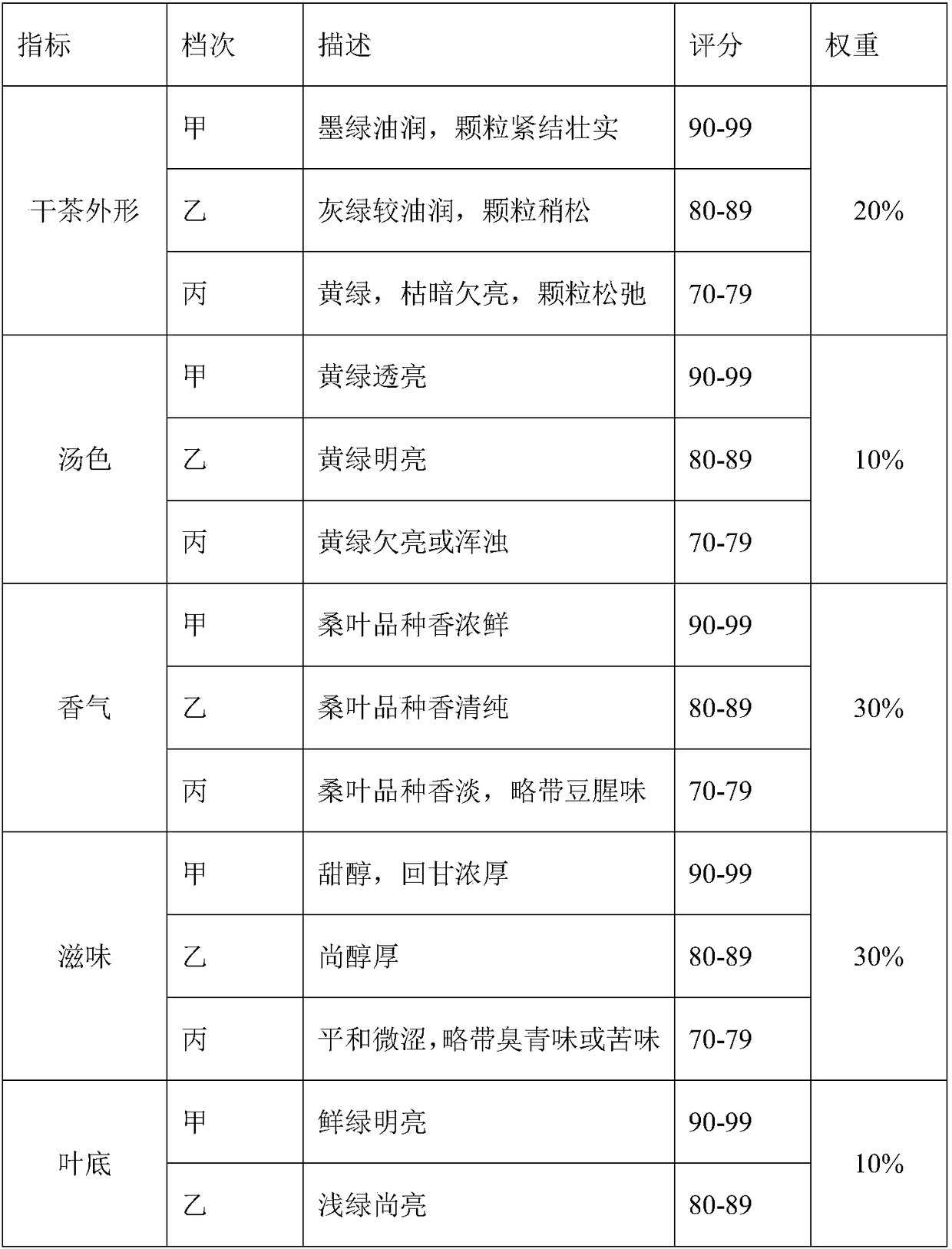

Mulberry leaf green-tea and preparation technology thereof

ActiveCN108432923AThe particles are tight and strongDark green oily colorTea substituesEpigallo-catechin gallateBiology

The invention provides mulberry leaf green-tea and a preparation technology thereof, and specifically relates to the technical field of tea preparation. The preparation technology of the mulberry leafgreen-tea comprises the following steps: a. Picking fresh mulberry leaves; b. withering the picked mulberry leaves; c. cutting the withered mulberry leaves into strips; d. carrying out drum fixation;e. carrying out spreading-cooling; f. carrying out secondary microwave fixation; g. carrying out cooling and water-regaining; h. carrying out rolling; and i. carrying out stir-frying and shaping. Thestep of withering moisture in the mulberry leaves, the fixation temperature and the rolling methods in the preparation technology are optimized so that the prepared mulberry leaf green-tea has uniquecharacteristic varietal aroma of mulberry leaves, and is tight and compact in granules, dark green and oily in color and lubricant in color and luster, yellowish green, translucent and bright in soupcolor, sweet and pure in taste, and mellow in after taste; moreover, the preparation technology of the mulberry leaf green-tea is stable and controllable in preparation processes, high in productionefficiency, and suitable for large-scale production.

