A unidirectional moisture-wicking fabric structure

A unidirectional moisture-wicking and fabric technology, applied in biochemical fiber processing, clothing, protective clothing, etc., can solve problems such as sweat, steam difficulty, hindrance to heat exchange, discomfort, etc., to increase capillary channels and reduce stickiness Uncomfortable feeling and good moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

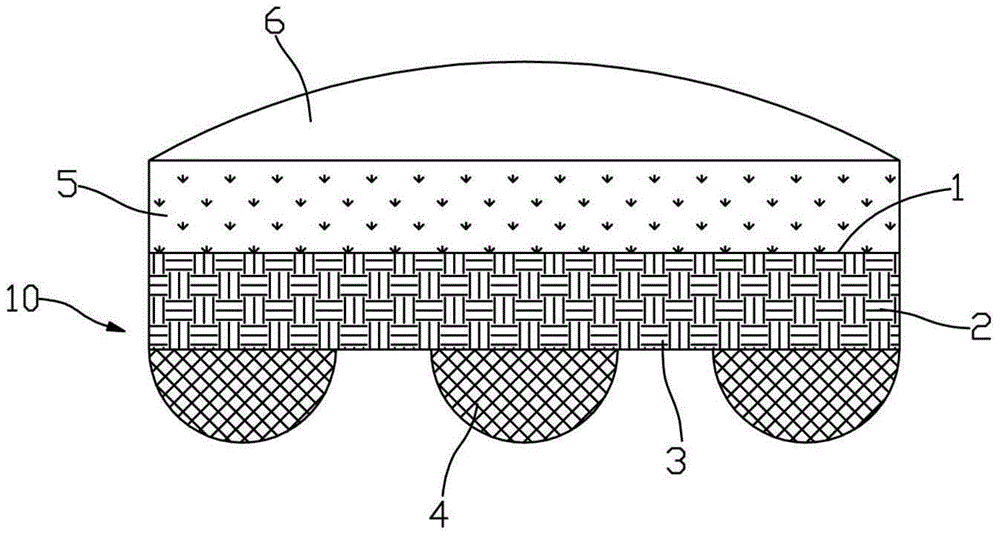

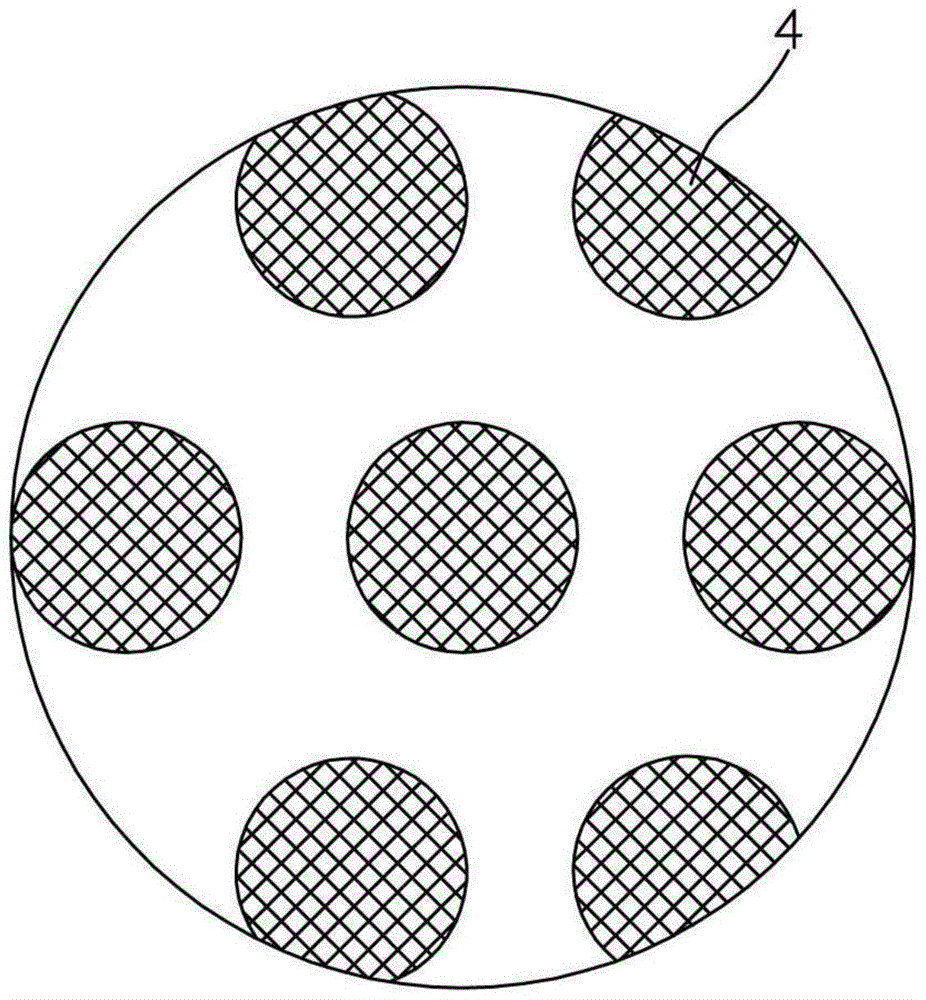

[0052] Such as Figure 1 and Figure II Shown:

[0053] A unidirectional moisture-wicking fabric structure includes: the bottom layer of the hemp-cotton blended fabric 3 and the porous silica gel pattern 4; the hemp-cotton blended fabric 3 has an inner surface 1 and an outer surface 2, the outer surface is attached with porous silica gel 4, the inner surface 1 and the outer surface 2 When the skin 6 contacts, when the human body is in a state of sweating significantly, there is a sweat layer 5 between the skin 6 and the hemp-cotton blended fabric 3 .

