Method for brewing dry type ginger brewed wine

A technology for fermenting wine and ginger, applied in the field of winemaking, can solve the problems of difficult clarification and post-turbidity of finished wine, and achieve the effects of outstanding style, complete wine body, and strong fruity wine aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

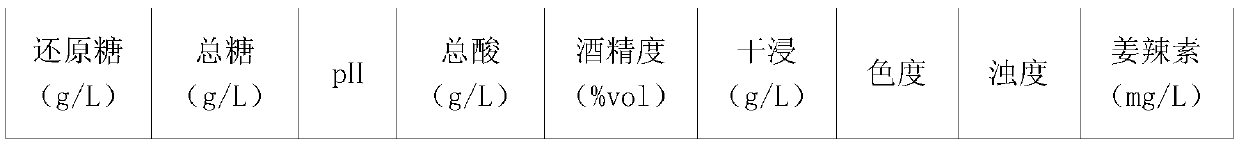

Embodiment 1

[0031] The brewing method of the dry ginger fermented wine adopts the following steps:

[0032] (1) Raw material cleaning: select Laiwu yellow ginger, wash away the sediment with running water, wash and drain the water, determine the raw material indicators as follows: moisture 90.28%, starch content 3.42%, protein content 1.54%, gingerol content 0.167%, reducing sugar 0.58%, total sugar 1.05%;

[0033] (2) Crushing and beating: Weigh 600g yellow ginger, use Songtai ginger paste machine to crush the yellow ginger raw material into filamentous pulp, add 1200mL of water, and extract for 30min;

[0034] (3) Squeezing and extracting juice: Use a plate and frame press to squeeze the dipped fruit pulp to extract juice, collect ginger juice, and record the volume of ginger juice as 1500 mL;

[0035] (4) Enzymatic hydrolysis: transfer the ginger juice into a stainless steel jacketed pot, add 7.5mL high temperature resistant α-amylase and 3.0mL glucoamylase to the ginger juice, stir evenly, he...

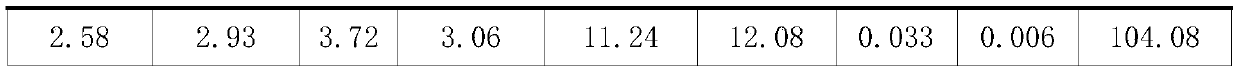

Embodiment 2

[0057] The brewing method of the dry ginger fermented wine adopts the following steps:

[0058] (1) Raw material cleaning: select Laiwu yellow ginger, wash away the sediment with running water, wash and drain the water, determine the raw material indicators as follows: moisture 88.30%, starch content 3.02%, protein content 1.32%, gingerol content 0.200%, reducing sugar 0.54%, total sugar 1.01%;

[0059] (2) Crushing and beating: Weigh 4950g yellow ginger, use Songtai ginger paste machine to crush the yellow ginger raw material into filamentous pulp, add 9900mL of water, stir and mix, and extract for 30min;

[0060] (3) Squeezing and extracting juice: Use a plate and frame type press to squeeze the dipped fruit pulp to extract juice, collect ginger juice, and record the volume of ginger juice as 12000 mL;

[0061] (4) Enzymatic hydrolysis: transfer the ginger juice into a stainless steel jacketed pot, add 60mL high temperature resistant α-amylase and 24mL glucoamylase to the ginger jui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com