Owner:柳城县国营伏虎华侨农场茶厂

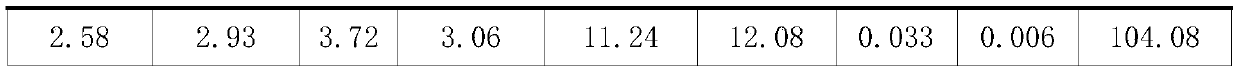

Brewing technology for cherry wine

The invention relates to a brewing technology for cherry wine and belongs to the technical field of wine brewing. The brewing technology comprises the following steps: picking cherries; cleaning and drying; removing stems and kernels; breaking; fermenting; filtering, thereby obtaining cherry wine, wherein in the step of fermenting, cherry juice is added into a fermentation tank; yeast is added; the fermenting starting temperature is controlled at 18-20 DEG C; after starting to ferment for 72 hours, cherry brandy is added till the alcoholic strength is 8-11% voL; sugar is remained and fermentation is interrupted; mixing the cherry brandy with the yeast for 30 days and then separating, thereby obtaining the raw cherry wine; the temperature is controlled at 8-10 DEG C; standing is performed for 58-62 days and centrifugal treatment is performed; and filtering is performed, thereby obtaining the cherry wine. The cherry wine brewed according to the brewing technology is complete and balanced in nutrition and wine body, pure in taste, and rich in fragrance and can meet the requirements of consumers at different levels.

Owner:QINHUANGDAO YINGYUN LIQUOR IND

Preparation method of fingered citron beverage

The invention provides a preparation method of a fingered citron beverage. The preparation method comprises the following steps of sequentially sorting, cleaning, debitterizing, mashing, performing enzymolysis, performing enzymic inactivation, and squeezing to obtain juice on fingered citron; performing centrifugation on the fruit juice; and performing compounding, homogenizing, sterilization, degassing, filling and secondary sterilization on the centrifuged fruit juice. The product prepared by the method can maintain the gentle feel after being put in mouths under the premise that additives of essence and the like are not added, the fragrance is fresh, and besides, the bioactive components and the medical efficacies of the fingered citron can be reserved as possible. The preparation method has the advantages of high juice yield and high content of solid matters.

Owner:ZHEJIANG JINSHOUBAO BIOLOGICAL TECH

Method for processing Lingyun pekoe yellow tea

The invention discloses a method for processing Lingyun pekoe yellow tea. The method comprises the following steps: firstly, picking tender leaves of Linyun pekoe, spreading for 4-8 hours, performing fixation for 2-3 minutes at 300-350 DEG C, kneading for 15-20 minutes while the tea leaves are hot, and further braising till the tea leaves are yellow; spreading the braised tender leaves for cooling; performing primary baking at 110-120 DEG C until the water content is 40%-50%, putting into a bamboo basket, and piling for 5-8 hours in a damp environment; further repeatedly kneading for 20-25 minutes by using a kneading machine, and performing secondary baking at 90-110 DEG C until the water content is 20% and below; and piling the tender leaves subjected to secondary baking for braising again for 10-15 hours, and finally, baking with sufficient fire until the water content is 6%-7%, thereby obtaining the Lingyun pekoe yellow tea. The Lingyun pekoe yellow tea processed by using the method is good in taste, tender yellow in pekoe, bright and yellow in tea soup, fresh in fragrance, mellow and pleasant in taste, and yellow-green and bright in leaf residue.

