Die forging hat type cylinder bottom

A cylinder bottom and cap-type technology, applied in the field of the cylinder bottom of the super hydraulic cylinder, can solve the problems of easy cracking and oil leakage of the cylinder, and achieve the effects of avoiding oil leakage, low cost and improving work stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention is described in further detail:

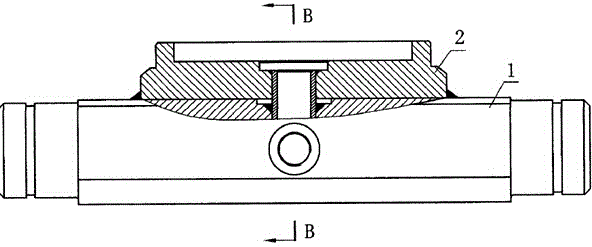

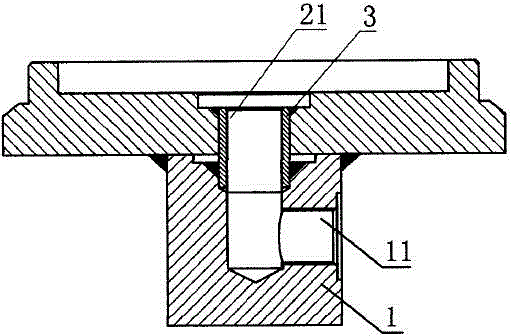

[0013] Such as figure 1 As shown, the present invention mainly consists of a piston cylinder bottom body 2 and a hinge shaft 1, and the cylinder bottom body 2 and the hinge shaft 1 are respectively provided with a cylinder bottom oil passage 21 and a hinge shaft oil passage 11 communicating with each other. The cylinder bottom body 2 and the hinge shaft 1 are integrally formed into a die forging structure. The piston cylinder bottom of this integral structure fundamentally solves the phenomenon of oil leakage caused by welding defects, and saves the welding process, and the structure Simple processing is convenient, greatly improving production efficiency. The overall molding die forging structure improves the compactness of the internal crystal grains, and further reduces the risk of internal oil leakage under high pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com