Cylinder bottom sealing structure

A technology of sealing structure and cylinder bottom, which is applied in the direction of engine sealing, fluid pressure actuating device, engine components, etc., can solve the problems of high cylinder bottom leakage ratio, bad working conditions, damage, etc., to improve working stability, The effect of low manufacturing cost and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail:

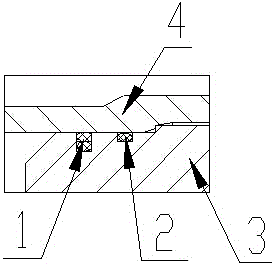

[0011] like figure 1 Shown, the present invention mainly is made up of including live 1 gray ring, 2O ring and 3 cylinder bottoms. The cylinder bottom (3) is installed in the cylinder barrel (4), the left end of the cylinder bottom is high-pressure oil, the gray ring (1) is installed on the side of the cylinder bottom close to the pressure oil, and the O-ring (2) is installed on the gray ring Later, when the pressure oil at the left end of the cylinder bottom hits the gray ring, a small amount of hydraulic oil will pass through the PTFE slip ring at the outer end of the gray ring and reach the O-ring. This part of the hydraulic oil will be blocked by the gray ring. A pressure drop acts as a buffer to protect the O-ring from damage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com