Automatic scenting machine and scenting method for jasmine tea

A technology of jasmine tea and processing method, which is applied in the direction of tea substitutes, etc., which can solve the problems of difficult to ensure the food hygiene and safety of jasmine tea, the uncontrollable humidity of scented flowers, and the uncontrollable temperature of piles, so as to avoid the difficulty of releasing fragrance and avoid opening The effect of exhaling fragrance too fast and controlling the humidity of scented flowers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

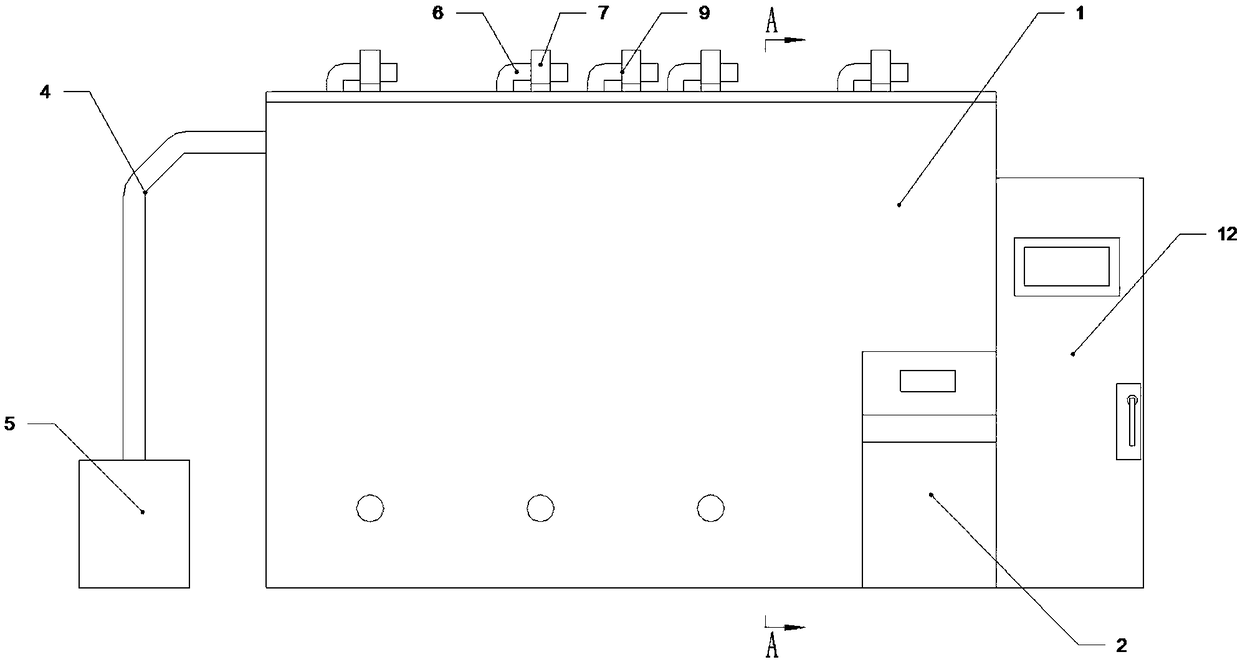

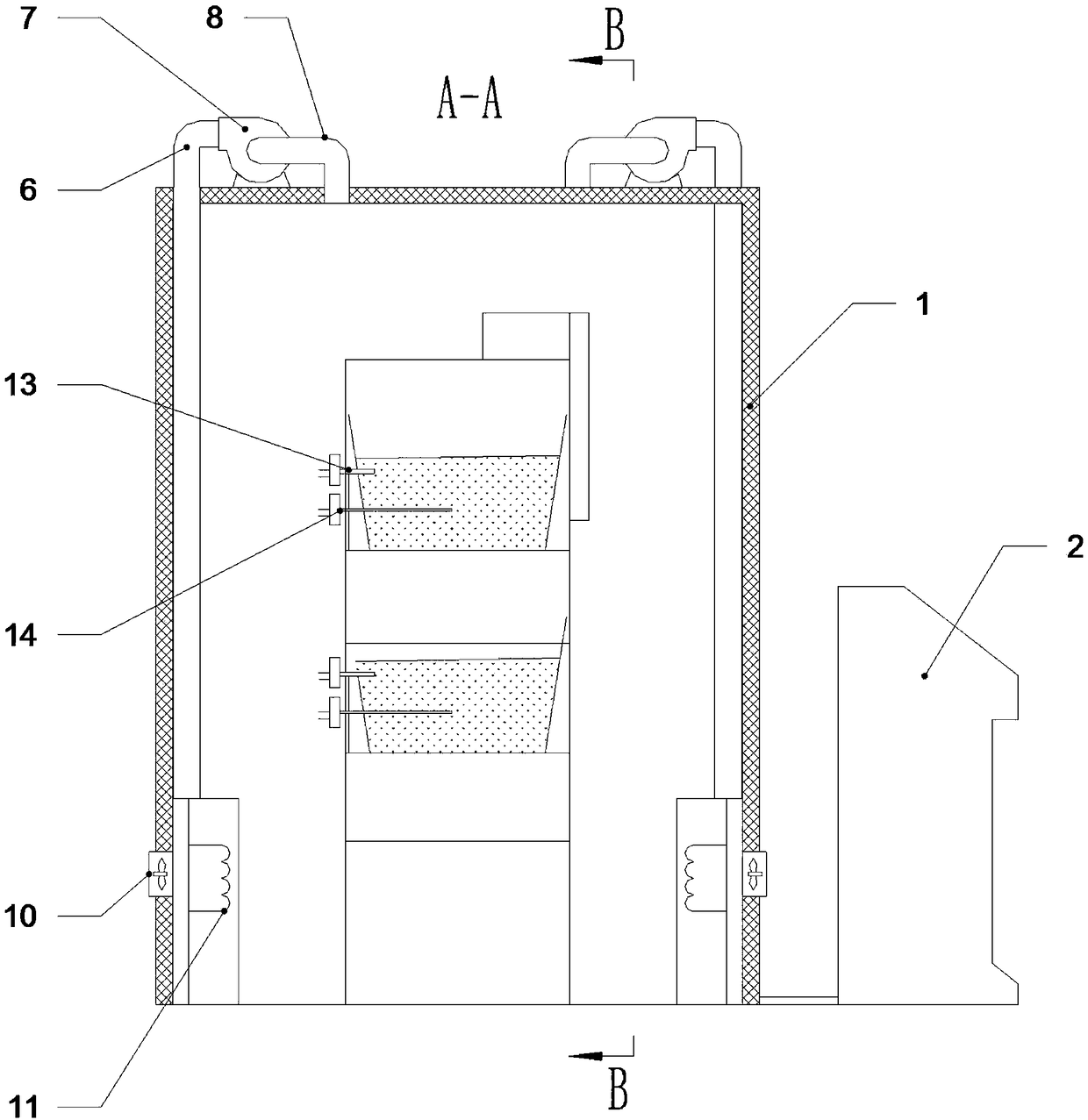

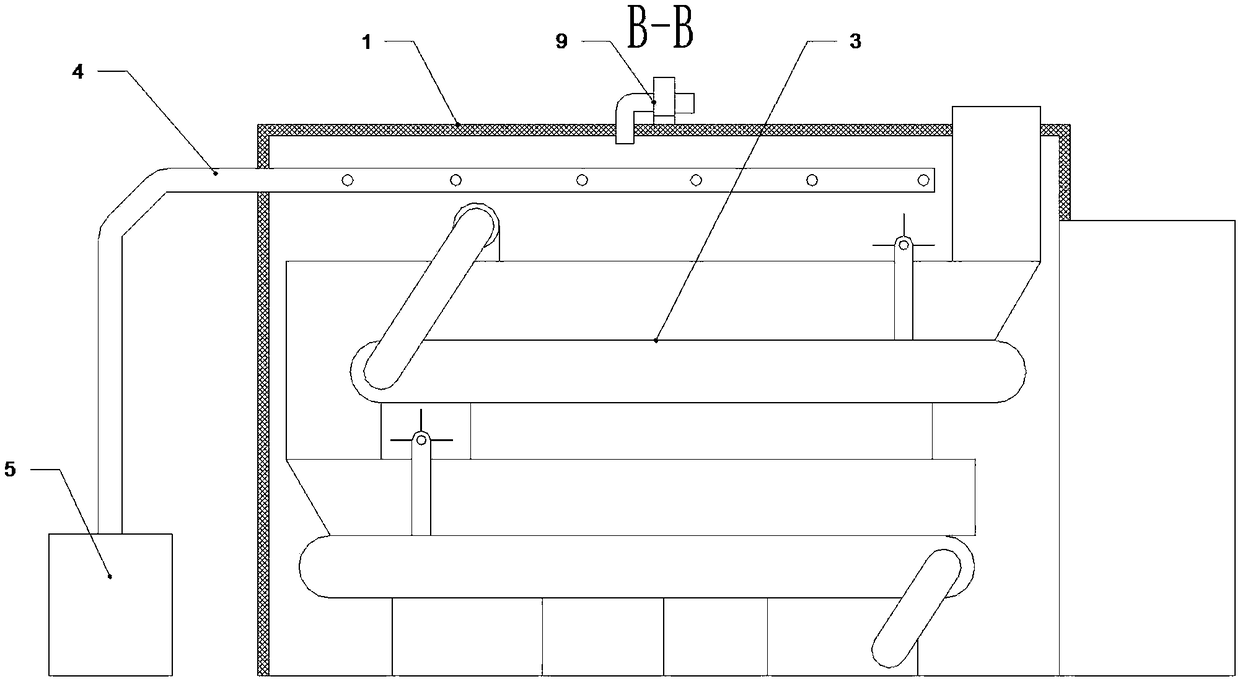

[0052] see Figure 1~4 , an automatic scenting machine for jasmine tea, comprising a cavity 1, a circulating mesh belt conveyor 3 is installed inside the cavity 1, a moisture exhaust fan 9, an air inlet pipe 8, an air outlet pipe 6 and The fan 7 connected to the air inlet pipe 8 and the air outlet pipe 6, the air inlet assembly 10 communicating with the chamber 1 is installed on the lower outside of the chamber 1, the heating assembly 11 is installed on the inner lower end of the chamber 1, and the humidifier is installed on the outside of the