Patents

Literature

84results about How to "Outstanding style" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

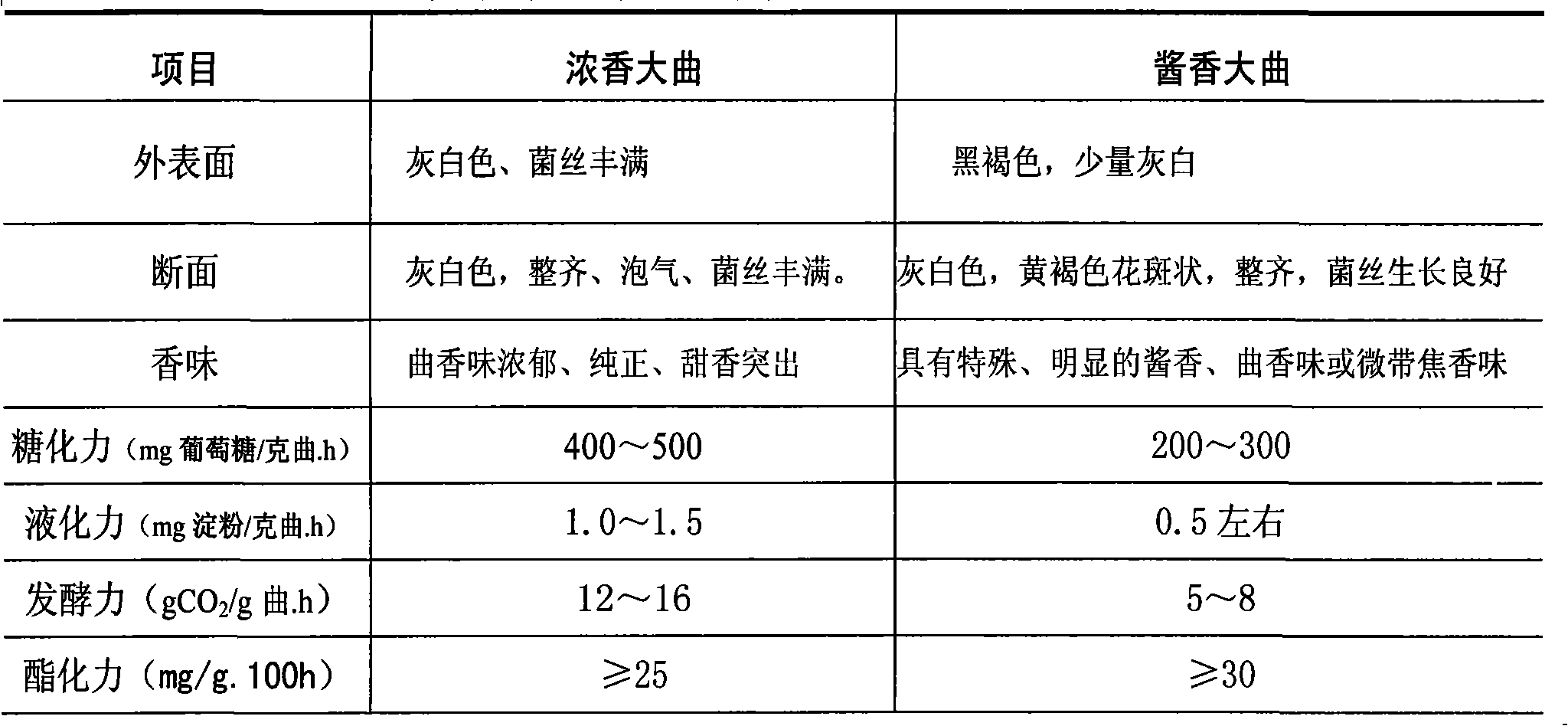

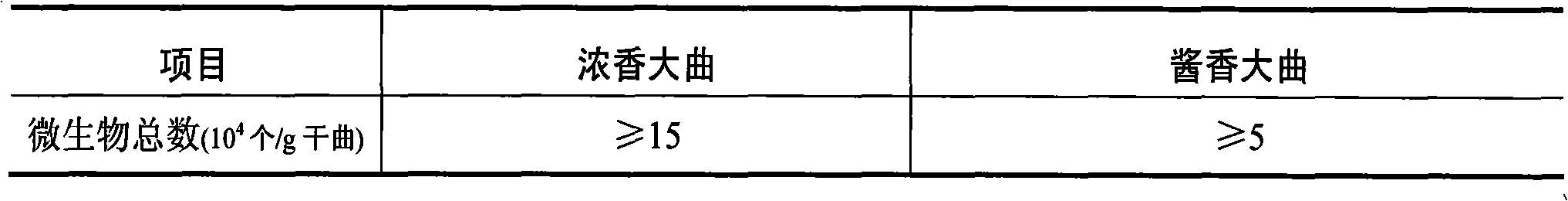

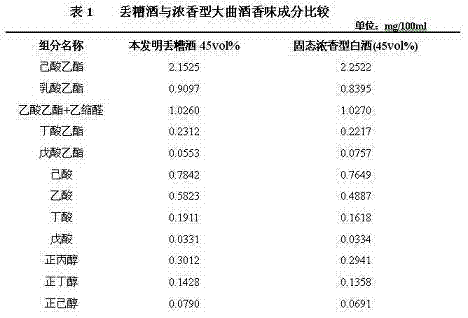

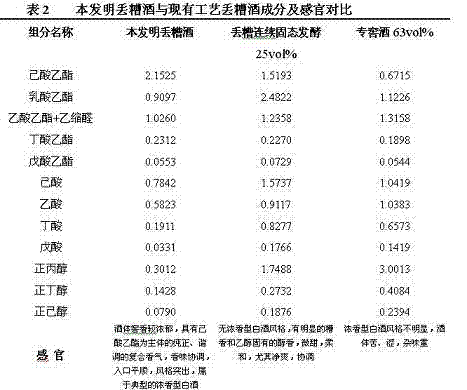

Production method of Maotai-flavor liquor

ActiveCN101602991ARemove Lao ChenEliminate pesticide residuesAlcoholic beverage preparationBiologyBrewing

The invention discloses a production method of Maotai-flavor liquor. Compared with conventional process, the invention replaces sorghum and wheat with rice, sticky rice, corn, wheat and sorghum which serve as brewing materials, replaces the process of only taking Maotai-flavor daqu as a ferment with the fermentation process of combining two daqu: Luzhou-flavor daqu and Maotai-flavor daqu for preparation, and replaces the convenient process of twice of grain addition, eight rounds of fermentation and seven rounds of liquor taking with the process of one-time grain addition, nine times of fermentation and eight times of liquor taking. The invention has the following advantages: the quality of each round of liquor and combined mixed body of each round of liquor is superior the quality of the existing method, thus obviously reducing the yield of liquor of inferior quality rounds, obviously improving the yield of liquor of superior quality rounds and improving the total yield, and the Maotai-flavor style of the product and aftertaste thereof are both superior to Maotai-flavor style and aftertaste of the Maotai-flavor liquor prepared by the existing method, and the product has elegant multi-grain compound flavor.