Owner:广西浪伏六堡茶业科技股份有限公司

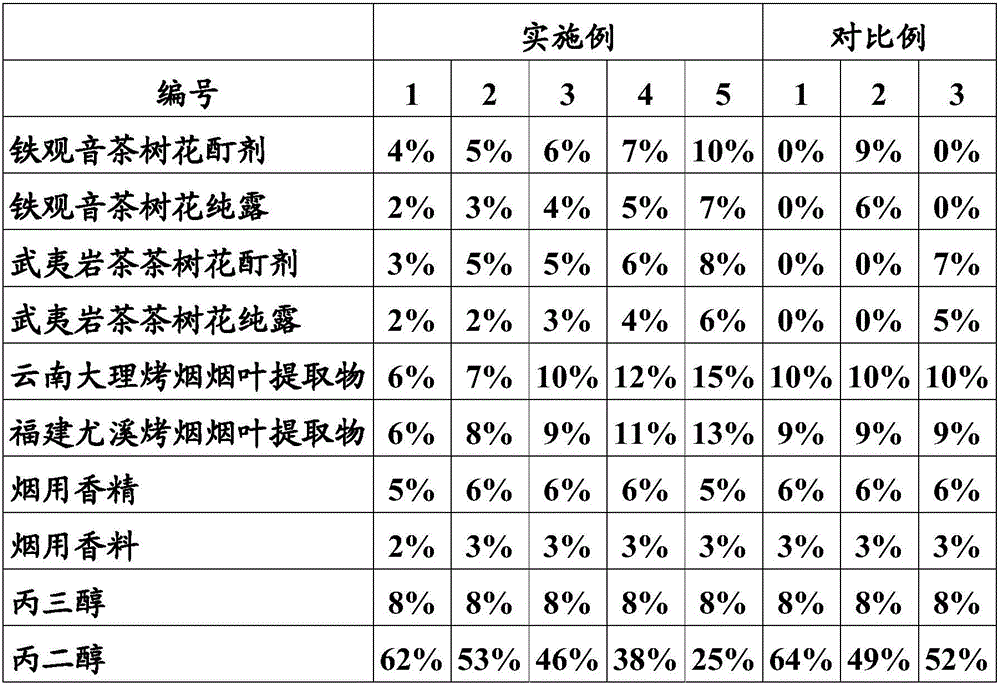

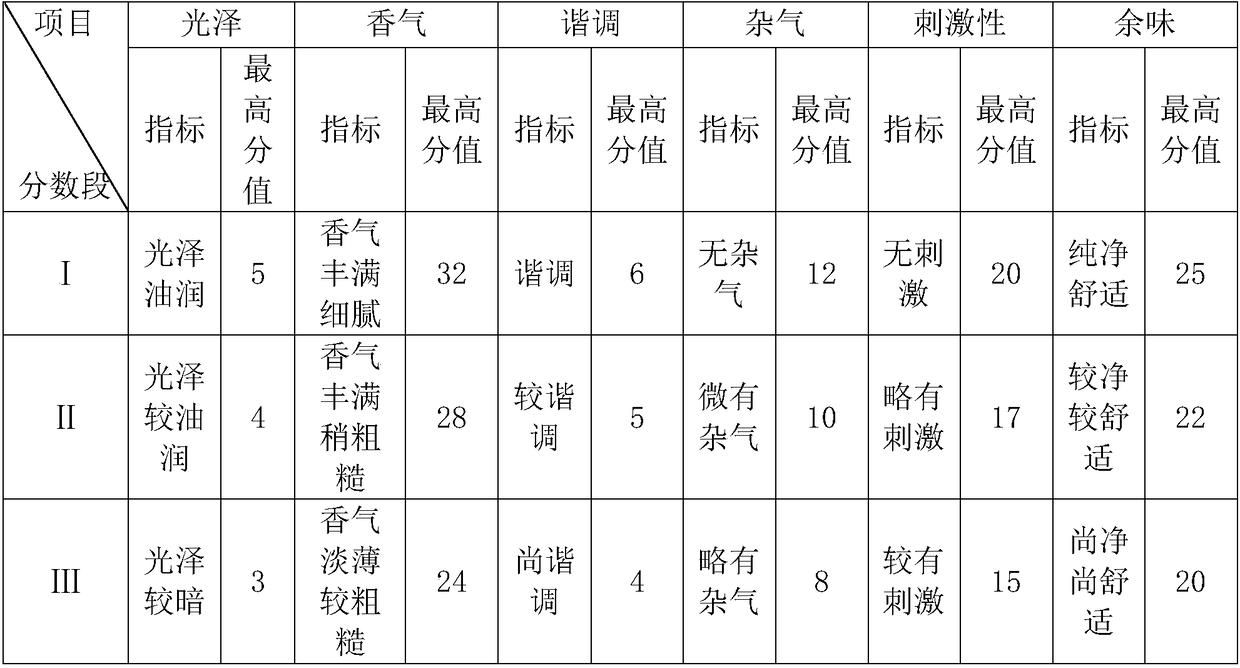

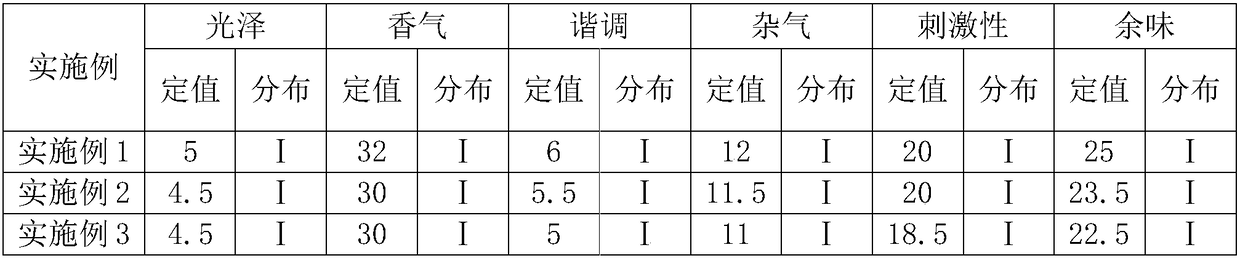

Electronic cigarette liquid

The invention relates to electronic cigarette liquid, in particular to a composition. The composition consists of the following components in parts by weight: 6-17 parts, 8-12 parts for example, of a Tieguanyin tea tree flower extract, 5-14 parts, 7-10 parts for example, of a Wuyi rock tea tree flower extract and 12-28 parts, 15-23 parts for example, of a tobacco extract. The electronic cigarette liquid, which is prepared from the composition, has fresh fragrance and moist sweet honey aroma as well as the orchid and sweet-scented osmanthus like flowery flavor of tea flowers when being smoked; and in addition, the electronic cigarette liquid, when being smoked, is relatively strong in sense of promoting the secretion of body fluid in oral cavities and is capable of relieving residues in throats.

Owner:CHINA TOBACCO FUJIAN IND

Preparation method of citrus peel tea

InactiveCN106343072APlay a two-way regulationGood for clearing heat and reducing firePre-extraction tea treatmentTea flavoringNutritive valuesExpiration date

The invention discloses a preparation method of citrus peel tea. The preparation method comprises the following steps of (1) preparing old Tieguanyin: selecting the old Tieguanyin for standby application; (2) preparing citrus peel: selecting mature moderate citruses with the fruit shape within 6 cm as raw materials, carefully selecting, cleaning, then forming round mouths in citrus pedicels, and removing pulp so as to obtain top covers and citrus shells for standby application; (3) loading the old Tieguanyin prepared in the step (1) in the citrus shells; (4) covering the top covers on the citrus shells, wrapping with tinfoil, then putting in a food steamer so as to be steamed, and then cooling; (5) releasing the tinfoil, baking the whole citruses by a drying machine, then cooling, and repeating the steps. The preparation method has the advantages of simplicity, high nutritive value and good fragrance of finished products, the adopted raw materials have the advantages of nature, safety and no chemical additive, and the citrus peel tea has the advantages of convenience in carrying and storage, rapidity in use and long expiration date and is healthy tea which can be drunk for a long time.