chamber 1 The humidifier 5 and the humidifier 5 are connected with a humidifying pipeline 4, and the humidifying pipeline 4 extends into the cavity 1, and a temperature sensor 14 and a humidity sensor 13 are installed at the center of the cavity 1.

[0053]As a preferred method, the circulating mesh belt conveyor 3 installed inside the chamber body 1 has at least two layers, and the two layers of circulating mesh belt conveyor 3 evenly t...

Embodiment 2

[0066] A kind of jasmine tea scenting processing method, comprises the following steps:

[0067] a: Tea base processing: spread the tea base to be scented on the circular mesh belt conveyor 3 of the automatic flower scenting machine described in Example 1, adjust the temperature inside the cavity 1 to 100°C through the heating assembly 11, and treat The scented tea base is baked and dried, and then stored in tea boxes or cloth bags and naturally cooled to the temperature of the tea base to room temperature for scenting.

[0068] b: flower maintenance: after the jasmine flower enters the factory, spread it on the circulating mesh belt conveyor 3 of the automatic scenting machine described in embodiment 1 to spread the heat, and reduce the temperature inside the cavity 1 by the blower fan 7 and the heating assembly 11. Control the temperature at 38°C, and 80% of the flower buds open to the shape of tiger claws. Store the well-maintained flowers for later use.

[0069] c: scenti...

Embodiment 3

[0082] A kind of jasmine tea scenting processing method, comprises the following steps:

[0083] a: Tea base processing: spread the tea base to be scented on the circular mesh belt conveyor 3 of the automatic flower scenting machine described in Example 1, adjust the temperature inside the cavity 1 to 130°C through the heating assembly 11, and treat The scented tea base is baked and dried, and then stored in tea boxes or cloth bags and naturally cooled to the temperature of the tea base to room temperature for scenting.

[0084] b: flower maintenance: after the jasmine flower enters the factory, spread it on the circular mesh belt conveyor 3 of the automatic scenting machine described in embodiment 1 to spread the heat, and control the internal temperature of the cavity 1 through the fan 7 and the heating assembly 11 At 28°C, 80% of the flower buds open to the shape of tiger claws, and the well-maintained flowers are stored for later use.

[0085] c: scenting flowers: spread ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com