Production process of nine-grain sesame-flavor liquor

A sesame-flavor type and production technology technology, applied in the field of wine making, can solve problems such as limitations and single taste of sesame-flavored liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

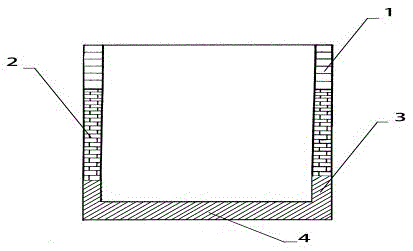

Image

Examples

example 1

[0067] One is 48% sorghum, 12% wheat, 7% bran, 14% rice, 5% corn, 5% glutinous rice, 2% sandy rice, 2% mung bean, and 5% tartary buckwheat. The raw materials are mixed in proportion and then moistened. The moistening is divided into three times for a total of 2 hours. The temperature of the moistening water is 90°C. Mix the Maotai-flavored fermented grains fermented for nine rounds with wine and the fragrant fermented grains after taking wine in proportion, then add the moistened raw materials according to the ratio of grain to fermented grains and stir three times, stir well, put in a retort, and Under the pressure of 0.16 MPa, steam for 1.5 hours to take out the retort, and when the grain unstrained spirits are cooled to 35°C, add white koji, high-temperature koji, medium-temperature koji, bacterial koji, and aromatic yeast for accumulation. At 43-45°C, the fermented grains are rapidly cooled to 35°C, and during the cooling process, 5% of the fermented glutinous grains of th...

example 2

[0069] One is 75% sorghum, 15% wheat, and 10% bran. Other preparation steps are identical with example 1.

example 3

[0071] One is 52% sorghum, 15% wheat, 10% bran, 15% rice, and 8% corn. Other preparation steps are identical with example 1. The specific formula is shown in Table 1:

[0072]

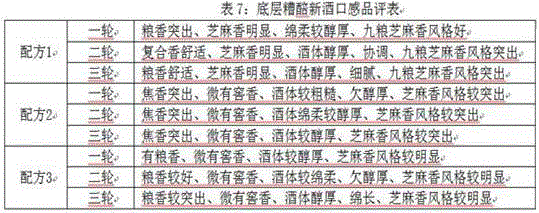

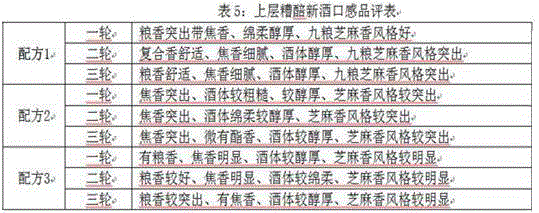

[0073] Each formula is tracked and carried out three tests respectively respectively, and the new wine of three tests is carried out conventional assay and chromatographic trace data analysis as table 2, table 3, table 4:

[0074]

[0075] From the above analysis data, it can be seen that the content of B stupid ethanol, n-propanol, furfural, 3-methylthiopropanol, pyrazines and furan compounds in the wine produced from the upper distilled grains in formula 1 is significantly higher than that in formula 2, 3; while the contents of isobutanol and isoamyl alcohol are significantly lower than those of formulas 2 and 3.

[0076]

[0077] From the above analysis data, it can be seen that the wine produced from the middle-layer distilled grains in formula 1 has significantly higher contents of et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com