Technique for preparing bonding fabric

A production process and technology of adhesive interlining, applied in clothing, clothing, textiles and papermaking, etc., can solve problems such as hard hand feel, inability to reflect fabric elasticity, affecting clothing shape and wearing performance, etc., to achieve soft hand feel, good beauty and comfort. The effect of sex, plump penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

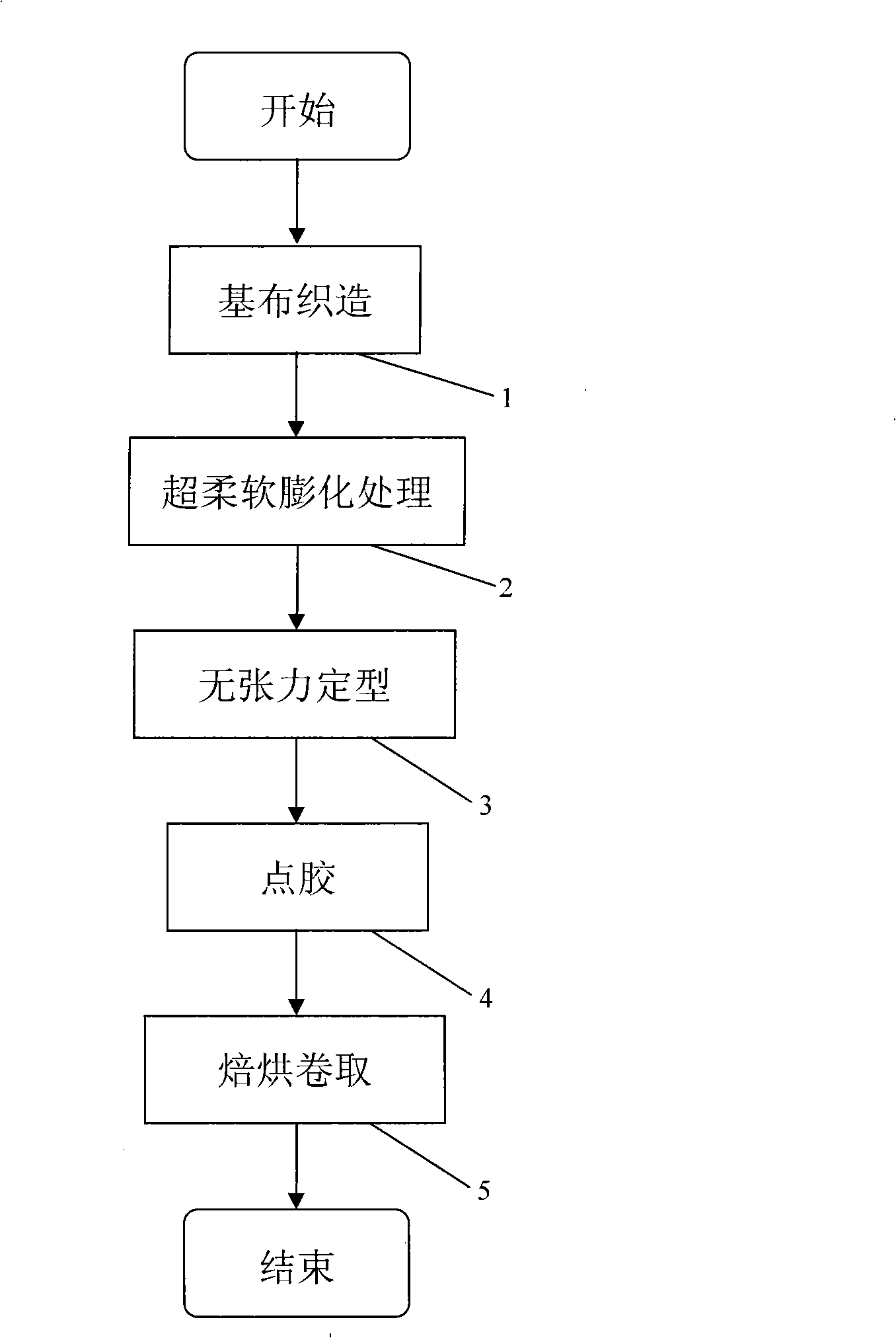

[0017] refer to figure 1 , a fusible interlining production process, comprising the following steps in turn:

[0018] Base fabric weaving 1: The base fabric is made of 15D / 5F N66 high-elastic yarn in warp and weft directions, and is woven by a fully automatic jet machine;

[0019] Super-soft puffing treatment 2: Mechanical soft finishing by extrusion and / or kneading, so that the stress of the fibers can be relaxed, and the internal stress generated by stretching during processing can be released, so that the fibers themselves are soft and loose. Chi, so as to obtain a soft effect;

[0020] Tension-free shaping 3: Using modified amino silicon microemulsion and fluorine-containing water repellent to prepare working liquid, using Italian bianco high-feeding tension-free cloth feeding system, feeding the cloth loosely into the trough to impregnate the working liquid, and then passing through the over-feeding roller The cloth soaked in the working liquid is sent into the pre-dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com