Patents

Literature

31 results about "Gas electron multiplier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas electron multiplier (GEM) is a type of gaseous ionization detector used in nuclear and particle physics and radiation detection. All gaseous ionization detectors are able to collect the electrons released by ionizing radiation, guiding them to a region with a large electric field, and thereby initiating an electron avalanche. The avalanche is able to produce enough electrons to create a current or charge large enough to be detected by electronics. In most ionization detectors, the large field comes from a thin wire with a positive high-voltage potential; this same thin wire collects the electrons from the avalanche and guides them towards the readout electronics. GEMs create the large electric field in small holes in a thin polymer sheet; the avalanche occurs inside of these holes. The resulting electrons are ejected from the sheet, and a separate system must be used to collect the electrons and guide them towards the readout.

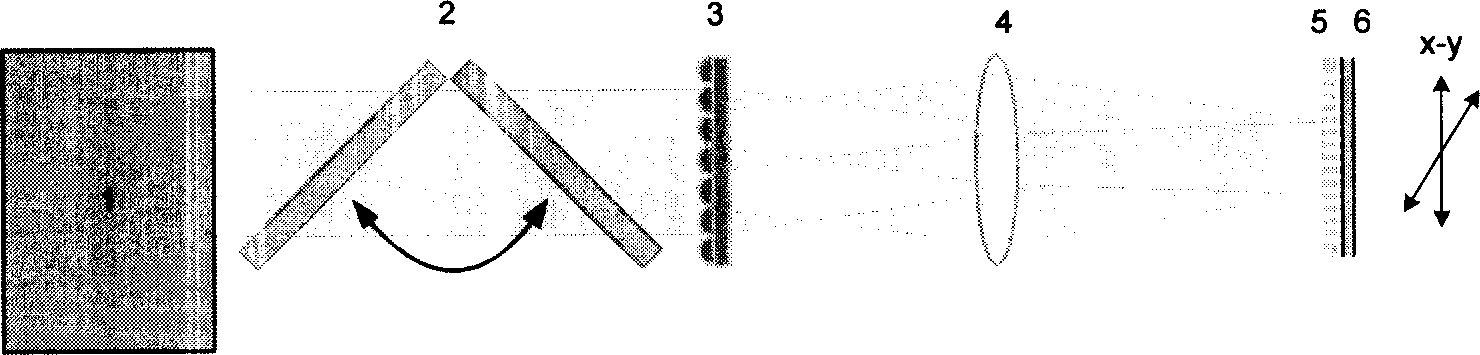

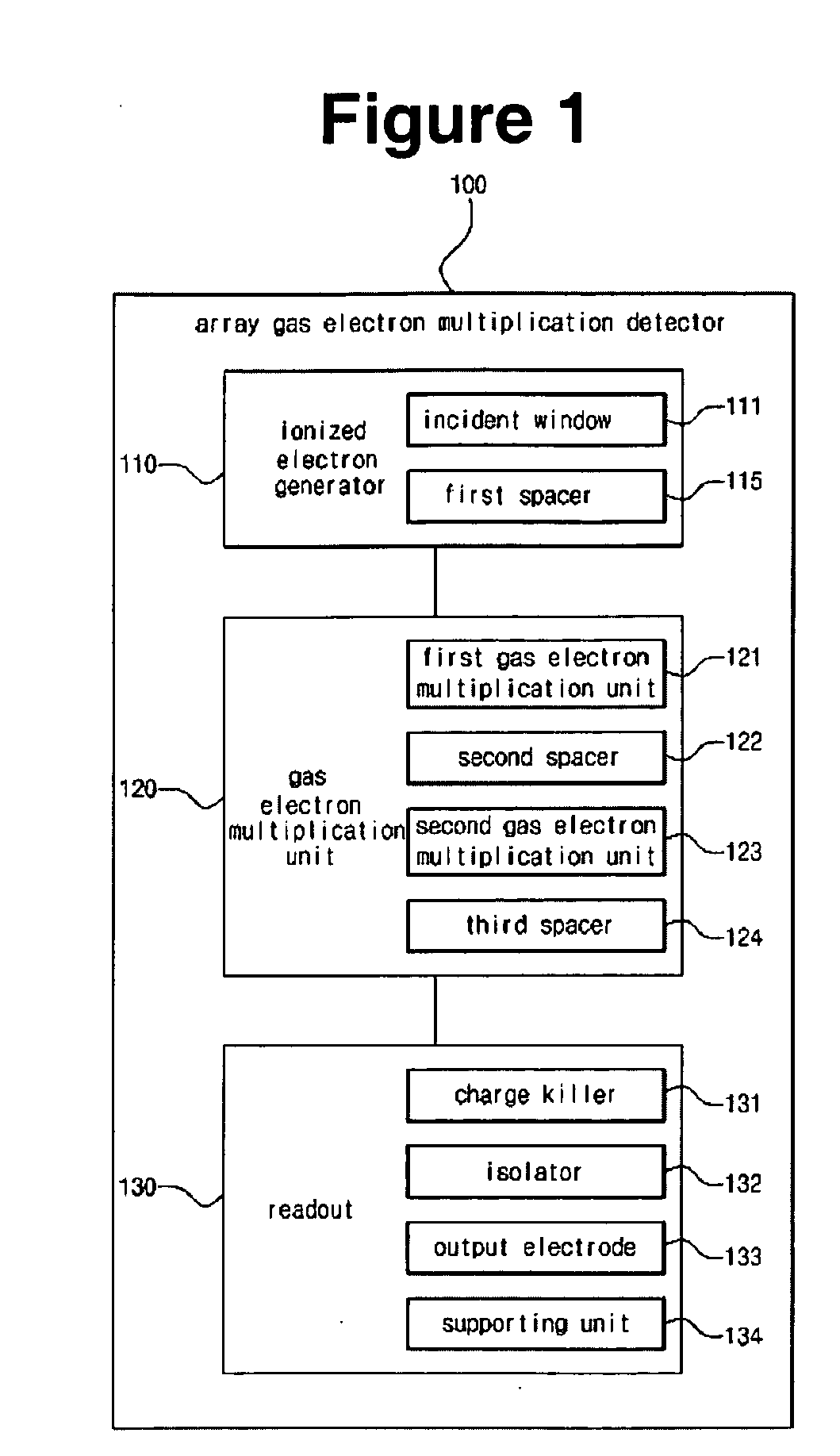

Apparatus for Digital Imaging Photodetector Using Gas Electron Multiplier

InactiveUS20080283725A1High decision measurementImprove stabilityMaterial analysis by optical meansPhotoelectric discharge tubesDigital imagingPhotodetector

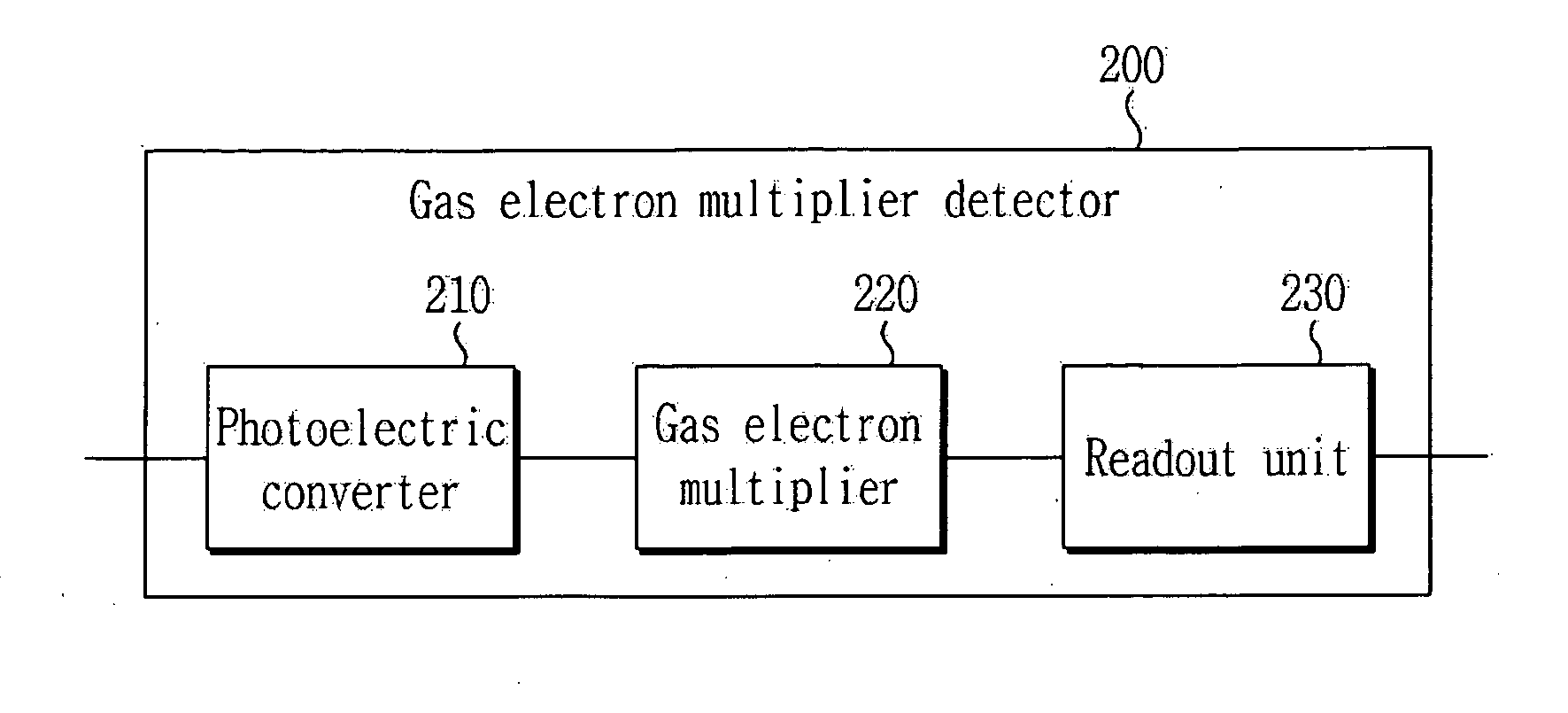

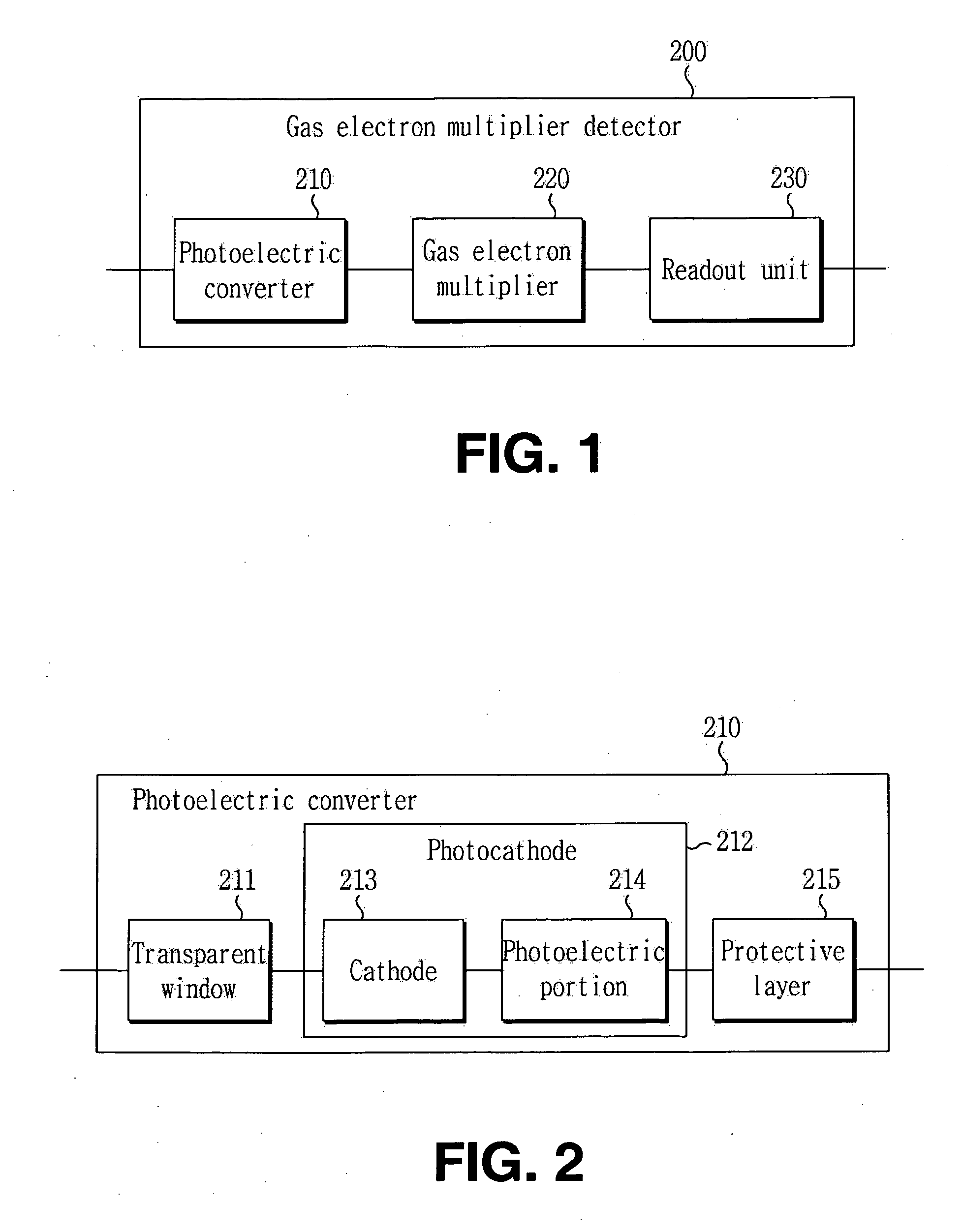

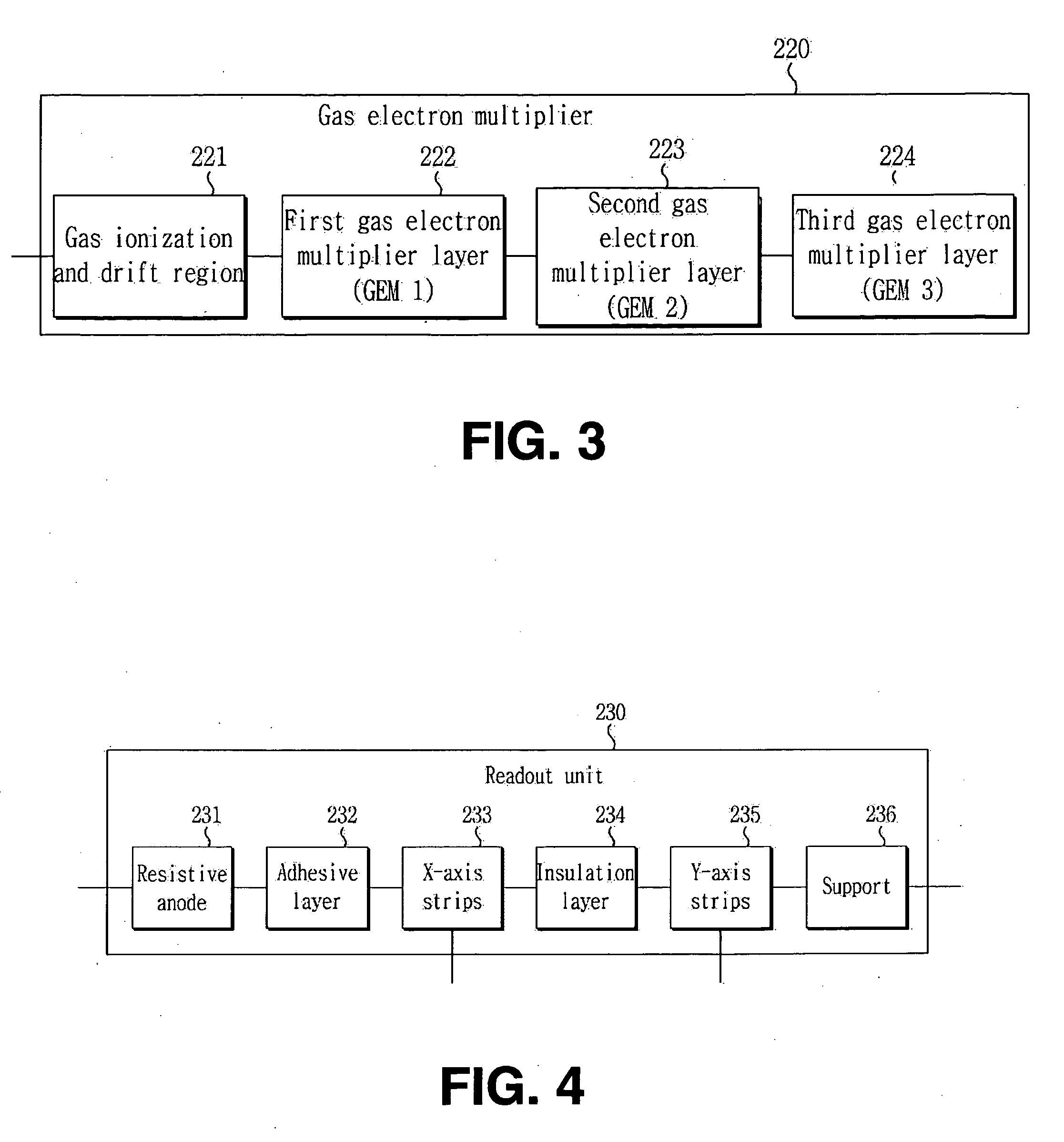

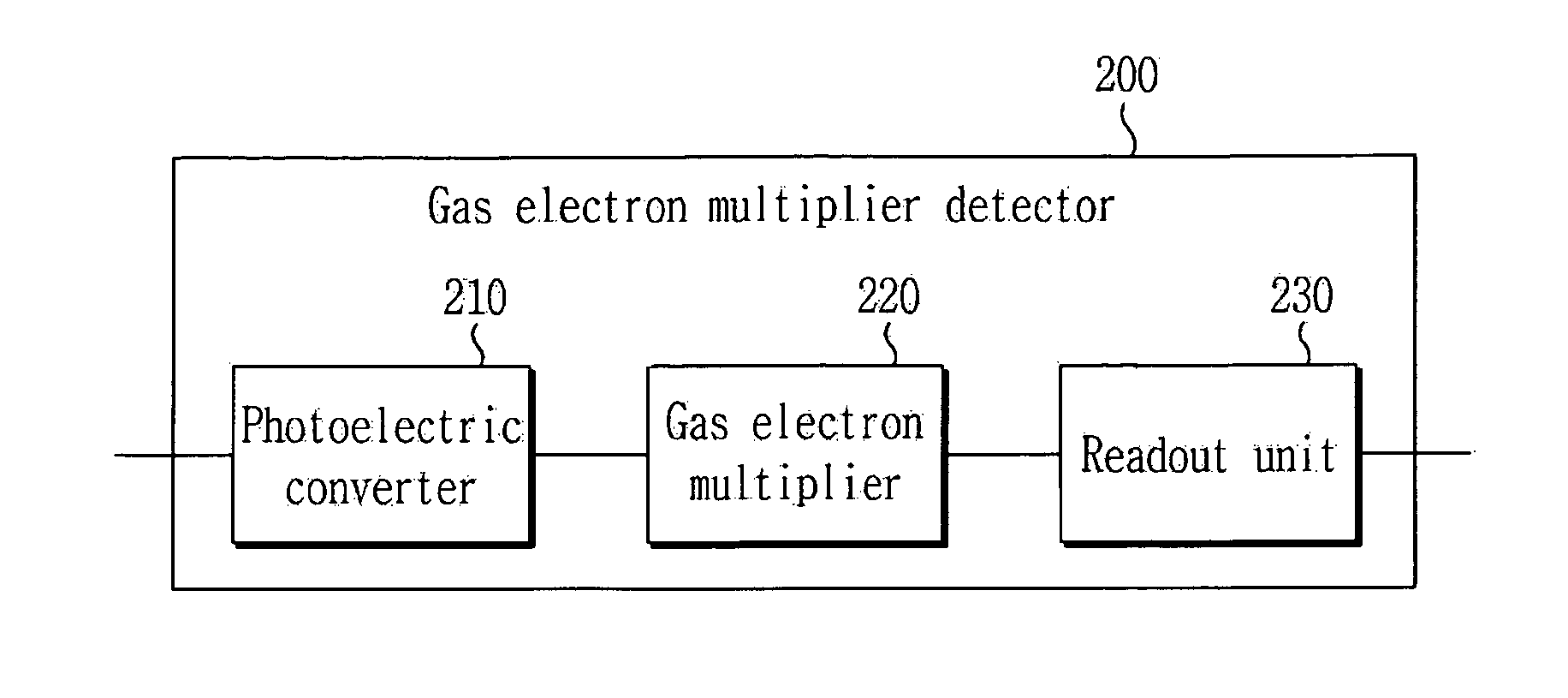

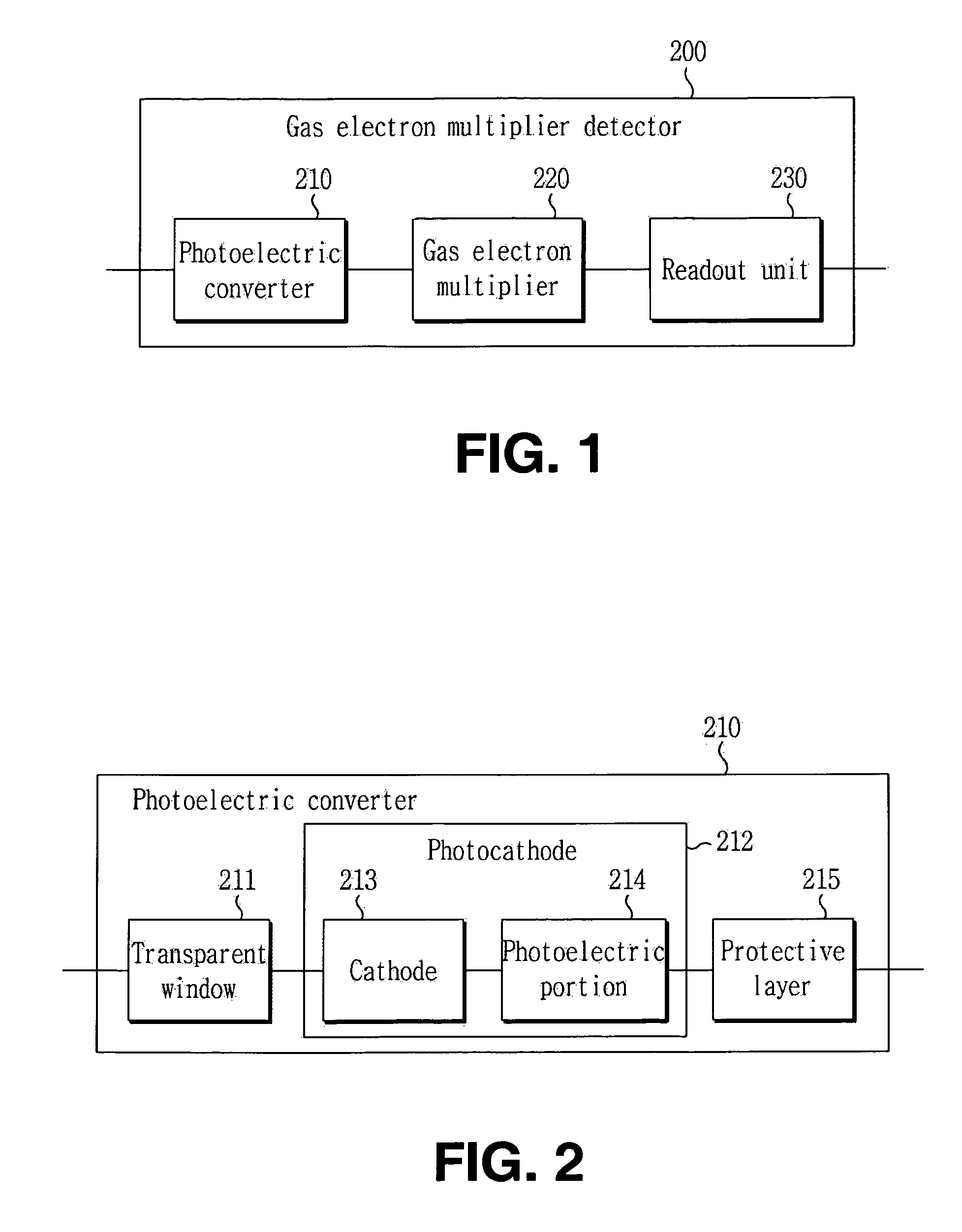

The present invention provides a digital imaging photodetector with a gas electron multiplier. The digital imaging photodetector comprises a gas electron multiplier detector. The gas electron multiplier detector includes a photoelectric converter for converting incident light into photoelectrons or Compton electrons; a gas electron multiplier (GEM) for receiving the photoelectrons or Compton electrons from the photoelectric converter and multiplying them; and a readout unit for receiving an electrical signal indicating a position where an electron cloud multiplied in the gas electron multiplier arrives on an anode, recognizing coordinates of the electron cloud based on the received signal, and outputting the coordinates of the electron cloud. According to the digital imaging photodetector of the present invention, real-time imaging of image information can be achieved by multiplying photoelectrons or Compton electrons, which are discharged due to a photoelectric effect or a Compton effect induced by visible rays, ultraviolet rays or X-rays, using the gas electron multiplier.