Owner:SICHUAN TUOPAI SHEDE WINE

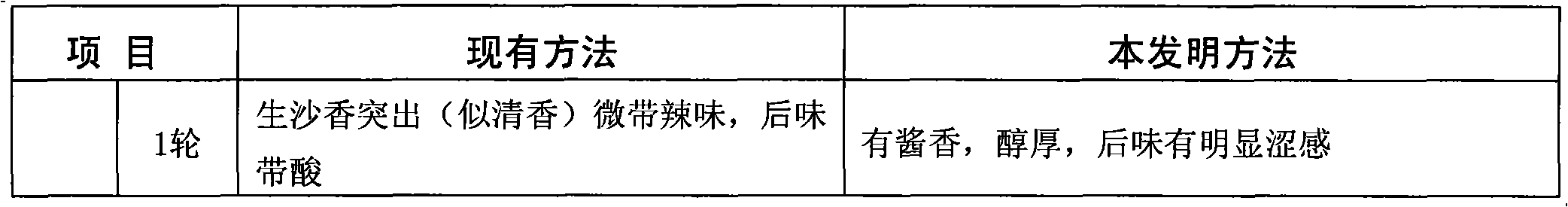

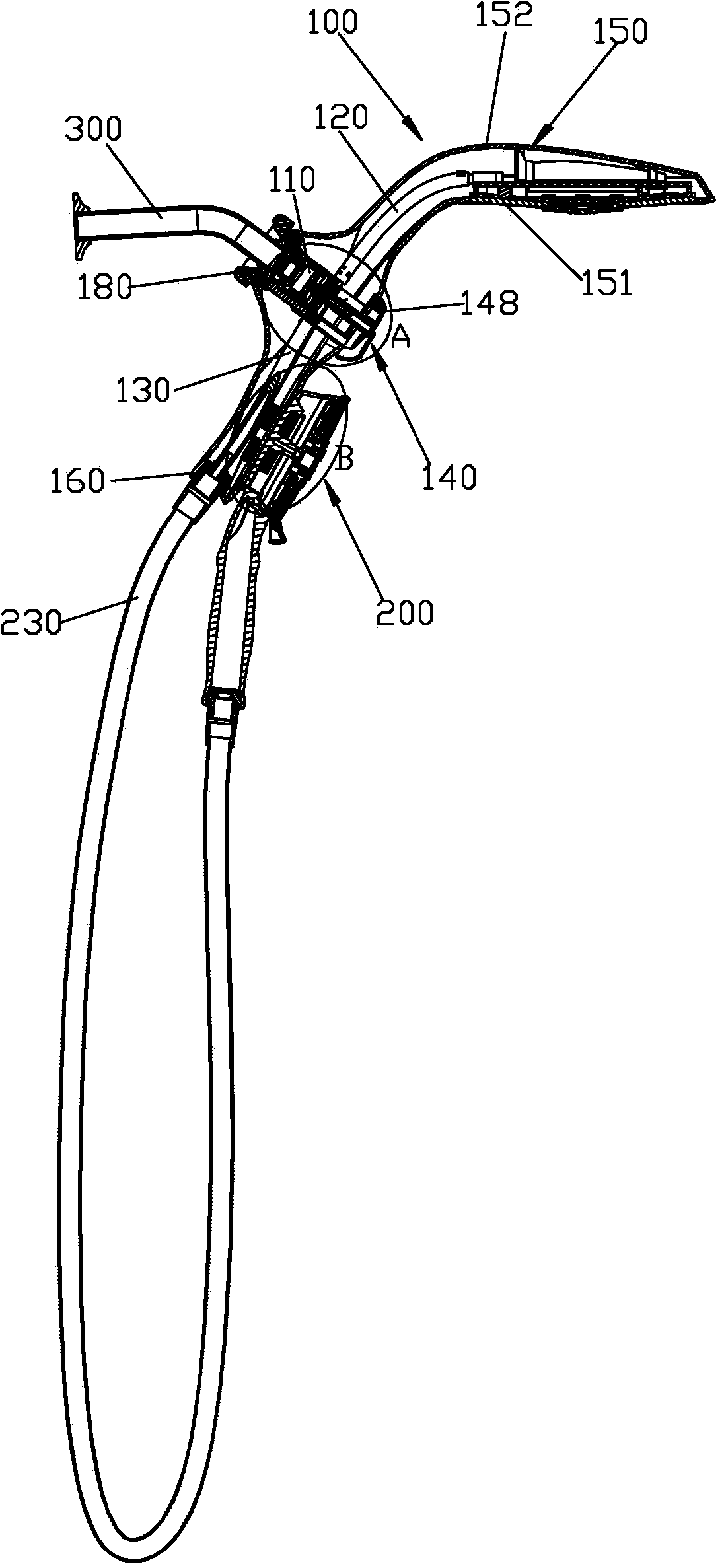

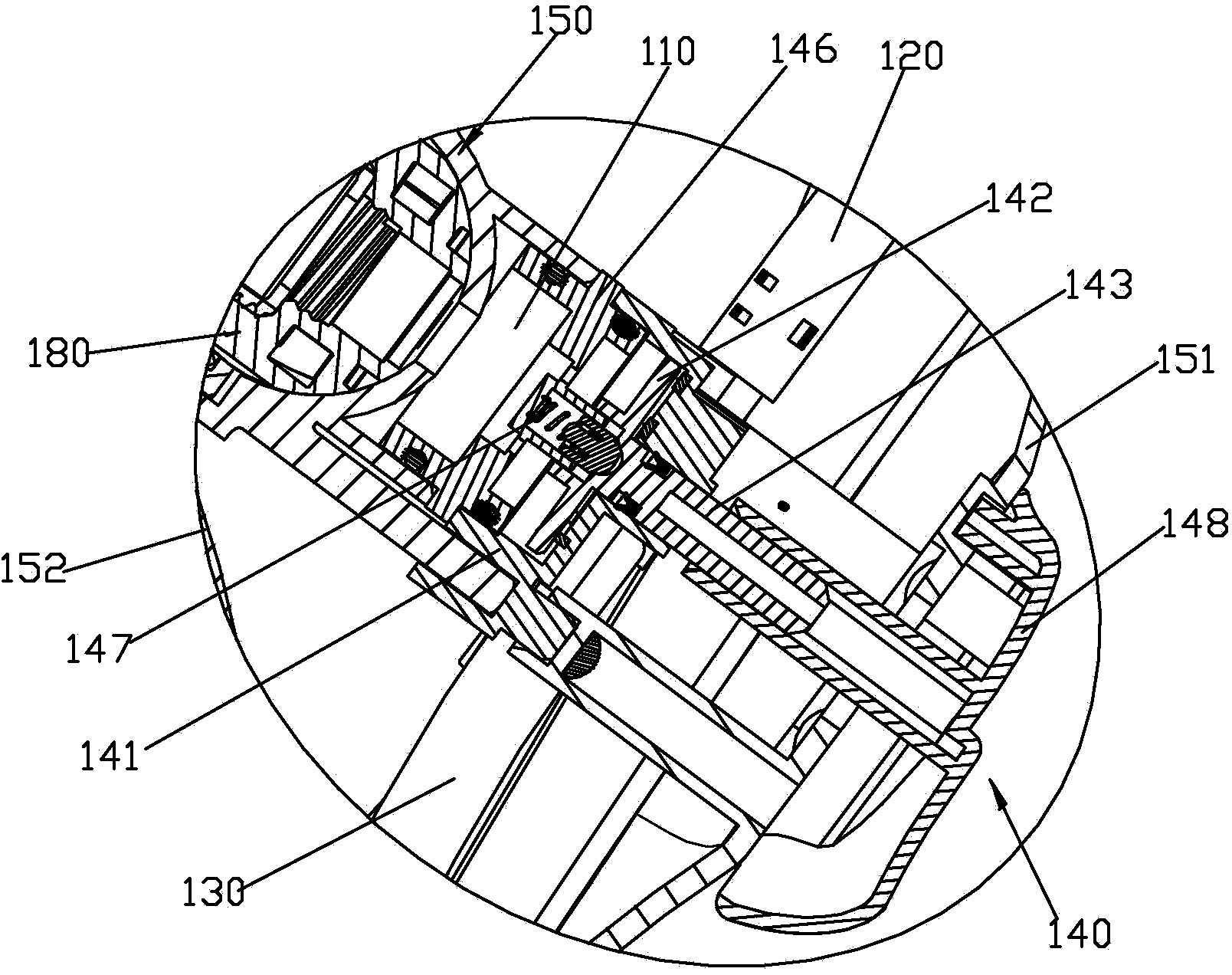

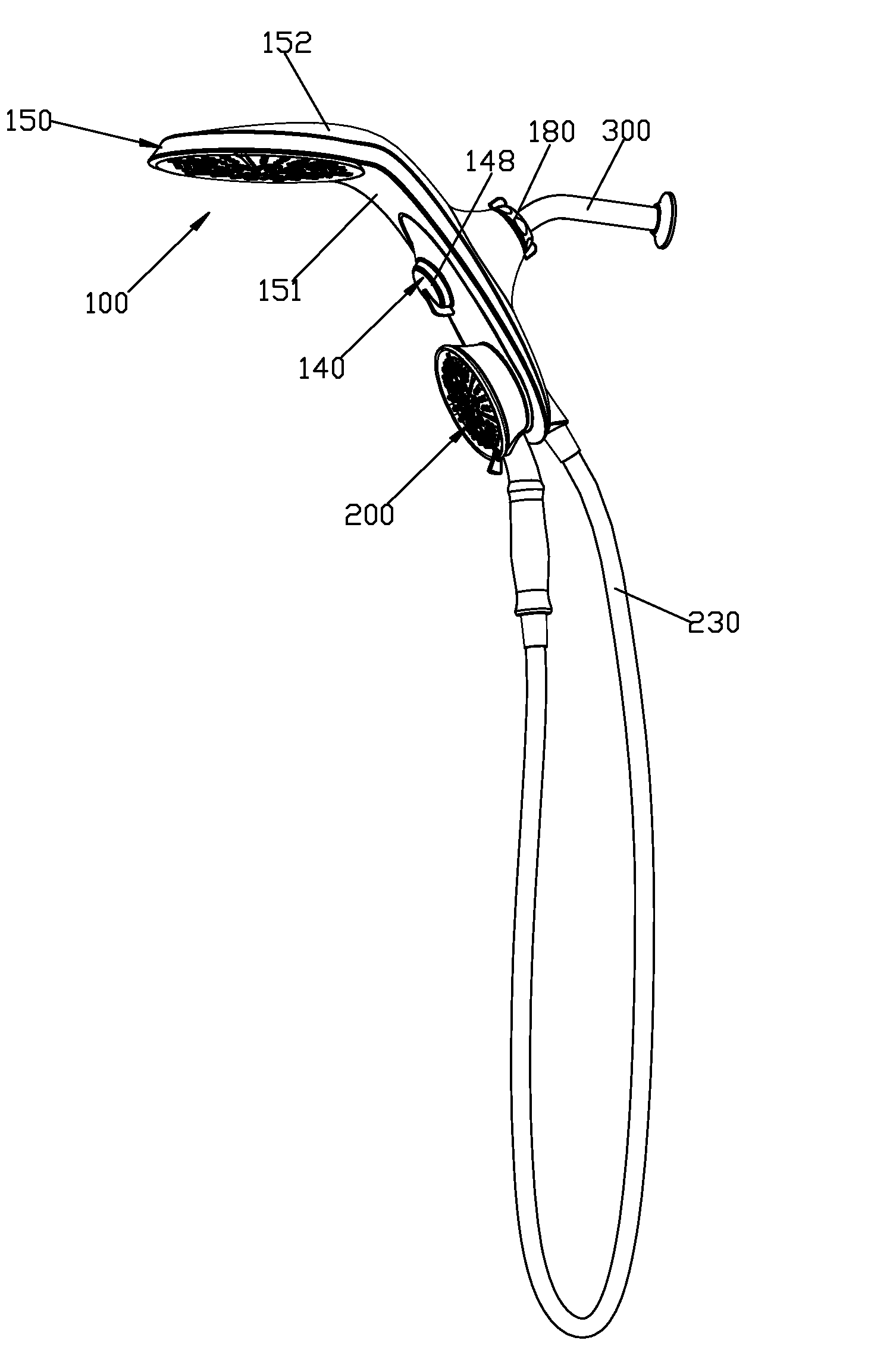

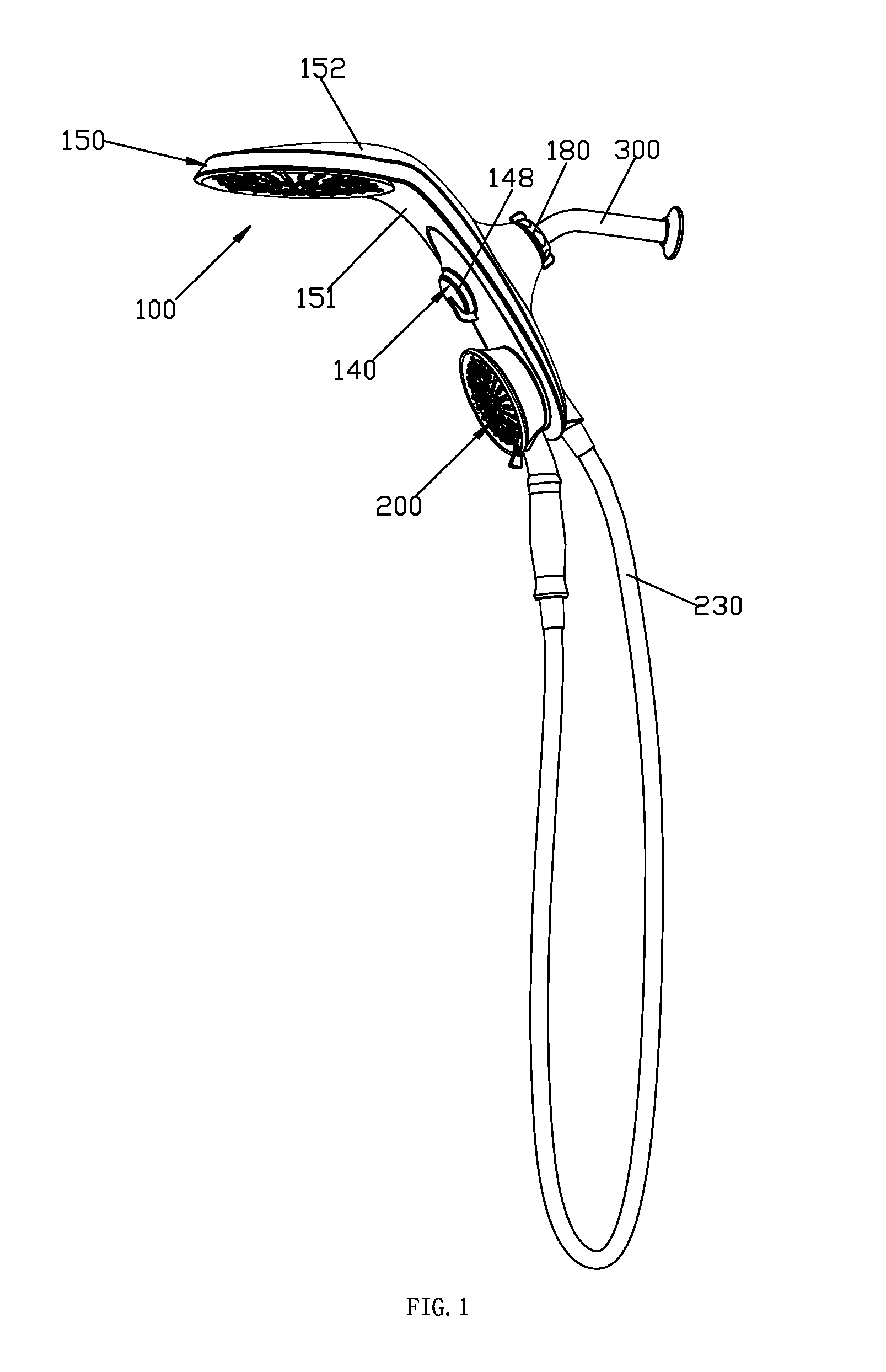

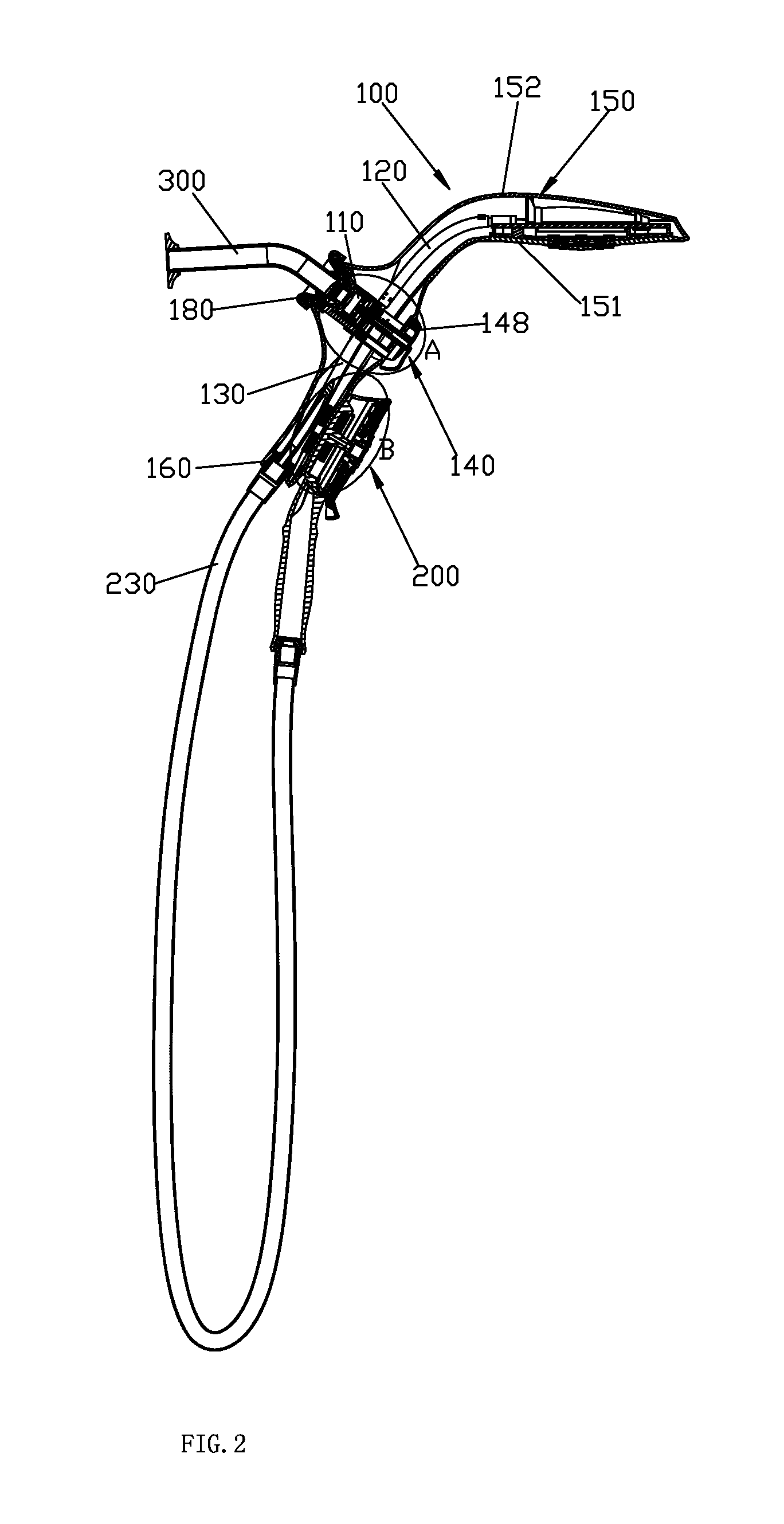

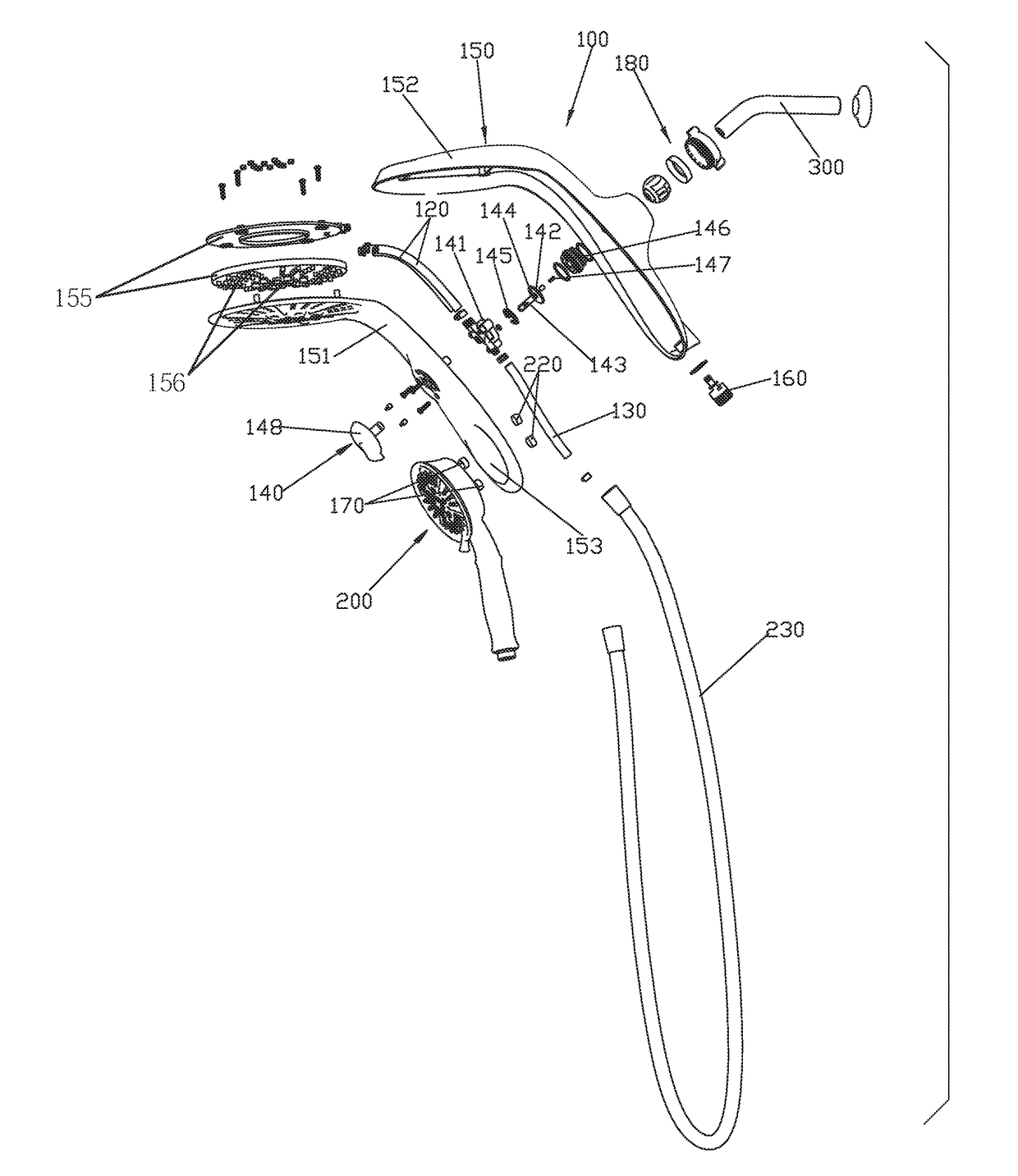

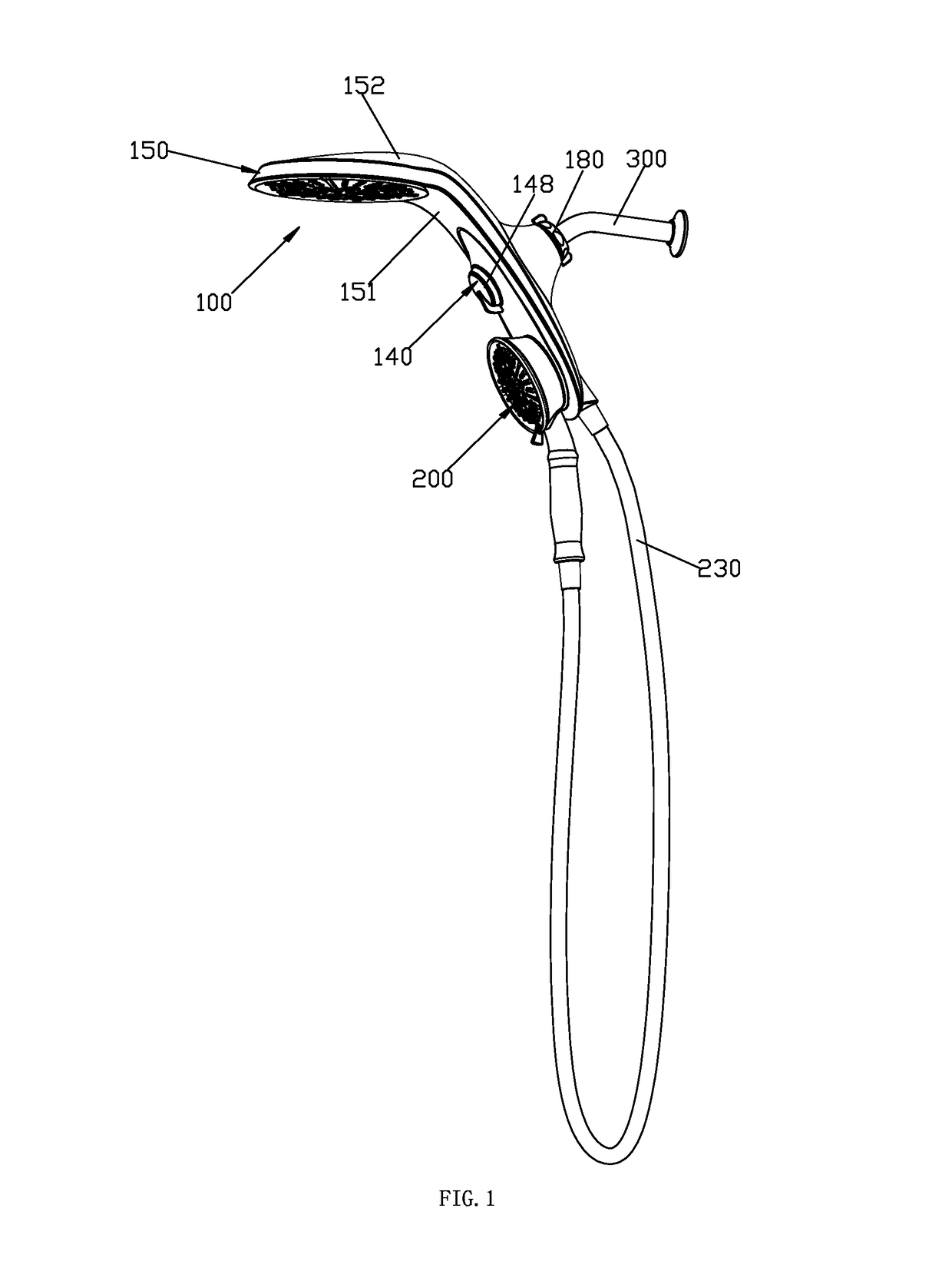

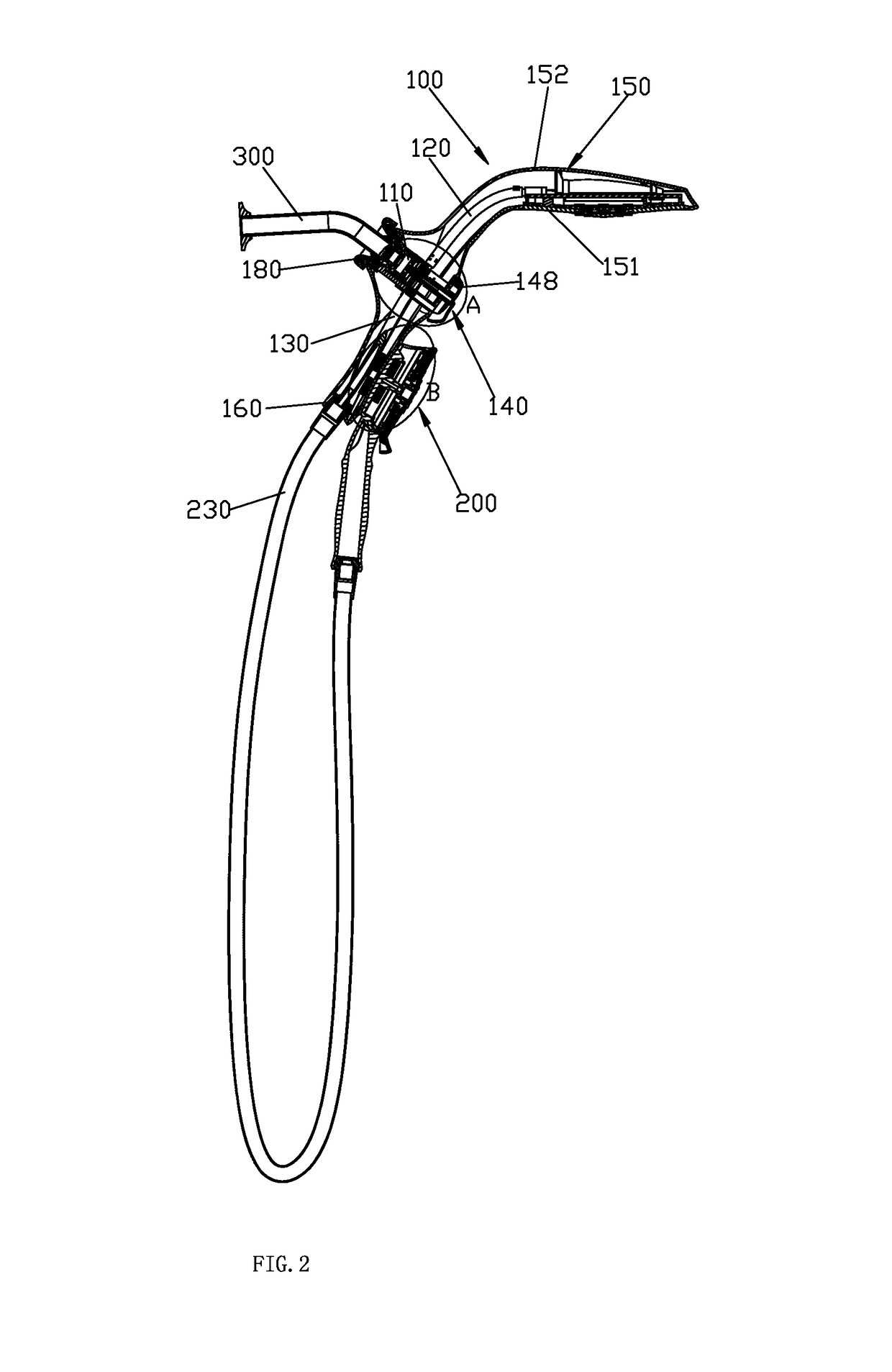

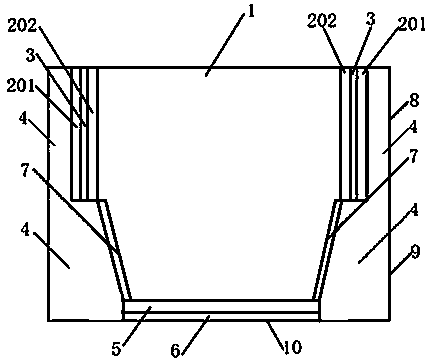

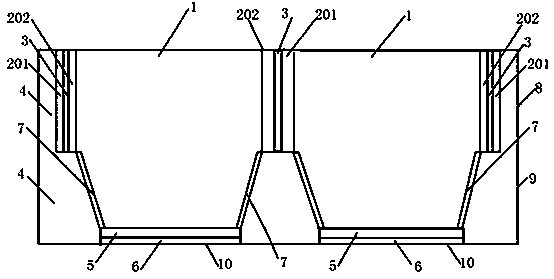

Shower system with combination of overhead shower and handheld shower

The invention discloses a shower system with combination of an overhead shower and a handheld shower. The shower system comprises the overhead shower which can spray water in at least two ways and the handheld shower. The overhead shower is provided with a water inlet passage communicated with a water supply source and a first water distributing passage in one-to-one correspondence with each way of water spray. The overhead shower is further provided with a second water distributing passage. The handheld shower is communicated with the second water distributing passage through an outer hose. A switching mechanism is disposed at the overhead shower. Water passage switching can be achieved by the switching mechanism in coordination with the water inlet passage, the first water distributing passage and the second water distributing passage. The optional water distributing passage can be selected to be communicated with the water inlet passage through water passage switching. The shower system has the advantages that water spray ways of the overhead shower can be selected through the switching mechanism, overall cost is lowered greatly, and the shower system is convenient and fast in switching, simple in overall structure, and outstanding in style.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

Bronzing pulp and preparation method thereof

ActiveCN103255646ARich styleRich wash fastnessTransfer printing processDyeing processWater basedSolvent

