Granular green tea processing method through combination of microwave drying of first-step roasting leaves and double-pot tea curling machine shaping

The technology of a double-pot Quhao machine and a processing method is applied in the direction of tea processing before extraction, which can solve the problems of high work efficiency and poor evenness of leaf picking by machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

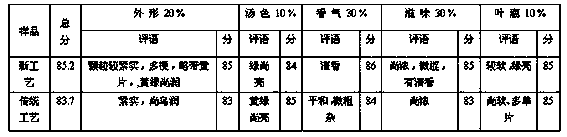

Embodiment 1

[0027] 1. Spread fresh leaves: Machine-harvested Longjing 43 tea tree fresh leaves are used as raw materials. The picking standard is two or three leaves per bud, and the proportion of fragmented leaves and single leaves is 30%. The fresh tea leaves are placed on the silage machine and spread out, the thickness of the leaves is 5cm, the time of spreading is 8h, and the moisture content drops to 70%.

[0028] 2. Fixing: The spread leaves are fixed by a roller fixing machine. The temperature and time of fixing are controlled at 190°C and 60s respectively, the enzyme activity is inactivated, and the fragrance of tea leaves is preserved.

[0029] 3. Cooling: Cool immediately after finishing, and let it rehydrate naturally for 10 minutes.

[0030] 4. Kneading: After the green leaves are cooled, use a rolling machine to knead to destroy the tea cells and tighten the tea sticks. The kneading time is 15 minutes, and the pressurization method is "light-heavy-light".

[0031] 5. Baking...

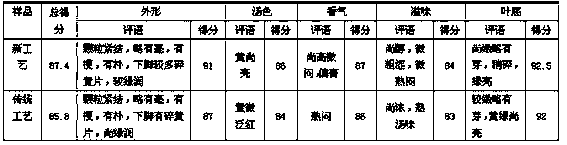

Embodiment 2

[0038] 1. Spread fresh leaves: Machine-picked fresh leaves of Beizhong tea tree are used as raw materials. The picking standard is one bud and two or three leaves, and the proportion of fragmented leaves and single leaves is 30%. The fresh tea leaves are placed on the silage machine and spread out, the thickness of the leaves is 10cm, the time of spreading is 4h, and the moisture content drops to 75%.

[0039] 2. Fixing: The spread leaves are fixed by a drum fixing machine, the temperature and time of fixing are controlled at 180°C and 75s respectively, the enzyme activity is inactivated, and the fragrance of tea leaves is retained.

[0040] 3. Cooling: Cool immediately after finishing, and let it rehydrate naturally for 20 minutes.

[0041] 4. Kneading: After the green leaves are cooled, use a rolling machine to knead to destroy the tea cells and tighten the tea sticks. The kneading time is 20 minutes, and the pressurization method is "light-heavy-light".

[0042] 5. Baking ...

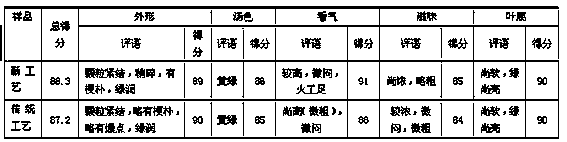

Embodiment 3

[0049]1. Spread fresh leaves: Machine-harvested Longjing 43 tea tree fresh leaves are used as raw materials. The picking standard is two or three leaves per bud, and the proportion of fragmented leaves and single leaves is 40%. The fresh tea leaves are placed on the silage machine and spread out, the thickness of the spread leaves is 8cm, the spread time is 6h, and the moisture content drops to 72%.

[0050] 2. Fixing: The spread leaves are fixed by a drum fixing machine. The temperature and time of fixing are controlled at 215°C and 67s respectively, the enzyme activity is inactivated, and the fragrance of tea leaves is retained.

[0051] 3. Cooling: Cool immediately after finishing, and let it rehydrate naturally for 18 minutes.

[0052] 4. Kneading: After the green leaves are cooled, use a rolling machine to knead to destroy the tea cells and tighten the tea sticks. The kneading time is 16 minutes, and the pressurization method is "light-heavy-light".

[0053] 5. Baking tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com