Owner:HAHN CHANG HIE

Radiographic image detector

InactiveUS20120018642A1High sensitivityExcellent in position resolutionCathode ray tubes/electron beam tubesSolid-state devicesHard X-raysLanthanum fluoride

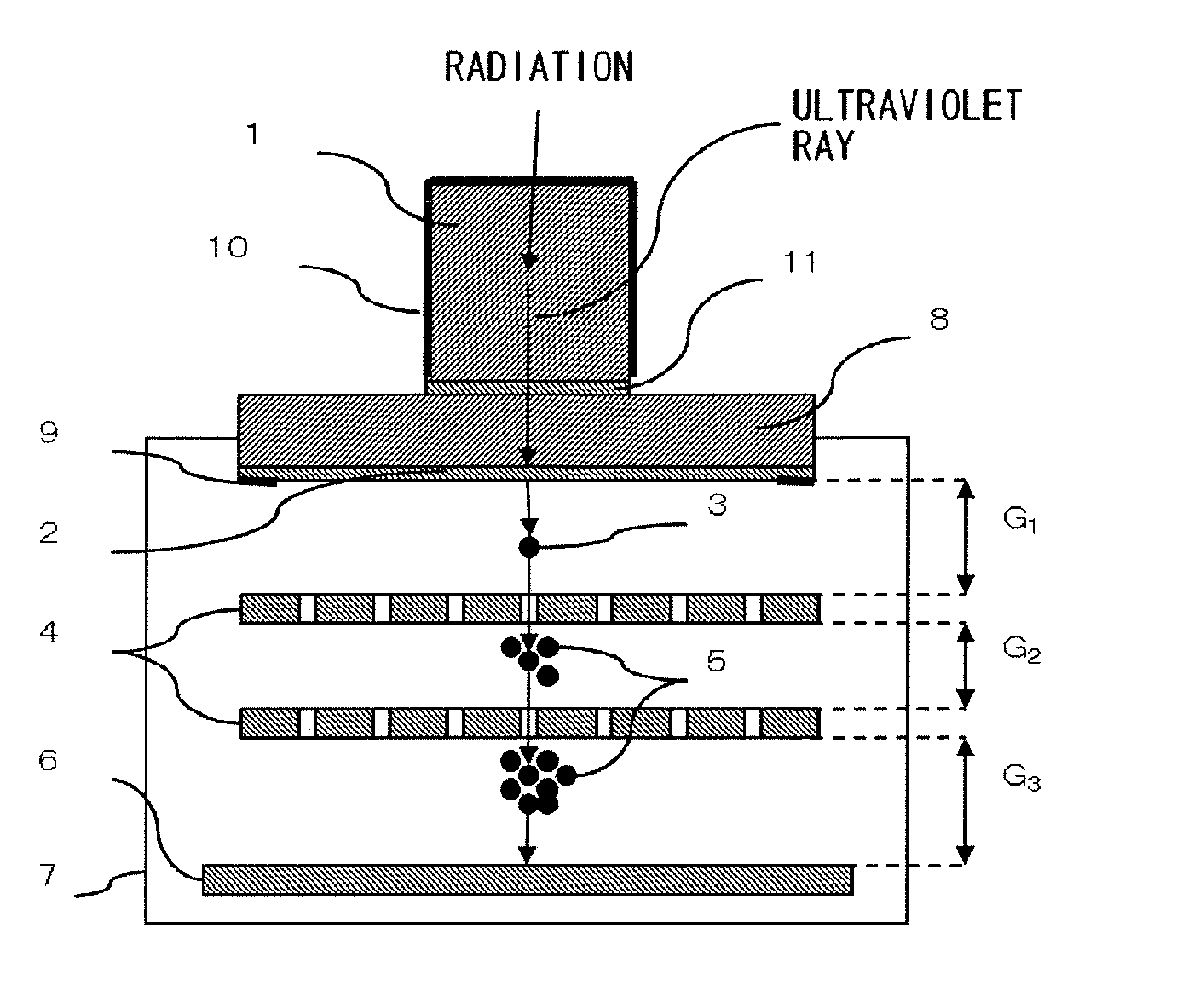

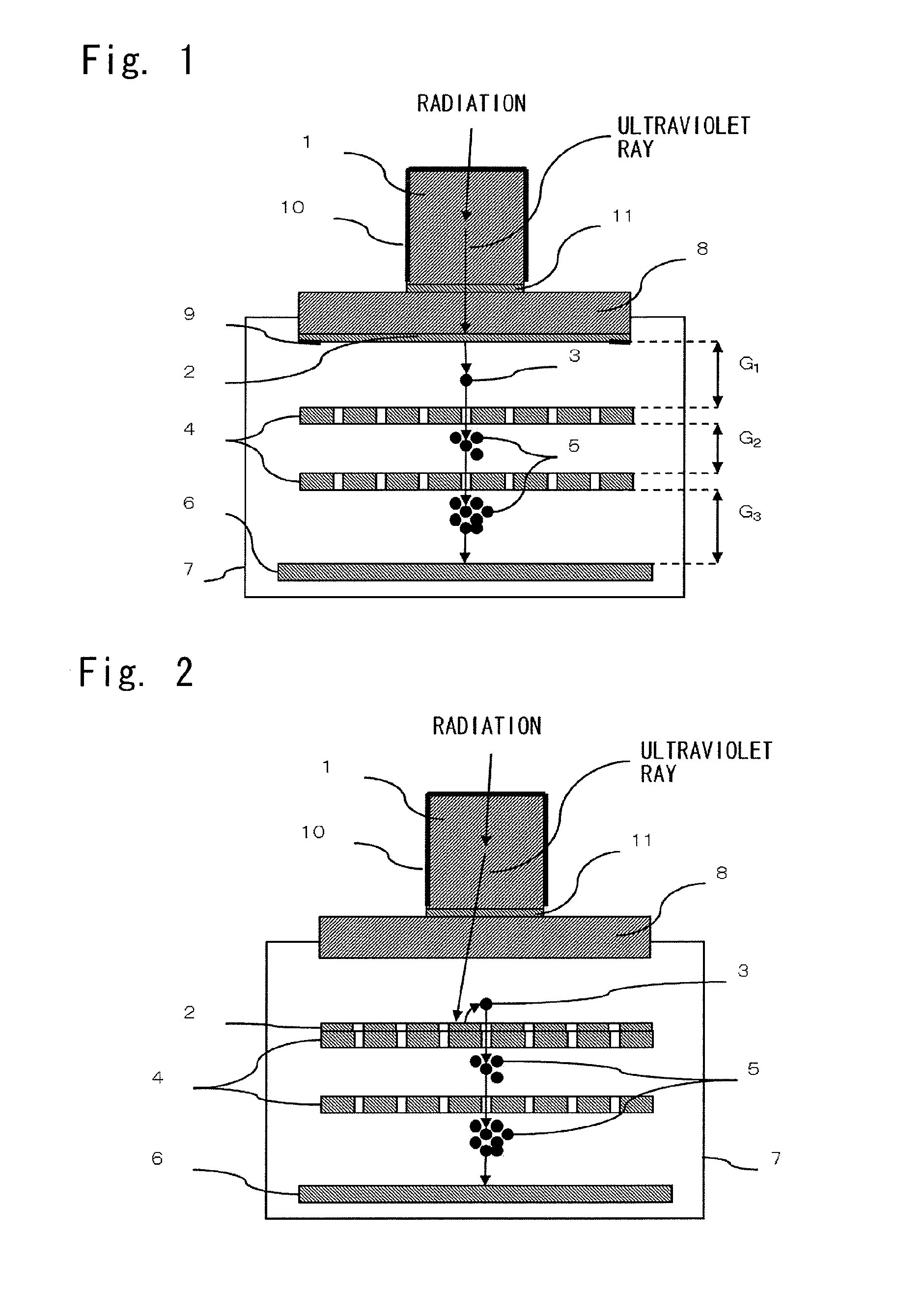

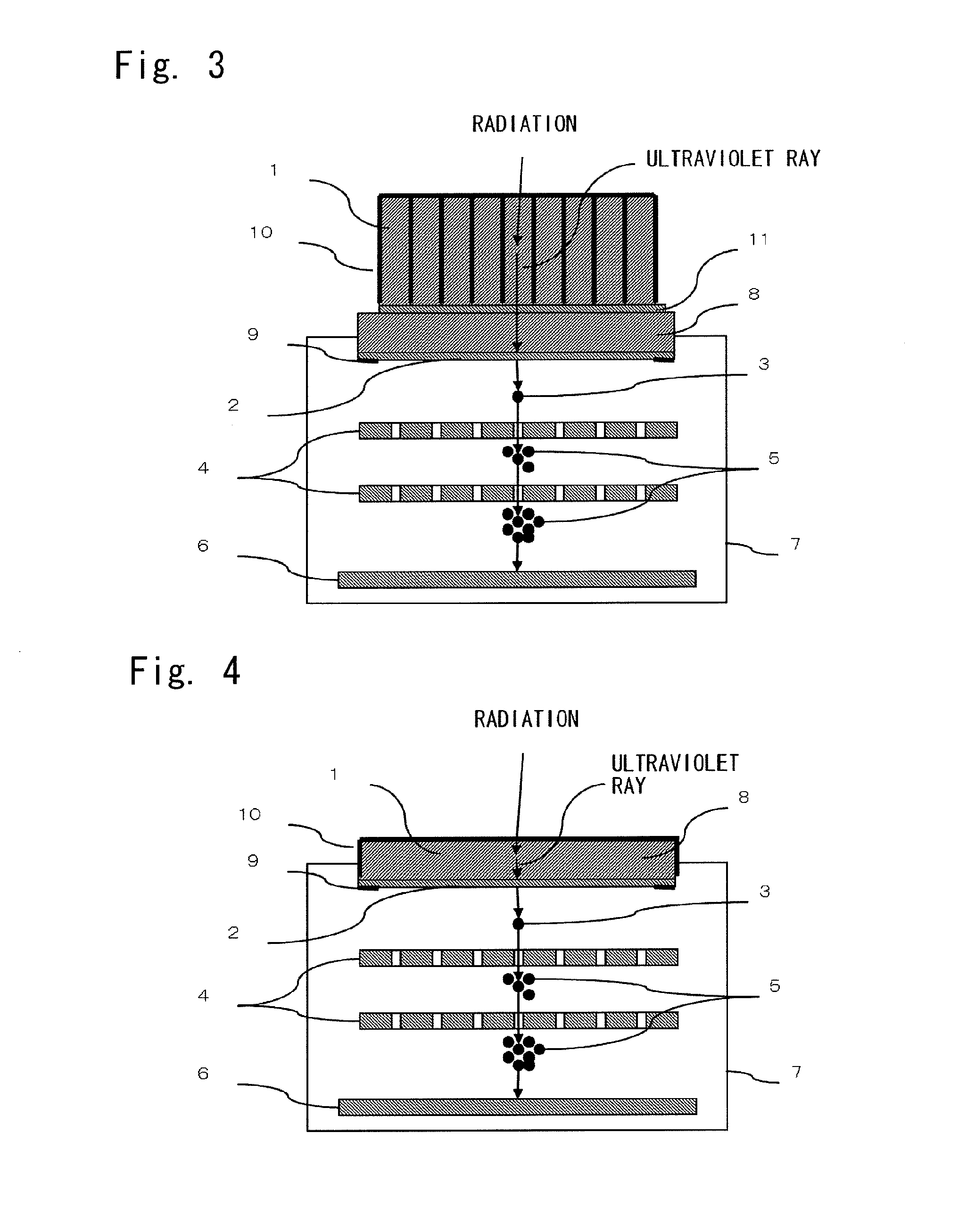

[Problems to be Solved] It is an object of the present invention to provide a novel radiographic image detector which can detect radiation, such as hard X-rays or γ-rays, with high sensitivity and which is excellent in position resolution and count rate characteristic.[Means to Solve the Problems] A radiographic image detector comprises a combination of a scintillator, such as a lanthanum fluoride crystal containing neodymium, for converting incident radiation into ultraviolet rays; and a gas multiplication ultraviolet image detector for converting ultraviolet rays into electrons, amplifying such electrons by use of a gas electron avalanche phenomenon, and detecting the electrons. The radiographic image detector is characterized in that the gas multiplication ultraviolet image detector is basically constituted by a photoelectric conversion substance, such as cesium iodide or cesium telluride, for converting ultraviolet rays into electrons; a gas electron multiplier for amplifying electrons by use of the gas electron avalanche phenomenon; and a pixel electrode having an amplification function and a detection function.

Owner:TOKUYAMA CORP +3

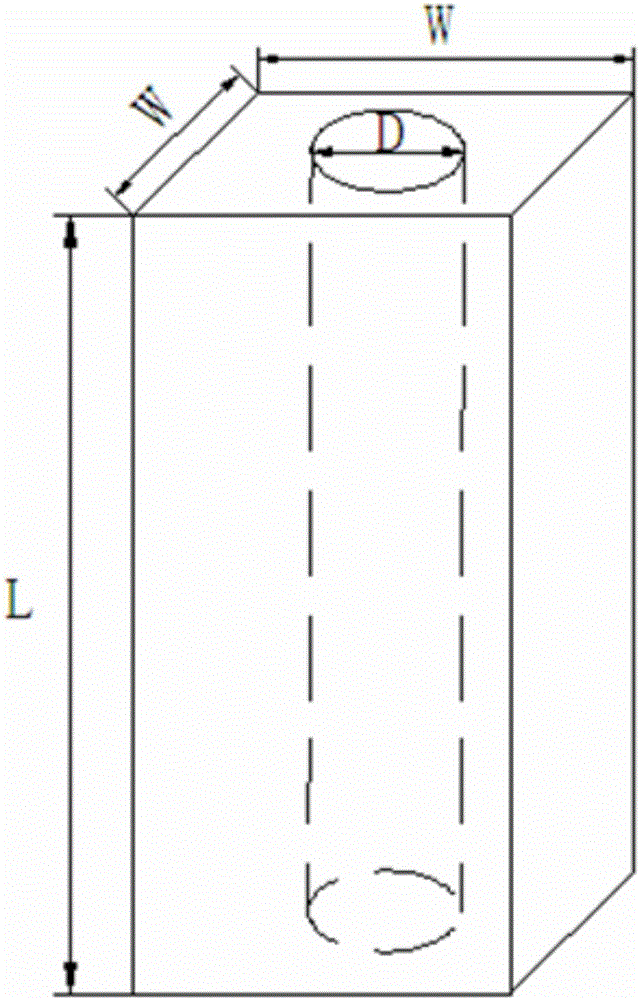

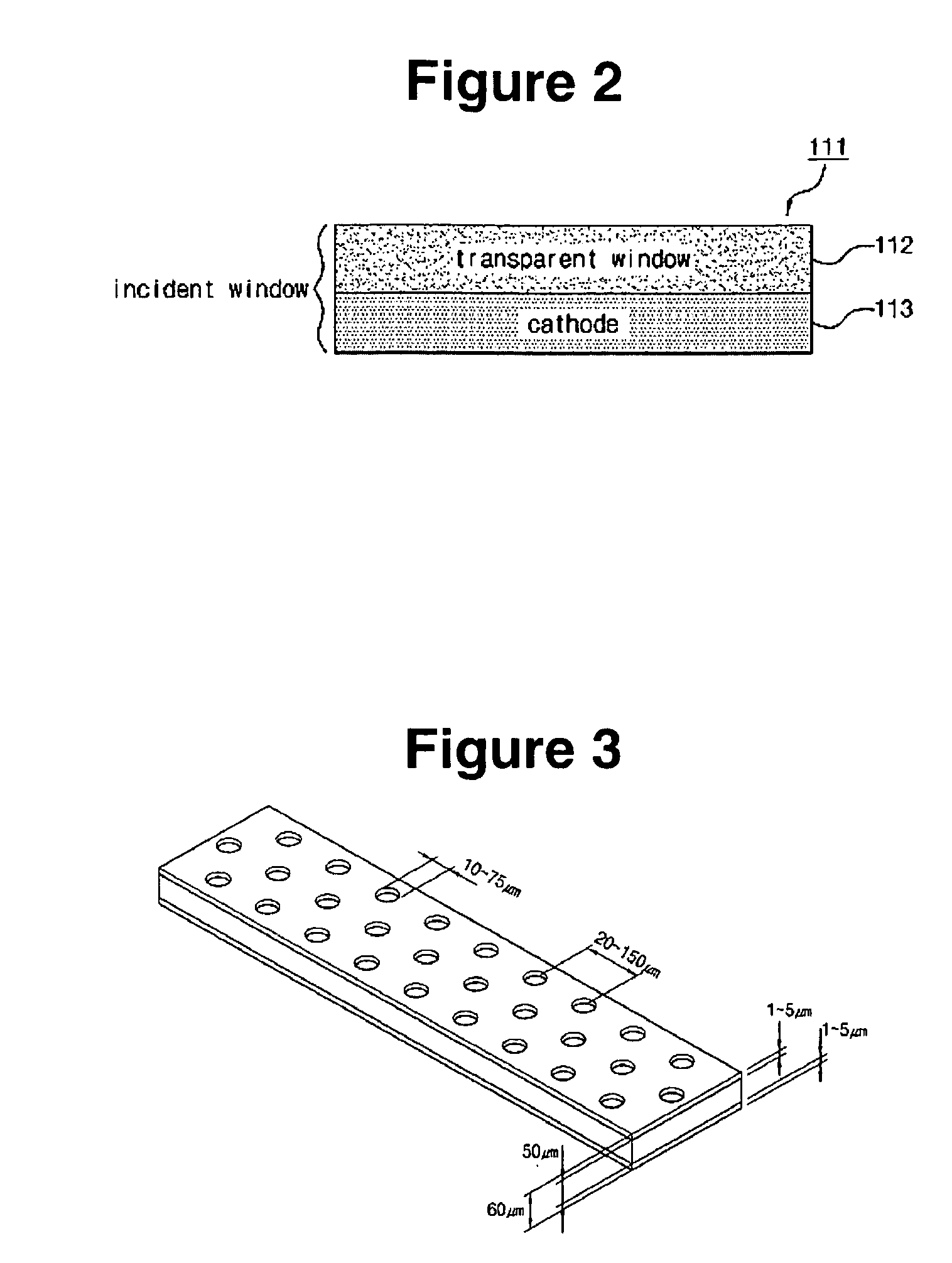

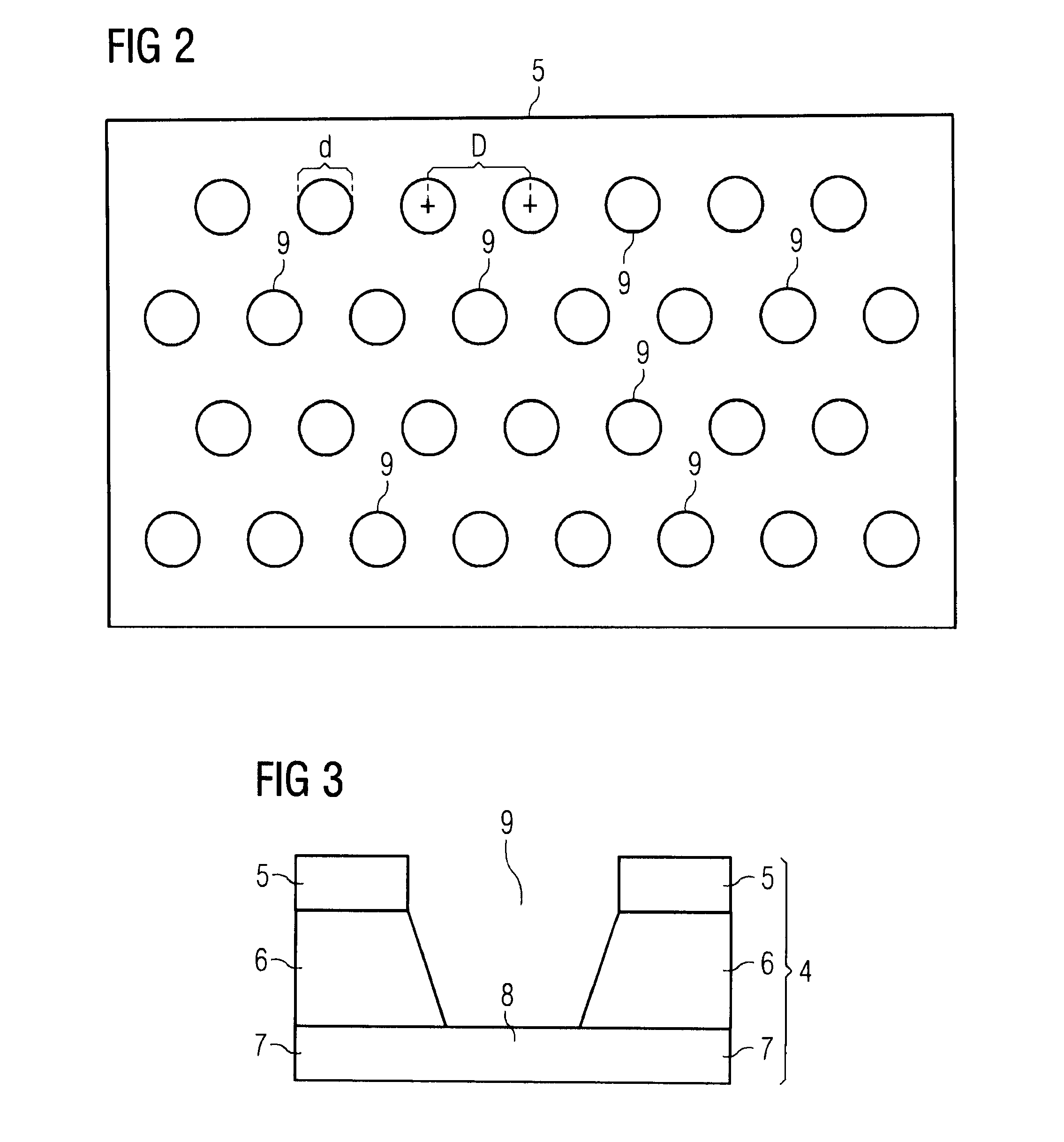

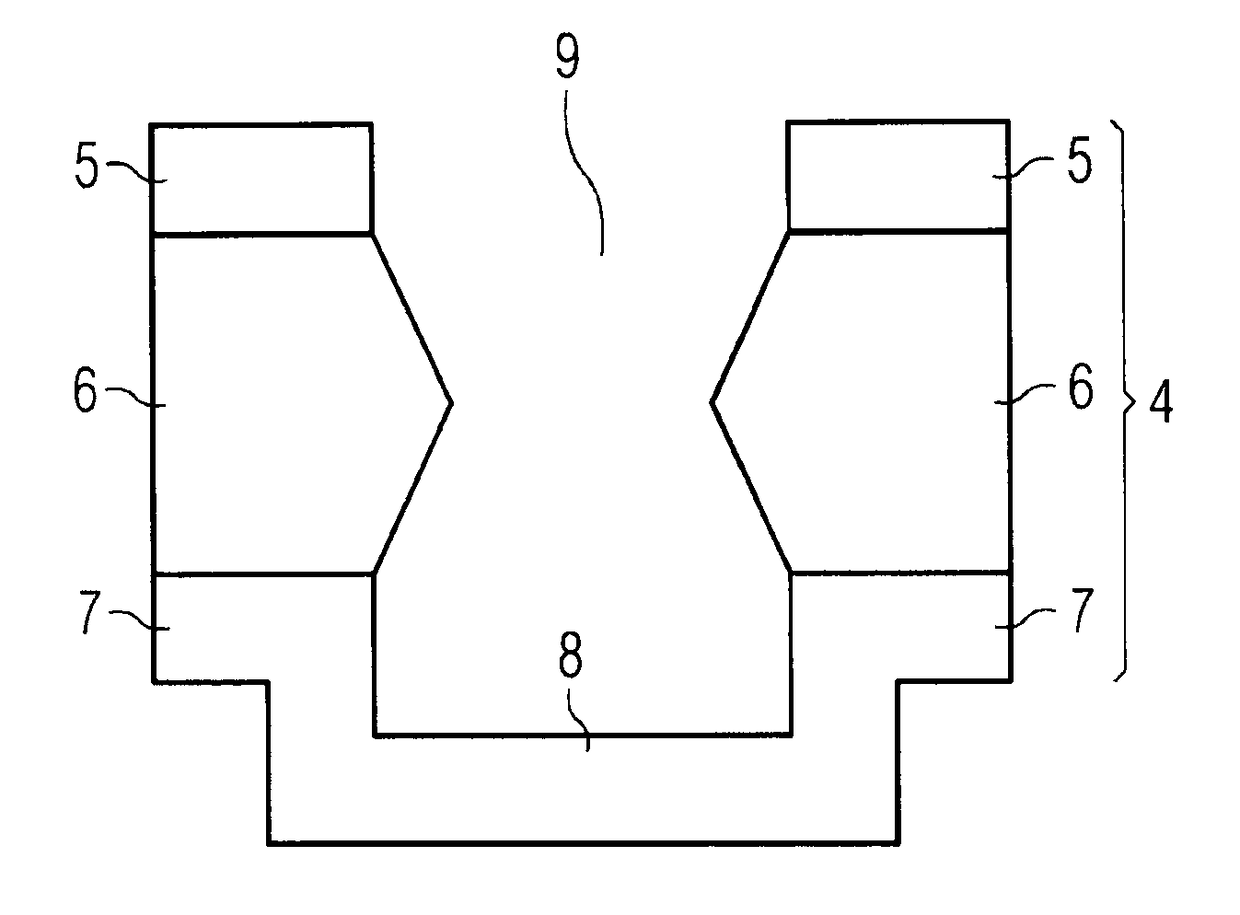

Gas electron multiplier and manufacturing method for gas electron multiplication foil used for same as well as radiation detector using gas electron multiplier

ActiveUS7994483B2Reduce transmissionGood effectElectric discharge tubesDecorative surface effectsInsulation layerImage resolution

To attain objects to reduce the spread of electrons as compared with a conventional one without degrading the multiplication factor of electrons; to provide a large electron multiplication factor; and to improve positional resolution, there is provided a gas electron multiplier using interaction between radiation and gas through photoelectric effects including: a chamber filled with gas and a single gas electron multiplication foil arranged in the chamber wherein the gas electron multiplication foil is made of a plate-like multilayer body composed by having a plate-like insulation layer made of a macromolecular polymer material having a thickness of around 100 μm to 300 μm and flat metal layers overlaid on both surfaces of the insulation layer, and the plate-like multilayer body is provided with a through-hole structure.