The invention discloses bronzing pulp. The bronzing pulp is prepared from the following raw materials in parts by weight: 60-80 parts of acrylic ester emulsion, 2-6 parts of deionized water, 3-10 parts of a solvent, 1-5 parts of a stabilizer, 10-20 parts of EVA (Ethylene-Vinyl Acetate) hot melt adhesive powder, 0.5-3 parts of silica, 0.2-0.5 part of a polyurethane defoaming agent, 0.1-0.5 part of a pH regulator, 0.1-0.2 part of a preservative, 0.3-1 part of an emulsion wetting agent and 0.4-2 parts of a thickener. The bronzing pulp has the beneficial effects that the bronzing pulp is water-based pulp, the raw materials are easy to obtain and environment-friendly, the production is convenient, the technology is mature, and substances harmful to the environment can not be produced; and the bronzing pulp is soft in handfeel, firm in fastness, outstanding in resistance to tension fracture and diversified in application mode, enriches the styles of textiles, and endows the textiles with the noble quality.

Owner:GUANGZHOU SHENGQIN IND

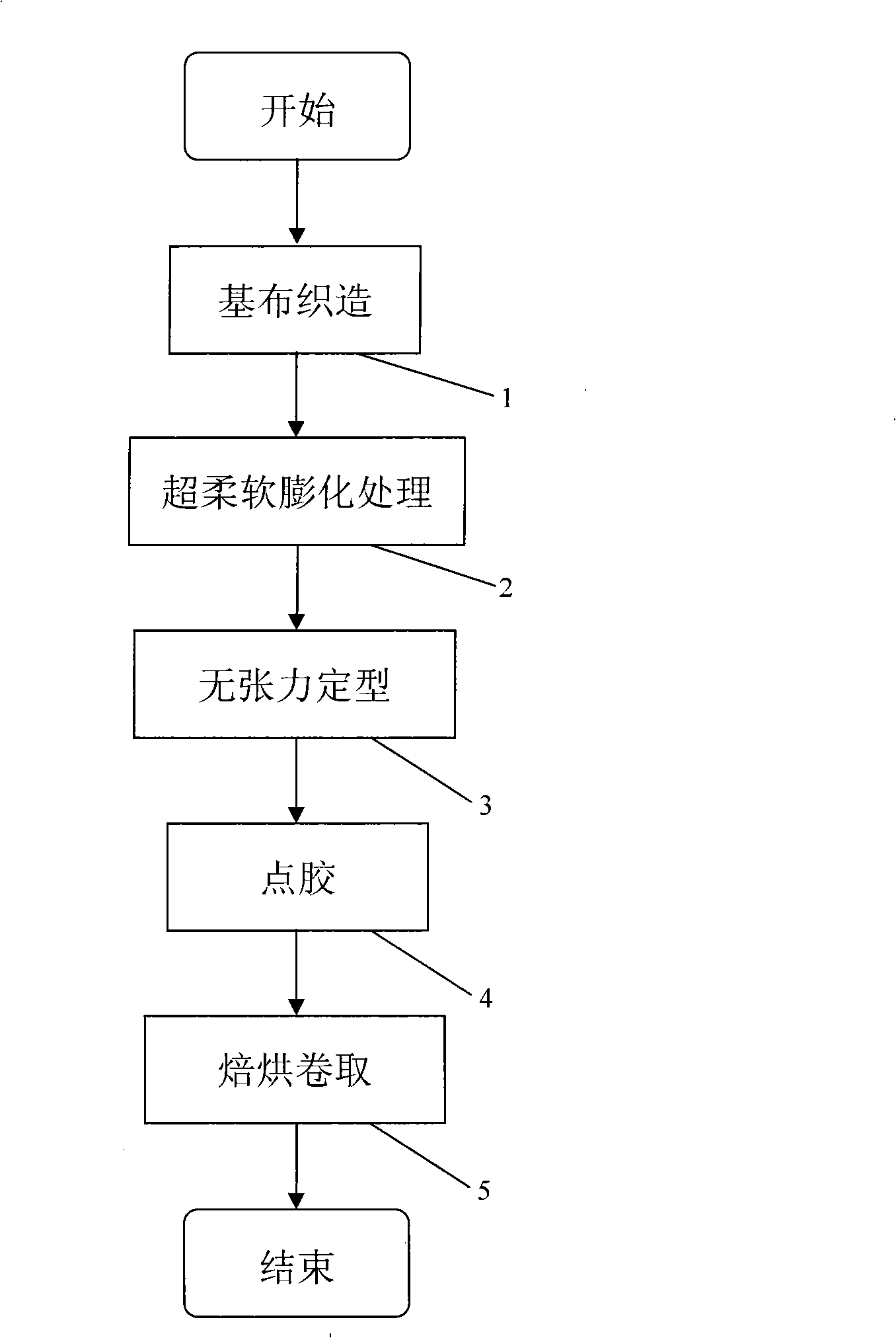

Technique for preparing bonding fabric

The invention discloses a production technology of adhesive interlining, which sequentially includes the steps of basic fabric weaving, super-soft swelling treatment, tension-free shaping, gluing, baking, rolling, etc. The super-soft swelling treatment is conducted to the basic fabrics and dual point coating is adopted; powderless basic pulp is adopted as underside pulp and super-low temperature modified nylon PA glue is adopted as the surface glue. The super-soft swelling treatment can soften and loosen the fibers, thus gaining the soft effect. A high-mesh coating adopted can solve not only the problem of handfeel but also the problem of the partial glue seeping; the ironing temperature of the adhesive interlining is only 90 DEG C to 120 DEG C, thus effectively remaining the style of the fabrics. The interlining is particularly soft in handfeel and has excellent elasticity. The products are mainly applied to various thin elastic clothes. The clothes selecting the interlining are voluminous, smooth, beautiful and comfortable and can eliminate 'ripple ring' appearing in super-thin Lycra fabrics after the ironing and realize the texture of transparence and integrating with the fabric.

