Hinge clamping carrying mechanism

A technology of conveying mechanism and clamping mechanism, which is applied in chucks, manipulators, manufacturing tools, etc. It can solve the problems of high cost, weak clamping force of cylinder, slipping of workpiece, etc., and achieve low maintenance cost, convenient operation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

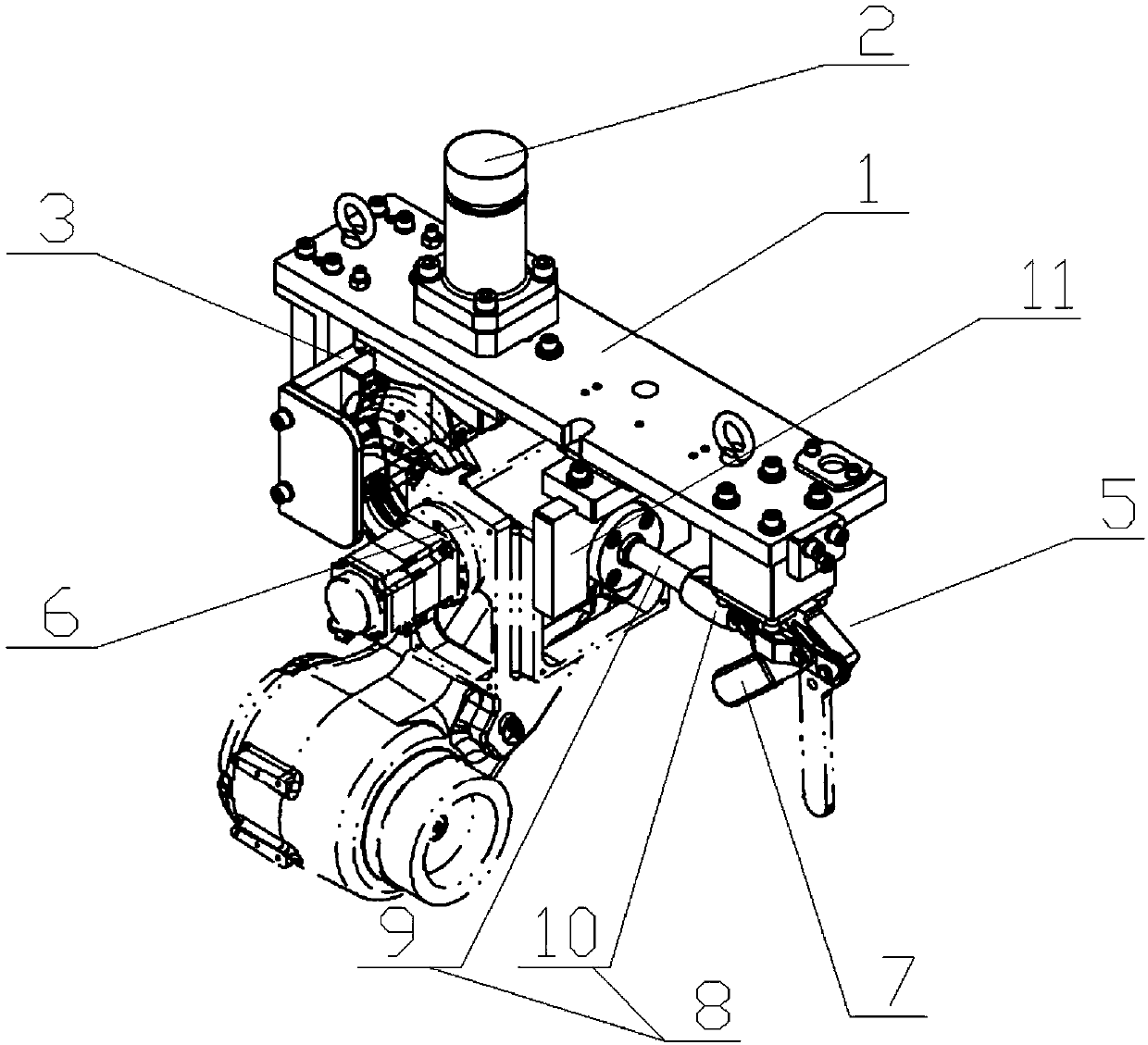

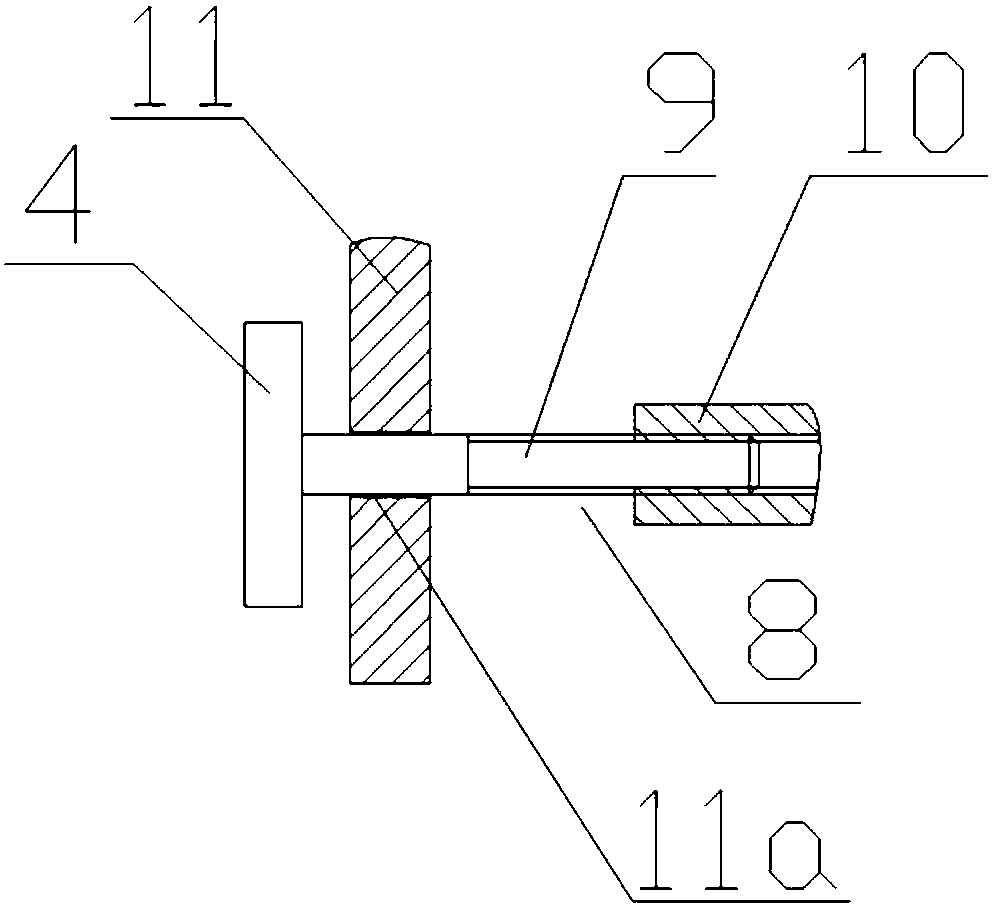

[0017] Such as Figure 1 to Figure 2 As shown, the hinge clamping and conveying mechanism corresponding to a preferred embodiment of the present invention includes a top plate 1, a manipulator grabbing part 2 connected to the top plate 1, and a first clamping plate connected to the top plate 1 and oppositely arranged. 3 and the second clamping plate 4, and the hinge clamping mechanism 5 connected between the top plate 1 and the second clamping plate 4, the hinge clamping mechanism 5 can drive the second clamping plate 4 relative to the first clamping plate 3 The workpiece 6 is clamped by the movement, and self-locking occurs when the first and second clamping plates 3 and 4 move to the closest distance.

[0018] The grabbing part 2 of the manipulator is used to be connected with the grabbing disc o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com