Owner:RIKEN +2

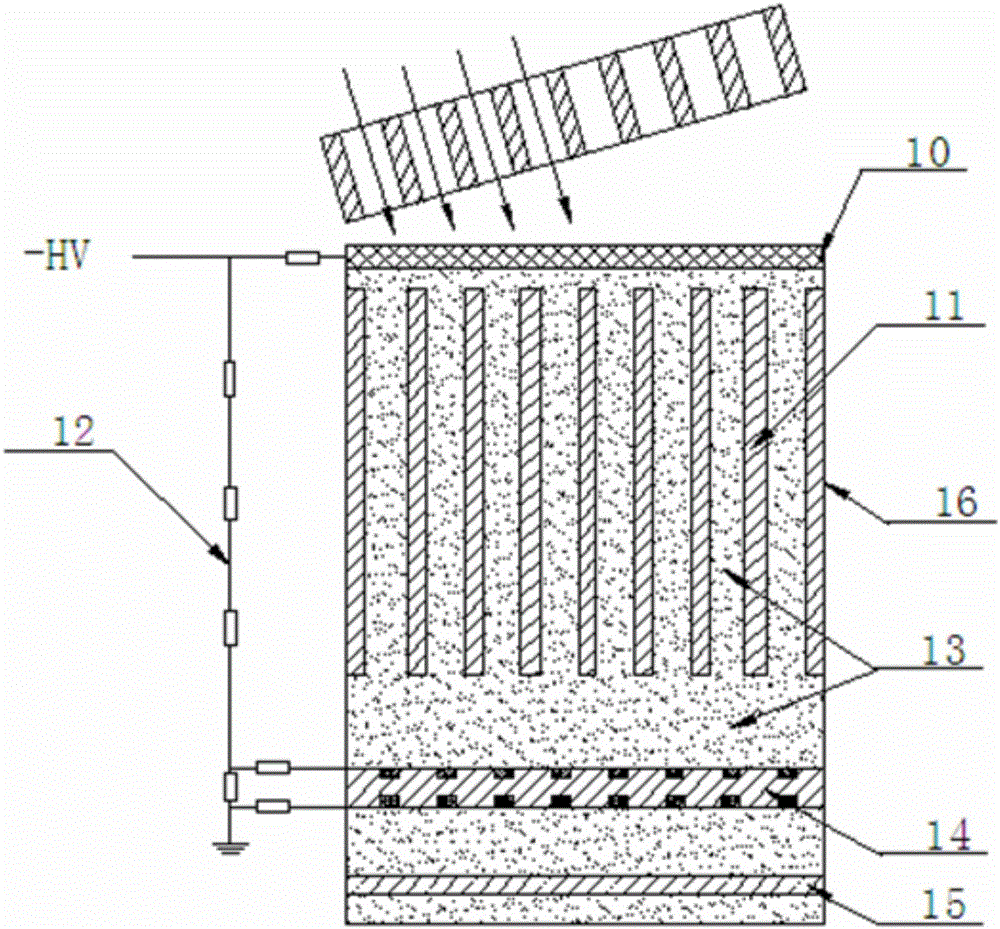

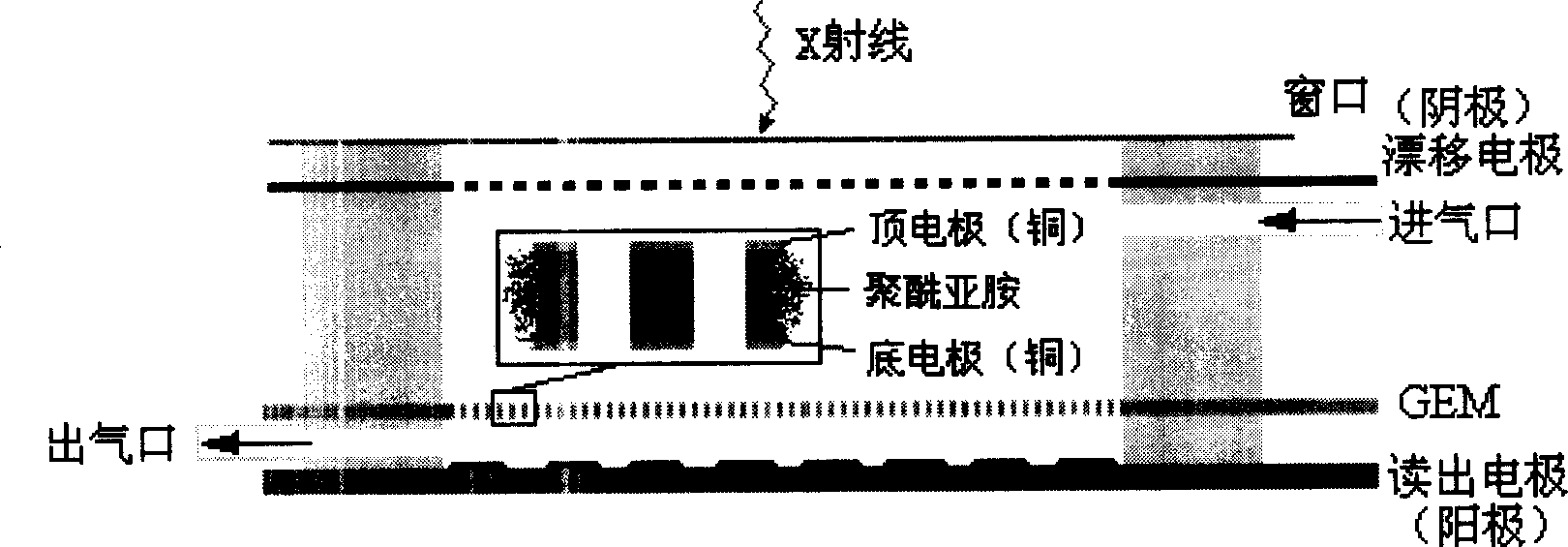

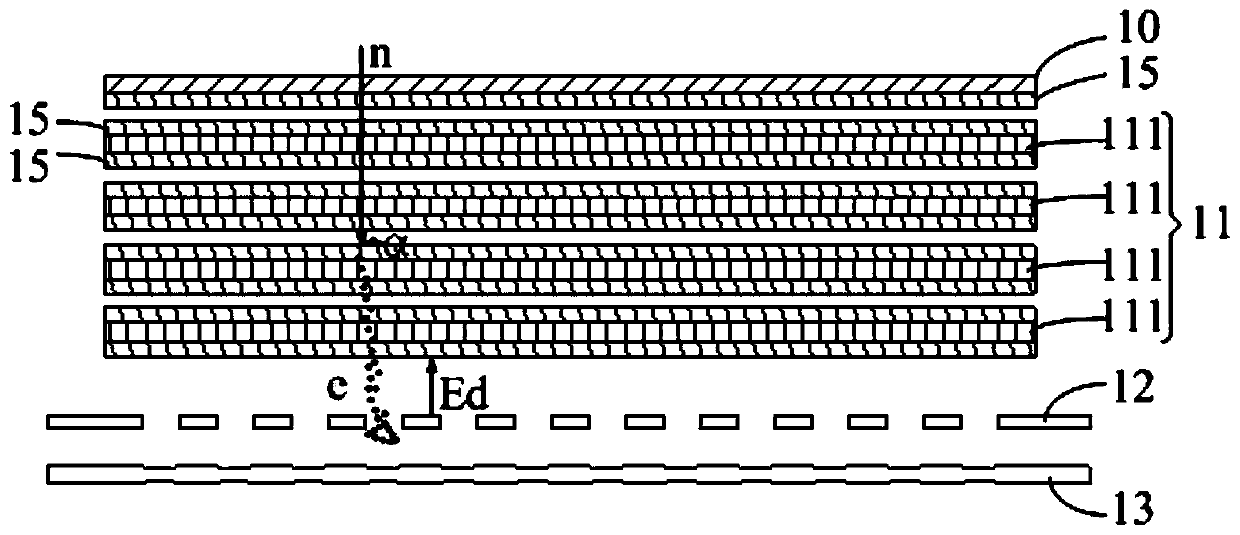

Microchannel plate type fast neutron position gas detector and detection method thereof

InactiveCN105929441AGet rid of dependenceLow costNeutron radiation measurementGas detectorHigh voltage

The invention provides a microchannel plate type fast neutron position gas detector and a detection method thereof, and relates to the field of nuclear technology applications. The detector comprises a gas chamber with an intake hole and an exhaust hole, a drift cathode, a microchannel structure plate, a gas electron multiplier, a high voltage dividing circuit, a read out PCB and a working gas. The drift cathode is arranged in the gas chamber with the intake hole and the exhaust hole. The microchannel structure plate is arranged below the drift cathode. The gas electron multiplier is arranged below the microchannel structure plate. The read out PCB is arranged below the gas electron multiplier. The working gas fills the whole chamber and a microchannel in the microchannel structure plate. The microchannel plate type fast neutron position gas detector provided by the invention can normally work at a high counting rate, and can be used for large part non-destructive detection and container scanning security check.