Owner:ZHEJIANG KINGSAFE INTERLINING

Method for brewing longan-fructus momordicae fruit wine

InactiveCN101602993AFull tasteDelicate tasteMicroorganism based processesAlcoholic beverage preparationThroatFruit wine

The invention discloses a method for brewing longan-fructus momordicae fruit wine, which is nutrient fruit wine brewed by using longan and fructus momordicae as main raw materials and adopting biological enzymolysis and low-temperature microbe fermentation. The wine combines the longan and the fructus momordicae which are two health-care invigorants rewarded by past doctors; and based on the drug-food advantages of the longan and the fructus momordicae, the method fully extracts effective components beneficial to the human body, increases a fermentation product and enlarges the prior nutrient efficacies of the longan and the fructus momordicae. The brewed longan-fructus momordicae fruit wine has full, exquisite, compatible and full-bodied mouth feel, has typical remarkable style, is a good product in wine beverage, has high nutrient and medicinal value, and has the functions of the longan for tonifying heart and spleen and nourishing qi and blood and the functions of the fructus momordicae for clearing heat and nourishing lung, relieving cough, nourishing throat, lubricating intestines and relaxing the bowels. The fruit wine overcomes the defects that the effective components of the steeping wine are not fully extracted, the steeping wine has single mouth feel, crude lees and the like, and is suitable for various groups of people.

Owner:叶长东

Shower system combining a top sprayer and a hand shower

A shower system includes a top sprayer with at least two water types and a hand shower. The top sprayer is disposed with an inlet waterway to connect to the water source and first diversion waterways corresponding to the water types one by one; wherein the top sprayer is further disposed with a second diversion waterway, the hand shower is connected to the second diversion waterway by an external flexible pipe; the top sprayer is disposed with a switch mechanism, the switch mechanism is cooperated to the inlet waterway, the first diversion waterways and the second diversion waterway to switch the waterways, thus switching any diversion waterway to connect to the inlet waterway.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

Sesame flavor and sauce flavor type liquor production technology

InactiveCN103740522ASuitable for improvementQuality improvementAlcoholic beverage preparationBiotechnologyCorn flour

The invention relates to a sesame flavor and sauce flavor type liquor production technology which is shown as follows: S01, using artificial old wine-wault mud for laying a 20cm thick substrate at a cement pool bottom; S02, taking 19 to 48 parts by weight of sorghum, 4 to 11 parts by weight of wheat, 3 to 8 parts by weight of rice, 2 to 4 parts by weight of corn powder for crushing into four-six petals, then adding 2 to 4 parts by weight of wheat bran; S03, using 80 DEG C hot water to moisten the materials to enable the moisture content of the mixed raw materials to be 50-60%; S04, steaming the materials for 50 to 60 minutes under the steam pressure of 0.1-0.2MPa and at the temperature of 100-110 DEG C; S05, adding 12-32 parts by weight of sesame flavor liquor special yeast for high temperature stacking for 1-2 days with the temperature of 45-50 DEG C, and stacking into a long strip shape; S07, fermenting in a cement pool of the step S01 with the fermentation temperature of 40-45 DEG C and the fermentation time of 30-60 days; S08, distilling and collecting liquor in sections; S09, storing; and S10, scientifically blending into finished liquor. The invention discloses the production technology for brewing the sesame flavor and sauce flavor type liquor with stable product quality and mellow taste by use of a sauce flavor type cement pool.

Owner:HENAN FUTAN WINE

Method for brewing longan Chinese-wolfberry nutritive fruit wine

InactiveCN101649270AFull tasteDelicate tasteMicroorganism based processesAlcoholic beverage preparationFruit wineMicroorganism

The invention discloses a method for brewing a longan Chinese-wolfberry nutritive fruit wine. Longan and Chinese wolfberry are used as the main raw materials, and proper amounts of auxiliary materialsare added in the preparation process so as to brew the nutritive fruit wine by biological enzymolysis and microorganism low-temperature fermentation. The method uses longan and Chinese wolfberry, which can be used as both medicines and food, as the raw materials, completely extracts effective components which are beneficial to human bodies, increases the fermentation products and enhances the nutritive effect. The longan Chinese-wolfberry fruit wine is rich and delicate in mouth feel and has a typical outstanding style, thereby being an ideal inebriant drink. The method overcomes the defectsof bad mouth feel, incomplete extraction of effective components, and the like. The nutritive fruit wine has the advantages of low cost, high added value, high nutrition and high medical value, is suitable for various people to improve the health and build up the body, and make due contributions to the development of deep processing of farm produces.

Owner:叶长东

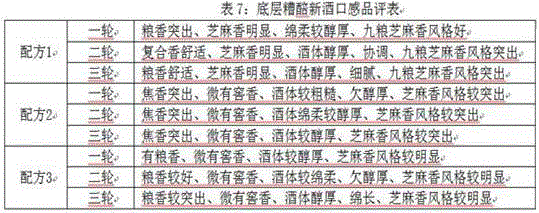

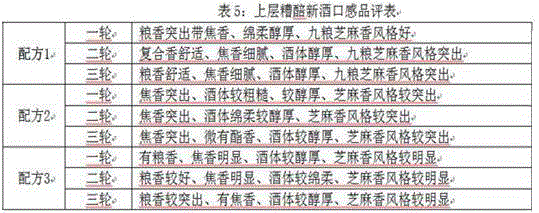

Production process of nine-grain sesame-flavor liquor

InactiveCN105543044AOutstanding styleDelicate and pleasant tasteAlcoholic beverage preparationPolygonum fagopyrumFlavor

A production process of nine-grain sesame-flavor liquor comprises steps as follows: nine raw materials including 48% of sorghum, 12% of wheat, 2% of Agriophyllum squarrosum, 14% of rice, 5% of glutinous rice, 5% of corn, 7% of bran, 5% of tartary buckwheat and 2% of mung beans are uniformly mixed and then wetted, the materials are wetted three times in 2 hour, and the temperature of water for wetting the materials is 90 DEG C; sauced fermented grains fermented for nine rounds and separated from liquor are uniformly mixed with scented fermented grains obtained after liquor taking in proportion, the nine wetted raw materials are added in the ratio of grains to fermented grains, turned three times and then put on a steamer after being uniformly turned, the raw materials are taken out of the steamer after being steamed for 1.5 h under the pressure of 0.16 MPa, white koji, high-temperature koji, medium-temperature koji, bacterial koji and aroma-producing yeast are added and stacked for 36-42 hours when the temperature is decreased to 35 DEG C, the fermented grains are rapidly cooled to 35 DEG C when the temperature is increased to 43-45 DEG C, 5% of highly-flavored type double-bottom-fermented grains which are fermented for 180 days and not separated from liquor are rapidly added in the cooling process, and the mixture is uniformly mixed and put in a cellar. The nine-grain sesame-flavor liquor produced through mixing with the production process of the nine-grain sesame-flavor liquor tastes particularly soft and fine, has a very unique flavor and has a very rich composite grain flavor.

Owner:GANSU BINHE FOOD IND GRP

Highly-flavored liquor production method capable of reducing extruded waste vinasse residual starch

ActiveCN102787040AReduce residue contentRich cellar aromaAlcoholic beverage preparationLeesYield (wine)

The present invention discloses a highly-flavored liquor production method capable of reducing extruded waste vinasse residual starch. The method comprises processes of: stripping a pit to take vinasse out of the pit; preparing vinasse and mixing; carrying out wine obtaining grain steaming; preparing nutrition vinasse; inoculating vinasse and culturing; preparing surface vinasse; splashing water and adding distiller's yeast powder; transferring to the pit; and carrying out pit sealing fermentation. With the method of the present invention, the extruded waste vinasse residual starch content issignificantly reduced to 2-5%, and waste lees can be prepared without secondary fermentation so as to significantly reduce production cost; the upper layer vinasse with poor quality can be changed into the surface vinasse, then changed into the extruded waste vinasse, and finally changed into the waste lees in each turn of the method, and the lower layer vinasse can be continuously adopted as thegrain vinasse to enter the pit so as to improve vinasse quality and wine quality; use amount of bran hulls, water and other ingredients between retorts are regular; acidity of the vinasse entering the pit, starch content, and water content of the vinasse are easily grasped; quality product rate and wine yield of the whole pit output are respectively increased by 0.5-1%; and the method has characteristics of simple process, easy operation, no addition of production equipment, and good quality of produced wine, and provides a reliable guarantee for promotion and application of highly-flavored liquor production enterprises.