Owner:FUJIAN EIGHT HORSES TEA

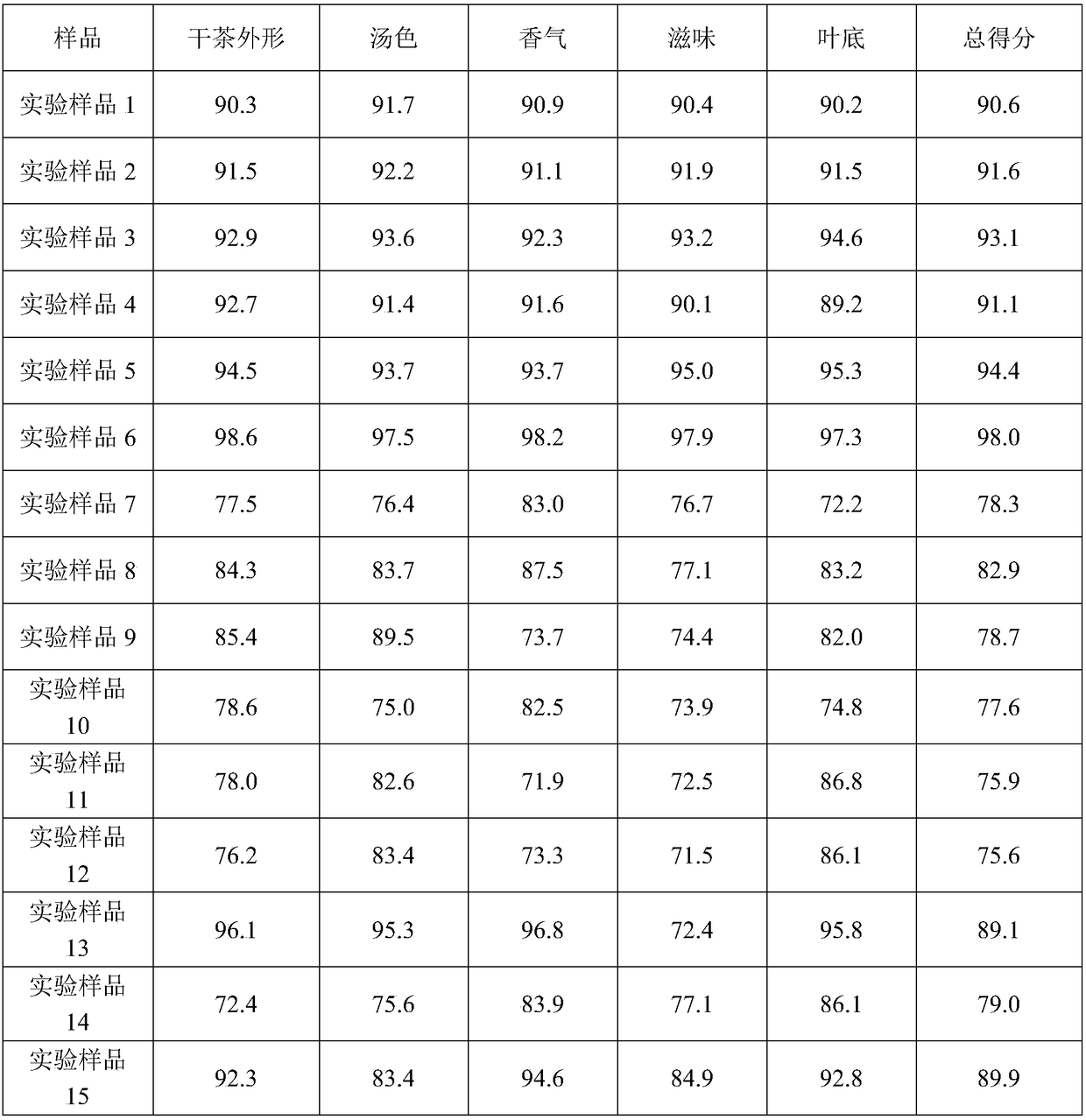

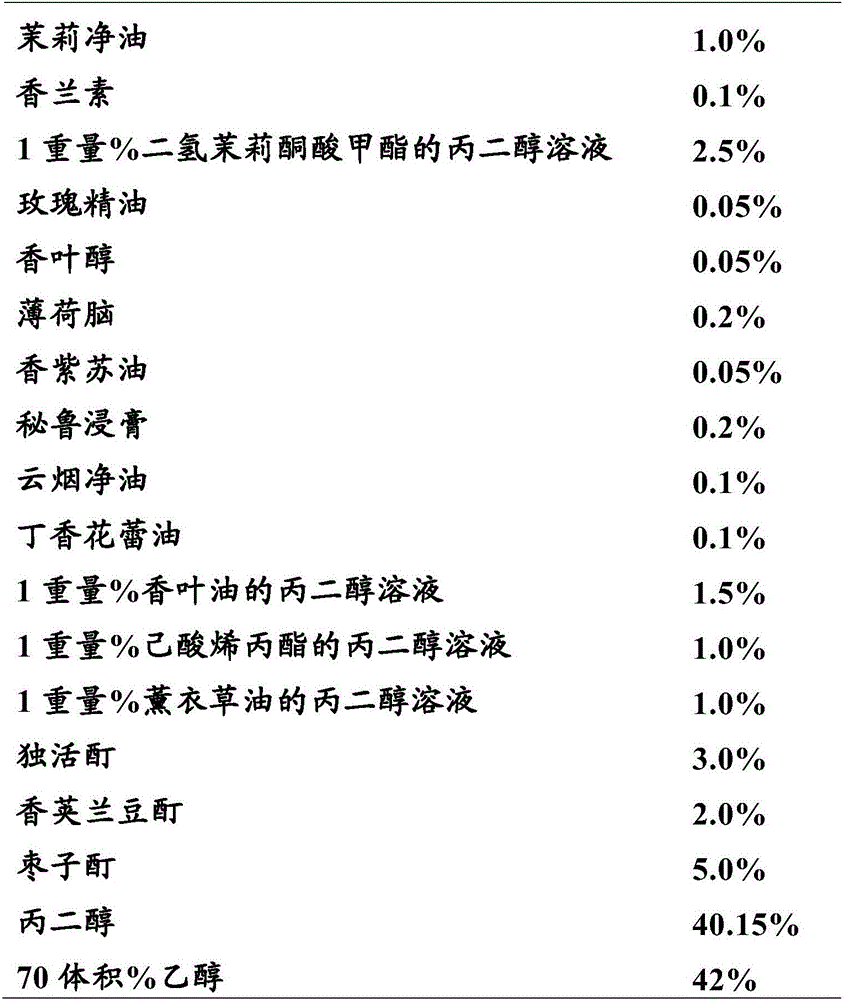

Tobacco essence, preparation method and tobacco product

InactiveCN108095186AIncrease the fragranceAlcohol and aromaTobacco preparationTobacco treatmentAdditive ingredientGas phase

The invention relates to a tobacco essence, which consists of the following components in percentage by mass: 3-6% of a vanilla planifolia extract, 5-8% of a refined extract of common fenugreek seeds,1-4% of actinidol, 10-20% of a natural tomato extract, 3-5% of a fermented plum refined extract, 2-6% of a natural chicory extract, 2-5% of a guarana refined extract, 5-15% of a fructus momordicae extract, 10-40% of propylene glycol and 20-50% of water. The tobacco essence provided by the invention that major ingredients are pure natural plant extracts can overcome shortcomings of a synthetic spice which is monotonous and rigid in fragrance since the synthetic spice is constituted by a single ingredient; in addition, the tobacco essence has the characteristic of being mellow in fragrance, andthe tobacco essence is harmonious with fragrance of tobacco and is fresh and natural in fragrance; meanwhile, the plant extracts in the essence can get heated by temperatures of different gradients in cigarettes, and the active ingredients can get distilled, gasified, volatilized and sublimated, so that a particle phase and gas-phase ingredients are formed; and through the materials, free radicals in smoke can be captured, the generation of harmful substances can be reduced and effects of 'reducing harm and tar' can be achieved.

Owner:HEBEI RUILONG BIOTECHNOLOGY CO LTD

Rose lotus leaf tea bag and preparation method thereof

InactiveCN103535463AFast dissolution rateMany extractsPre-extraction tea treatmentAdditive ingredientSemen

The invention relates to a rose lotus leaf tea bag and a preparation method of the rose lotus leaf tea bag. The rose lotus leaf tea bag is processed by 7-10 parts of rose, 8-12 parts of lotus leaf, 4-6 parts of green tea, 2-5 parts of chrysanthemum and 1-4 parts of semen cassiae. The preparation method of the rose lotus leaf tea bag comprises the following steps: crushing raw materials, namely crushing the rose, lotus leaf, green tea, chrysanthemum and semen cassiae in