Owner:章先鸣

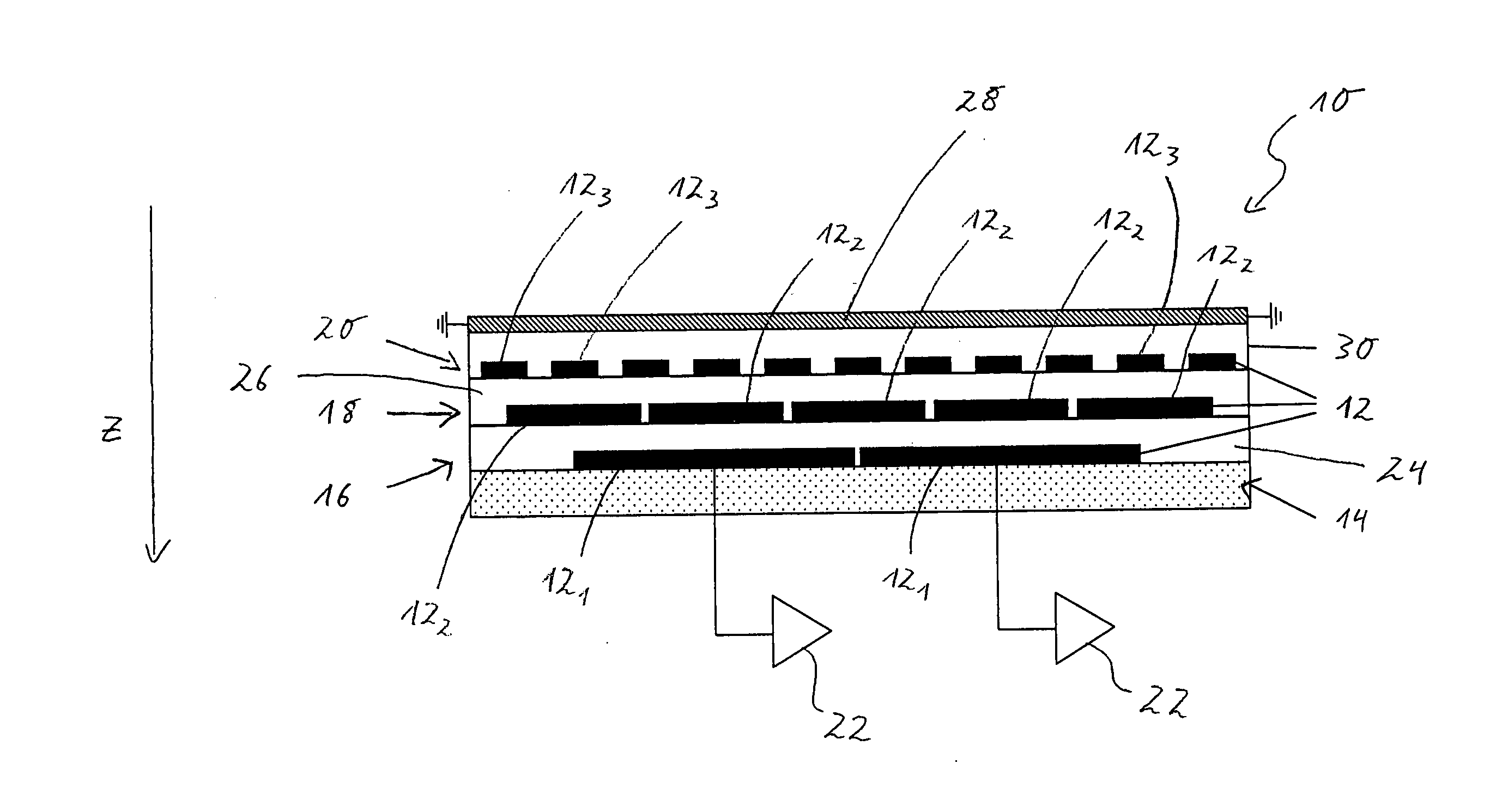

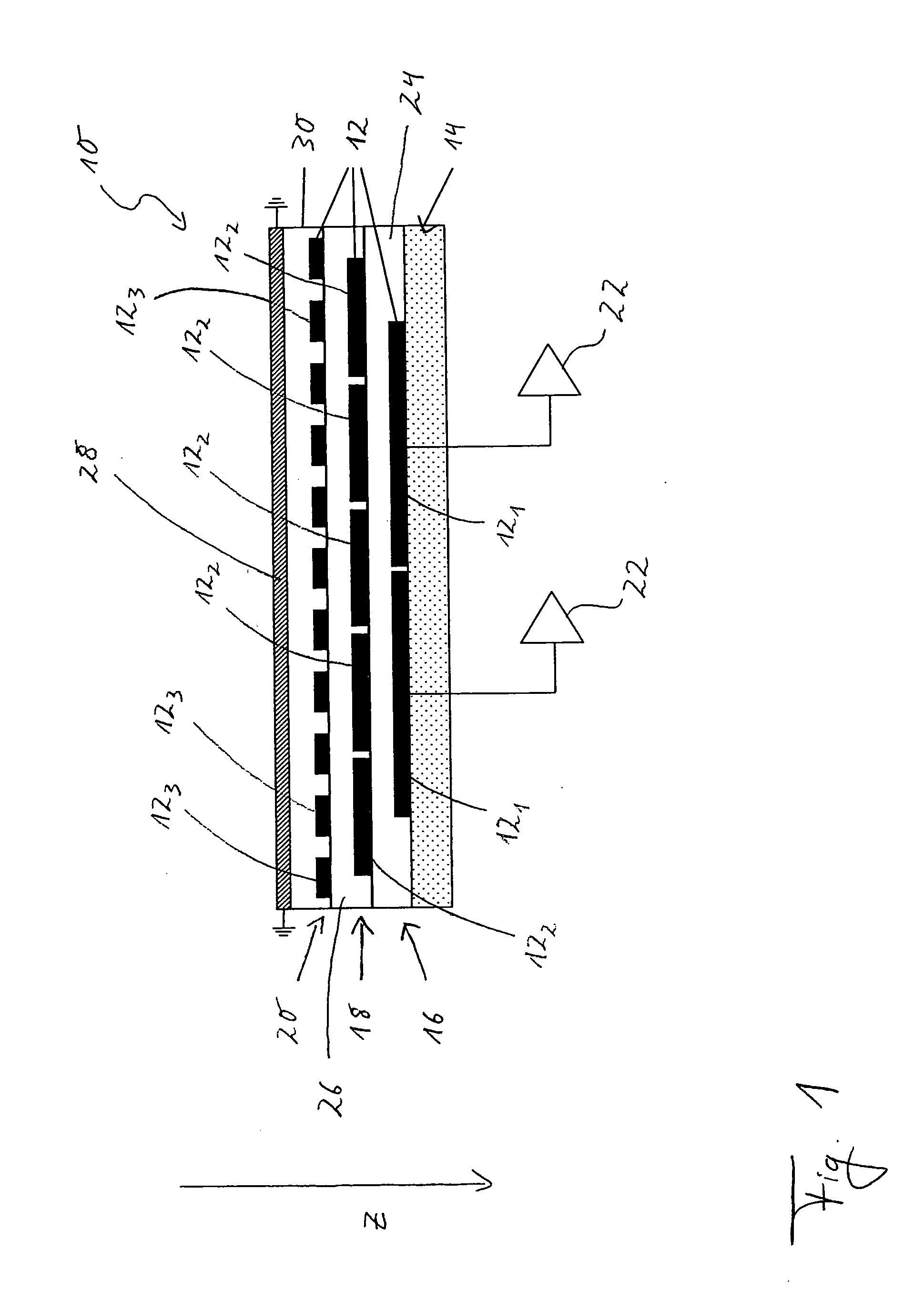

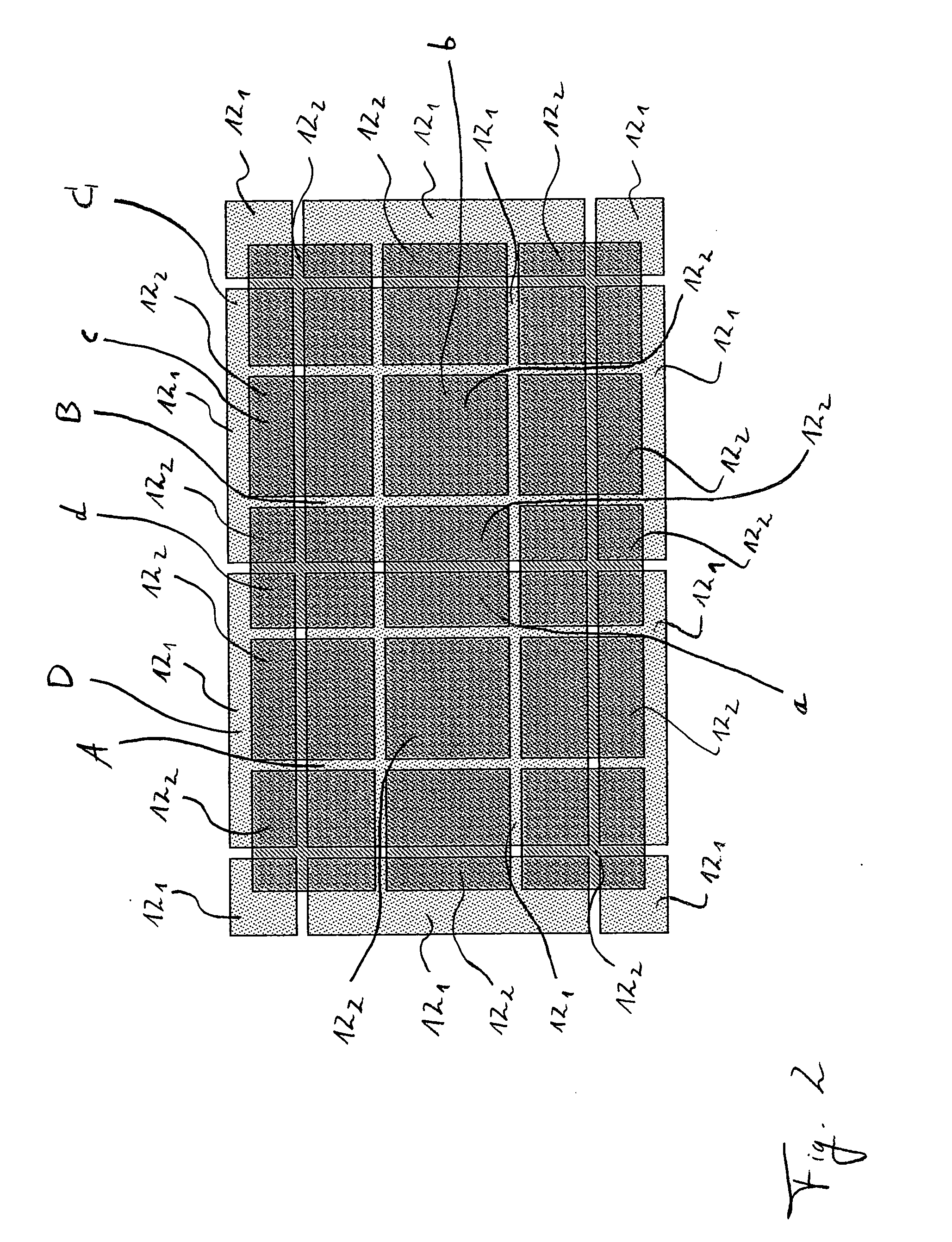

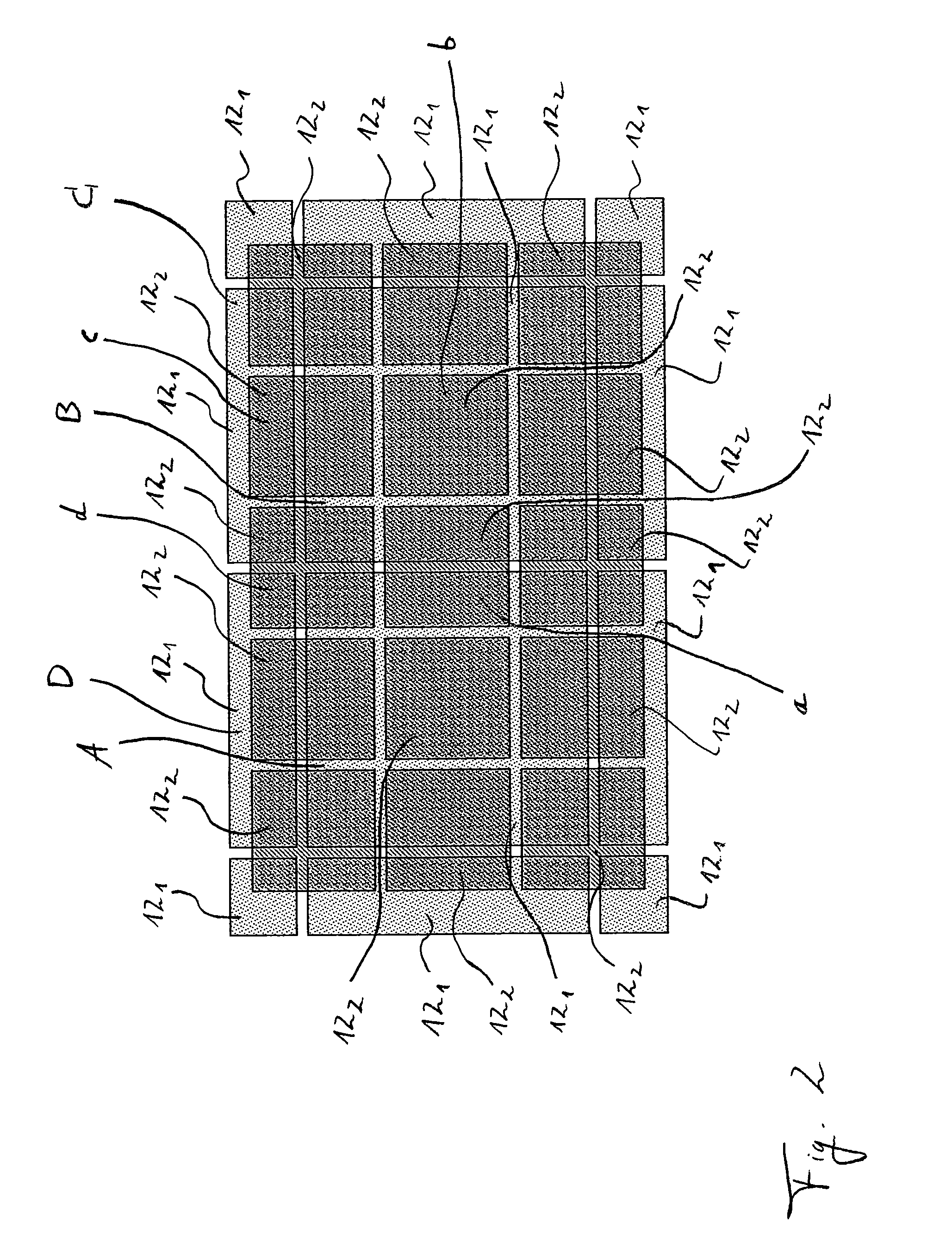

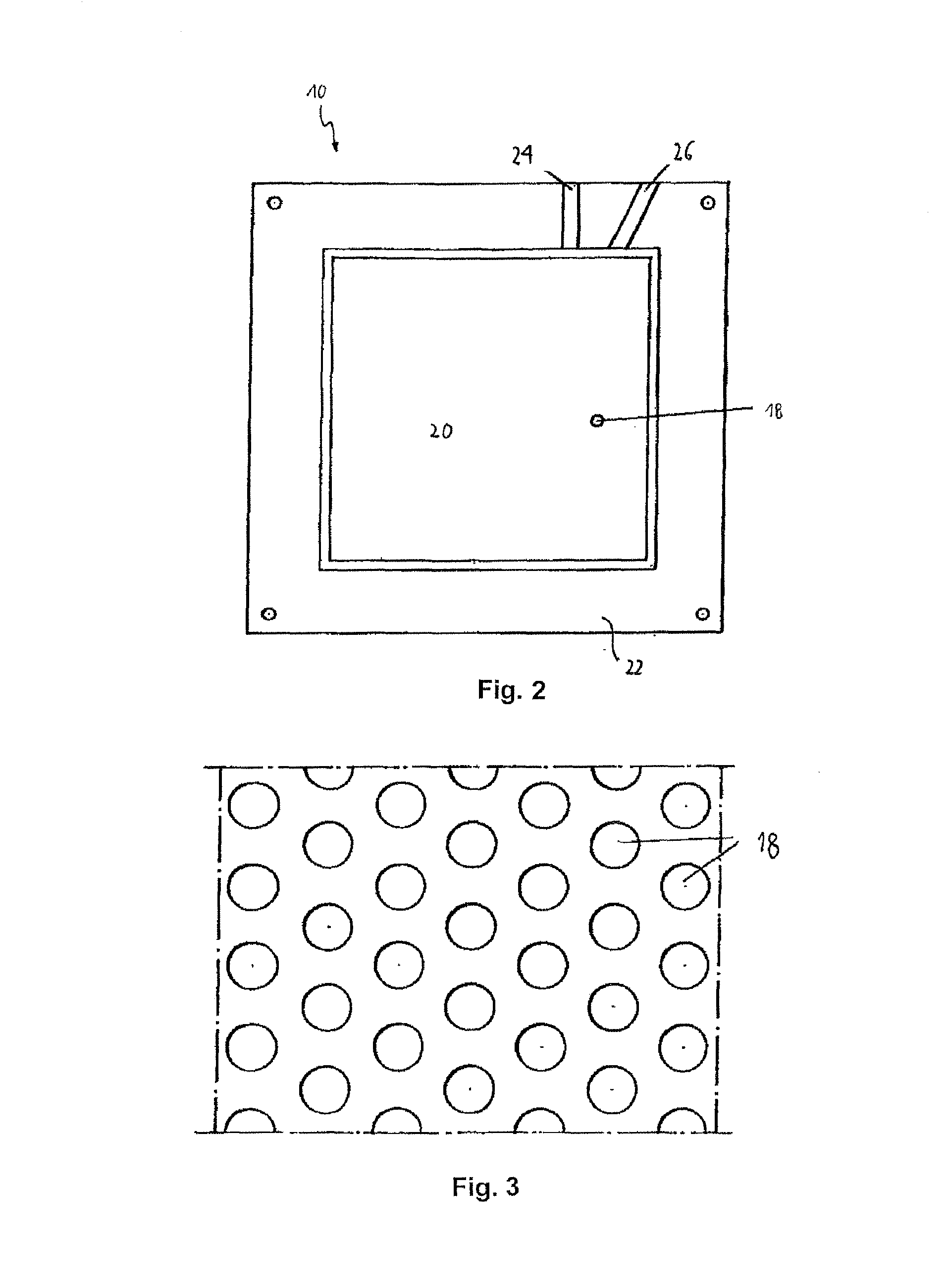

Capacitive Spreading Readout Board

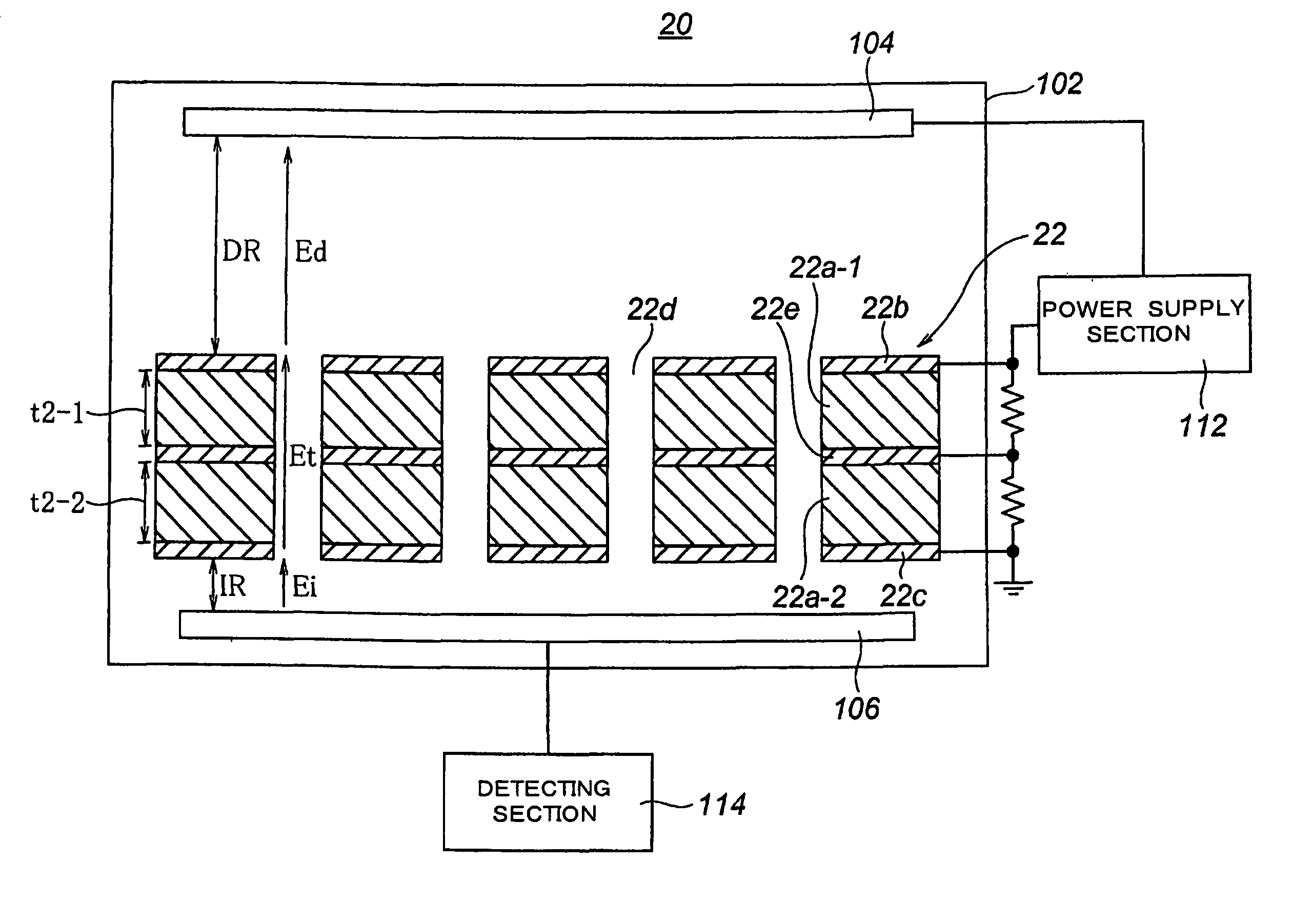

InactiveUS20120261585A1Reduces cost and overall complexity of readoutIncreased physical sizeElectric discharge tubesMaterial analysis by optical meansDielectricCapacitance

A readout board for use in a micropattern gas detector comprises a plurality of detector pads arranged into a plurality of consecutive layers that are separated by dielectric spacer material. An electron cloud hitting the front side of the readout board will induce a charge on one of the detector pads of the uppermost layer. By capacitive coupling, the signal will propagate downwards through the consecutive layers until it reaches the bottom layer, from which the charges are read out and analyzed. The position of the impact can be determined by comparing the charges that have spread to neighboring readout pads. Since only the bottommost layer of the readout pads needs to be connected to readout electronics, incident particles can be localized at high precision despite the relatively large size of the readout pads in the bottom layer. The invention is effective both in a gas electron multiplier (GEM) and in a MicroMegas detector.

Owner:EUROPEAN ORGANIZATION FOR NUCLEAR RESEARCH

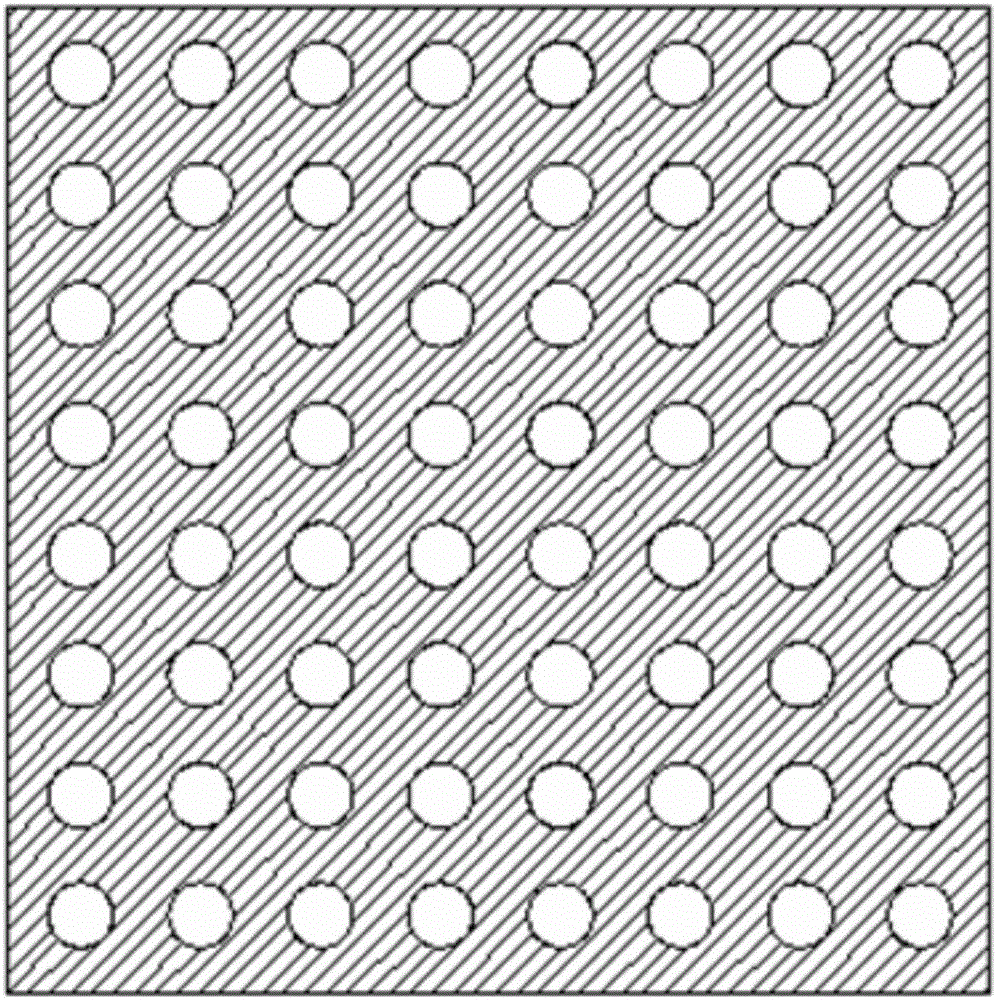

Method for making gas electron multiplier polymer film grid

The invention is a manufacturing method for gas electron multiplier polymers film mesh applied to the X ray detection. The invention uses 308nm norm molecular laser to irradiate the polyimide (PI) coated with red copper film at the two surfaces, the micro-aperture mesh are formed on the PI film by using the effect of the micro-aperture array mask board attached on the PI film. The mesh with any size can be acquired with X-Y scanning platform. The invention produces the gas electron multiplier polymer film mesh can be acquired by using 308nm norm molecular laser poring method. It is simple and effective.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

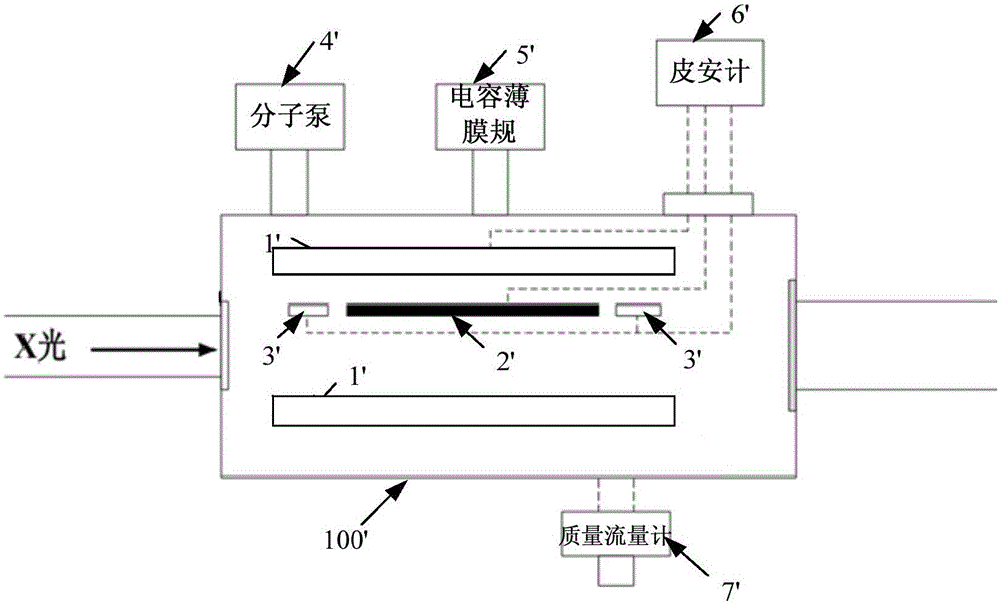

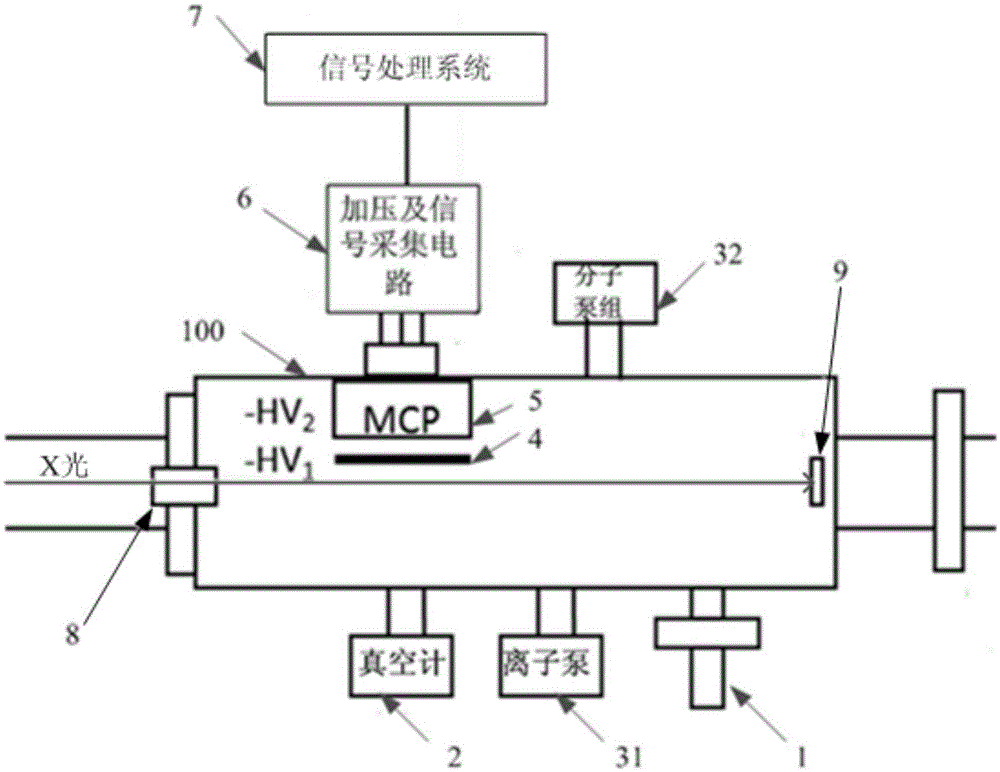

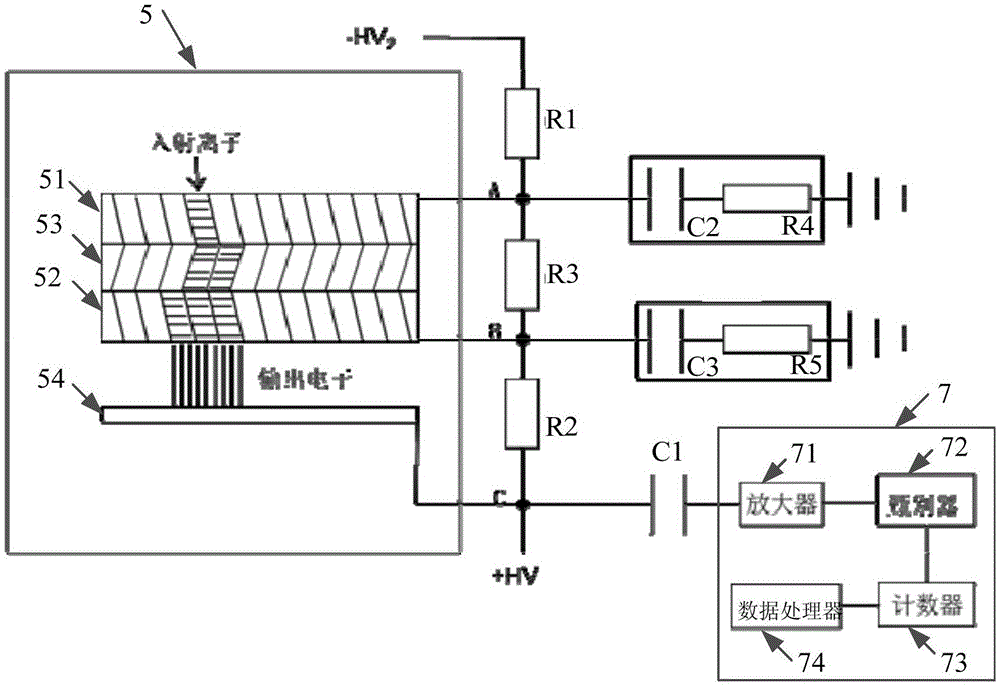

Ionization absorption spectrum detection device based on multi-channel electron multiplier

ActiveCN105092690AReduce air pressureReduce measurement impactMaterial analysis by electric/magnetic meansChannel electron multiplierElectron multiplier

The invention provides an ionization absorption spectrum detection device based on a multi-channel electron multiplier; the ionization absorption spectrum detection device includes an ionization chamber for ionizing gas, a golden net, the multi-channel electron multiplier, a voltage increasing and signal acquisition circuit, and a signal processing system; the golden net is arranged in the ionization chamber and arranged for collecting ions generated from ionization in the ionization chamber; the multi-channel electron multiplier is arranged in the ionization chamber, has the position opposite to the position of the golden net so as to form an electric field between the multi-channel electron multiplier and the golden net, receives the ions collected by the golden net through the action of the electric field and outputs a corresponding ion signal; the voltage increasing and signal acquisition circuit is connected to the multi-channel electron multiplier and arranged for providing voltage for the multi-channel electron multiplier and acquiring and outputting the ion signal; the signal processing system is arranged for receiving the ion signal and acquiring a corresponding ionization absorption spectrum according to the ion signal. The ionization absorption spectrum detection device can improve the accuracy degree of measurement beam line energy resolution ratio and reduce the influence of gas collision broadening on a final result.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