Owner:SICHUAN TUOPAI SHEDE WINE

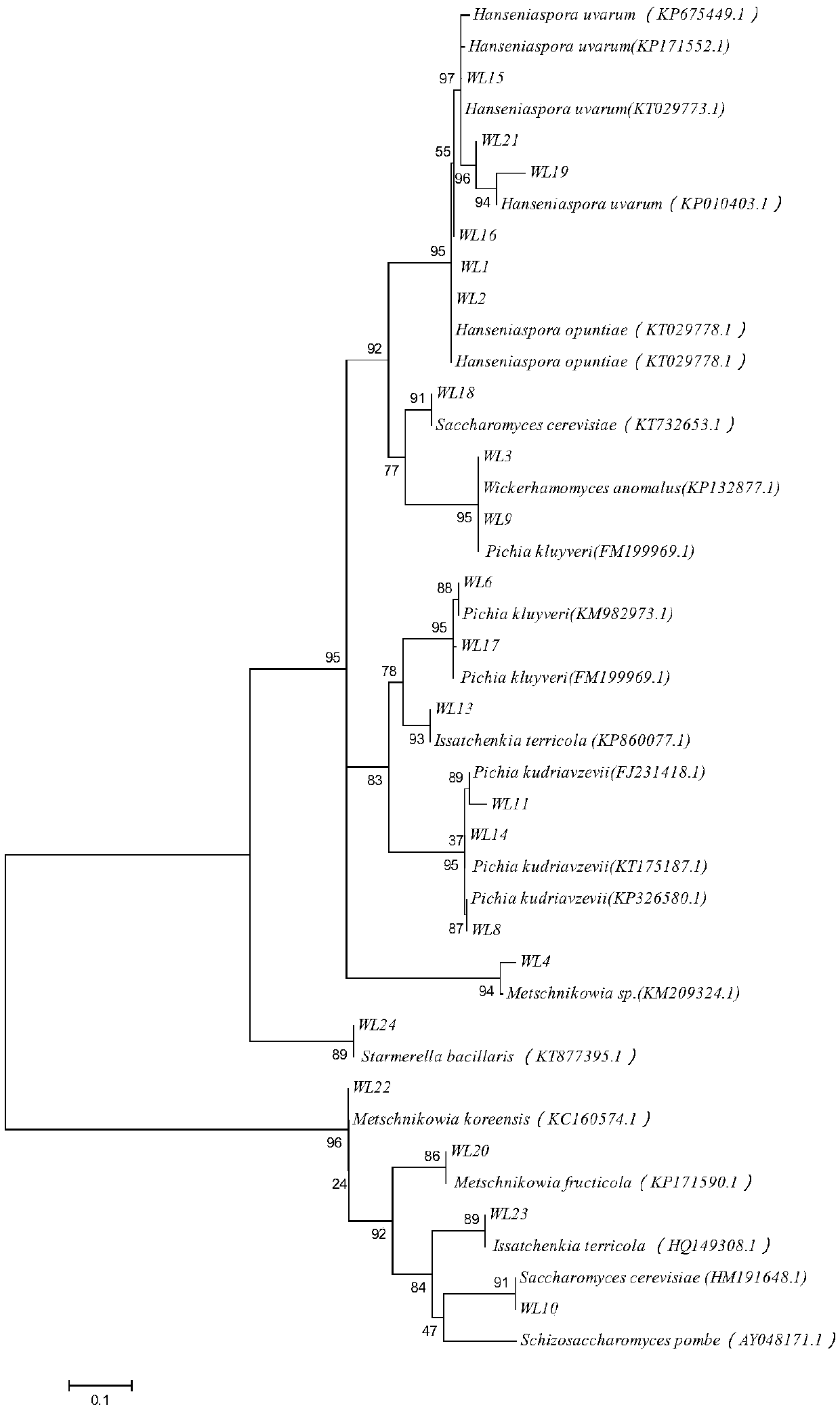

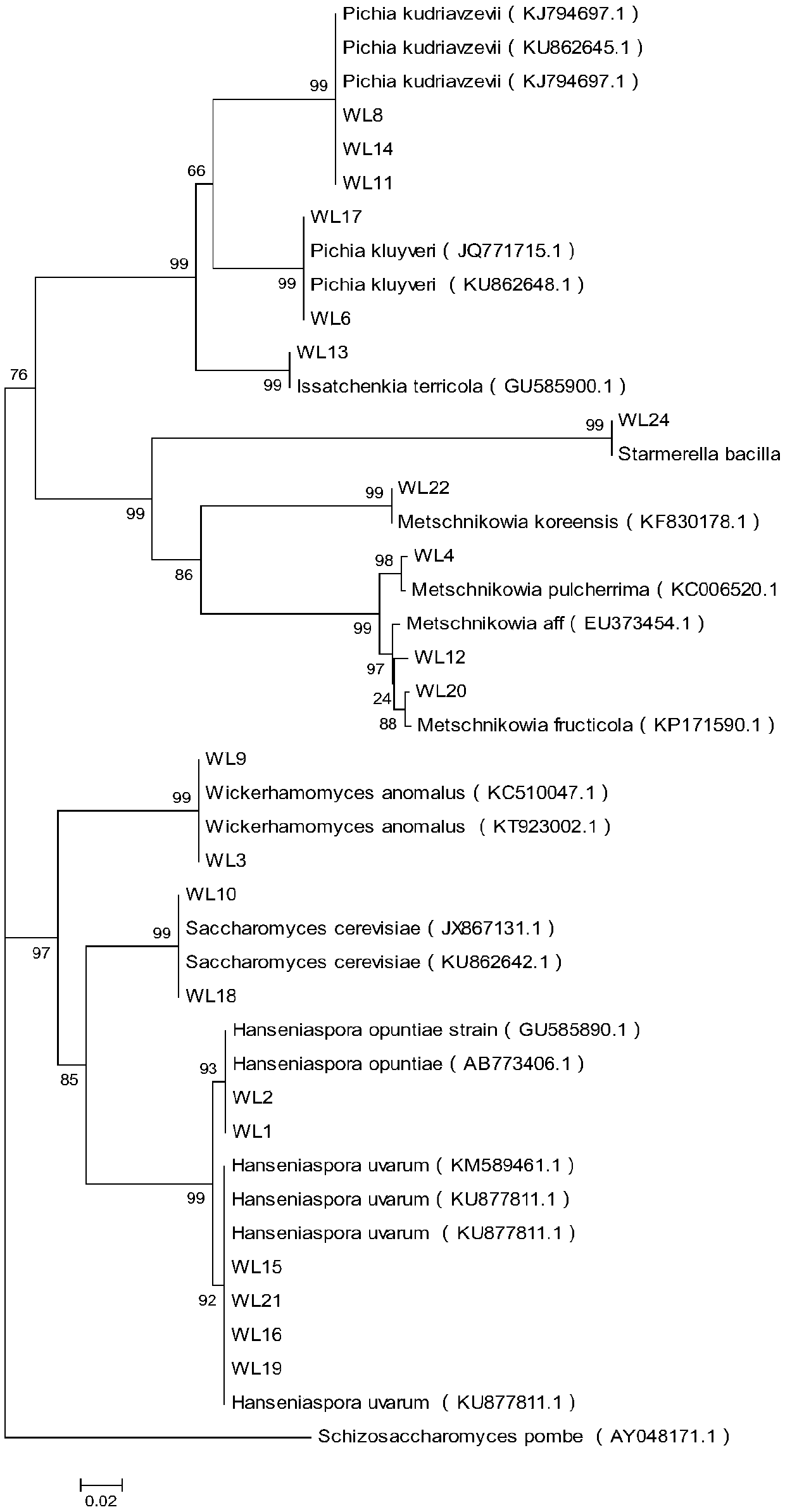

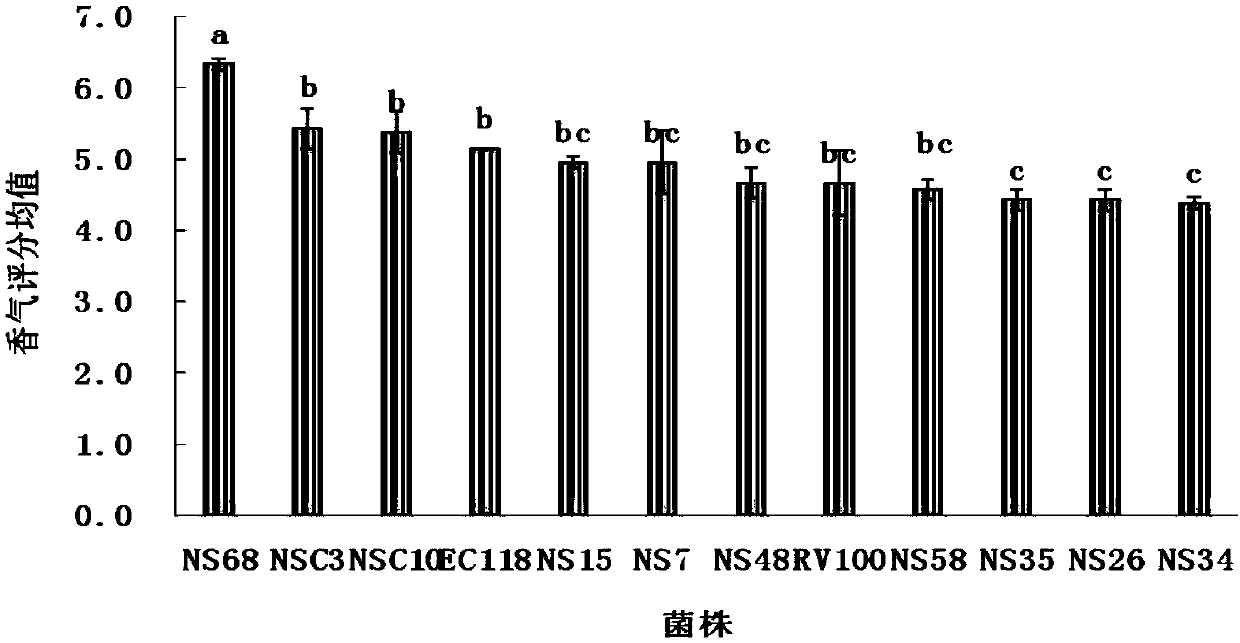

Composite fermentation group agent and application thereof in brewing cabernet sauvignon straw wine

ActiveCN109097291ARich layersHelps to enhance fragranceFungiMicroorganism based processesFermentation brothBrewing

The invention discloses a composite fermentation group agent and an application thereof in brewing a cabernet sauvignon straw wine. A non-saccharomyces cerevisiae Pichia kudriavzevii F0-N475-5 is obtained by separating, sampling, cultivating and screening from a wine early fermentation liquor from a brewing location in Shihezi area in Xinjiang; the prepared non-saccharomyces cerevisiae F0-N475-5 secondary fermentation liquor and the S.cerevisiae GTGM-E2 secondary fermentation liquor are mixed in the ratio of 1:1. The prepared composite fermentation group agent is applied to fermentation of thesouth Xinjiang cabernet sauvignon straw wine with complex taste, prominent layering, rich and complex fragrance, elegant and delicate taste, long aftertaste, harmonious aroma and taste, excellent overall quality and outstanding style. The single style of relying on active dry yeast fermentation of the wine is broken through, and remarkable good technical effects are achieved.

Owner:TARIM UNIV

Deodorization fabric

ActiveCN105040406AGood thermoregulation effectOutstanding styleWoven fabricsVegetal fibresFiberGraphene

The invention relates to a deodorization fabric. The deodorization fabric is formed by interweaving graphene modified composite fiber warps and shaping wefts, wherein composite fibers are woven by aupoz fibers, cotton fibers and silver fibers, and the outer surface of the fabric is coated with nano-zinc oxide and nano-titanium dioxide coatings. The deodorization fabric is low in cost, cloth produced by using the deodorization fabric has excellent temperature adjusting effect, and the deodorization fabric can be used for producing carpets, clothes, shoes, socks and the like, has deodorization and fungi-proofing functions and is in an excellent style.

Owner:吴江市孚华纺织品有限公司

Method for producing huang ginseng liquor

ActiveCN102796644AReduce exposureAvoid infectionAlcoholic beverage preparationBiotechnologyPlant roots

The invention discloses a method for producing a huang ginseng liquor, which takes huang ginseng as a raw material, takes self-made yeast as a saccharification and leavening agent, is prepared by solid fermentation, storage and blend, and is a compound aroma distilled liquor. The method takes a wild plant root system-huang ginseng as the raw material to make the liquor, i.e. the 'golden ginseng liquor' which is produced by a company, not only is grain saved, but also the liquor is rich in nutrition, so a user can enjoy the green, environmental-friendly and healthy food, and furthermore, the blank of the traditional technological brewery industry is made up.

Owner:SHANDAN LANCHI FOOD CO LTD

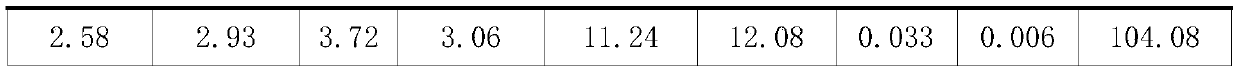

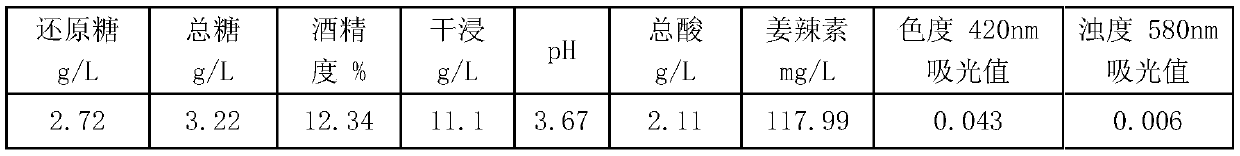

Method for brewing dry type ginger brewed wine

ActiveCN105505686AFresh aromaFruity bouquetMicroorganism based processesAlcoholic beverage preparationFiltrationTurbidity

The invention relates to the technical field of wine brewing, and particularly discloses a method for brewing a dry type ginger brewed wine. The method comprises the steps of raw material cleaning, breaking and pulping, squeezing and juice extraction, enzymolysis, adjustment, canning, yeast inoculation, yeast nutrient salt adding, temperature controlled fermentation, main fermentation endpoint control, wine pouring and after fermentation, secondary wine pouring, aging, clarification, filtration and filling. Laiwu yellow ginger is taken as the main raw material, pulping, squeezing and enzymolysis are conducted to generate pure ginger juice, fermentation is conducted with active dry yeast, and after clarification and filtration are conducted with an egg white powder and bentonite mixed clarifying agent, the dry type ginger brewed wine which has a fresh fragrance and the alcohol concentration of 11-13% is prepared. The dry type ginger brewed wine is rich in hygiene factors in yellow ginger, meets the consumption requirement of modern people for mild fermented wine, and solves the problems of hard clarification and post turbidity of finished wine caused by high content of macromolecule substances such as protein and starch in ginger.

Owner:SHANDONG AGRICULTURAL UNIVERSITY +1

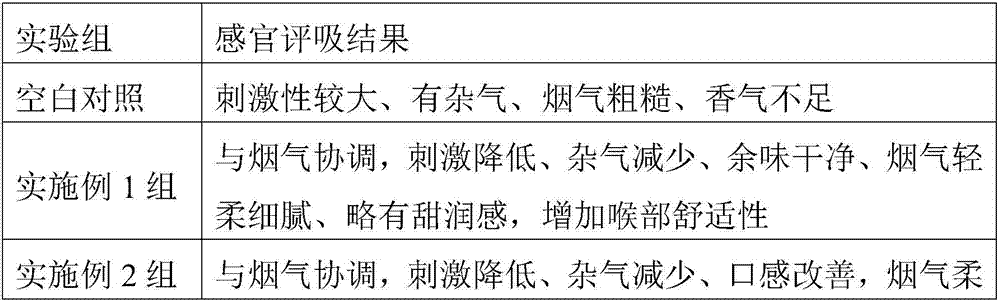

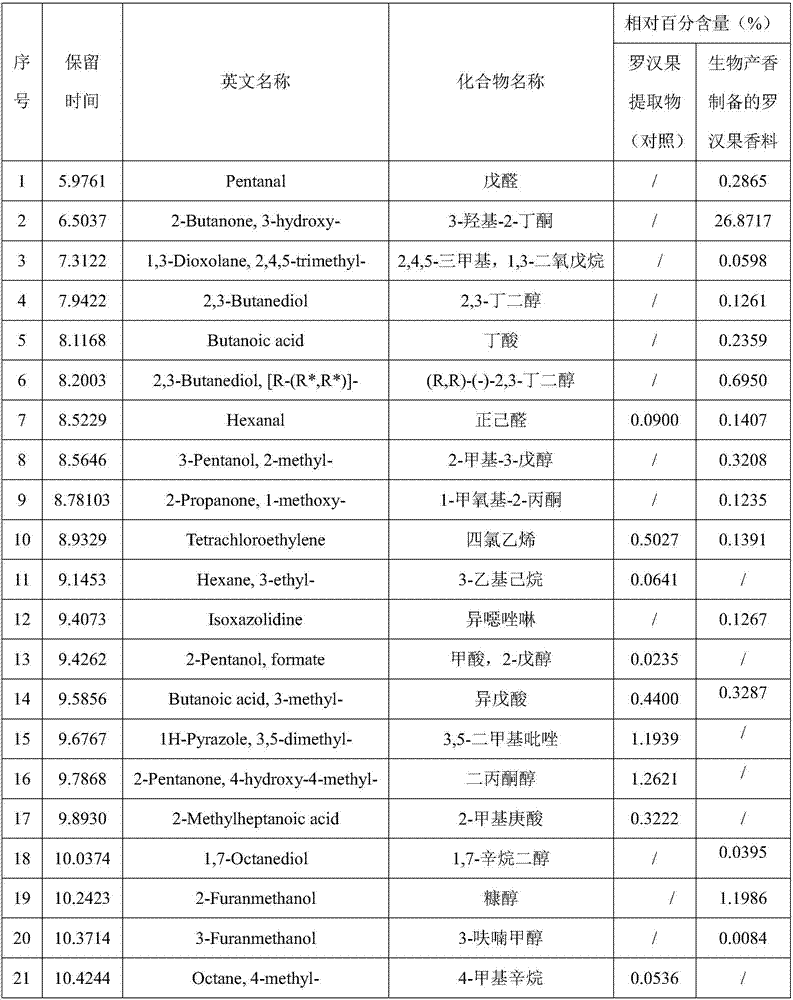

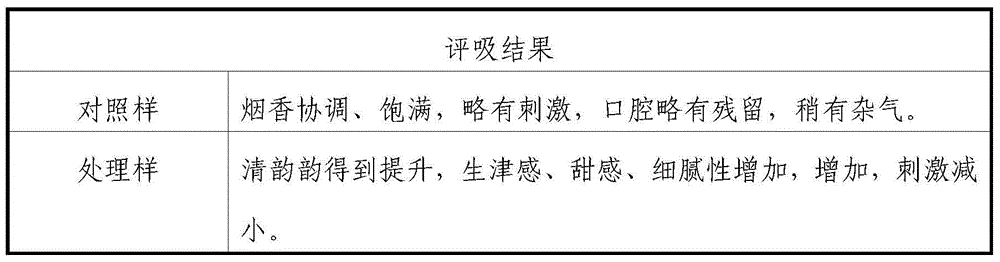

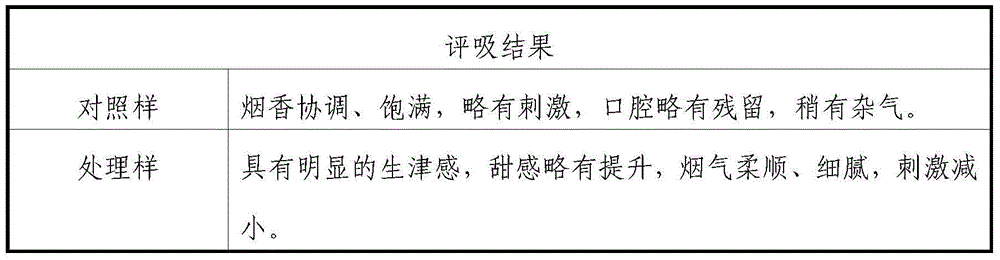

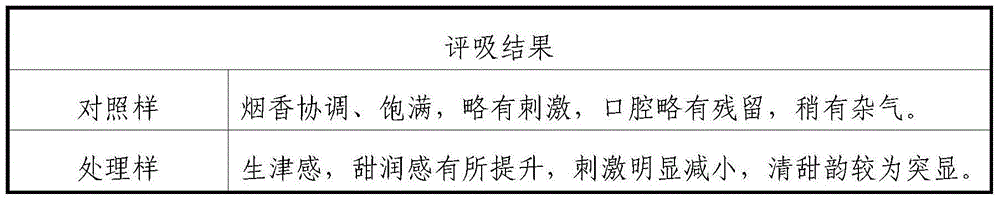

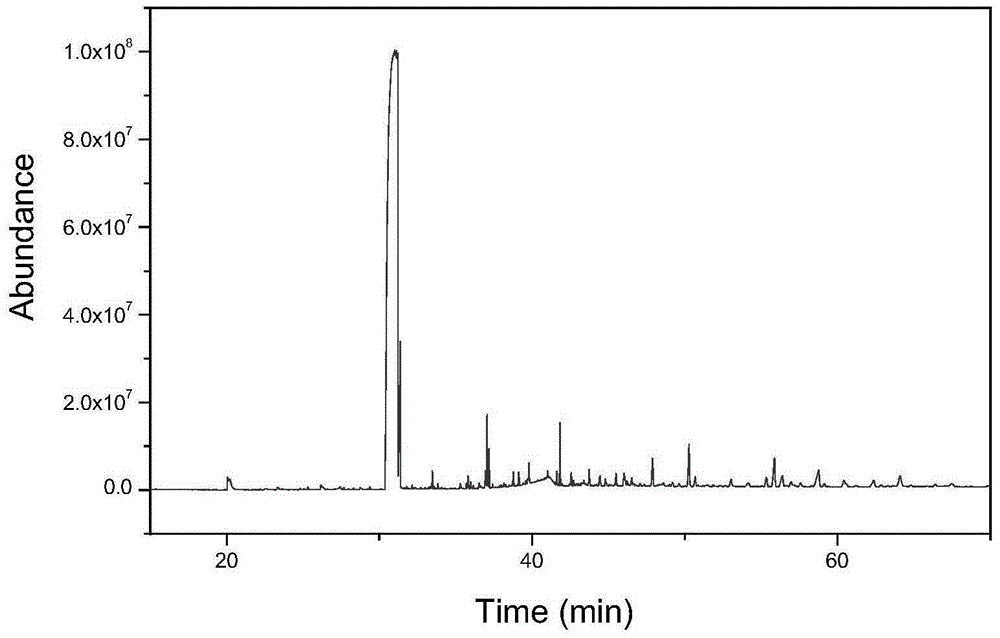

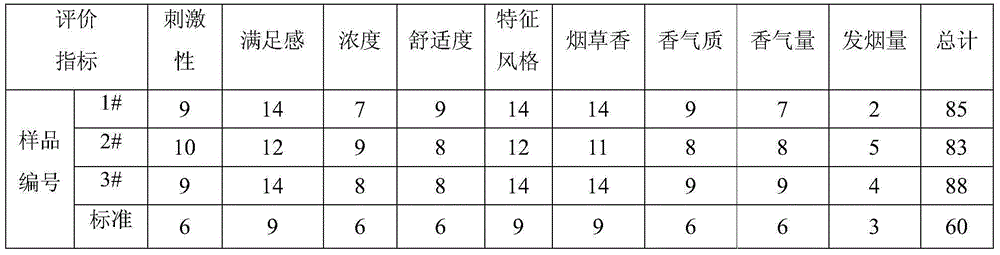

Method for preparing momordica grosvenori spice by means of biological aroma-producing, and application of momordica grosvenori spice

InactiveCN106929536AImprove the quality of cigarette aromaReduce irritating ingredientsTobacco preparationMicroorganism based processesIrritationMacromolecular Substances

The invention provides a method for preparing momordica grosvenori spice by means of biological aroma-producing, and application of the momordica grosvenori spice. The method comprises the steps of firstly, extracting effective components of momordica grosvenori by carrying out water solution reflux on the momordica grosvenori; then, carrying out fermentation by using an aroma-producing strain-Raoultella planticola VP4-4 under the condition that momordica grosvenori extract is taken as substrate, and degrading and converting the macromolecular substances in the momordica grosvenori extract so as to generate micromolecular aroma substances, reduce stimulating components, enrich the aroma and improve aroma quality; when being applied to cigarettes, the momordica grosvenori spice is harmonious with smoke, reduces the smoke irritation, enriches cigarette fragrance, enables the smoke to be sweet, improves cigarette fragrance quality and highlights the style characteristics of Yellow Crane Tower brand cigarettes; the method provided by the invention overcomes the defects that the momordica grosvenori extract is high in irritation, thick in offensive odor and not clear in aftertaste.