weight proportion into powder by virtue of a crushing machine at the temperature of 18-30 DEG C and the humidity of 30-70%; sieving, namely sieving the raw material powder crushed by virtue of a vibrating sieving machine; blending, namely stirring and blending the sieved raw material powder; packaging, namely packaging the blended raw material powder in bags; sterilizing. The rose lotus leaf tea bag is composed of all natural ingredients, tea soup is yellow green and clear, fragrance is fresh, and taste is pure; meanwhile, dissolution rate of the rose lotus leaf tea bag is high, extracts are more, content of amino acid and tea polyphenol nutrition and health care components is high, the rose lotus leaf tea bag is easy to carry and drink, and new beverage with the effects of losing weight, maintaining beauty and keeping young is provided for people.

Owner:HANGZHOU EFUTON TEA

Method for brewing dry type ginger brewed wine

ActiveCN105505686AFresh aromaFruity bouquetMicroorganism based processesAlcoholic beverage preparationFiltrationTurbidity

The invention relates to the technical field of wine brewing, and particularly discloses a method for brewing a dry type ginger brewed wine. The method comprises the steps of raw material cleaning, breaking and pulping, squeezing and juice extraction, enzymolysis, adjustment, canning, yeast inoculation, yeast nutrient salt adding, temperature controlled fermentation, main fermentation endpoint control, wine pouring and after fermentation, secondary wine pouring, aging, clarification, filtration and filling. Laiwu yellow ginger is taken as the main raw material, pulping, squeezing and enzymolysis are conducted to generate pure ginger juice, fermentation is conducted with active dry yeast, and after clarification and filtration are conducted with an egg white powder and bentonite mixed clarifying agent, the dry type ginger brewed wine which has a fresh fragrance and the alcohol concentration of 11-13% is prepared. The dry type ginger brewed wine is rich in hygiene factors in yellow ginger, meets the consumption requirement of modern people for mild fermented wine, and solves the problems of hard clarification and post turbidity of finished wine caused by high content of macromolecule substances such as protein and starch in ginger.