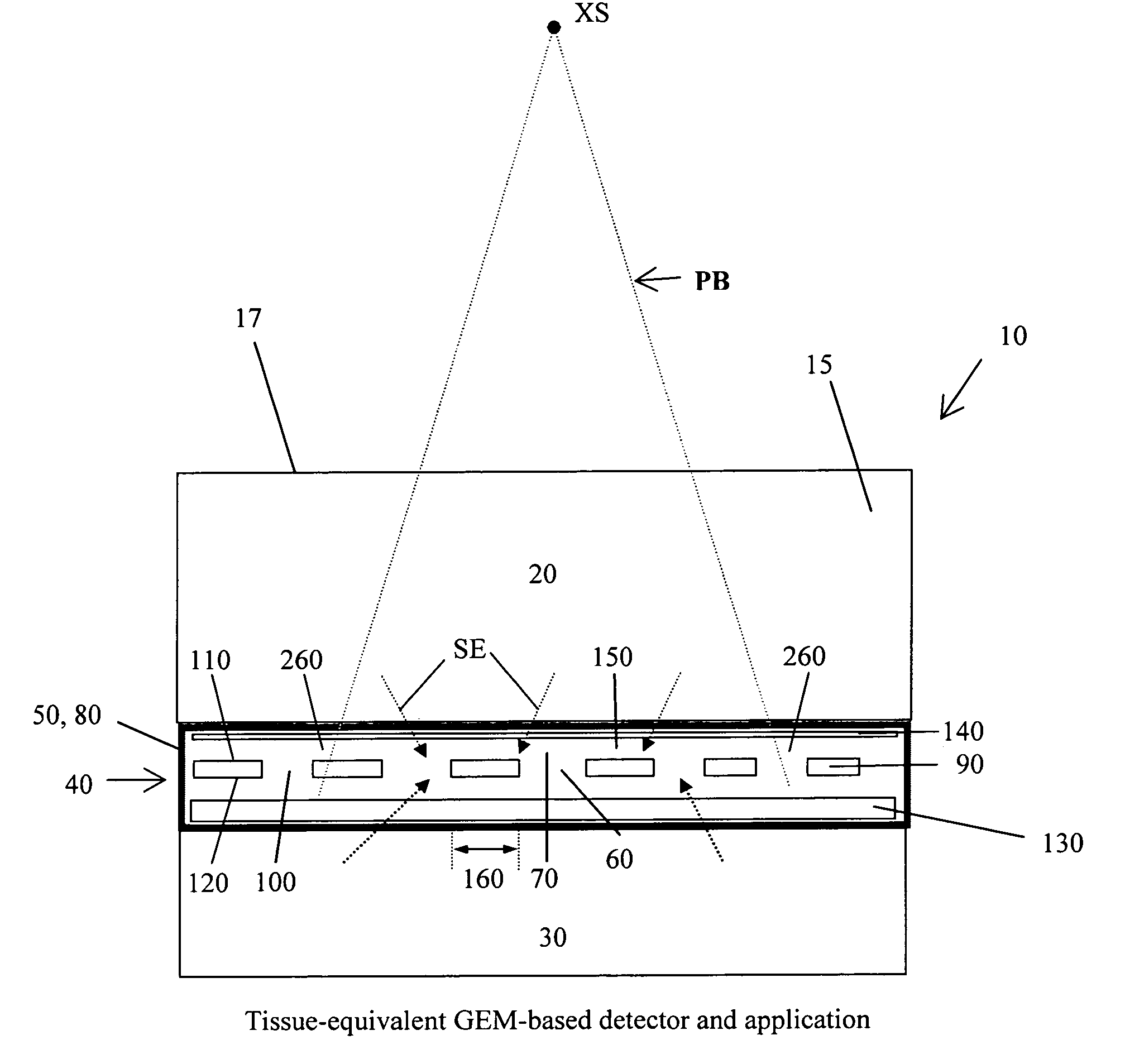

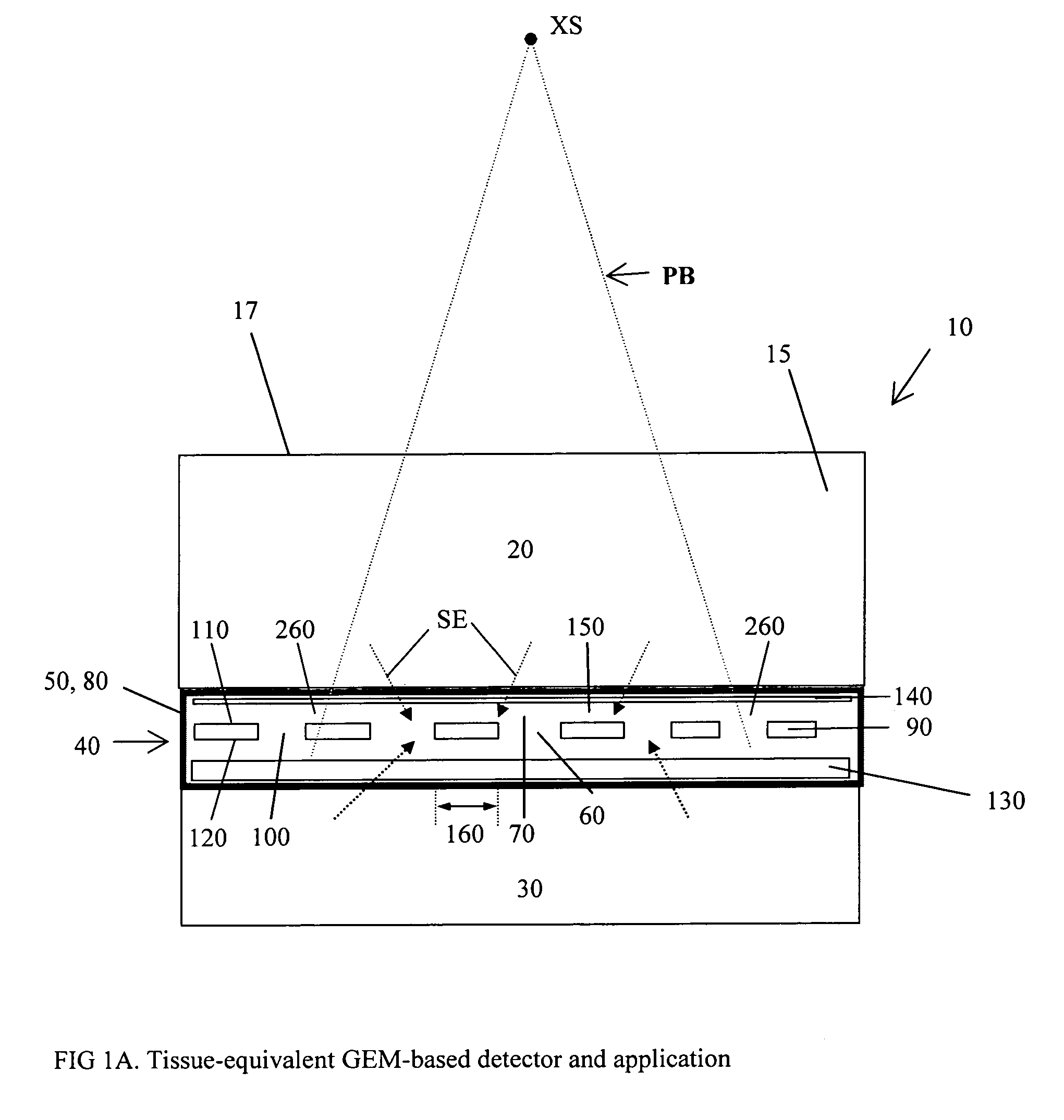

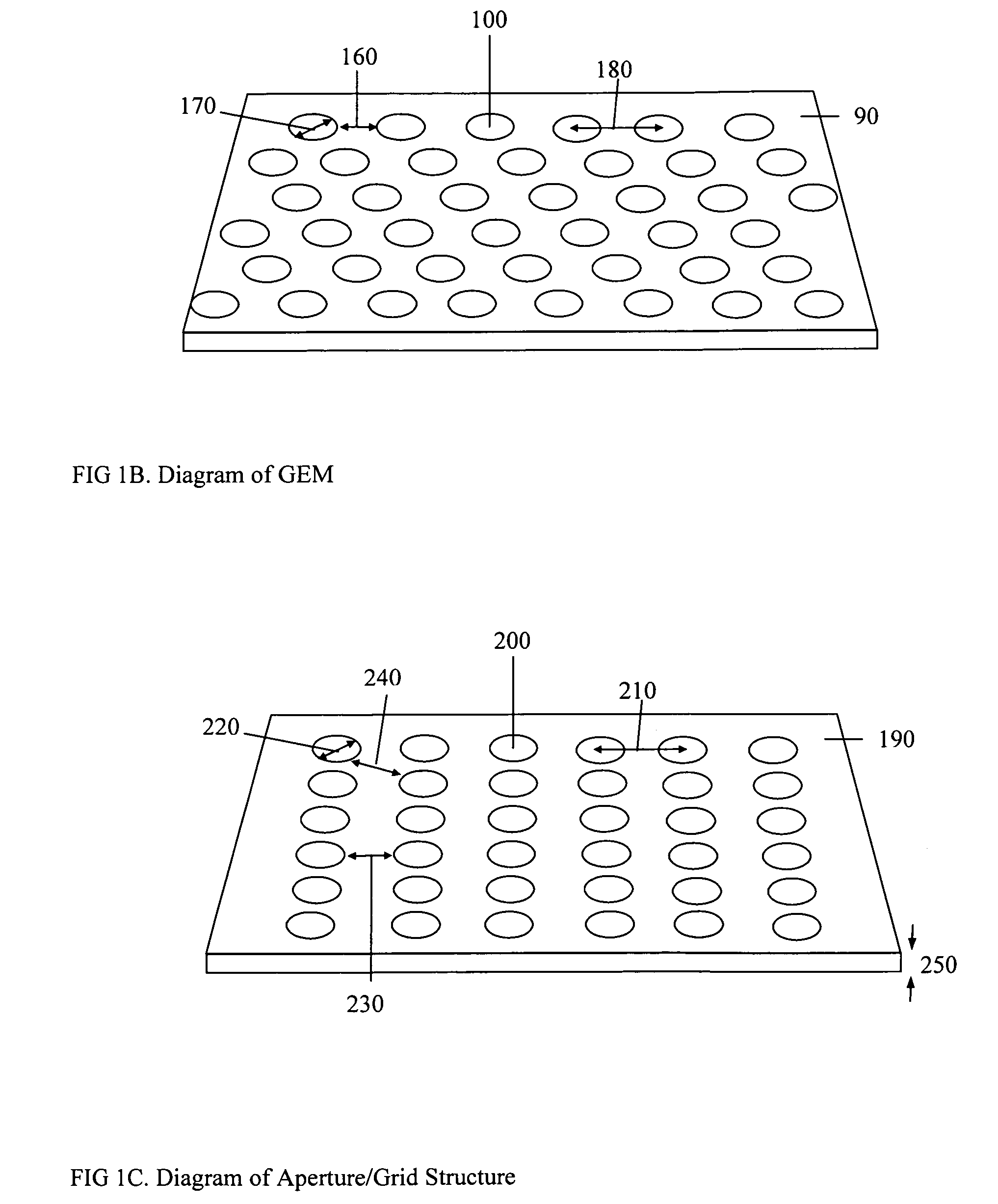

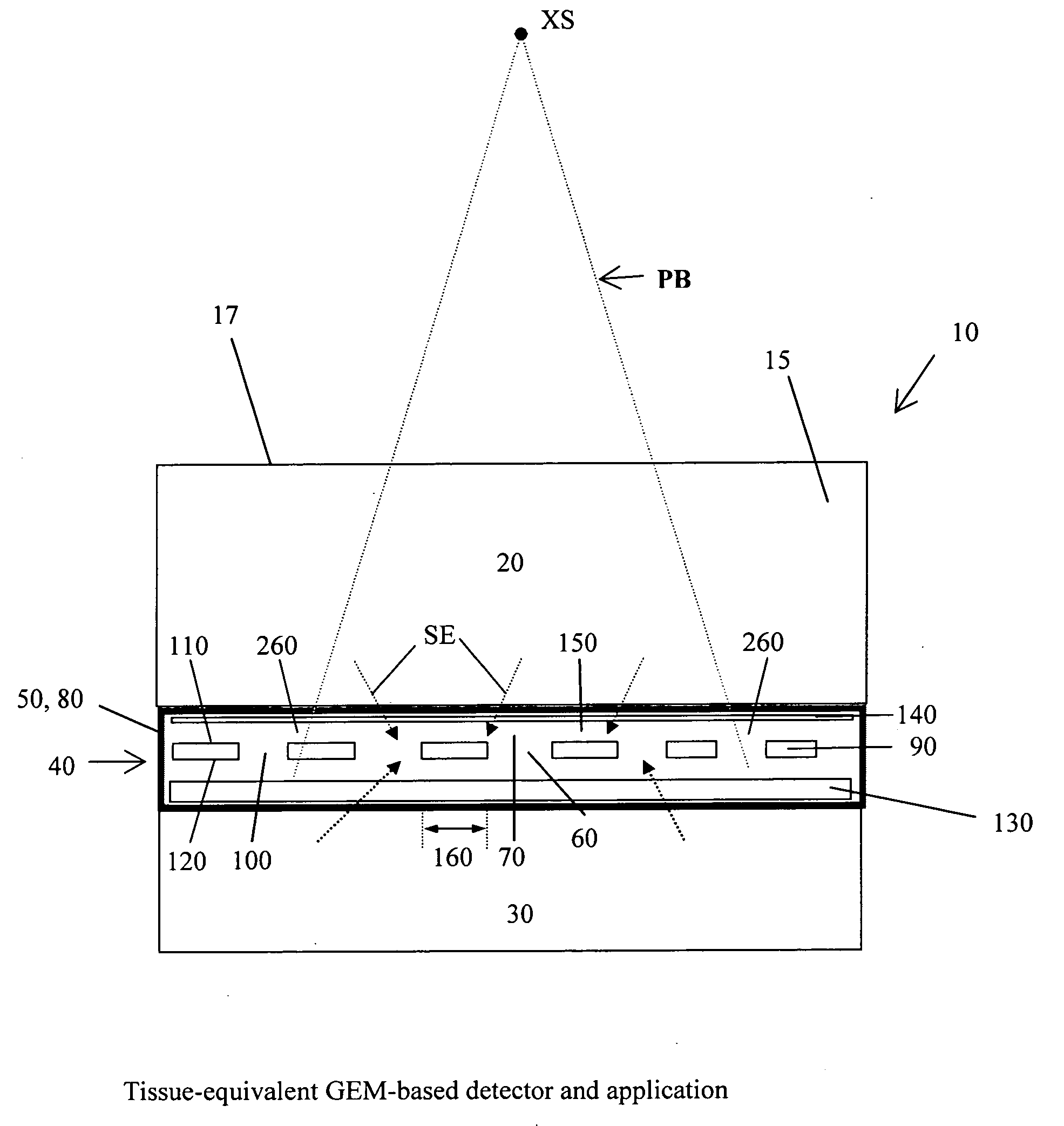

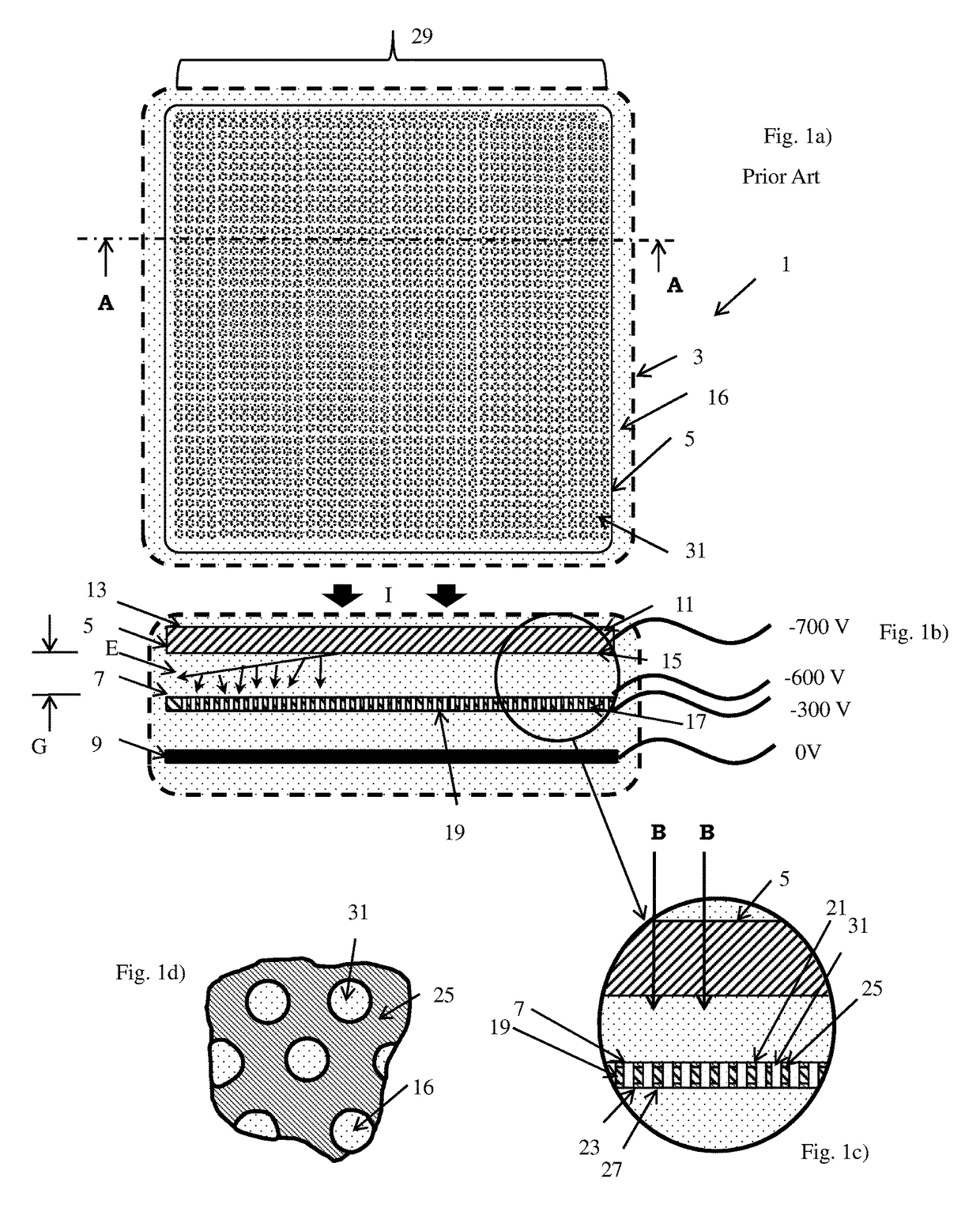

Dosimeter based on a gas electron multiplier for dose measurements of therapeutic radiation