Owner:HUBEI CHINA TOBACCO IND

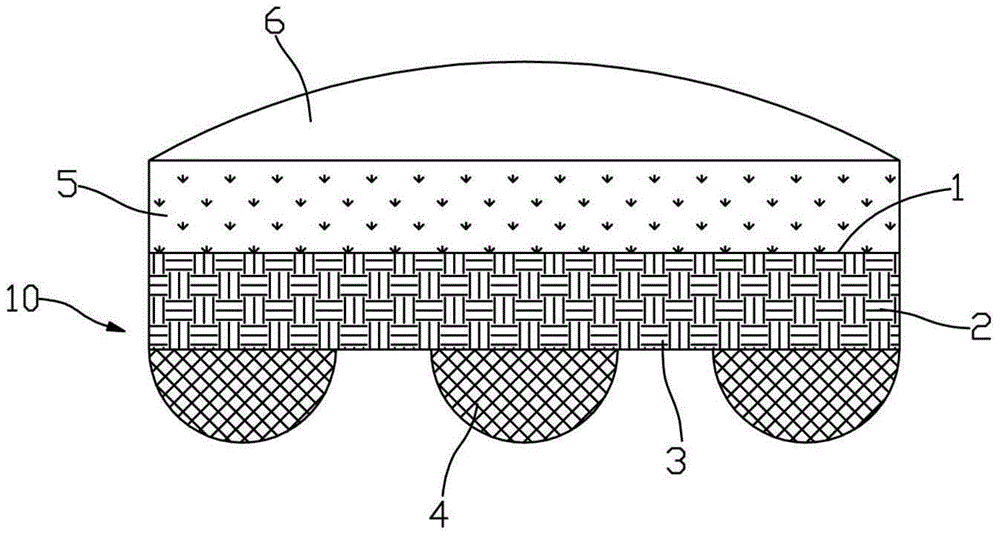

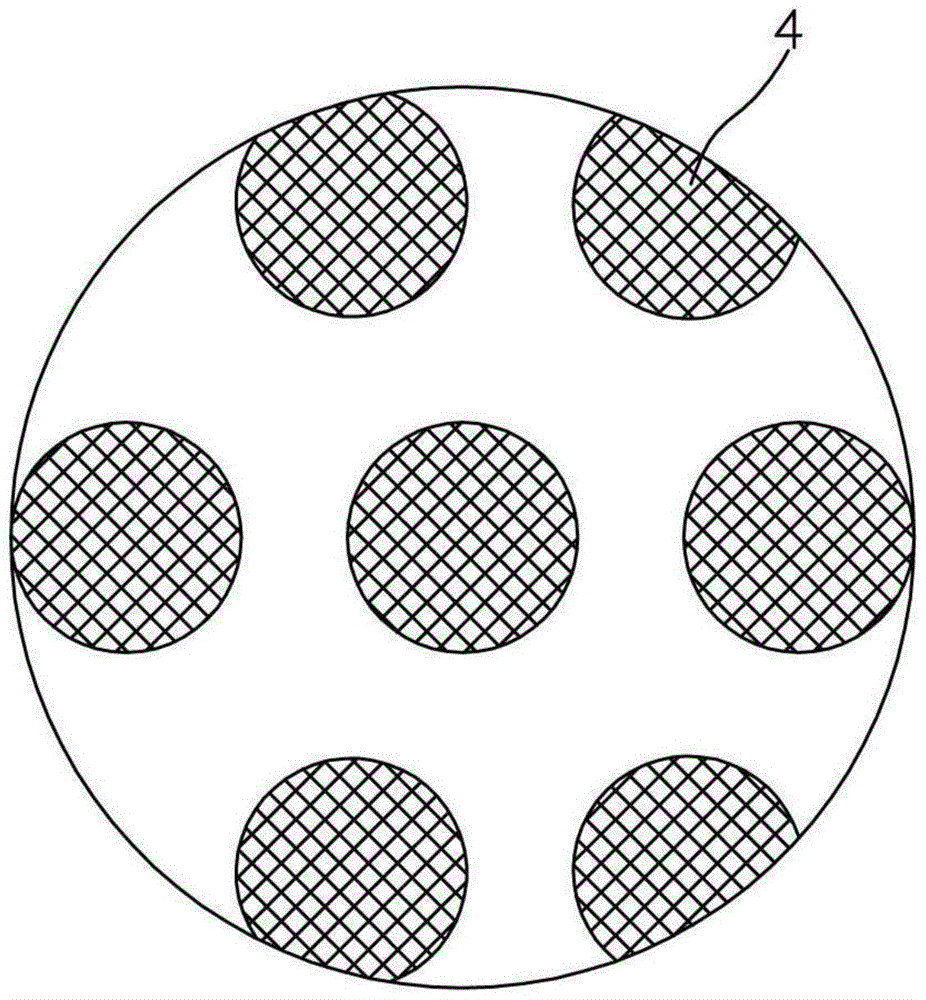

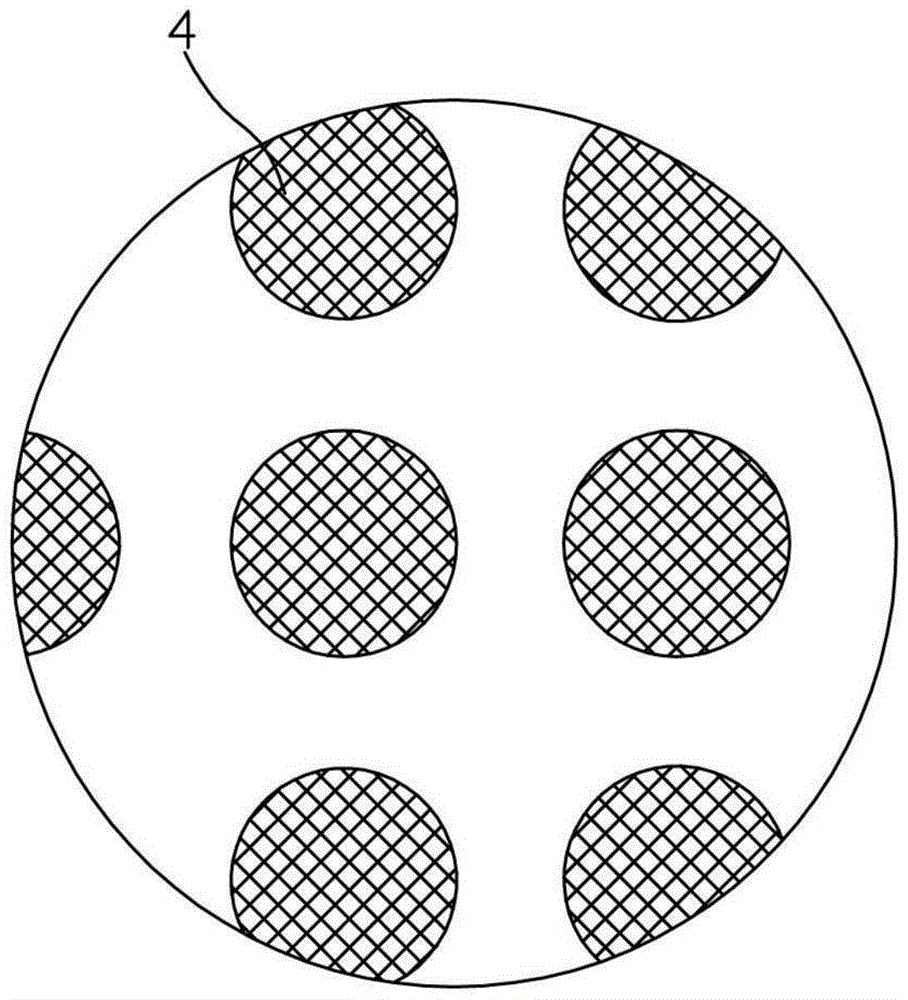

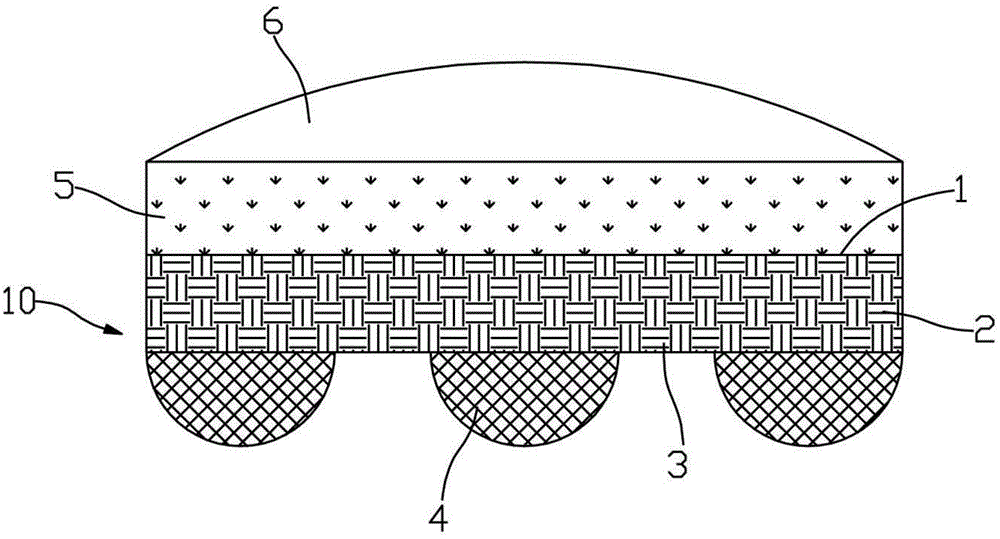

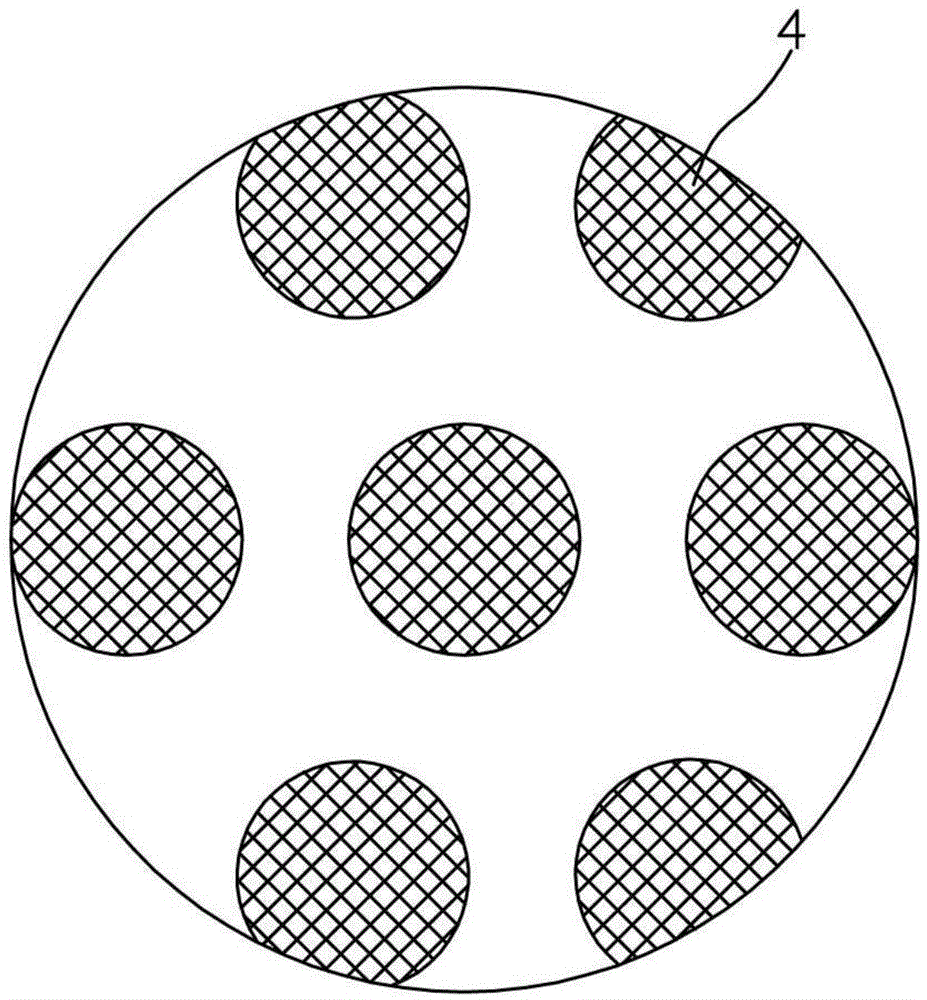

A unidirectional moisture-wicking fabric structure

ActiveCN104786576BHigh speedReduce sticky discomfortGarment special featuresWeft knittingHuman bodySurface layer

Owner:NEWSEGA TEXTILE NANTONG CO LTD

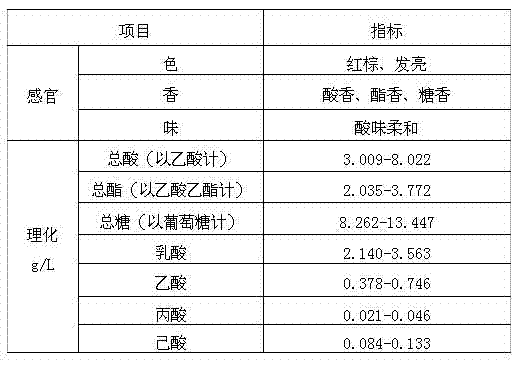

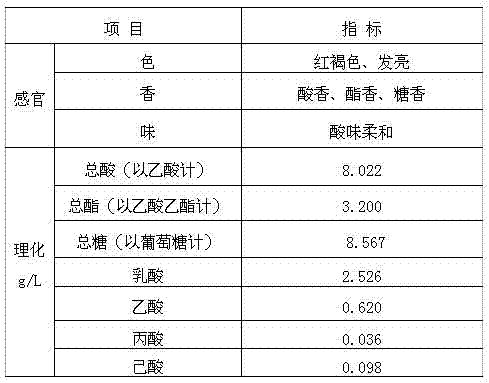

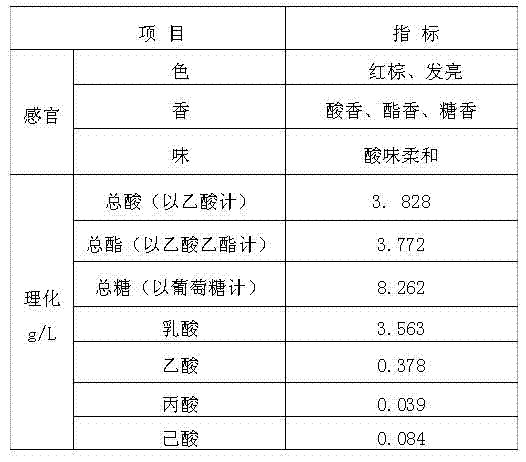

Pickled vegetable brine produced by using white wine byproducts, and preparation method thereof

ActiveCN102754804AGreat tasteOutstanding styleClimate change adaptationFood preparationSaline waterOrganic acid

The invention discloses pickled vegetable brine produced by using white wine byproducts, and a preparation method thereof. The pickled vegetable brine is prepared by taking esterified residual liquid as basic materials and other auxiliary materials in parts by weight in 1L of esterified residual liquid, including 5-8g of clove, 10-30g of green pepper, 5-40g of ginger, 3-10g of lysimachia sikokiana, 2-8g of pepper, 5-8g of anise, 5-10g of diphtheria, 3-10g of orange peel, and 20-50g of edible salt. The pickled vegetable has high shelf life, and is not heated in preparation process; the esterified residual liquid contains abundant organic acid, so as to be capable of effectively restraining the other bacteria infection; the pickled vegetable does not produce flowers, is long in shelf life, short in fermentation time, and can be eaten after the vegetables are soaked for hours at normal temperature; and the pickled vegetable is acid and crisp and tasty in mouthfeeling, thick in fragrance,proper for both acid and hot, unique in flavor, and is bright in color and good in luster.