Owner:SHANDONG AGRICULTURAL UNIVERSITY +1

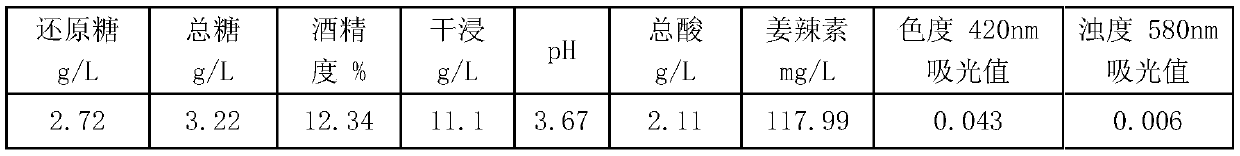

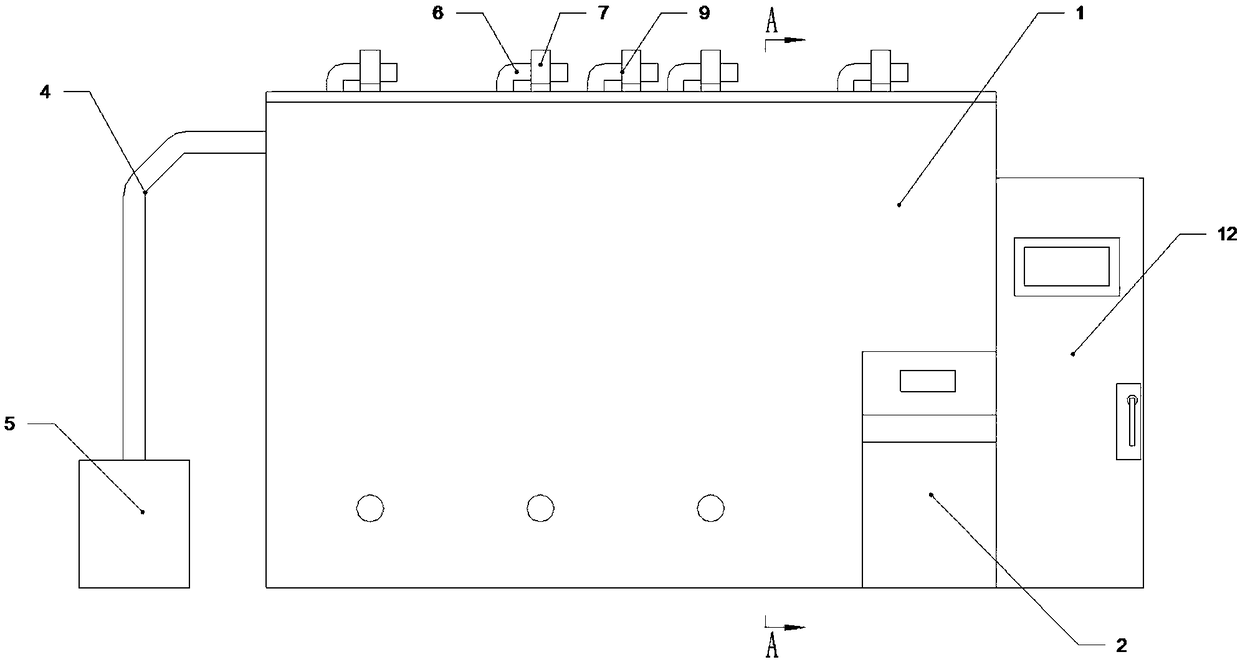

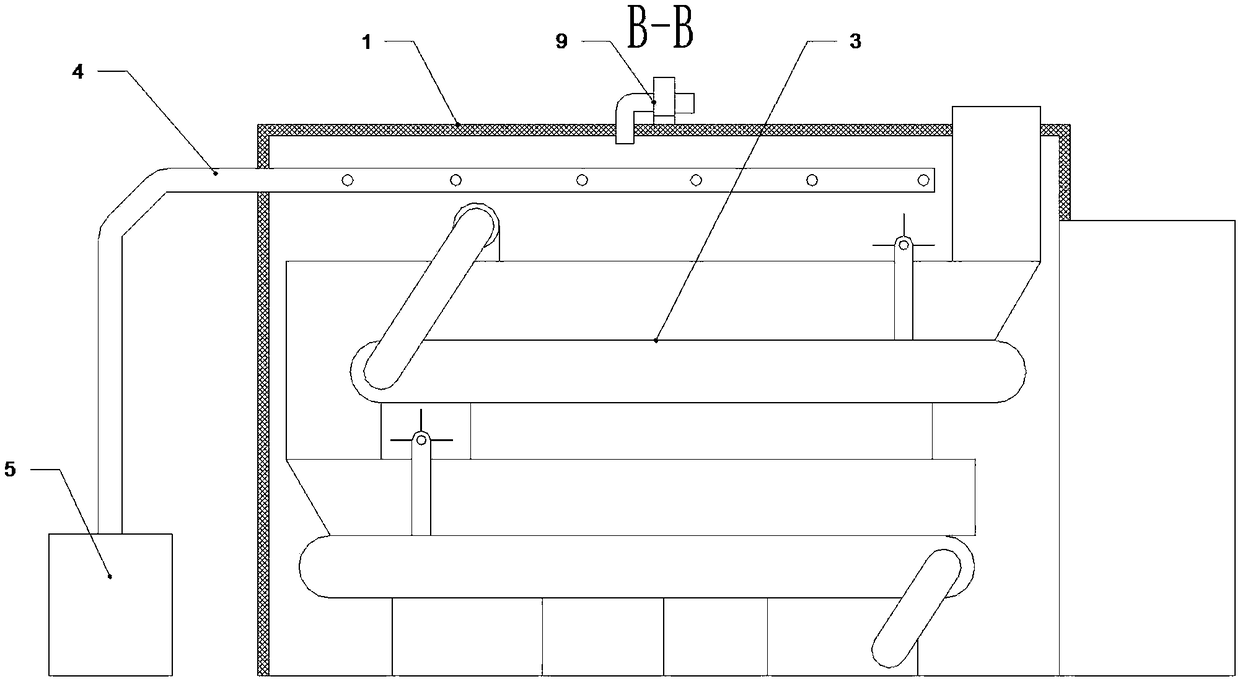

Automatic scenting machine and scenting method for jasmine tea

The invention relates to the field of the processing of jasmine tea, in particular to an automatic scenting machine and scenting method for jasmine tea. The automatic scenting machine is characterizedby comprising a cavity body, wherein a circulating mesh belt conveyor is installed inside the cavity body, the top of the cavity body is provided with a dehumidifying fan, an air inlet pipe, an air outlet pipe and a fan communicated with the air inlet pipe and the air outlet pipe, the outer side lower part of the cavity body is provided with an air inlet assembly communicated with the cavity body, a heating assembly is installed on the inner lower end of the cavity body, the outer side of the cavity body is provided with a humidifier, the humidifier is connected with a humidifying pipeline, the humidifying pipeline stretches into the cavity body, and a temperature sensor and a humidity sensor are installed on the center position inside the cavity body. By adopting the automatic scenting machine for the jasmine tea, the temperature, the humidity and the material flow can be precisely controlled, the clean, programmed-control and automatic processing can be realized, the scenting quality of the jasmine tea is ensured to be clean, hygienic, stable, uniform and consistent, the scented jasmine tea is fresh and strong in fragrance, sweet and mellow in taste and bright in soup color.

Owner:四川省清溪茶业有限公司

Skin-beautifying wet tissue

InactiveCN105878116AFresh aromaSoft textureCosmetic preparationsToilet preparationsSide effectIrritation

The invention relates to a skin-beautifying wet tissue, which is prepared from fully-degradable non-woven fabrics and wet tissue liquid, wherein the wet tissue liquid comprises the following components in parts by weight: 10-16 parts of water, 3-5 parts of grape seed oil, 1-5 parts of gleditsia sinensis extracts, 2-4 parts of matrine, 5-11 parts of aloe juice, 1-3 parts of sanitizers and 2-6 parts of olive oil. The skin-beautifying wet tissue can play a special role in effectively protecting the skin, is natural and fresh in fragrance, soft in texture, free of irritation to skin, and free of a side effect after long-term use.

Owner:俞凤鸣

Method for preparing chrysanthemum flower spice powder

InactiveCN105995903AImprove qualityIncrease aromaFood homogenisationFood ingredient as flavour affecting agentFlavorOrganic solvent

