Processing method of Tuling aged tea

A technology of Tuling old tea and production process, which can be used in tea treatment before extraction, climate change adaptation, etc., and can solve the problems of different product quality and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

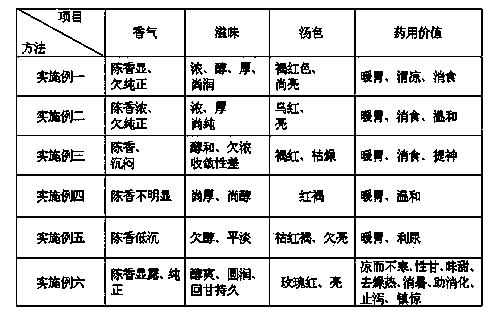

Examples

Embodiment 1

[0029] A kind of manufacture craft of Tuling old tea, it comprises the following steps:

[0030] 1) Picking fresh leaves;

[0031] 2) Stand still: put the fresh leaves harvested each time in the indoor drying room for ventilation and heat dissipation;

[0032] 3) Green drying: After three o’clock in the afternoon, move the fresh leaves that have been left to dissipate heat and emit heat outside to dry green until the leaf color is dark green, and 10% to 20% of the edge of the leaf turns red. Knead into a ball;

[0033] 4) Let it stand again: After drying the fresh leaves moderately, move them into the indoor drying room again and let them stand until the temperature is consistent with the room temperature;

[0034] 5) Kneading: Use a kneading machine to knead the tea leaves; the kneading process lasts for 35 minutes, in which the first light pressure is 10 minutes, then heavy pressure is 20 minutes, and finally light pressure is 5 minutes;

[0035] 6) Wohong: Dissolve the t...

Embodiment 2

[0044] The difference from Example 1 is that the temperature of artificial storage is 38°C and the relative humidity is 85%.

Embodiment 3

[0046] The difference from Example 1 is that the temperature of artificial storage is 20°C and the relative humidity is 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com