Owner:SICHUAN TUOPAI SHEDE WINE

Shower system combining a top sprayer and a hand shower

ActiveUS10046341B2The process is convenient and fastLow costLiquid surface applicatorsDomestic plumbingMarine engineeringWater source

A shower system includes a top sprayer with at least two water types and a hand shower. The top sprayer is disposed with an inlet waterway to connect to the water source and first diversion waterways corresponding to the water types one by one; wherein the top sprayer is further disposed with a second diversion waterway, the hand shower is connected to the second diversion waterway by an external flexible pipe; the top sprayer is disposed with a switch mechanism, the switch mechanism is cooperated to the inlet waterway, the first diversion waterways and the second diversion waterway to switch the waterways, thus switching any diversion waterway to connect to the inlet waterway.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

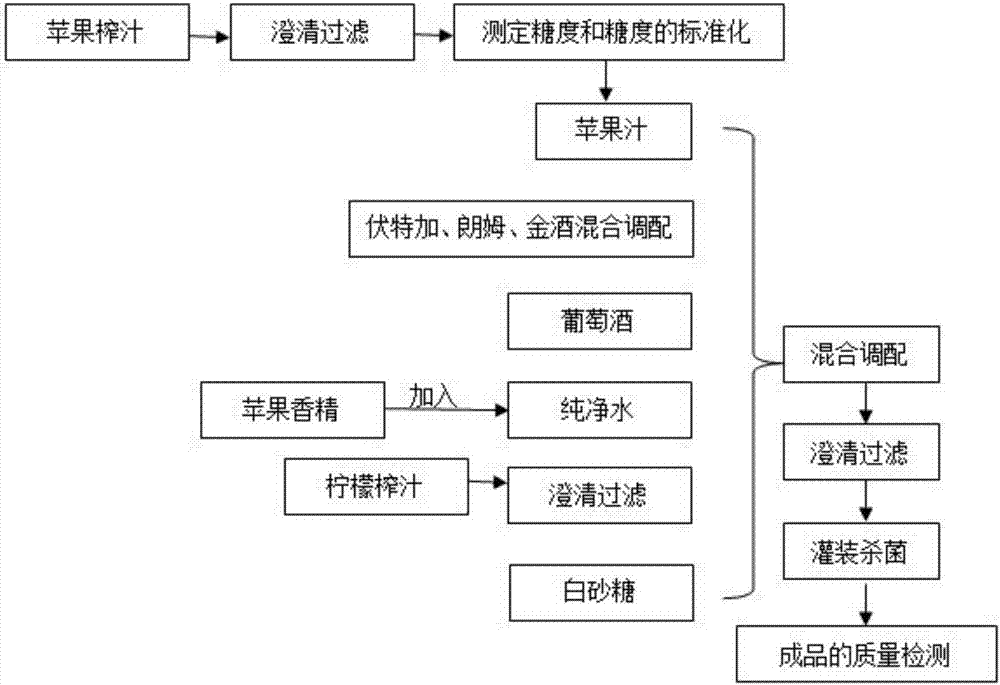

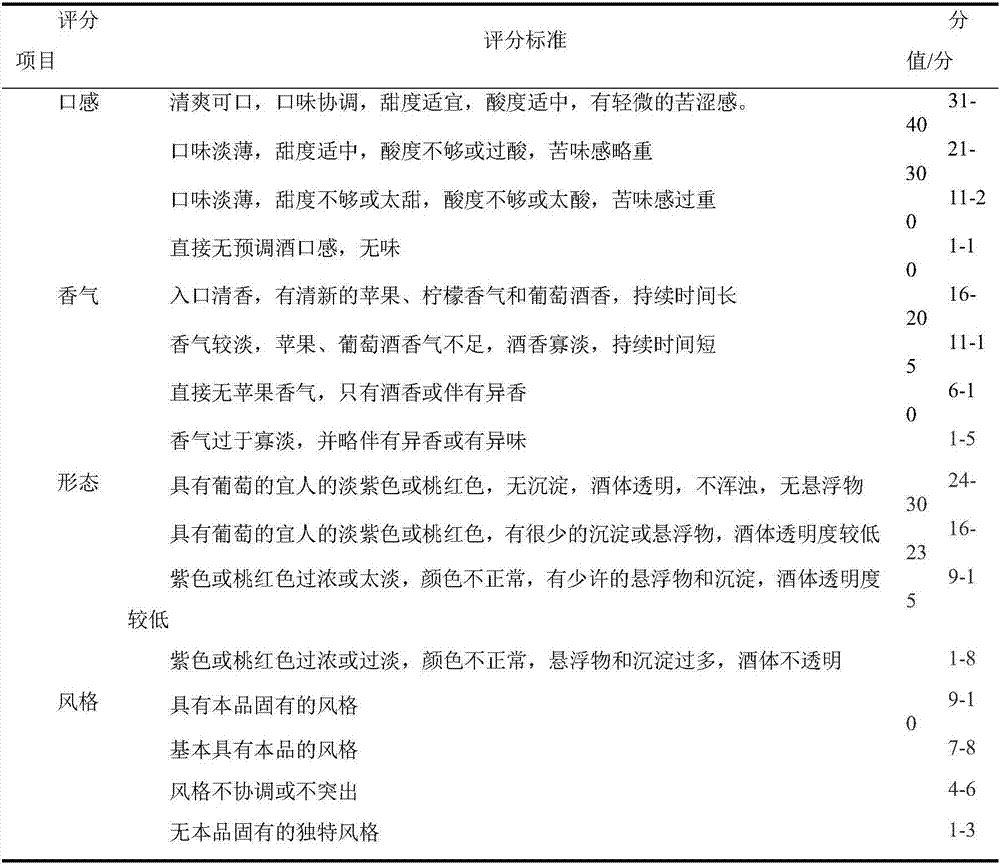

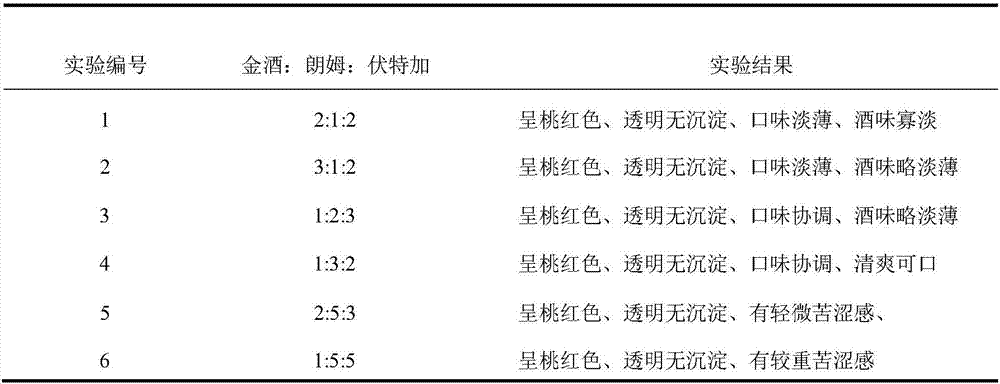

Grape and apple mixed ready-to-drink wine and preparation process thereof

InactiveCN107090395AOutstanding styleRich tasteAlcoholic beverage preparationAlcohol contentVitis vinifera

The invention discloses grape and apple mixed ready-to-drink wine and a preparation process thereof. The grape and apple mixed ready-to-drink wine is prepared from 150 to 180 parts of grape wine, 15 to 18 parts of vodka, 35 to 45 parts of rum, 22 to 28 parts of gin, 90 to 120 parts of apple juice, 28 to 35 parts of lemon juice, 500 to 1000 parts of water, 30g / L to 40g / L of white granulated sugar and 0.1g / L to 0.3g / L of apple essence. The preparation process comprises the following steps: mixing the vodka, the rum and the gin according to a ratio to form base liquor; adding the freshly pressed apple juice, the grape wine, the apple essence, the freshly pressed lemon juice, the white granulated sugar and the water into the base liquor and uniformly mixing; clarifying, filtering, filling, sterilizing and packaging a mixed solution to prepare the grape and apple mixed ready-to-drink wine. The prepared ready-to-drink wine has a cherry-red color, is transparent and glossy, has grape and apple flavors and has proper sweetness and alcohol content. The styles and characteristics of the grape wine, the gin, the rum and the vodka are fused so that the styles and characteristics of the ready-to-drink wine are more prominent. The ready-to-drink wine adopts two types of flavor raw materials, namely grapes and apples, so that a product prepared by the process has the characteristic of high nutrient value and the taste of the ready-to-drink wine is more abundant, and furthermore, the market of the ready-to-drink wine is more diversified.

Owner:ZUNYI MEDICAL UNIVERSITY

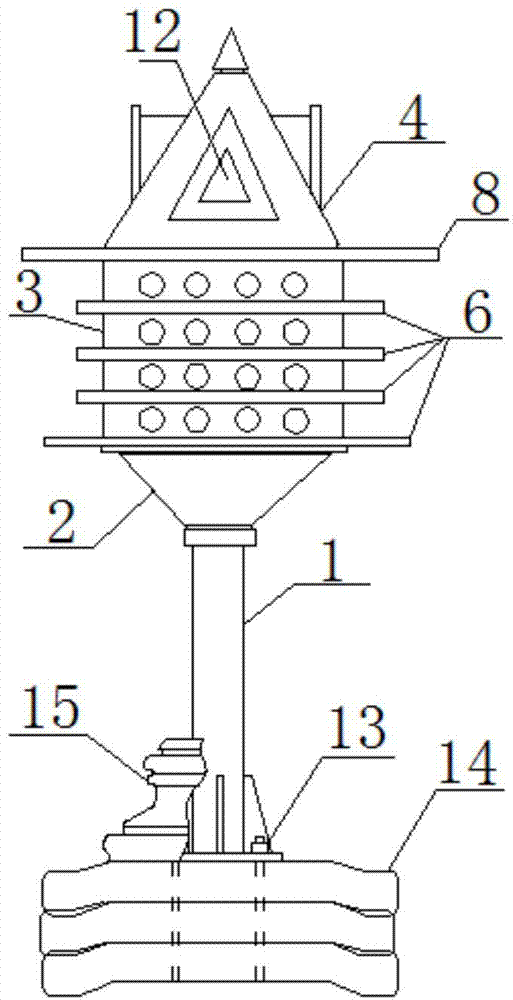

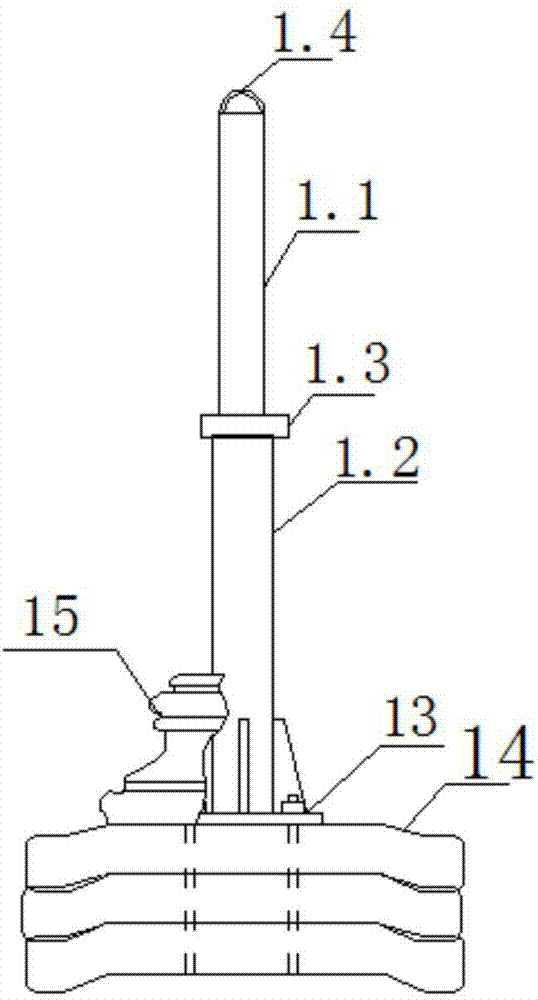

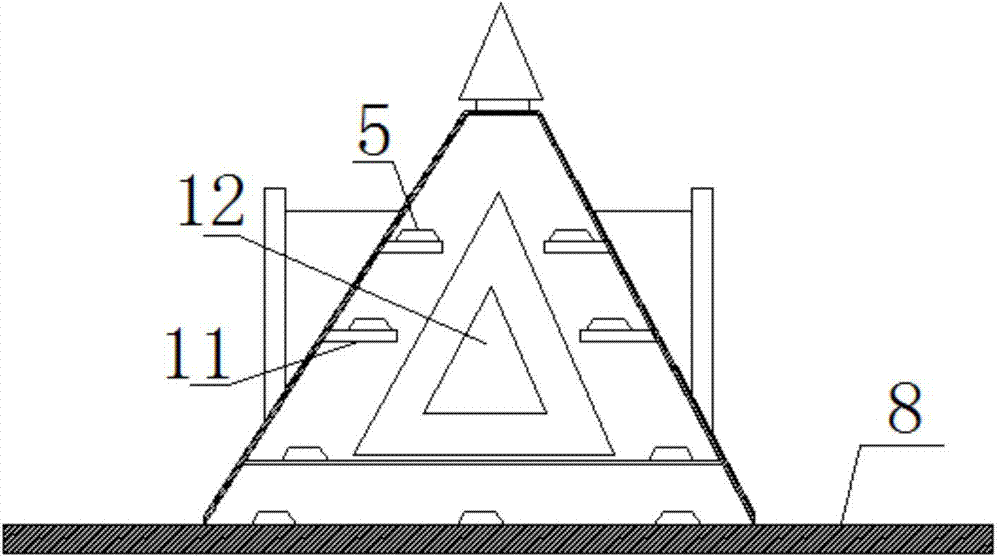

Overhead pigeon house

The invention discloses an overhead pigeon house. The overhead pigeon house comprises a support pole fixed on the ground, the upper end of the support pole is fixedly provided with a pigeonhole, and the pigeonhole is composed of a base support, a pigeonhole body and a pigeonhole roof, wherein the pigeonhole body is fixed onto the base support, and the pigeonhole roof is fixed onto the pigeonhole body; nests for pigeons to perch are arranged inside the pigeonhole body and the pigeonhole roof, and the outer walls of the pigeonhole body and the pigeonhole roof are provided with inlets and outlets for the pigeons to enter and exit. The overhead pigeon house has the advantages of being small in space occupation, simple and labor-saving in pigeon management, sanitary, environmentally-friendly, high in safety performance and comfort level, convenient to mount and move, wide in application range and the like.