The invention discloses a method for preparing chrysanthemum flower spice powder. Chrysanthemum flower extract is extracted by adopting drinking chrysanthemum flower as raw materials through a supercritical CO2 method and then subjected to emulsify embedding through an embedding agent, then homogenizing and spray drying are carried out, and the high-expansion chrysanthemum flower spice powder with the characteristic aroma and taste of the chrysanthemum flowers is prepared. The problems that in a traditional process, organic solvent residues are generated, the production period is long, the aroma concentration of aroma extract is not high, aroma ingredients are likely to be oxidized, and thermosensitive substances are likely to be damaged can be effectively avoided, and the chrysanthemum flower spice powder high in quality is obtained at low temperature within a short production time. The prepared chrysanthemum flower spice powder is lasting and fresh in aroma, the fragrance of food is improved, use is convenient, and a very good fragrance increasing effect is achieved. The chrysanthemum flower spice powder can be widely applied to biscuits, beverages, sauce products, cooked wheaten food seasoning and the like.

Owner:上海旭梅食品科技股份有限公司 +1

Key preparation method for crisp biscuits containing genmaicha tea

InactiveCN105660805APromote digestion and absorptionDelicate tasteDough treatmentBakery productsBiotechnologyIcing sugar

The invention relates to a key preparation method for crisp biscuits containing genmaicha tea. The method comprises the following steps: preprocessing an egg liquid and sugar powder; fermenting and freezing a dough; and moulding and baking. The process temperature and time are controlled accurately, so that the nutritional effects of the biscuits and the genmaicha tea can be effectively stored. By improving a cooking method, the biscuits and the genmaicha tea are reasonably combined and cooked together to make a food with attractive appearance, unique flavor and balanced nutriments.

Owner:李建贤

Method for processing Lingyun pekoe filiform white tea

The invention discloses a method for processing Lingyun pekoe filiform white tea, and belongs to the technical field of tea leaf processing. The method comprises the following steps: picking old or mature leaves of Lingyun pekoe, sunning for 10-20 minutes, transferring into a room, spreading for 1-2 hours, and shredding the tea leaves to obtain shreds of 0.3-0.5cm; further spreading the shreds in a bamboo screen to wither the shreds for 50-60 hours, wherein the spreading thickness is 2-3cm, the temperature is controlled to be 18-25 DEG C, and the air humidity is controlled to be 60%-70%; further drying the withered tea leaves, namely, drying with first fire at 67-70 DEG C, and further drying with sufficient fire at 110-120 DEG C to highlight the fragrance until the water content of the tea leaves is 7% and below, thereby obtaining crude tea; and finally, separating the crude tea with air, screening, and separating out non-tea impurities, thereby obtaining a finished product, that is, the Lingyun pekoe filiform white tea. The finished product, that is, the dried Lingyun pekoe filiform white tea, disclosed by the invention is filiform, and is apricot yellow in soup, fresh in fragrance, mellow and pleasant in taste and sweet in aftertaste and tea soup is smooth when taken.