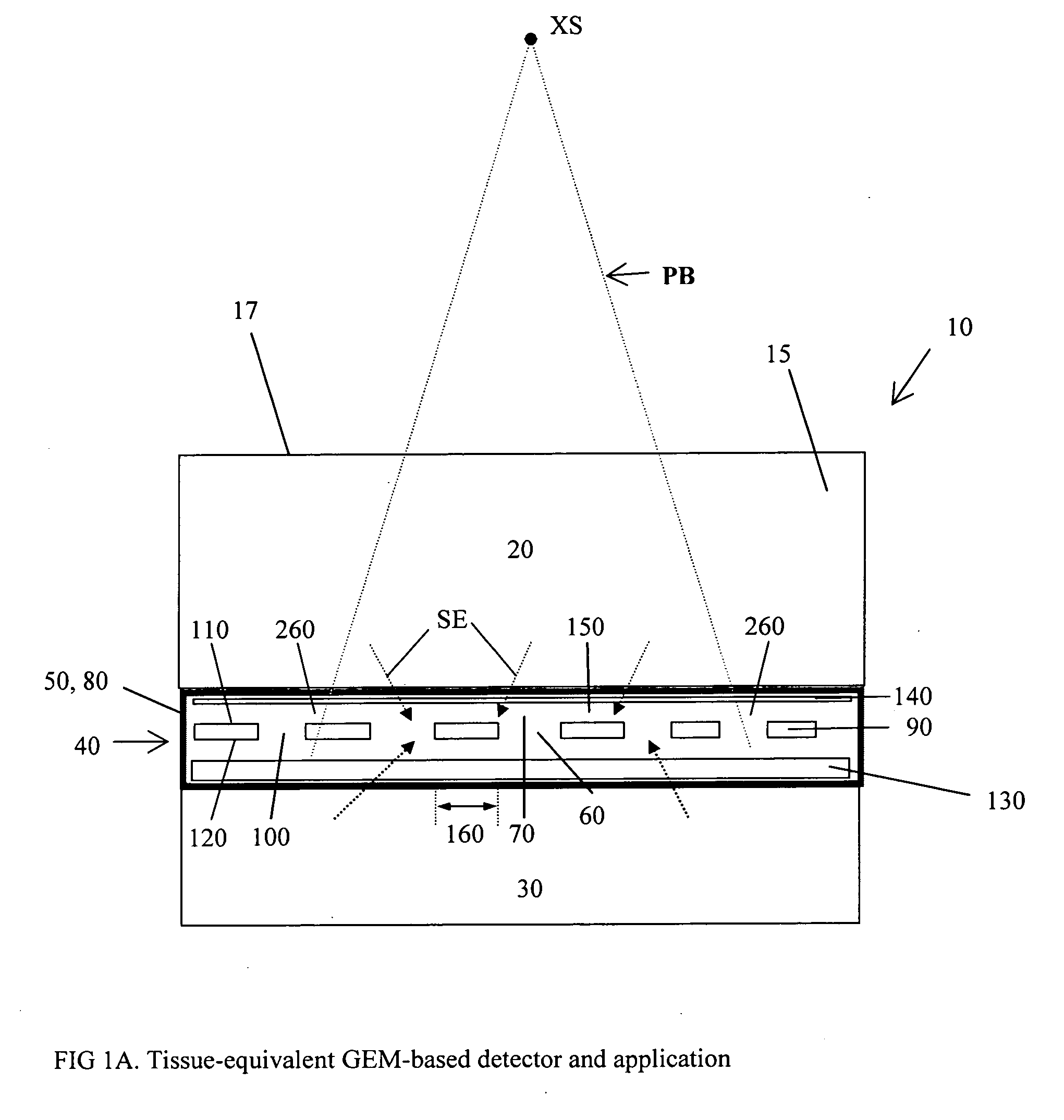

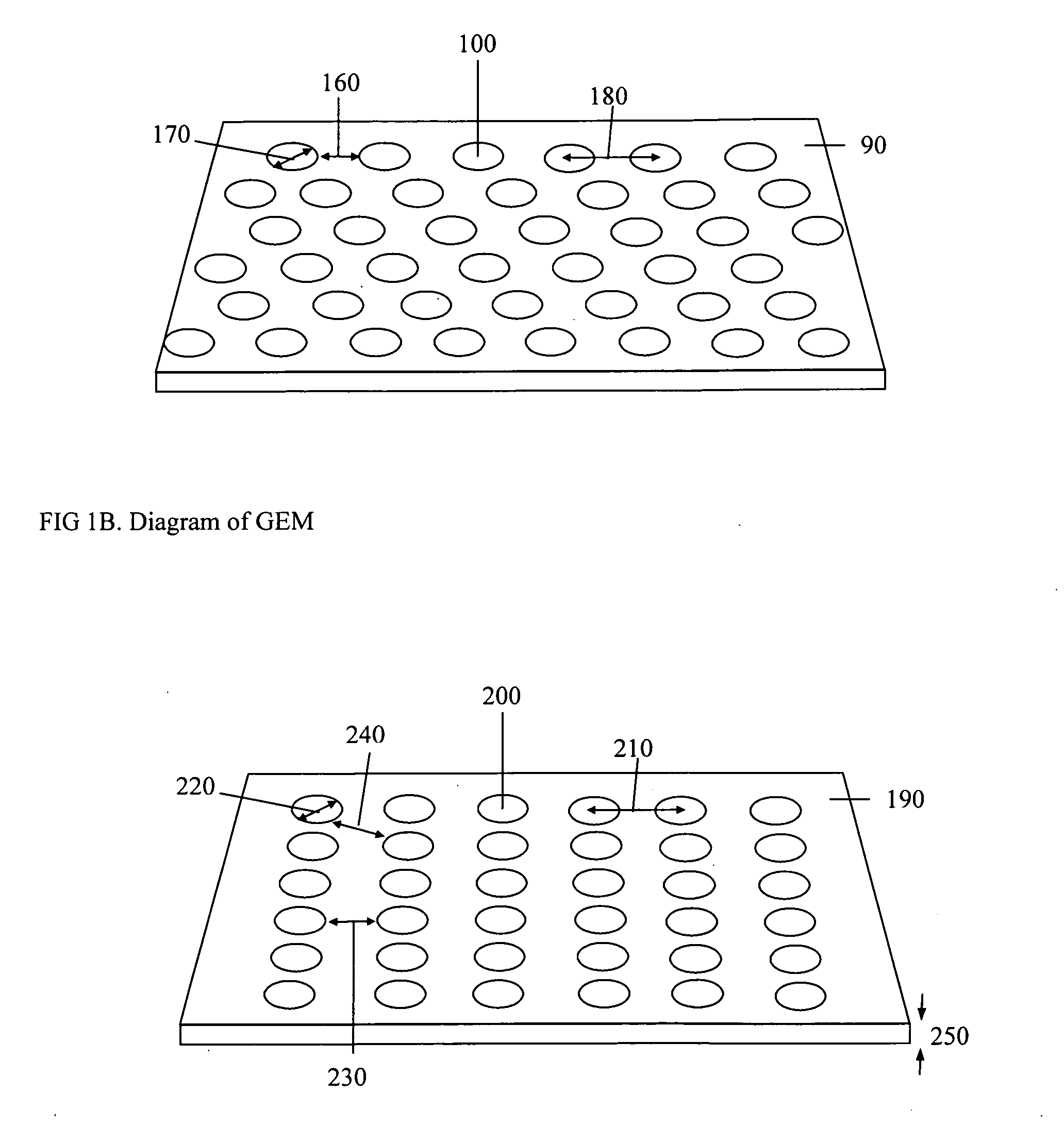

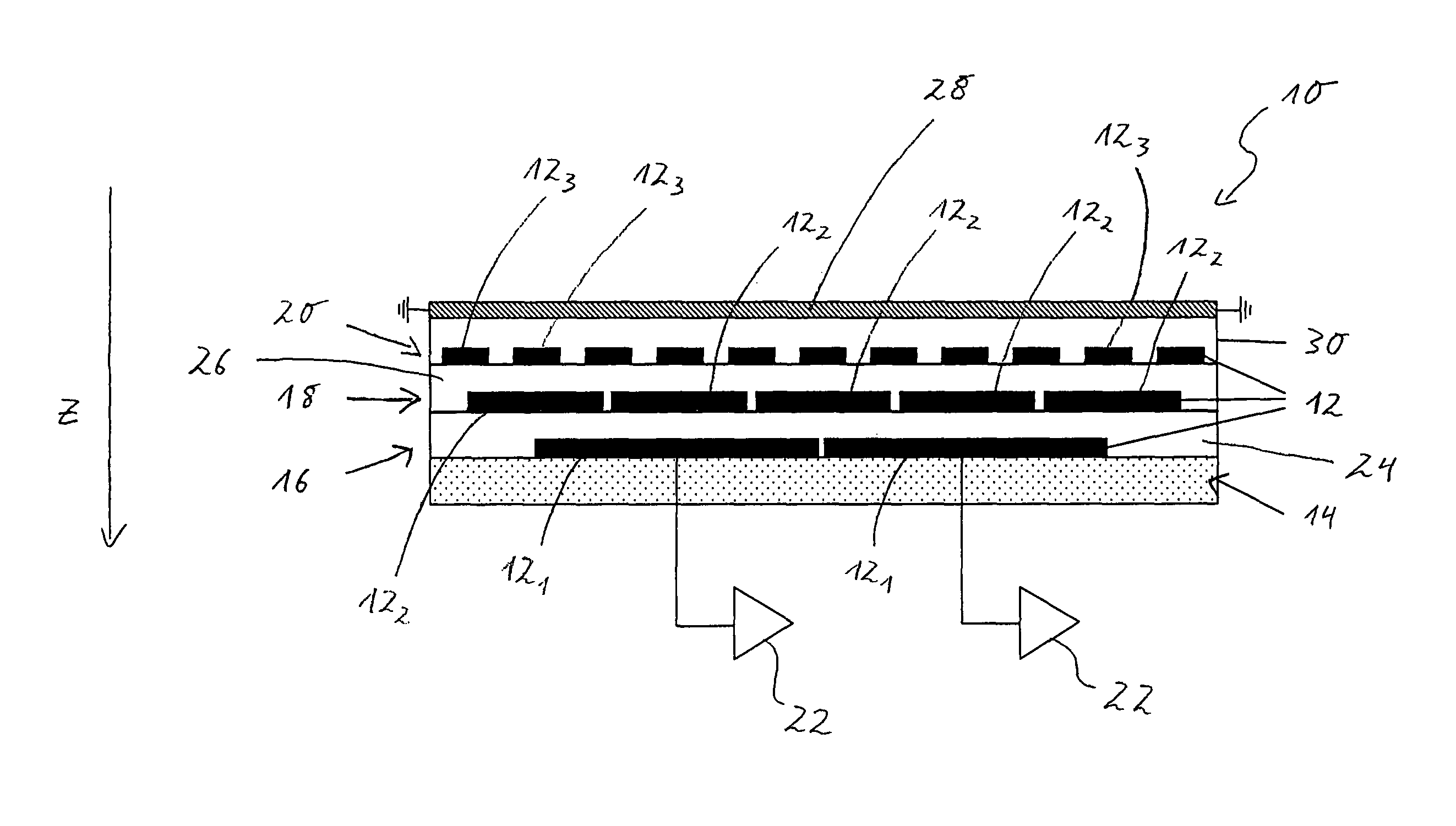

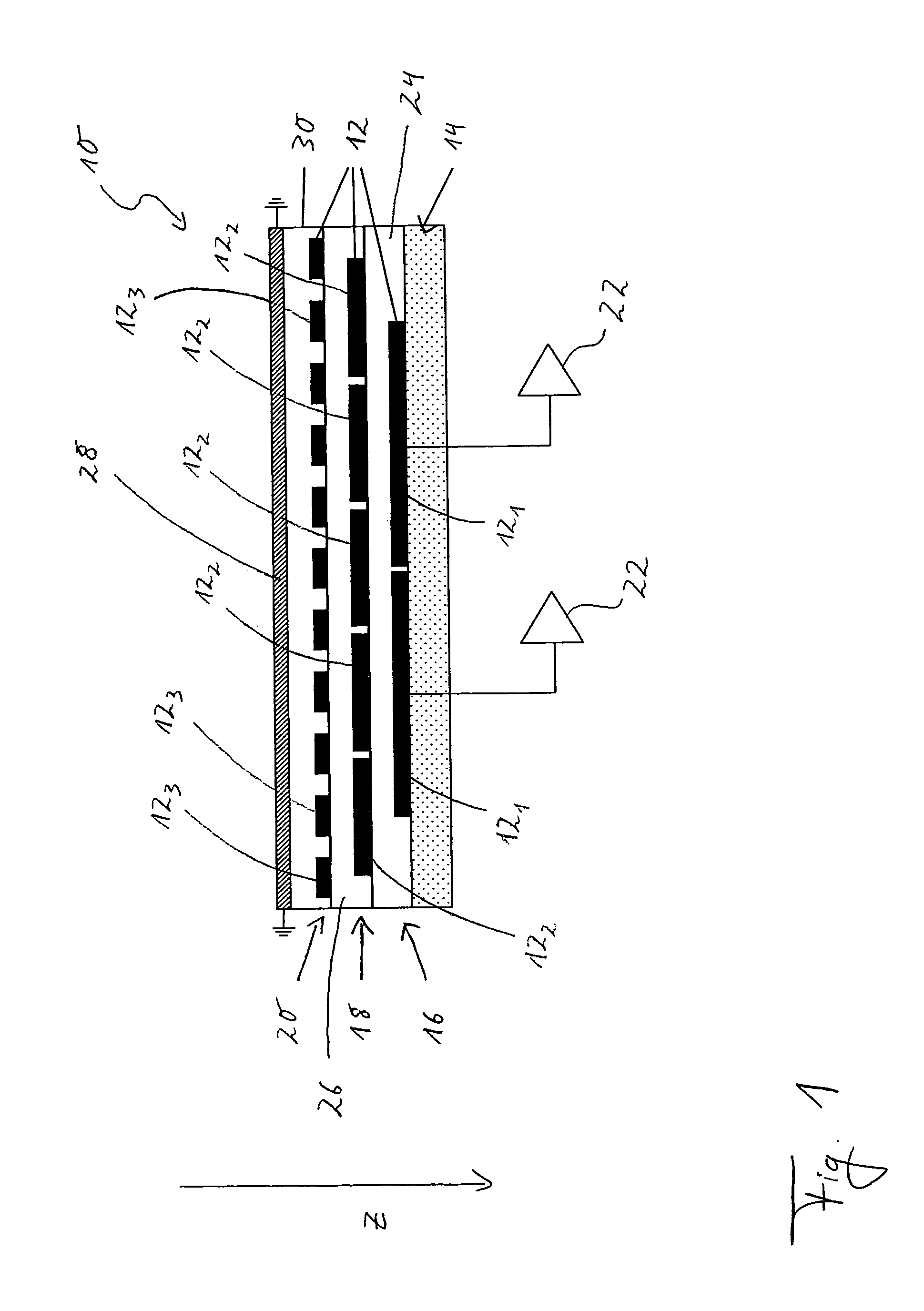

InactiveUS7432510B2Facilitate sandwichingElectric discharge tubesMaterial analysis by optical meansDosimeterTherapeutic radiation

A dosimeter based on a gas electron multiplier and method of use thereof for measurement of doses of therapeutic radiation to which a tissue-phantom is exposed. Subsequent to the in-phantom measurement and verification of radiation beam delivery, radiation can be effectively delivered to a human target organ, based on the verification of radiation quantities to which the phantom was exposed. Use of a gas electron multiplier-based dosimeter facilitates precise and accurate verification of the radiation dose within a phantom by taking measurements in real time, with no need for subsequent film processing.

Owner:PRECISION DOSIMETRY SYST

Dosimeter based on a gas electron multiplier for dose measurements of therapeutic radiation

InactiveUS20080029709A1Real-time acquisitionFacilitate sandwichingElectric discharge tubesMaterial analysis by optical meansDosimeterTherapeutic radiation

A dosimeter based on a gas electron multiplier and method of use thereof for measurement of doses of therapeutic radiation to which a tissue-phantom is exposed. Subsequent to the in-phantom measurement and verification of radiation beam delivery, radiation can be effectively delivered to a human target organ, based on the verification of radiation quantities to which the phantom was exposed. Use of a gas electron multiplier-based dosimeter facilitates precise and accurate verification of the radiation dose within a phantom by taking measurements in real time, with no need for subsequent film processing.

Owner:PRECISION DOSIMETRY SYST

Apparatus for digital imaging photodetector using gas electron multiplier

InactiveUS7663081B2Real-time imagingImprove performanceMaterial analysis by optical meansPhotoelectric discharge tubesDigital imagingPhotodetector

The present invention provides a digital imaging photodetector with a gas electron multiplier. The digital imaging photodetector comprises a gas electron multiplier detector. The gas electron multiplier detector includes a photoelectric converter for converting incident light into photoelectrons or Compton electrons; a gas electron multiplier (GEM) for receiving the photoelectrons or Compton electrons from the photoelectric converter and multiplying them; and a readout unit for receiving an electrical signal indicating a position where an electron cloud multiplied in the gas electron multiplier arrives on an anode, recognizing coordinates of the electron cloud based on the received signal, and outputting the coordinates of the electron cloud. According to the digital imaging photodetector of the present invention, real-time imaging of image information can be achieved by multiplying photoelectrons or Compton electrons, which are discharged due to a photoelectric effect or a Compton effect induced by visible rays, ultraviolet rays or X-rays, using the gas electron multiplier.