Owner:济南空中鸽楼园林工程有限公司

Baijiu-brewing compound enzyme containing acid protease and preparation method of Baijiu-brewing compound enzyme containing acid protease

InactiveCN105524901AEnsure food safetyIncrease profitHydrolasesAlcoholic beverage preparationAntioxidantEnzyme system

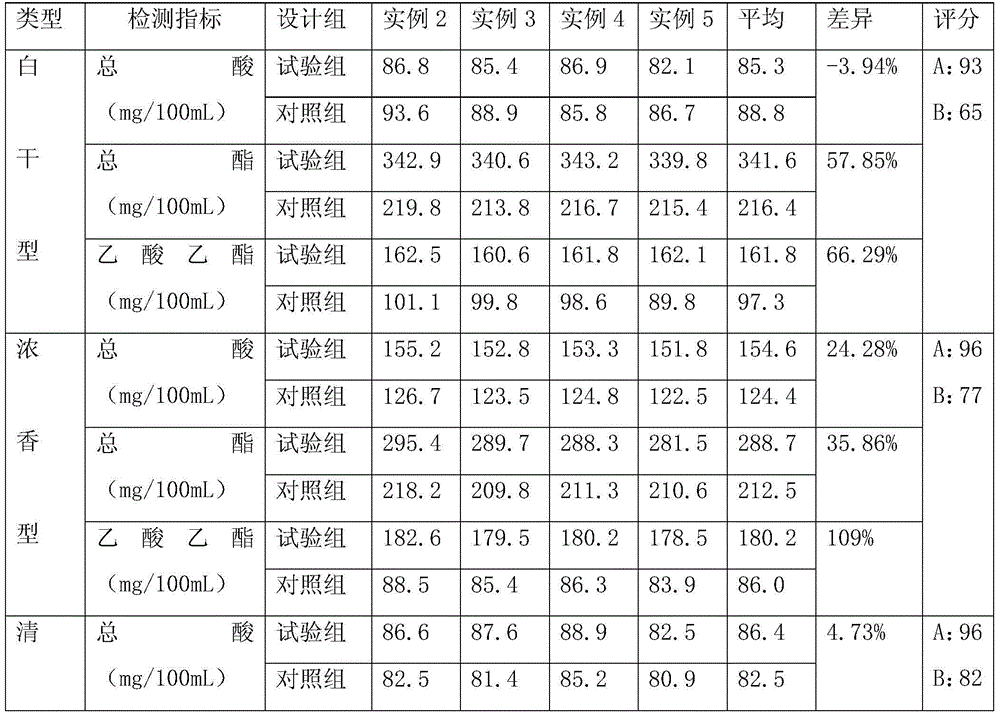

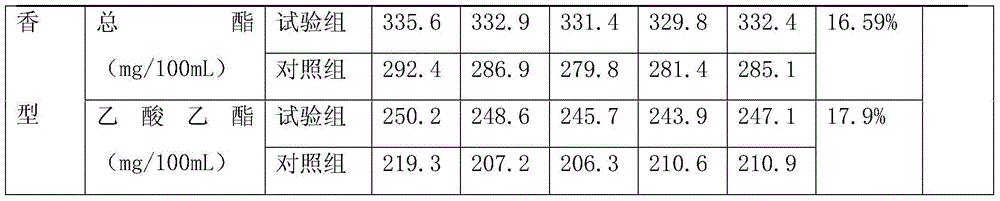

The invention discloses a Baijiu-brewing compound enzyme containing acid protease and a preparation method of the Baijiu-brewing compound enzyme containing the acid protease and belongs to the technical field of compound enzyme preparation. The Baijiu-brewing compound enzyme containing the acid protease and the preparation method have the advantages that on the basis of scientific compounding of food-grade enzyme preparations, high-activity acid protease and plant extracts containing plant enzymes and nutrient substances are compounded specially to enable an enzyme system of the compound enzyme to be more complete; activating agents enabling enzyme activity to be completely released and protective agents and antioxidants enabling enzyme activity to be more stable are added, and esterified red yeast and aroma-producing active dry yeast which make Baijiu more sufficient in aroma are compounded scientifically, so that starch, protein, fat, cellulose, hemicellulose, pectin and the like in grain can be hydrolyzed sufficiently and effectively, Baijiu yield can be increased by 24% to 29% remarkably, total ester content can be increased from 16.59% to 57.85%, and ethyl acetate content can be increased from 17.9% to 109%; taste of various types of Baijiu can be improved remarkably, and the compound enzyme can be suitable for brewing various types of Baijiu and addition of different Baijiu brewing methods.

Owner:湖南新鸿鹰生物工程有限公司

Bronzing pulp and preparation method thereof

ActiveCN103255646BRich styleRich wash fastnessTransfer printing processDyeing processWater basedSolvent

The invention discloses bronzing pulp. The bronzing pulp is prepared from the following raw materials in parts by weight: 60-80 parts of acrylic ester emulsion, 2-6 parts of deionized water, 3-10 parts of a solvent, 1-5 parts of a stabilizer, 10-20 parts of EVA (Ethylene-Vinyl Acetate) hot melt adhesive powder, 0.5-3 parts of silica, 0.2-0.5 part of a polyurethane defoaming agent, 0.1-0.5 part of a pH regulator, 0.1-0.2 part of a preservative, 0.3-1 part of an emulsion wetting agent and 0.4-2 parts of a thickener. The bronzing pulp has the beneficial effects that the bronzing pulp is water-based pulp, the raw materials are easy to obtain and environment-friendly, the production is convenient, the technology is mature, and substances harmful to the environment can not be produced; and the bronzing pulp is soft in handfeel, firm in fastness, outstanding in resistance to tension fracture and diversified in application mode, enriches the styles of textiles, and endows the textiles with the noble quality.

Owner:GUANGZHOU SHENGQIN IND

Production method for increasing 3-methylthio propanol and tetramethylpyrazine in Luzhou- and sesame-flavor Baijiu

InactiveCN105695225ASesame flavor is prominentElegant and delicateAlcoholic beverage preparationMicroorganismFlavor

The invention relates to a production method for increasing 3-methylthio propanol and tetramethylpyrazine in Luzhou- and sesame-flavor Baijiu.To be more specific, on the basis of traditional methods, the method produces the Luzhou- and sesame-flavor Baijiu by using microorganisms containing 3042 soybean sauce strains to perform fermentation.The contents of the 3-methylthio propanol and the tetramethylpyrazine of the Baijiu produced by the method can reach a high level.The sensory evaluation of the Baijiu produced by the method shows that the Baijiu has the features of Luzhou-flavor Baijiu and is full in Baijiu body, prominent in scorch aroma and fragrant in first taste.

Owner:晋江尚京富本环保科技有限公司

Method for brewing beauty and health care wine

InactiveCN101602994AImprove qualityHigh nutritional valueMicroorganism based processesWine preparationNutritive valuesFruit wine

The invention relates to beauty and health care wine and a brewing method. Longan which is a health-care invigorant rewarded by past doctors, grape which has high nutritive value and health-care function and lemon which has quite high beauty value beside the efficacy of body building are used as raw materials; and the three raw materials with respective advantages are elaborately brewed into the beauty and health care wine by adopting a modern biological fermentation process. The method fully extracts effective components beneficial to the human body, increases a fermentation product and enlarges the prior beauty and health care efficacies of the wine. The brewed fruit wine has aromatic and unique smell and elegant and mellow mouth feel, is full bodied, and is high-quality catering wine and ideal gift.

Owner:叶长东

Perfume prepared by taking edible flowers as raw materials and used for featured cigarettes and application of perfume

InactiveCN104312725AConvenient researchImprove developmentTobacco preparationTobacco treatmentIrritationMoisture

The invention discloses a perfume prepared by taking edible flowers as raw materials and used for featured cigarettes and application of the perfume. The perfume disclosed by the invention is prepared from one or more of birchleaf pear flowers, sophora viciifolia hance, caragana sinica, azalea, mayodendron igneum, Japanese banana flowers and begonia by the following steps: adding an organic solvent to the raw material to perform microwave-assisted extraction, filtering an extract solution, concentrating and processing by an MCI reverse-phase chromatographic column to obtain a perfume extract for the cigarettes; and the extract is further added into the cigarettes. The featured perfume for the cigarettes has the effects of increasing fluid production sense, sweetness and moisture of the cigarettes, enriching the cigarette fragrance, reducing irritation, softening the fragrance, increasing comfort and effectively upgrading the smoking quality of the cigarettes, and is conductive to highlighting the style feature of the product. The perfume disclosed by the invention is conductive to improving the economic utilization value of featured plants, the process is simple, the industrialized production is convenient to implement, and the perfume has good development and application prospects.

Owner:CHINA TOBACCO YUNNAN IND

Method for brewing longan cane-juice wine

ActiveCN101649269AKeep healthyKeep replenishing qi and bloodMicroorganism based processesAlcoholic beverage preparationFruit wineRaw material

The invention discloses a longan cane-juice wine and a brewing method thereof. Longan and cane juice are used as the main raw materials, and biological enzymolysis and microorganism low-temperature fermentation are used for brewing the nutritive fruit wine. The method uses longan and cane juice, which can be used as both medicines and food, as the raw materials, completely extracts effective components which are beneficial to human bodies, increases the fermentation products and enhances the nutritive effect. The longan cane-juice wine is rich and delicate in mouth feel and has a typical outstanding style, thereby being an ideal inebriant drink.

Owner:叶长东

One-way moisture-conducting fabric structure

ActiveCN104786576AImprove perspiration and moisture wicking speedReduce sticky discomfortGarment special featuresWeft knittingWettingBiomedical engineering

The invention discloses a one-way moisture-conducting fabric structure. The one-way moisture-conducting fabric structure comprises a ramie and cotton blended fabric bottom layer and porous silica gel patterns, wherein the ramie and cotton blended fabric bottom layer is provided with an inner surface and an outer surface; porous silica gel is adhered to the outer surface; the inner surface is in contact with skin. According to the one-way moisture-conducting fabric structure disclosed by the invention, sweat generated by the surface of a body can be absorbed rapidly and diffuses outside the fabric structure; the moisture absorbing and sweat releasing property and the moisture absorbing and sweat releasing speed are improved; the sticky wetting discomfort feeling generated by the sweating of the surface layer of the skin of a human body is reduced.

Owner:NEWSEGA TEXTILE NANTONG CO LTD

Preparation method of solidified tobacco extract and application of solidified tobacco extract in electronic cigarette

ActiveCN106418667AAvoid problems such as oil spillsOutstanding styleTobacco treatmentFlavorLiquid smoke

The invention provides a preparation method of a solidified tobacco extract. The preparation method comprises the following steps: 1) conducting extracting: drying, crushing and sieving tobacco raw materials, and conducting supercritical extraction; 2) conducting separating: dissolving an extract obtained in the step 1) and uniformly mixing the dissolved extract, cooling an obtained solution until the solution becomes layered, conducting filtering to remove lower liquid, and reserving an upper solid so as to obtain a primary shaped material; and 3) conducting shaping: dissolving the primary shaped material with the addition of an atomizing agent, oscillating and uniformly shaking, and condensing and shaping so as to obtain the solidified tobacco extract. Furthermore, the invention also provides an application of the solidified tobacco extract prepared by the method as an aerosol forming matrix in an electronic cigarette. According to the preparation of the solidified tobacco extract and the application of the solidified tobacco extract in the electronic cigarette provided by the invention, various problems caused by the addition of additives as well as flavors and fragrances can be avoided, and such problems as tar leakage and the like caused by conventional electronic cigarette liquid can be also avoided; therefore, the solidified tobacco extract is quite worthy of popularizing and applying.

Owner:SHANGHAI TOBACCO GRP CO LTD

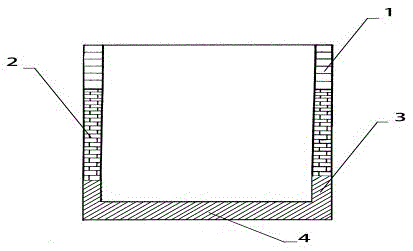

Fuya flavor liquor fermentation pit and construction method

PendingCN110747100APremium BreedingHigh quality living environmentCellar toolsBiotechnologyMicroorganism

The invention belongs to the technical field of liquor production and particularly relates to a Fuya flavor liquor fermentation pit. The Fuya flavor liquor fermentation pit is surrounded by a pit walland a pit bottom; the side wall of the lower portion of the pit wall is provided with Fuya flavor artificial pit mud with the thickness of 8-12 cm; the side wall of the upper portion of the pit wallis a brick wall, and an anti-seepage layer is poured in the middle of the brick wall; the lower bottom portion of the pit bottom is soil, a tamped and non-seeping pottery clay cushion layer of 8-12 cmis laid on the pit bottom, and the Fuya flavor artificial pit mud of 13-17 cm is laid on the pottery clay cushion layer. The pit provided by the invention has the beneficial effects that a high-quality reproduction and living environment is provided for the bottom fermentation microorganism; compared with the strong-flavor pit, the upper brick pit wall of the pit of the invention produces flavorsubstances different from the strong flavor, and the flavor substances are enriched; and the liquor produced by the Fuya flavor liquor fermentation pit is colorless, transparent, elegant in the Fuya flavor, soft, fine, full, smooth in aftertaste and unique in style.

Owner:SHANDONG YIMENGLAOQU WINE IND

A preparing method of spicy fish paste having different pungency degrees

A preparing method of spicy fish paste having different pungency degrees is disclosed. The method includes a) weighing 10 jin of bighead carps, slicing the bighead carps, cleaning the slices and keeping the slices for later use, b) preparing plant pickling auxiliary materials, and pickling the bighead carps for 8 h or above, c) taking the fish out when the fish is drained to a degree that the water content of is 40%, and keeping the fish for subsequent stir-frying, d) mixing 4 jin of sesame oil, 4 jin of red oil and 4 jin of scallion oil to obtain mixed oil, heating the oil to 80 DGE C or above, adding the fish into a pan and stir-drying the fish, e) when the fish is light yellow, adding stir-frying auxiliary materials, and stir-frying the mixture continuously until the fish is golden yellow, f) performing low-temperature refrigeration and sterilization, g) performing deoxygenation and h) subpacking and sealing a product. The method is suitable for industrial, standardized and large-scale production.

Owner:成都鲜誉海洋科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com