Preparation method of solidified tobacco extract and application of solidified tobacco extract in electronic cigarette

A technology of tobacco extracts and electronic cigarettes, applied in the field of electronic cigarettes, can solve the problems of increased production cost and process difficulty of additives, unverified safety problems, leakage of liquid electronic cigarette liquid, etc., and achieves improved economic benefits and obvious style. , the effect of avoiding oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

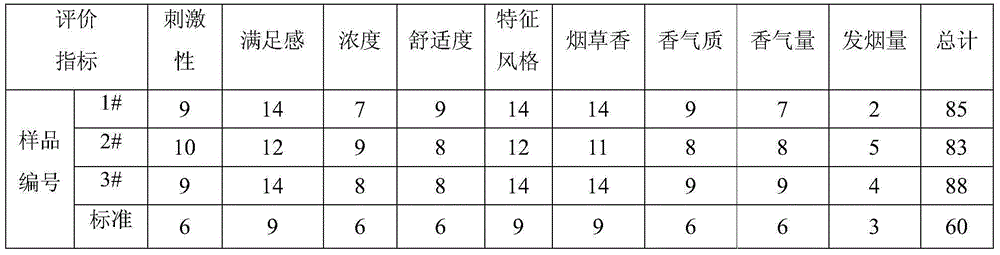

Embodiment 1

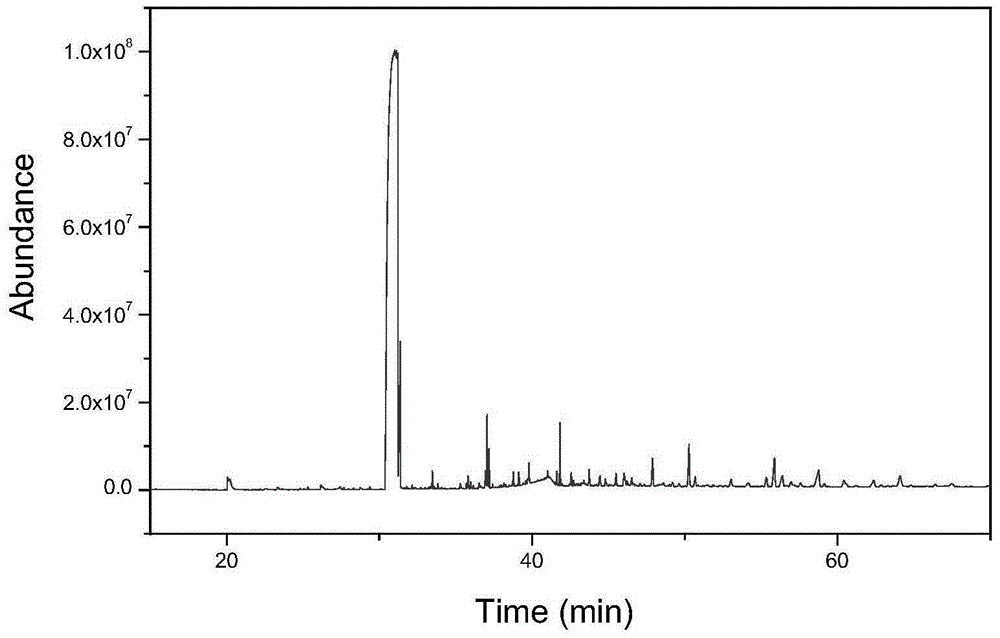

[0047] (1) Extraction: Take 160g of Burley tobacco leaves and dry them at 110°C for 10 minutes, grind them with a mill, pass through a 250-mesh sieve, and perform supercritical CO extraction. 2 extraction. Among them, supercritical CO 2 The extraction conditions are: extraction temperature: 120°C; extraction time: static extraction for 1 h, dynamic extraction for 5 h; mobile phase (CO 2 ) flow rate is 4L / min; extraction pressure: 200bar.

[0048] (2) Separation: Melt and mix the extract obtained in step (1) in a water bath, wherein the reaction conditions of the water bath are: water bath temperature: 60° C.; oscillation time: 5 min; oscillation frequency: 150 times / min. After standing and cooling, the mixture is divided into upper and lower layers, the lower layer is liquid, and the upper layer is solid matter, the liquid in the lower layer is filtered out, and the solid matter in the upper layer is taken to obtain the initial shape. After the primary substance is detected...

Embodiment 2

[0052] (1) Extraction: Take 160g of Burley tobacco leaves and dry them at 110°C for 10 minutes, grind them with a mill, pass through a 250-mesh sieve, and perform supercritical CO extraction. 2 extraction. Among them, supercritical CO 2 The extraction conditions are: extraction temperature: 120°C; extraction time: static extraction for 1 h, dynamic extraction for 5 h; mobile phase (CO 2 ) flow rate is 4L / min; extraction pressure: 200bar.

[0053] (2) Separation: Melt and mix the extract obtained in step (1) in a water bath, wherein the reaction conditions of the water bath are: water bath temperature: 60° C.; oscillation time: 5 min; oscillation frequency: 150 times / min. After standing and cooling, the mixture is divided into upper and lower layers, the lower layer is liquid, and the upper layer is solid matter, the liquid in the lower layer is filtered out, and the solid matter in the upper layer is taken to obtain the initial shape.

[0054] (3) Molding: take the initial ...

Embodiment 3

[0057] (1) Extraction: Take 160g of Burley tobacco leaves and dry them at 110°C for 10 minutes, grind them with a mill, pass through a 250-mesh sieve, and perform supercritical CO extraction. 2 extraction. Among them, supercritical CO 2 The extraction conditions are: extraction temperature: 120°C; extraction time: static extraction for 1 h, dynamic extraction for 5 h; mobile phase (CO 2 ) flow rate is 4L / min; extraction pressure: 200bar.

[0058] (2) Separation: Melt and mix the extract obtained in step (1) in a water bath, wherein the reaction conditions of the water bath are: water bath temperature: 60° C.; oscillation time: 5 min; oscillation frequency: 150 times / min. After standing and cooling, the mixture is divided into upper and lower layers, the lower layer is liquid, and the upper layer is solid matter, the liquid in the lower layer is filtered out, and the solid matter in the upper layer is taken to obtain the initial shape.

[0059] (3) Molding: take the initial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com