Owner:HAHN CHANG HIE

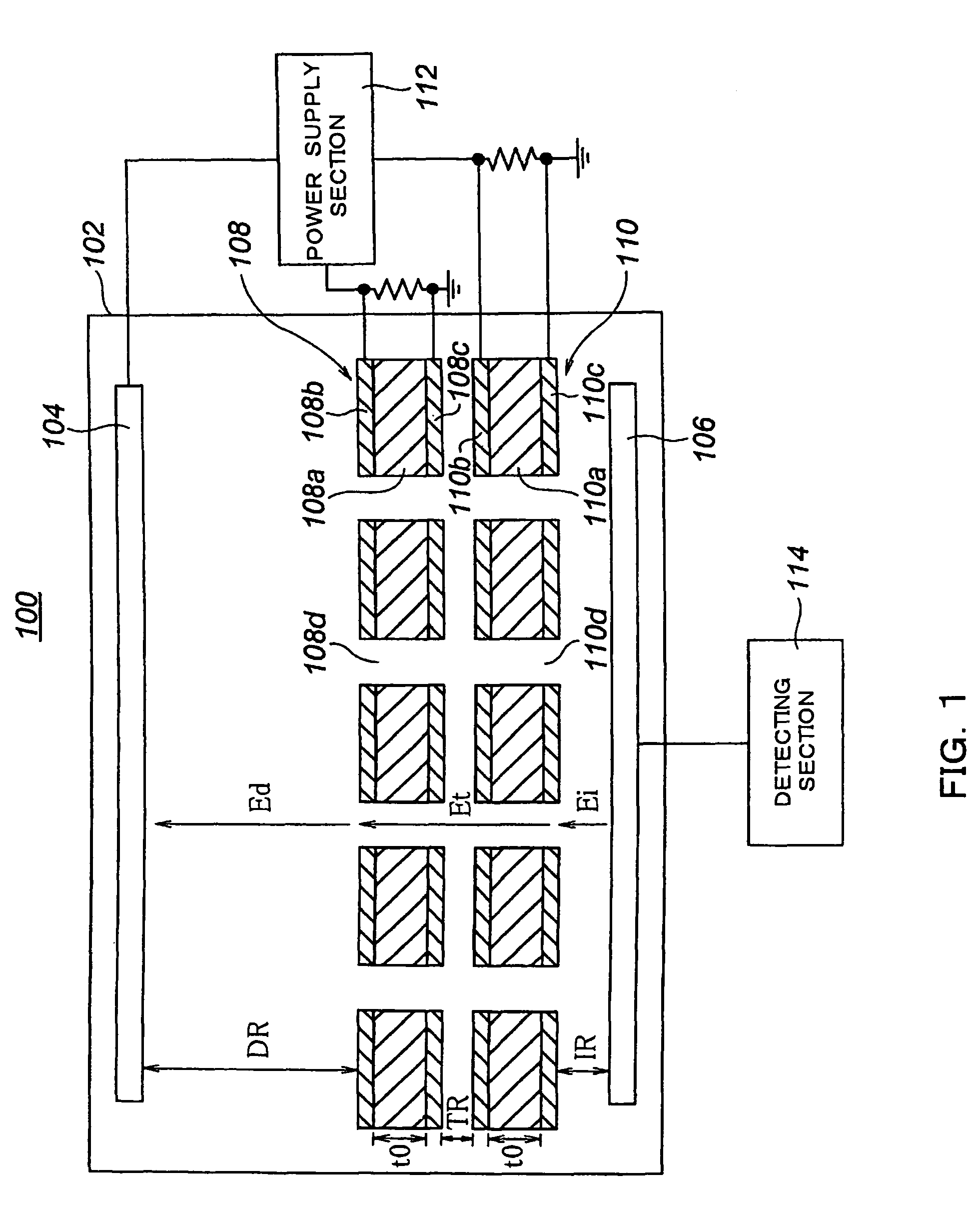

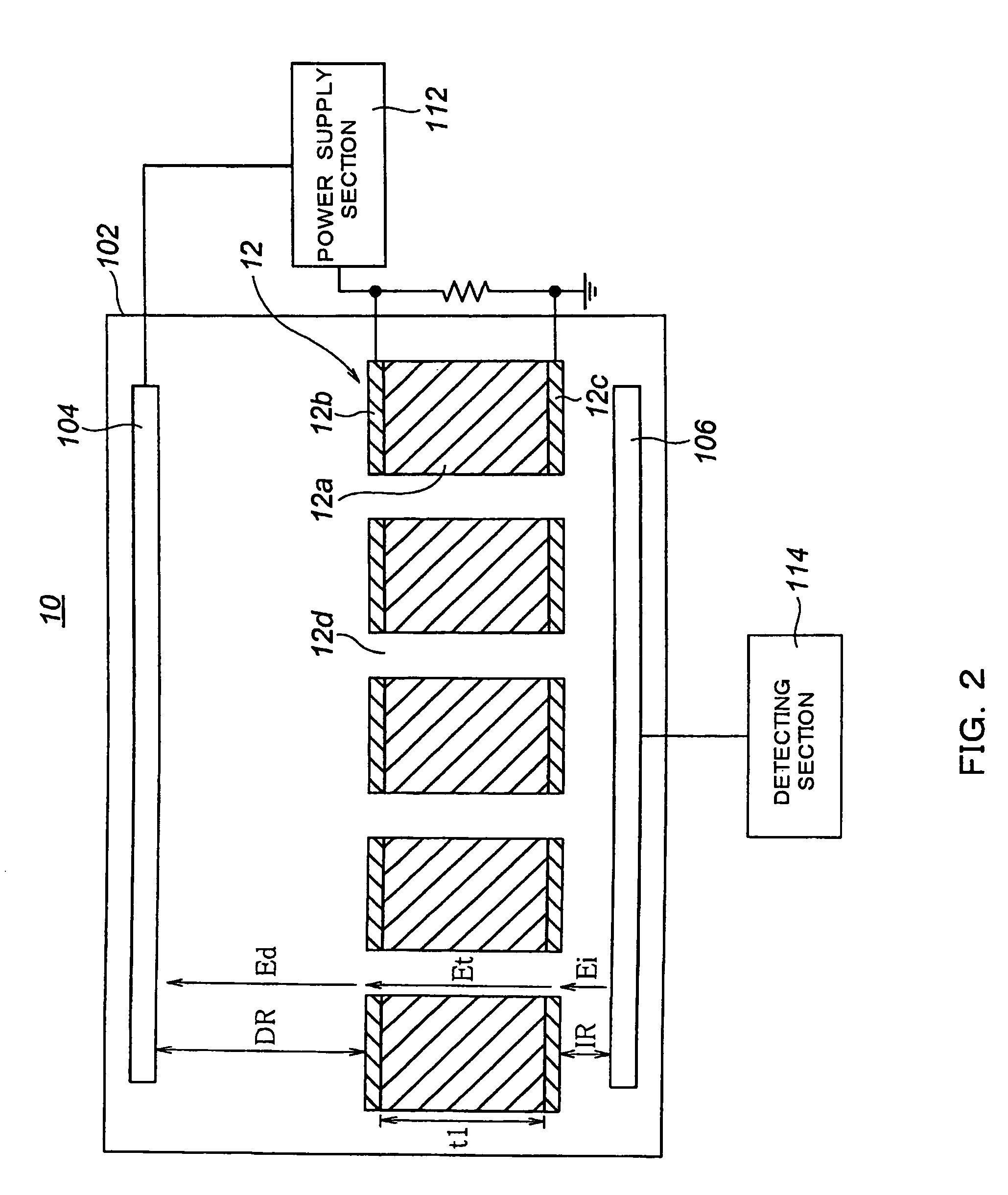

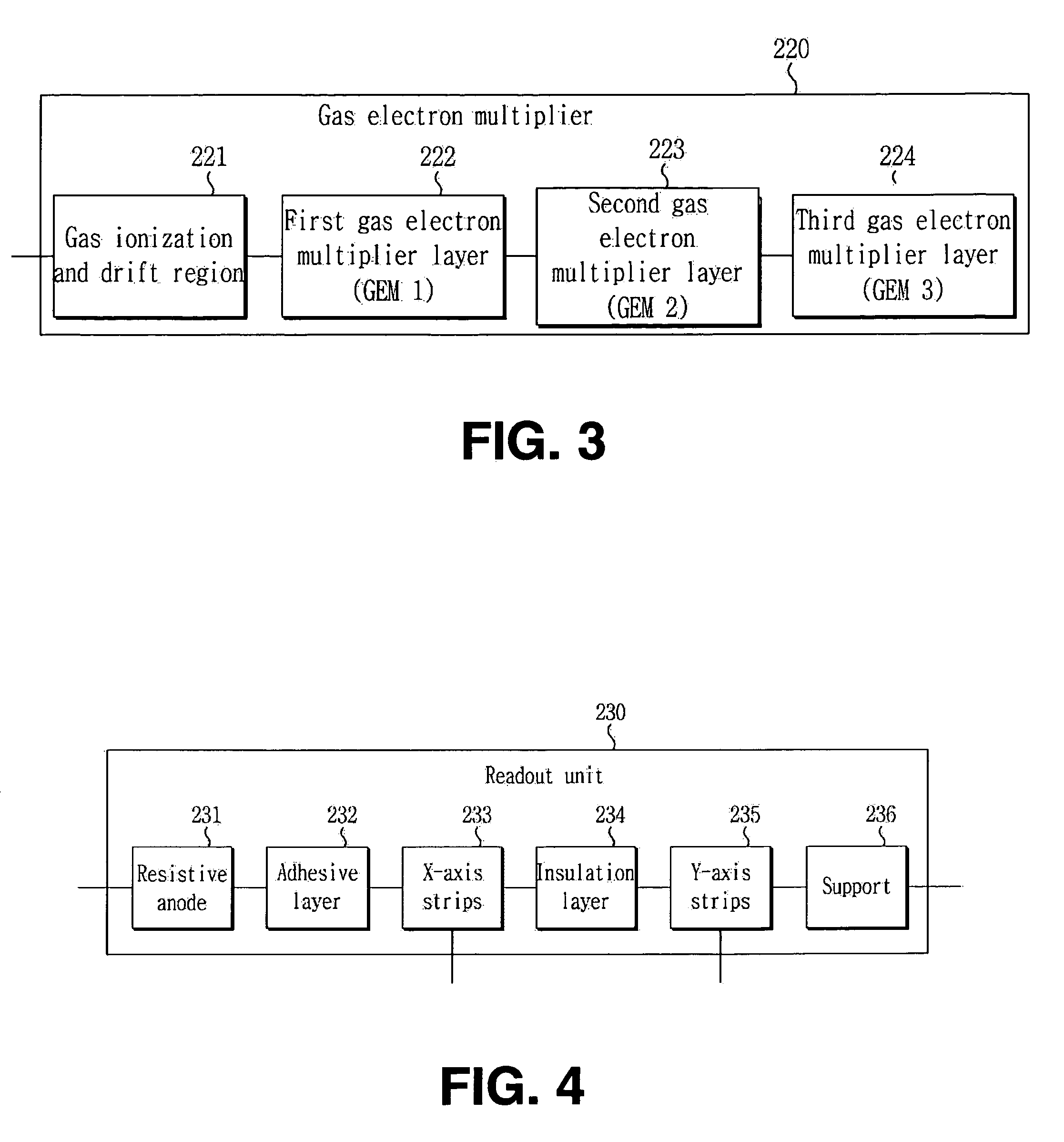

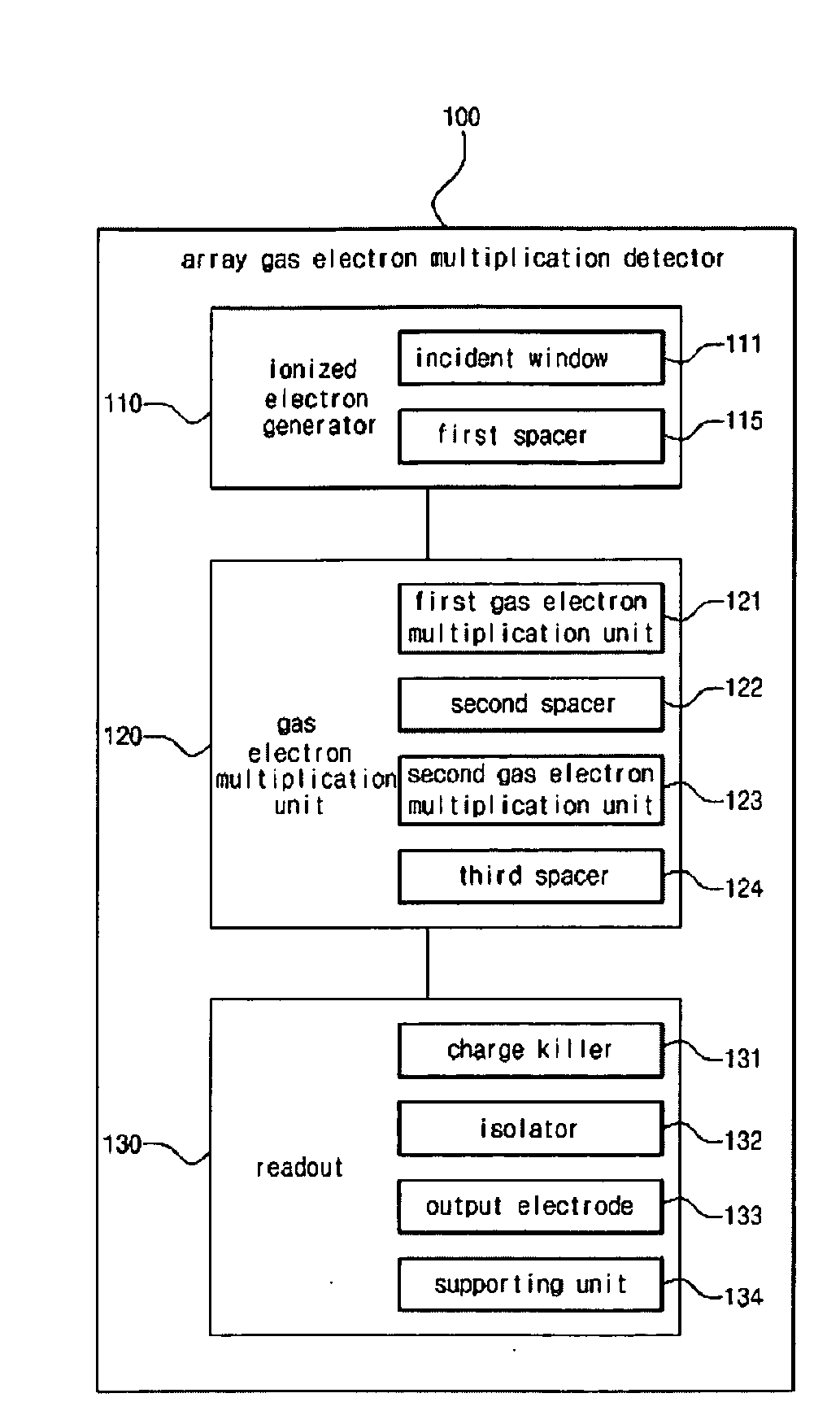

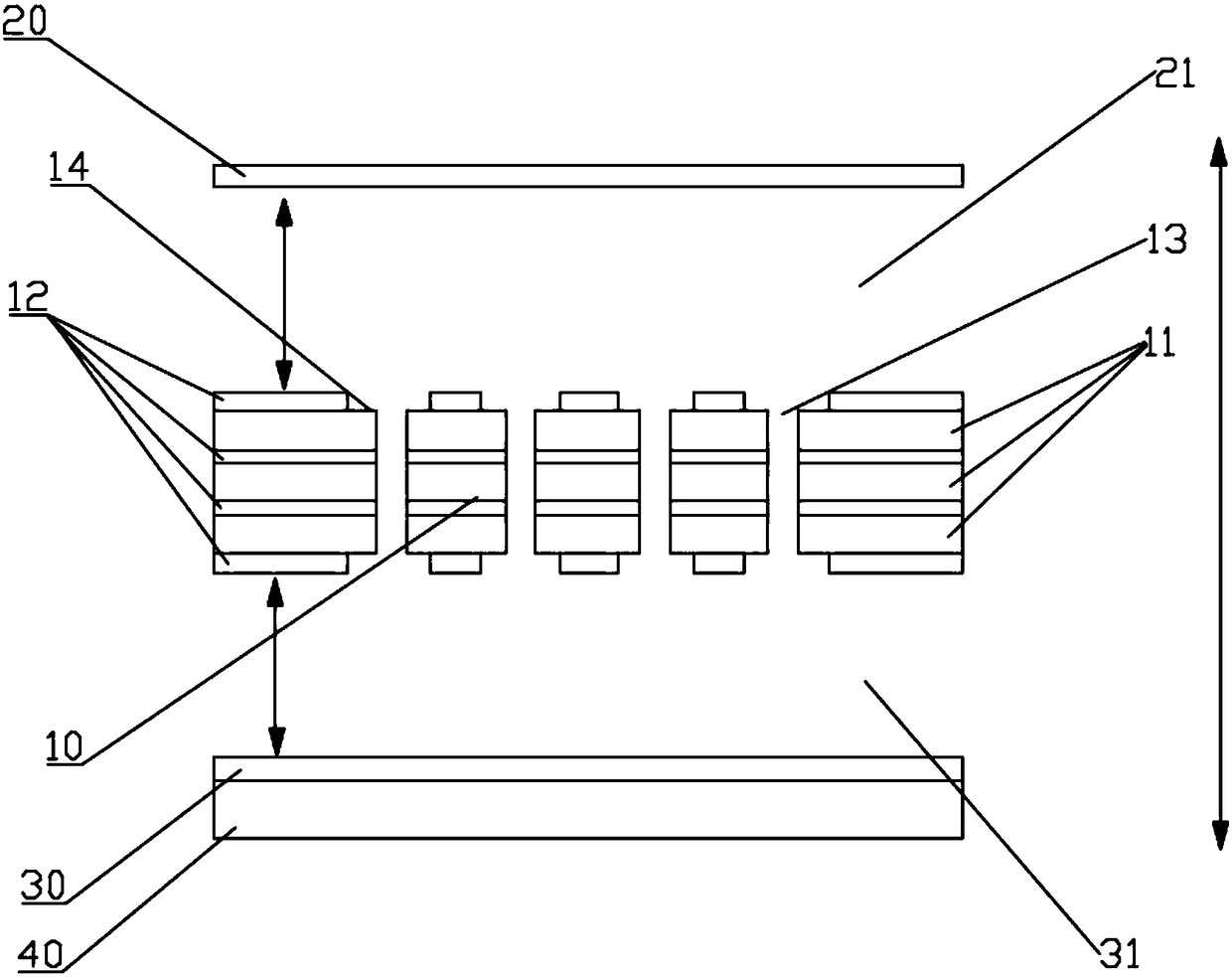

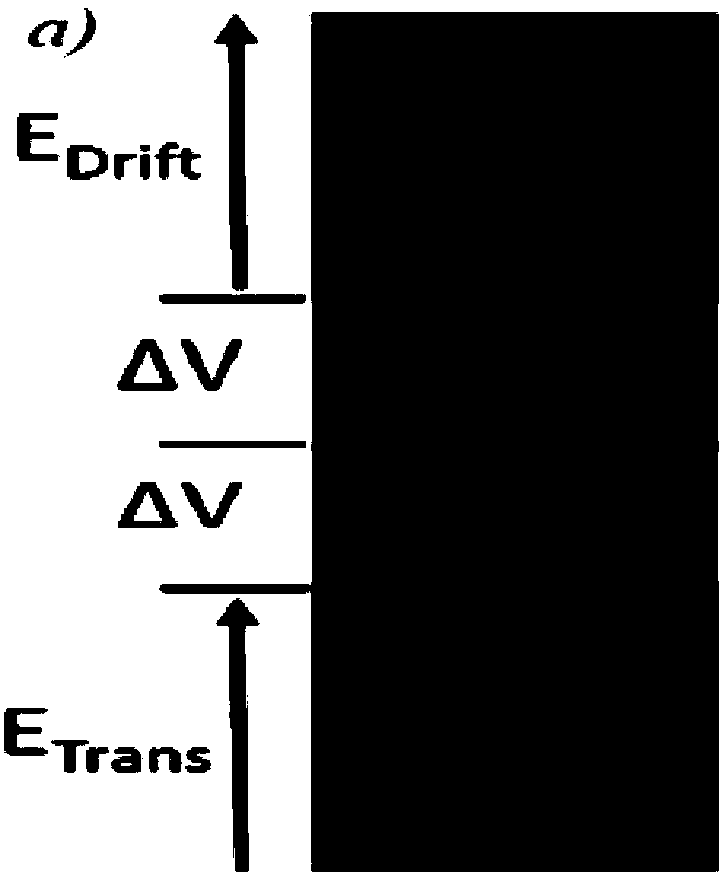

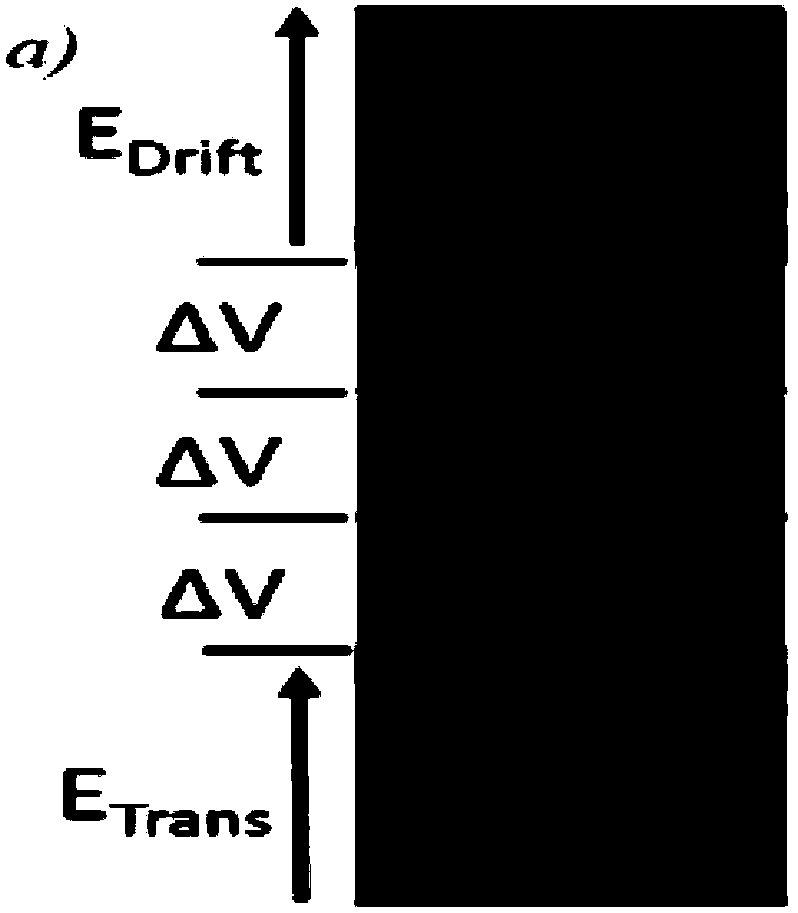

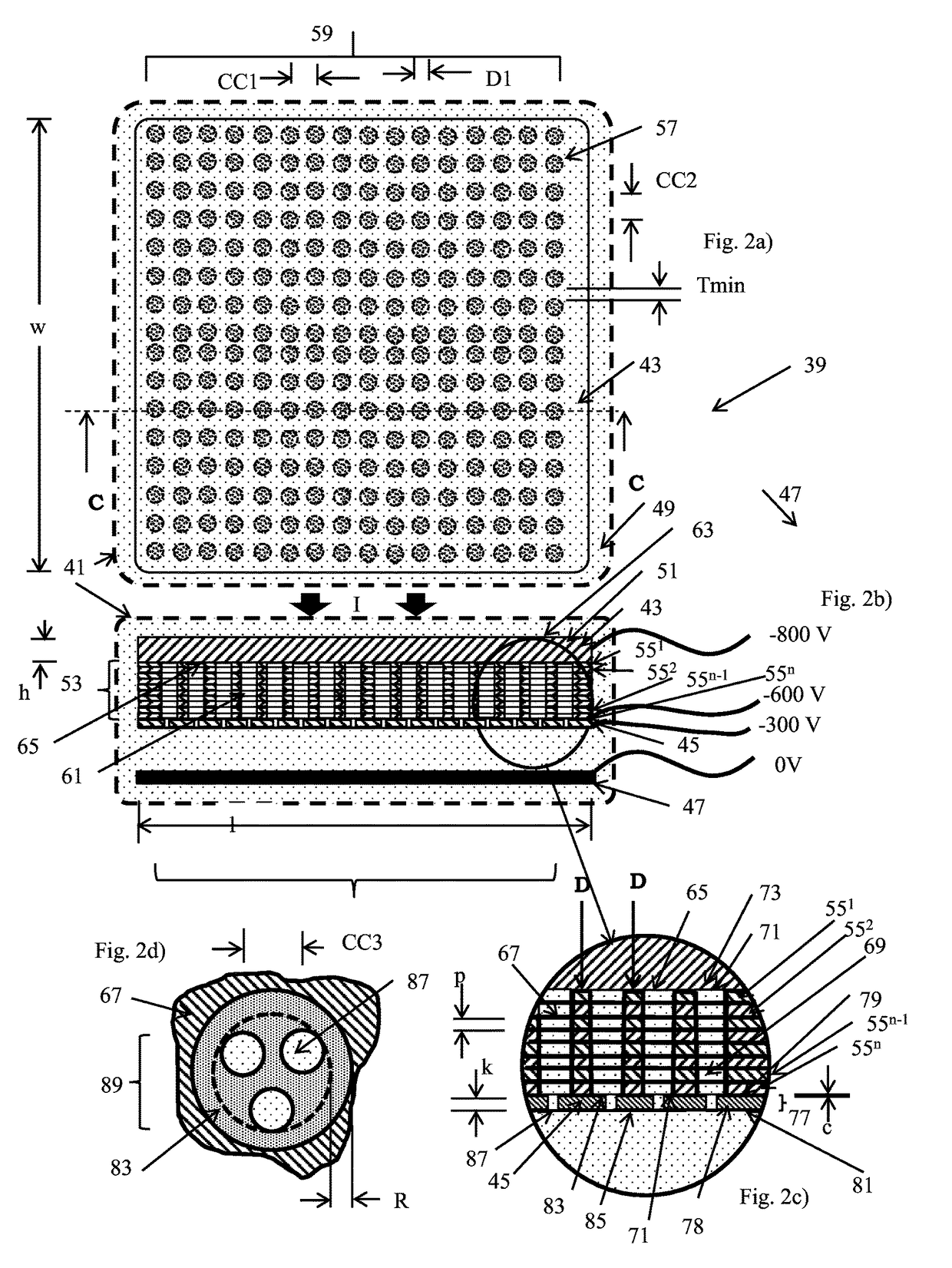

Apparatus and method for array gem digital imaging radiation detector

InactiveUS20090261265A1Accurate securityImprove performanceElectric discharge tubesMaterial analysis by optical meansDigital imagingElectron multiplication

An array gas electron multiplier (GEM) digital imaging radiation detector and a control method thereof are disclosed. The array gas electron multiplier (GEM) digital imaging radiation detector includes an array GEM detector. The array GEM detector includes: an ionized electron generation unit for generating ionized electrons in internal filling gas by incident X-rays or gamma rays or by incident charged particles; a gas electron multiplication unit for multiplying the ionized electrons of the ionized electron generation unit in filling gas inside hole of a gas electron multiplier (GEM), through electron avalanche effect, using the GEM, to form electron clouds; a readout for detecting and outputting coordinates of the electron clouds as the readout receives positions through electrical signals, in which the positions of the electron clouds, being multiplied and formed in the gas electron multiplication unit, reach output electrodes. Therefore, the present invention can multiply ionized electrons of internal filling gas as a gas electron multiplier (GEM) generates an electron avalanche effect in the hole thereof, in which the ionized electrons are generated as a photo-electron effect or a Compton effect is induced by high energy incident light, such as X-rays or gamma rays, or which are directly generated by incident charged particles, and can convert image information of the inside or outside of an target object into images of two-dimensions, in real time, such that the detector can be properly used as a security search apparatus in a harbor or an airport, or can be adapted as a core part of industrial nondestructive testing apparatus.

Owner:HAHN CHANG HIE

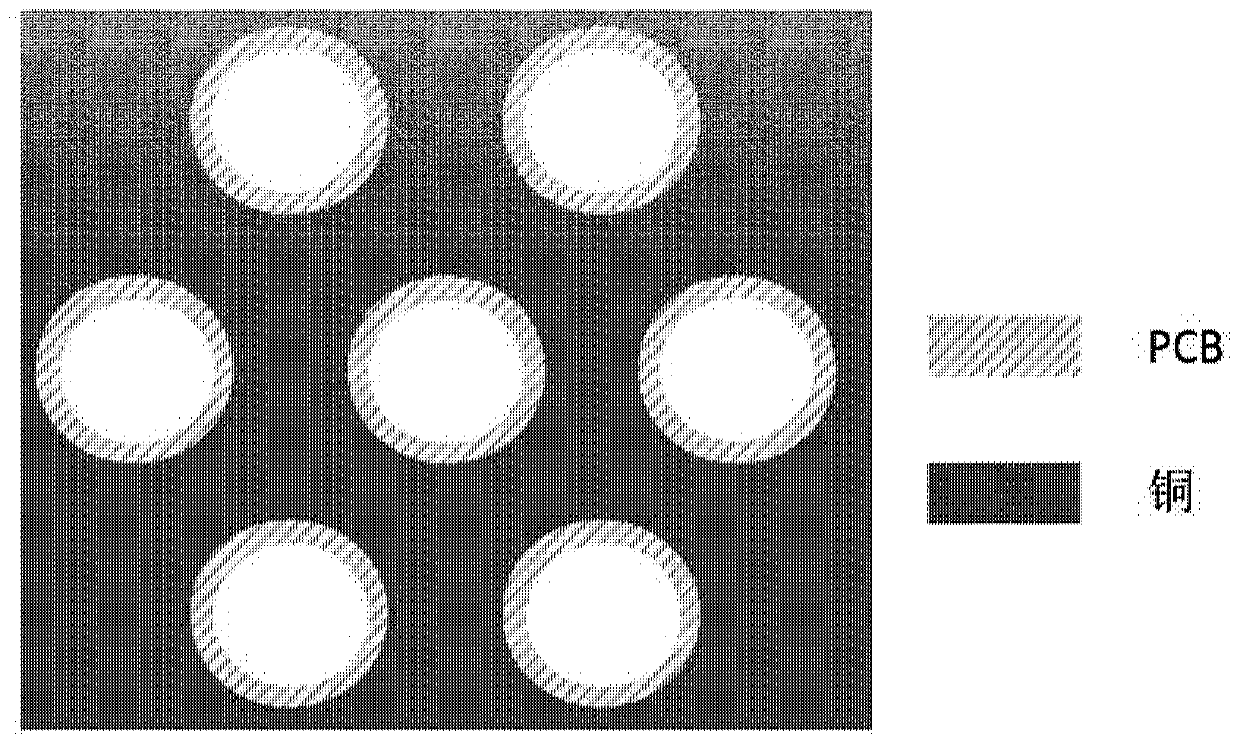

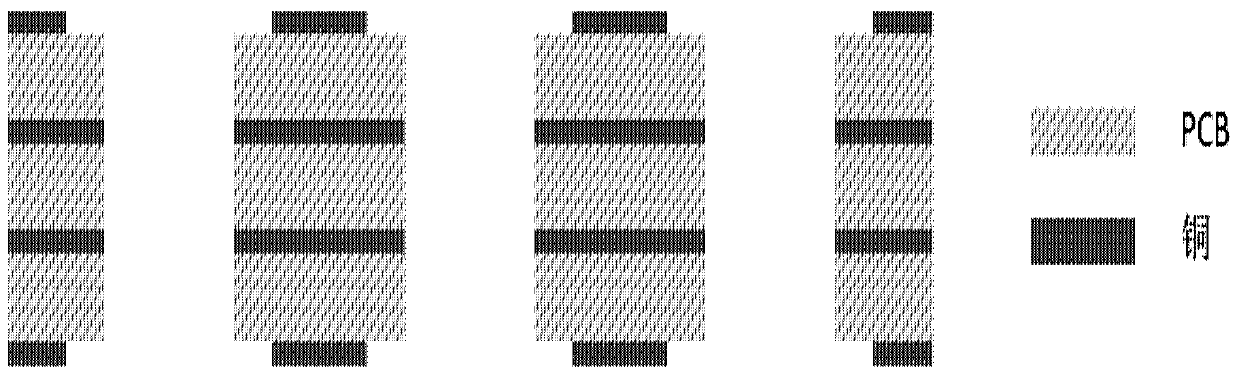

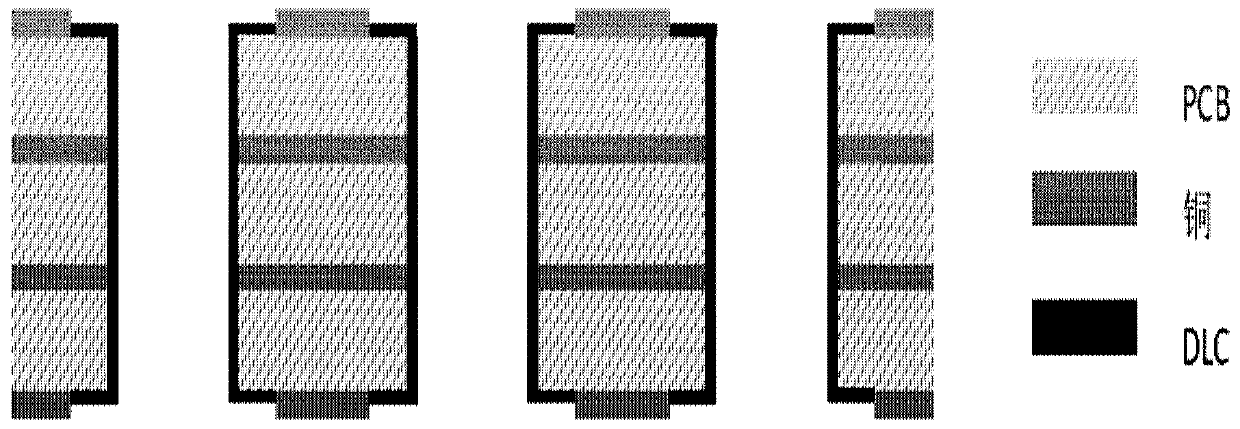

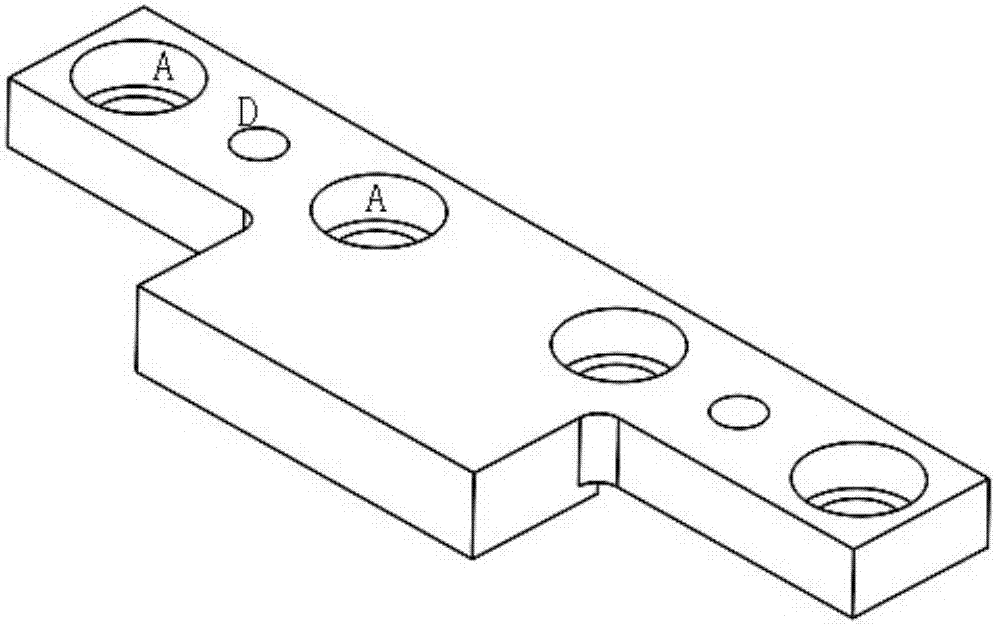

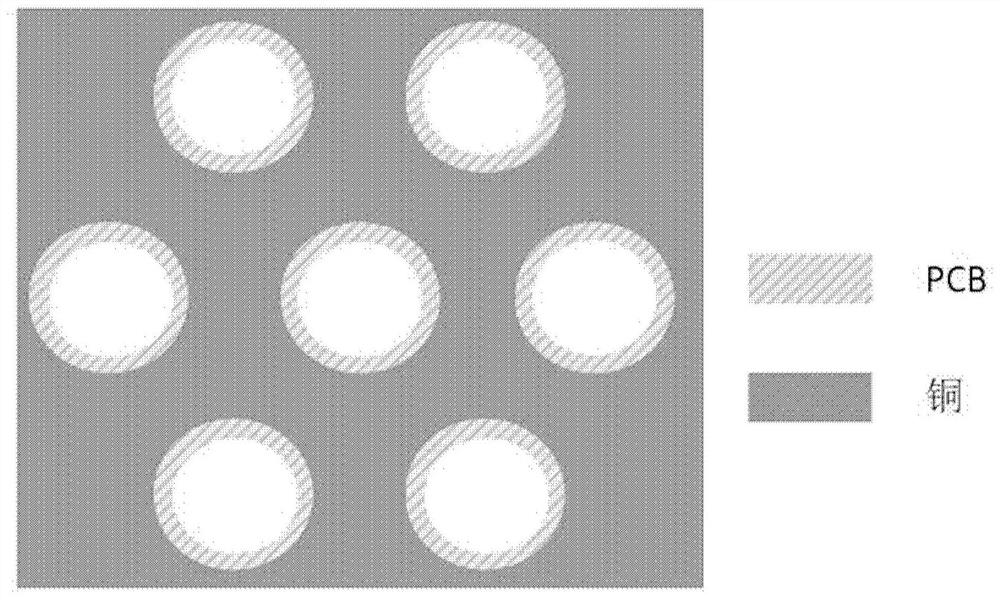

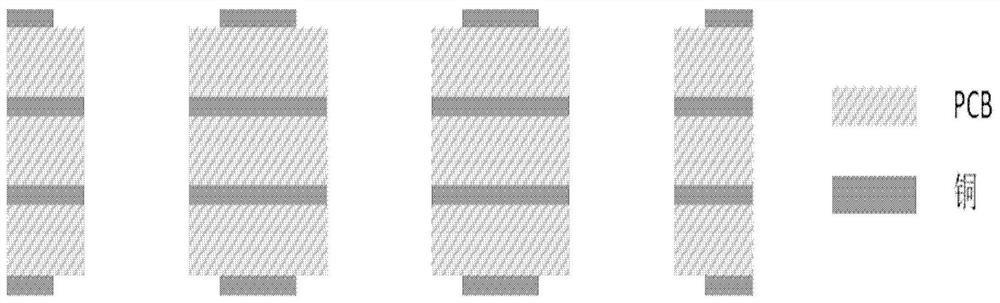

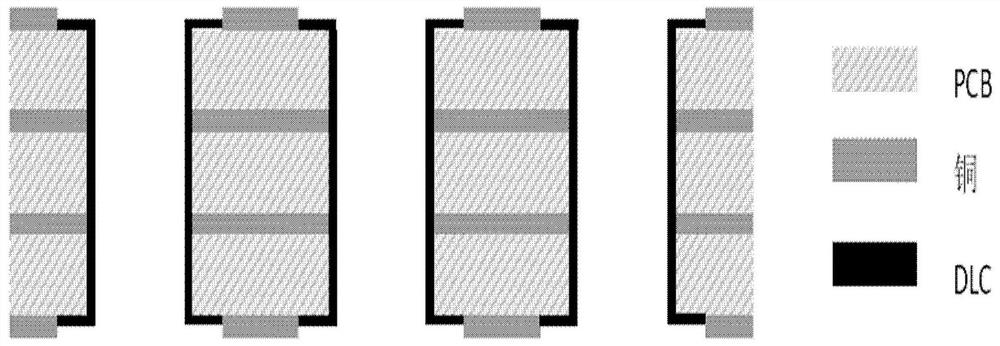

Thick gas electron multiplier having multilayer-structure single film

InactiveCN108415059AGuaranteed alignmentReduce thicknessRadiation intensity measurementCopperMolecular physics

