Fuya flavor liquor fermentation pit and construction method

A technology of Fuya fragrance type and fermentation cellar, which is applied in the direction of wine cellar appliances, biochemical equipment and methods, etc., can solve the problems of inability to enrich brewing biological flora, single microbial living environment, and indistinct differences in liquor styles, etc. Achieve effects that are conducive to the reproduction and survival of fermenting microorganisms and enrich flavor substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

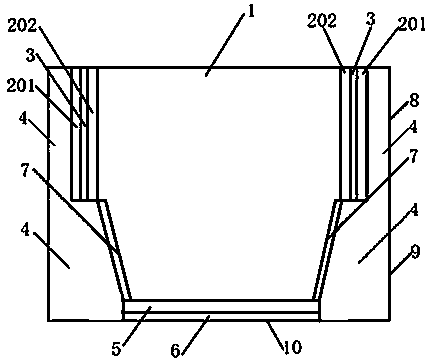

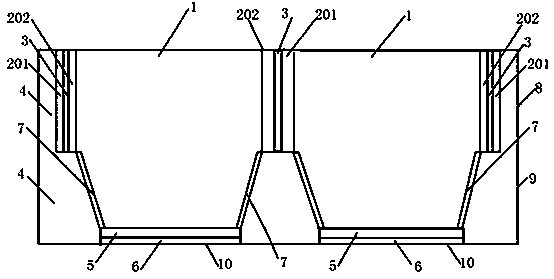

[0037] A Fuya-flavor liquor fermentation cellar (taking a single cellar as an example), its structure is as follows:

[0038] The cross section of the cellar 1 is roughly rectangular in cross section, and the cellar 1 is surrounded by the wall of the cellar and the bottom 10 of the cellar;

[0039] The cellar wall is composed of an upper cellar wall 8 located at the upper part of the cellar wall and a lower cellar wall 9 located at the lower part of the cellar wall;

[0040] The wall of the upper cellar from the outside to the inside is the earth wall layer 4, the first brick wall 201, the anti-seepage layer 3 made of concrete, and the second brick wall 202; the cement in the concrete used for the anti-seepage layer is acid-resistant cement.

[0041] From the outside to the inside of the lower cellar, the wall of the cellar is the earth wall layer 4 and the first Fuya fragrance artificial cellar mud layer 7;

[0042] From bottom to top, the bottom of the cellar is successivel...

Embodiment 2

[0057] Using the cellar provided in Example 1, put the winemaking raw materials in the cellar, pure mud cellar and pure brick cellar, the temperature of entering the cellar is 22°C, the fermentation time is 60 days, and a certain amount is taken out after distillation Chromatographic analysis and comparison of white wine;

[0058]After testing, it is found that the content of each component in the white wine produced by three kinds of cellar ponds is compared as shown in table 1, 2, 3, as can be seen from table 1, 2, 3 (under the same chromatographic internal standard situation, after purification There are 29 kinds of aroma components that can be detected in the liquor fermented in the mud cellar, 30 kinds of aroma components can be detected in the liquor fermented in the pure brick pit, and 45 kinds of aroma components can be detected in the liquor fermented in the cellar of the present invention), The white wine fermented in the cellar of the invention has the characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com