[0054] Among them, the basic parameters of linen-cotton blended fabric are:

[0055] Yarn raw material: JL / C 40s;

[0056] Fabric structure: plain knitted fabric;

[0057] Longitudinal density (row / 5cm): 75;

[0058] Horizontal density (longitudinal row / 5cm): 78;

[0059] Total density (coil / 25cm 2 ):5925;

[0060] Surface density (g / m 2 ): 111.69;

[0061] Coil length (mm): 3.41;

[0062] Underfill factor: 23.71.

...

Embodiment 2

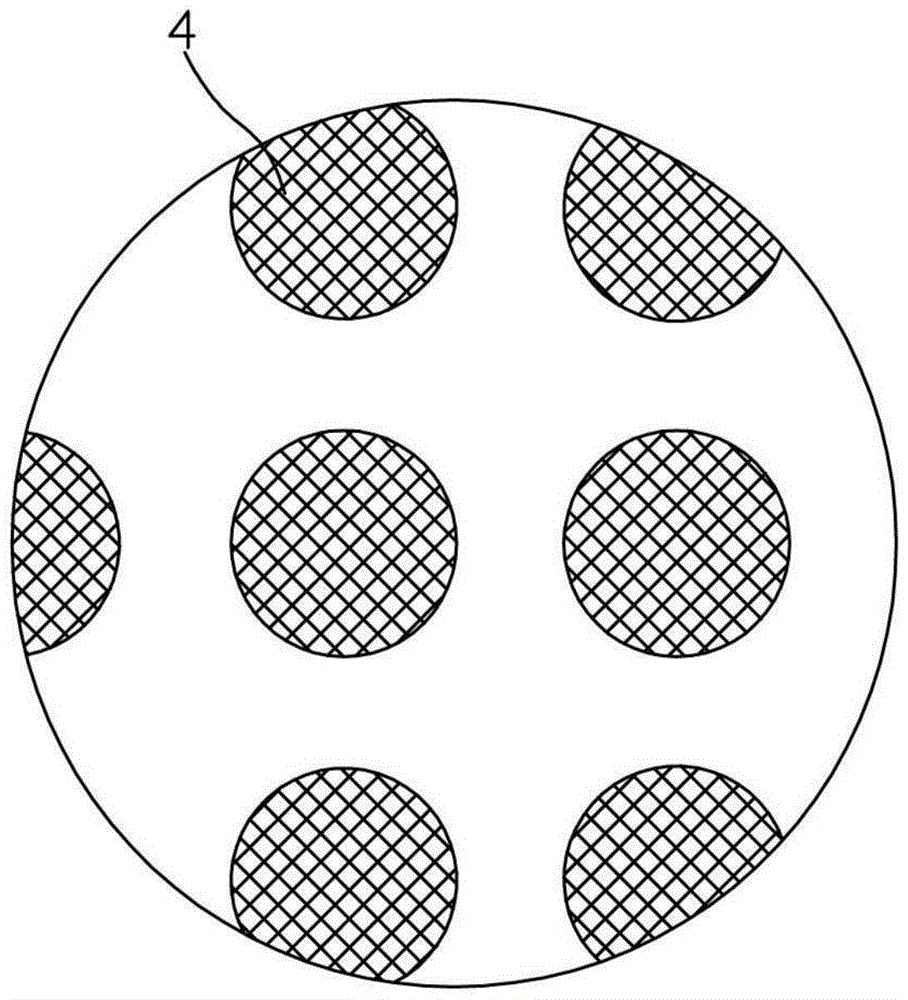

[0065] Such as Figure 1 and Figure three Shown:

[0066] A unidirectional moisture-wicking fabric structure includes: the bottom layer of the hemp-cotton blended fabric 3 and the porous silica gel pattern 4; the hemp-cotton blended fabric 3 has an inner surface 1 and an outer surface 2, the outer surface is attached with porous silica gel 4, the inner surface 1 and the outer surface 2 When the skin 6 contacts, when the human body is in a state of sweating significantly, there is a sweat layer 5 between the skin 6 and the hemp-cotton blended fabric 3 .

[0067] Among them, the basic parameters of linen-cotton blended fabric are:

[0068] Yarn raw material: JL / C 30s;

[0069] Fabric structure: plain knitted fabric;

[0070] Longitudinal density (row / 5cm): 74;

[0071] Horizontal density (longitudinal row / 5cm): 75;

[0072] Total density (coil / 25cm 2 ):5552;

[0073] Surface density (g / m 2 ): 148.43;

[0074] Coil length (mm): 3.53;

[0075] Underfill factor: 19.47. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com