Owner:广西浪伏六堡茶业科技股份有限公司

Odor type Qianliang tea and preparation method thereof, as well as odor type Qianliang tea cakes and preparation method thereof

PendingCN107712136AThe solution is only Chen Xiang,Solve the problem of no tea flower and fruit fragrancePre-extraction tea treatmentTea flavoringEconomic benefitsHigh mountain

The invention provides odor type Qianliang tea and a preparation method thereof, as well as odor type Qianliang tea cakes and a preparation method thereof, relates to a processing method of flowery cylindrical tea and the flowery cylindrical tea. The preparation method the Qianliang tea comprises the following steps of ageing raw materials, wherein the humidity is controlled to be 45-70%, the temperature is controlled to be 30 DEG C or below, and the time is controlled to be 1-2 years; preparing new tea; performing aroma increasing on the raw materials; assorting the raw materials: 60-90 partsof mountain top organic dark unfinished tea, and 10-40 parts of same-year 2-3-grade high mountain and barren mountain dark unfinished tea; and performing steaming, stepping, airing and drying. The Qianliang tea has the characteristics that tea columns can naturally give off flower and fruit fragrance of tea leaves, after the Qianliang tea is cut into slices, tea fragrance is rich, the fragrance is rich, plum, fresh and long-lasting, and after the Qianliang tea is stored for many years, the fragrance is not reduced; the product namely the Qianliang tea is mellow and gentle in mouth feel, sweetand long, after the Qianliang tea is drunk, the lingering fragrance is continuous, the problem that conventional Qianliang tea only has aged fragrance but does not have the flower and fruit fragranceof the tea leaves is solved, the product does not need to be stored, can directly appear on the market, and adapts to the new consumption concept of safe, green and fresh dark tea; and besides, quality risks existing in long-term storage of the Qianliang tea are avoided, the fund turnover is accelerated, and the economic benefits are increased.

Owner:王崟

Dogbane tartary buckwheat tea and preparation process thereof

InactiveCN102934717AExact health benefitsThe composition of the formula is reasonableTea substituesDrum dryingGuar gum

Disclosed are a dogbane tartary buckwheat tea and a preparation process thereof. The tartary buckwheat tea is composed of 500 to 900 parts of tartary buckwheat husk powders, 300 to 400 parts of dogbane powders, 50 to 100 parts of folium mori powders, 50 to 100 parts of chrysanthemum powders, 50 to 100 parts of tartary buckwheat extract, 2 to 10 parts of guar gum, 2 to 10 parts of xanthan gum and 2 to 10 parts of konjac glucomannan. The preparation process of the tartary buckwheat tea includes breading, forming, drying and fragrance enhancing. The preparation process specifically includes firstly uniformly mixing the tartary buckwheat husk powders, the dogbane powders, the folium mori powders, the chrysanthemum powders, the tartary buckwheat extract, the guar gum, the xanthan gum and the konjac glucomannan until the colour and luster are uniform, still standing for 20 minutes, then taking out uniformly stirred tea powders, adding 25% to 40% of water, uniformly mixing by a pressurization forming machine, screening through a sieve with 30 meshes, performing granulation, placing formed tartary buckwheat tea particles in a plate, placing the plate in a hot air drying oven, drying at the temperature of 50 DEG C to 55 DEG C until the moisture content is within 8%, then placing the plate in a far infrared toaster, baking at the temperature of 200 DEG C to 220 DEG C for 2 to 3 minutes, naturally cooling, finally placing cooled tartary buckwheat tea in a rotary drum drying oven, and baking at the temperature of 110 DEG C to 145 DEG C until the moisture content is not more than 5%.

Owner:太原市素有苦荞食品有限公司

Acanthopanax tartary buckwheat tea and preparation process thereof

InactiveCN102919456AExact health benefitsThe composition of the formula is reasonableTea substituesPolygonum fagopyrumDrum drying

Provided is acanthopanax tartary buckwheat tea and a preparation process thereof. The acanthopanax tartary buckwheat tea is formed by 500 to 850 parts of tartary buckwheat cortex powder, 200 to 400 parts of acanthopanax leaf powder, 50 to 100 parts of eucommia leaf powder, 25 to 50 parts of tartary buckwheat extractive, 2 to 10 parts of guar gum and 2 to 10 parts of xanthan gum. The preparation process of the tartary buckwheat tea comprises the steps of stirring powder, shaping, drying and enhancing incense. Firstly, the tartary buckwheat cortex powder, the acanthopanax leaf powder, the eucommia leaf powder, the tartary buckwheat extractive, the guar gum and the xanthan gum are evenly mixed until color is uniform to stand for 20 minutes. Then, 25% to 40% of water is added into evenly-mixed tea powder to be mixed evenly through a pressing forming machine, and the tea powder is sieved by 30 meshes to granulate. Formed tartary buckwheat tea particles are arranged in a disk to be in a hot air drying box to be dried at the temperature of 50 DEG C to 55 DEG C until the water content is within 8%, then the tea powder is positioned in an infrared oven to be baked for 2 to 3 minutes at the temperature of 200 DEG C to 220 DEG C, and the tea powder is cooled naturally. Finally, cooled tartary buckwheat tea is arranged in a drum drying box to be baked at the temperature of 110 DEG C to 145 DEG C until the water content is not higher than 5%.

Owner:太原市素有苦荞食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com