The application discloses a thick gas electron multiplier having a multilayer-structure single film. The thick gas electron multiplier comprises a membrane plate formed by alternating lamination of copper layers and insulating layers; the copper layers and the insulating layers are in tight contact; and the copper layers are arranged at the bottom and top of the membrane plate. A plurality of through straight holes are formed in the membrane plate and penetrate the top layer and the bottom layer; and insulating rings are arranged at the inner walls of the through straight holes and are used for isolating the copper layers from the inner cavities of the through straight holes. Because the membrane plate formed by alternating lamination of copper layers and insulating layers is arranged andthe copper layers and the insulating layers are in tight contact, the through zone formed between the conventional multilayer superposed structures is removed and thus the thickness of the multi-layerstructure is reduced; and the through straight holes are formed in the membrane plate in an overall manner and thus hole alignment is ensured and deformation and parallelism between layers are the same, so that problems of misalignment of the holes of the multi-layer structure and large multi-layer deformation and parallelism difference are solved.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACAD OF SCI

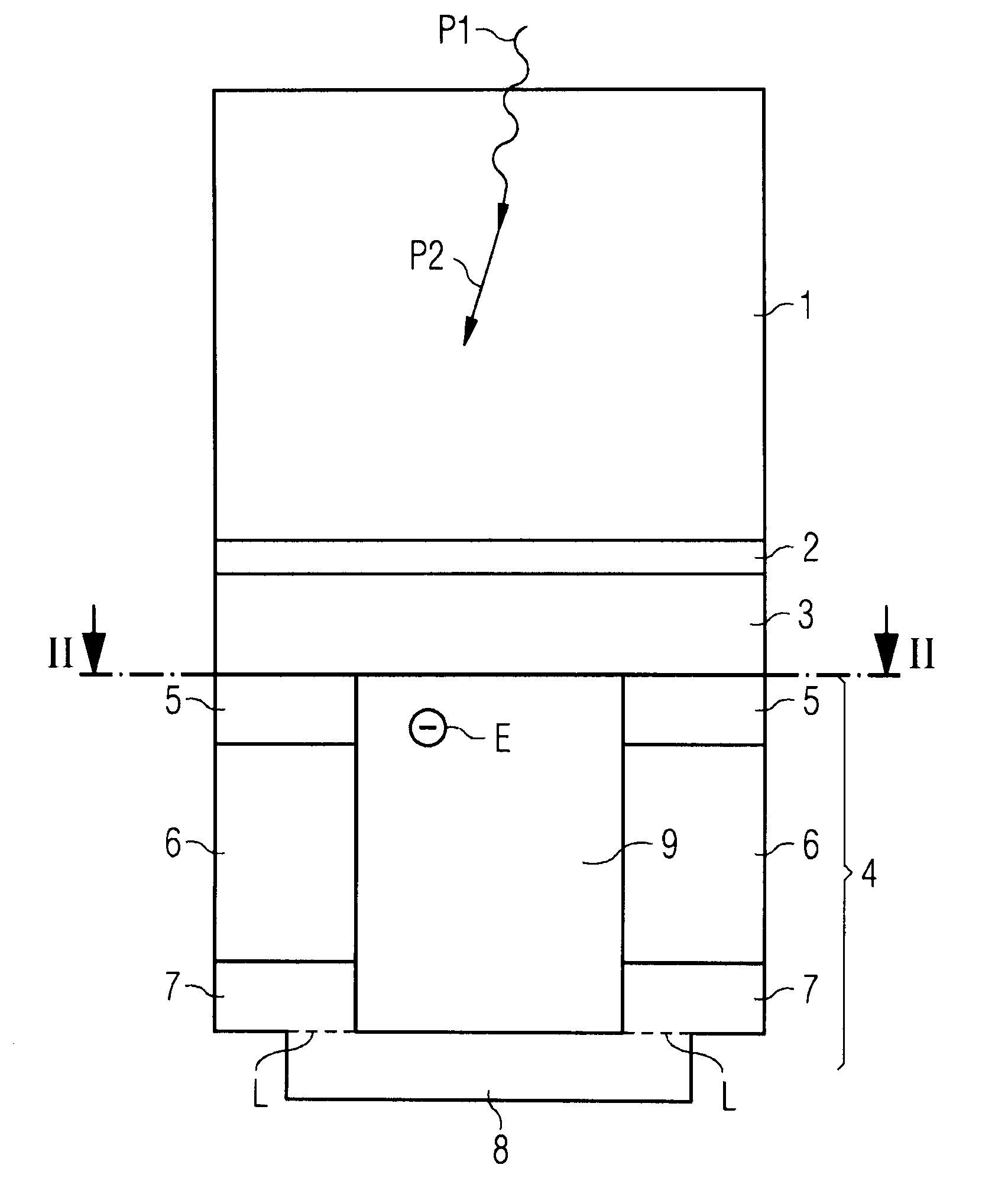

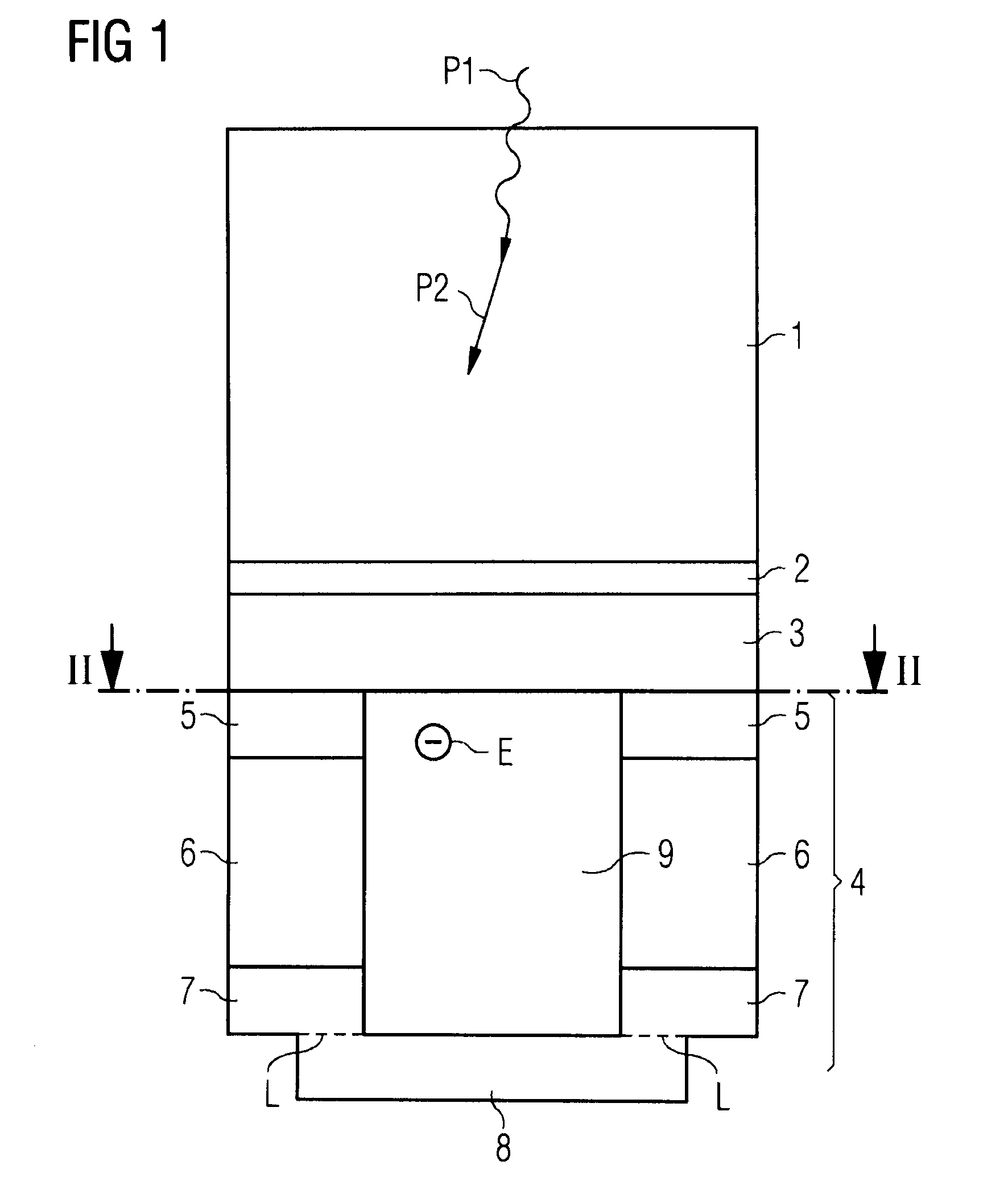

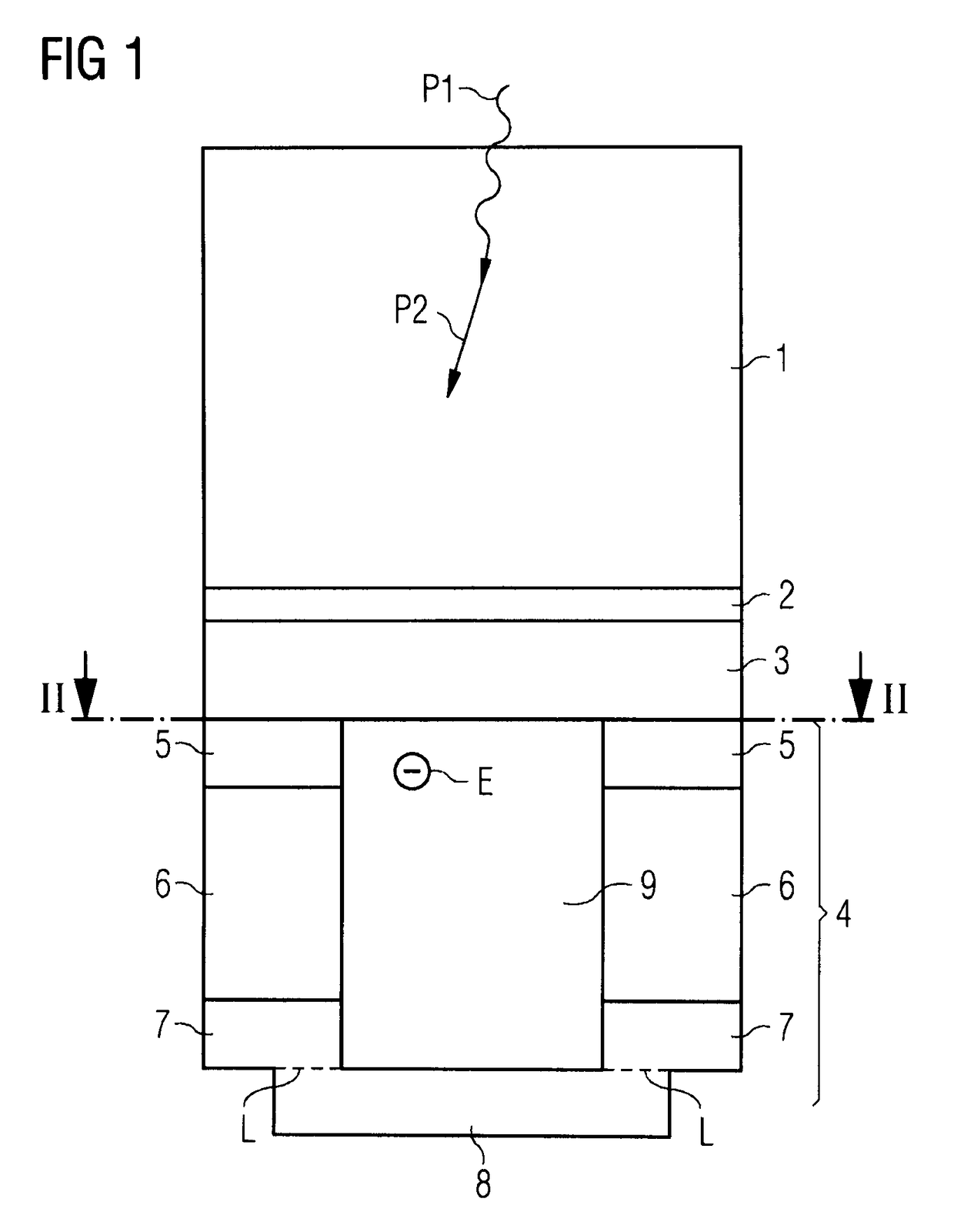

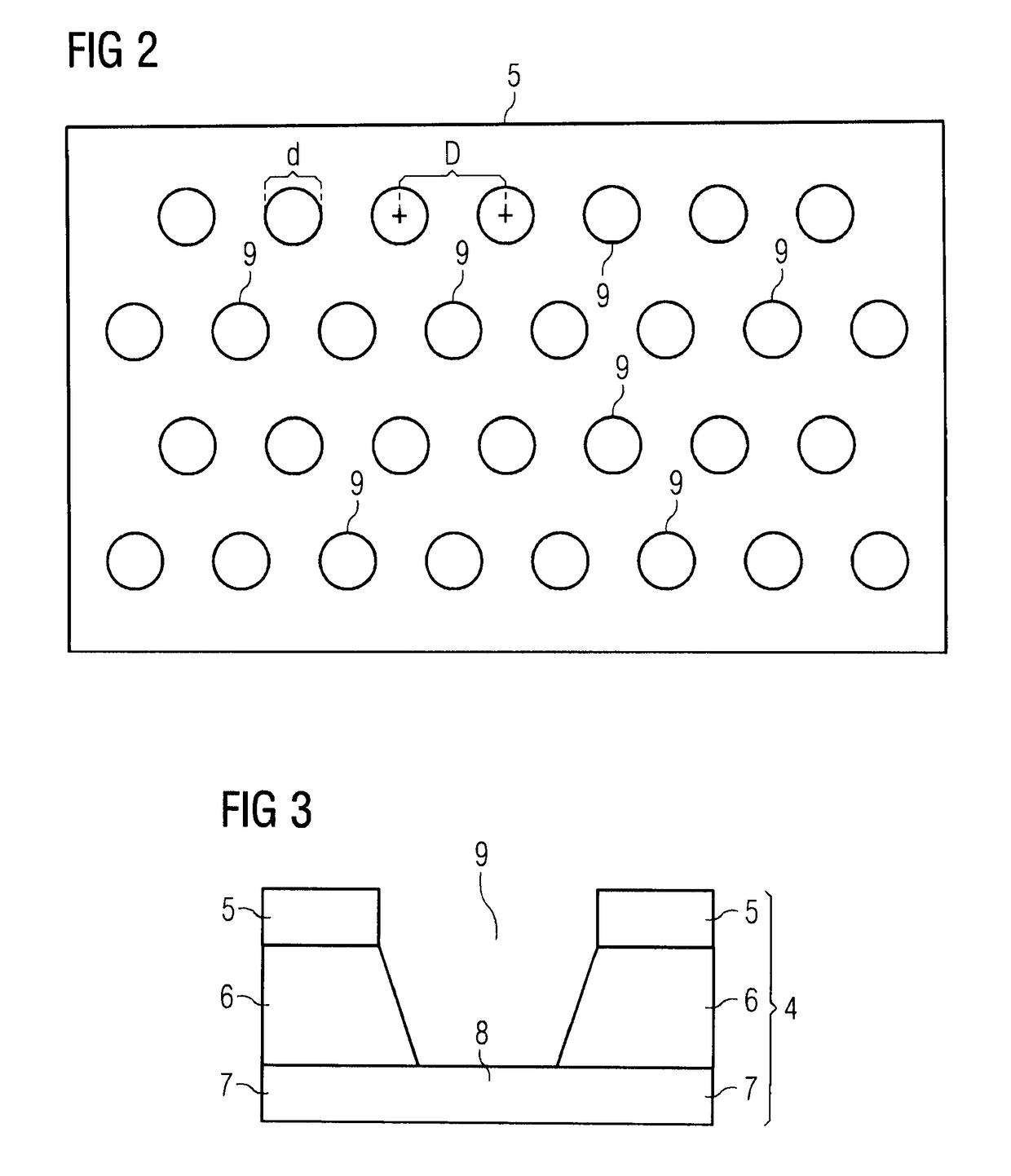

A detector for radiation, particularly high energy electromagnetic radiation

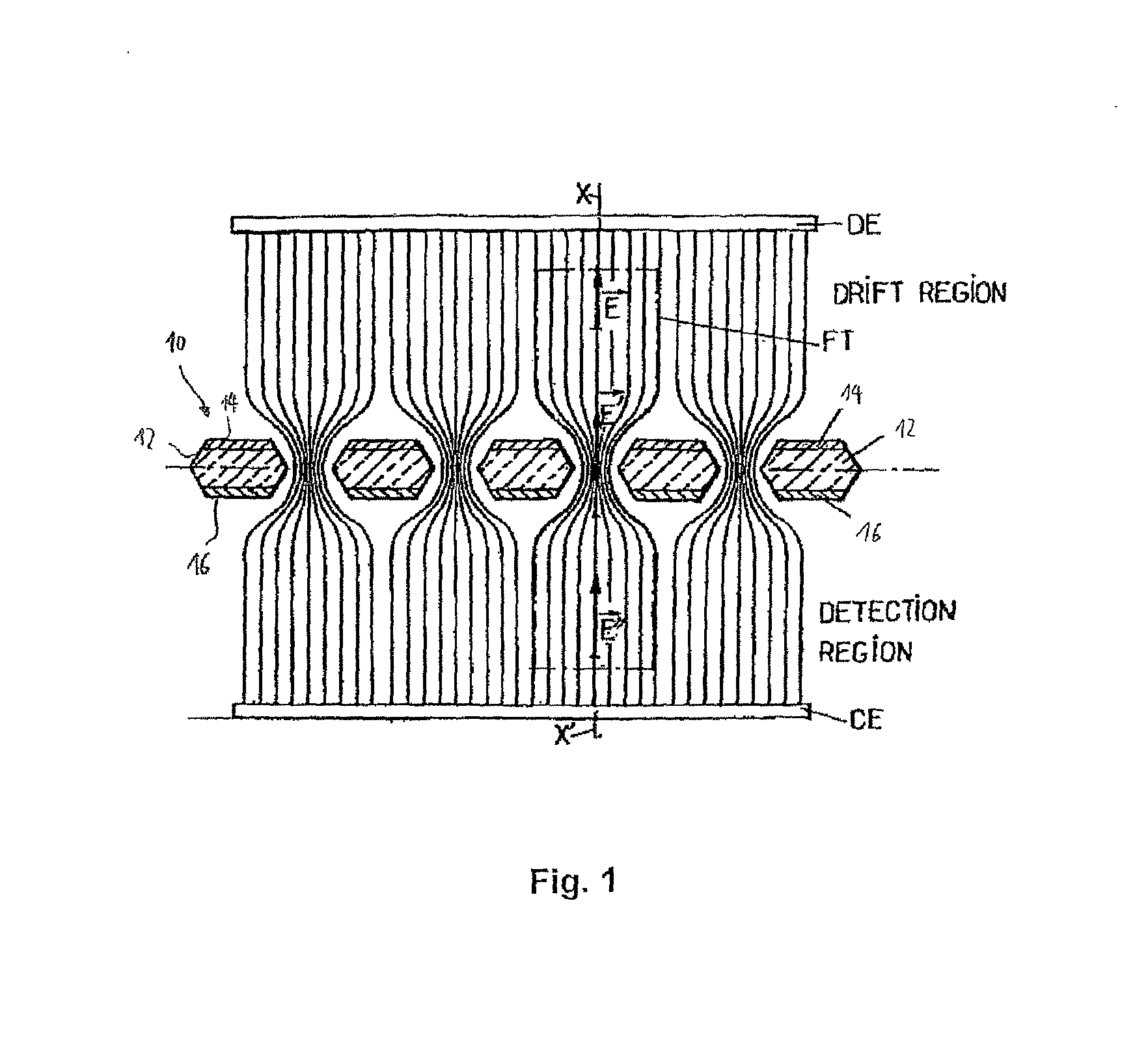

InactiveUS20150338527A1Accurate measurementSmall sizeElectric discharge tubesMaterial analysis by optical meansGas electron multiplierHigh energy

A detector for radiation, particularly high energy electromagnetic radiation is provided. The detector includes a converting section including a cathode for converting the radiation incident on the converting section in electrons by the photoelectric effect. The detector further includes a gas electron multiplier for generating an electron avalanche from electrons which are generated by the converting section and enter the gas electron multiplier, the gas electron multiplier including a first electrode, a dielectric layer and a second electrode, the first electrode being disposed at a first side of the dielectric layer adjacent to the converting section and the second electrode being disposed at a second side of the dielectric layer opposite to the first side. The gas electron multiplier includes a number of holes filled with gas, the holes extending through the first electrode, the dielectric layer and the second electrode.

Owner:SIEMENS AG

Multilayer thick gas electron multiplier for suppressing charging effect and preparation method thereof

ActiveCN110137070AImprove job stabilityEffective Gain StabilizationMeasurement with semiconductor devicesOptical/shielding coatings applicationDiamond-like carbonPhysics

A multilayer thick gas electron multiplier for suppressing a charging effect and a preparation method thereof are provided. The multilayer thick gas electron multiplier comprises a substrate unit anda diamond-like carbon-based film, wherein a plurality of arrayed through holes are disposed on the substrate unit; isolating rings are disposed in the circumferential direction of the through holes and are located on the upper and lower surfaces of the substrate unit; the diamond-like carbon-based film is formed in a surface of the substrate unit not covered by the isolating rings. The multilayerthick gas electron multiplier is improved in working stability, greatly increased in gain, and expanded in application range.

Owner:UNIV OF SCI & TECH OF CHINA

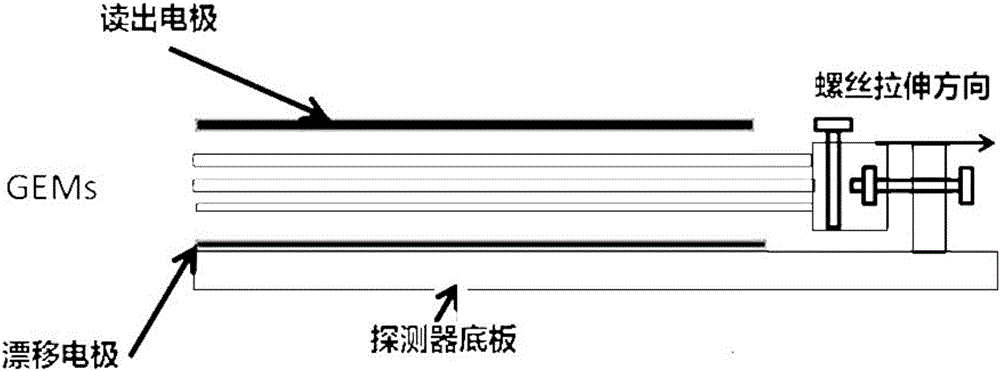

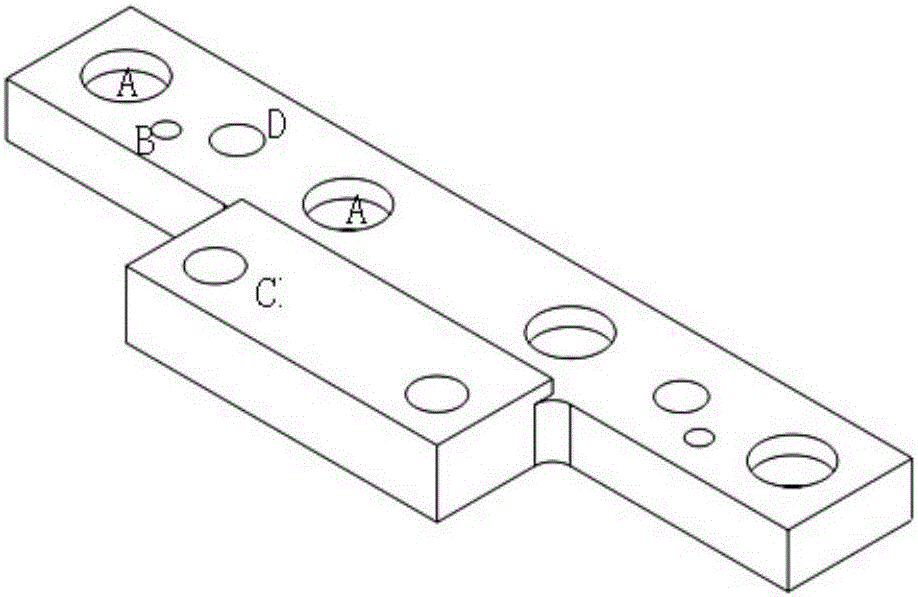

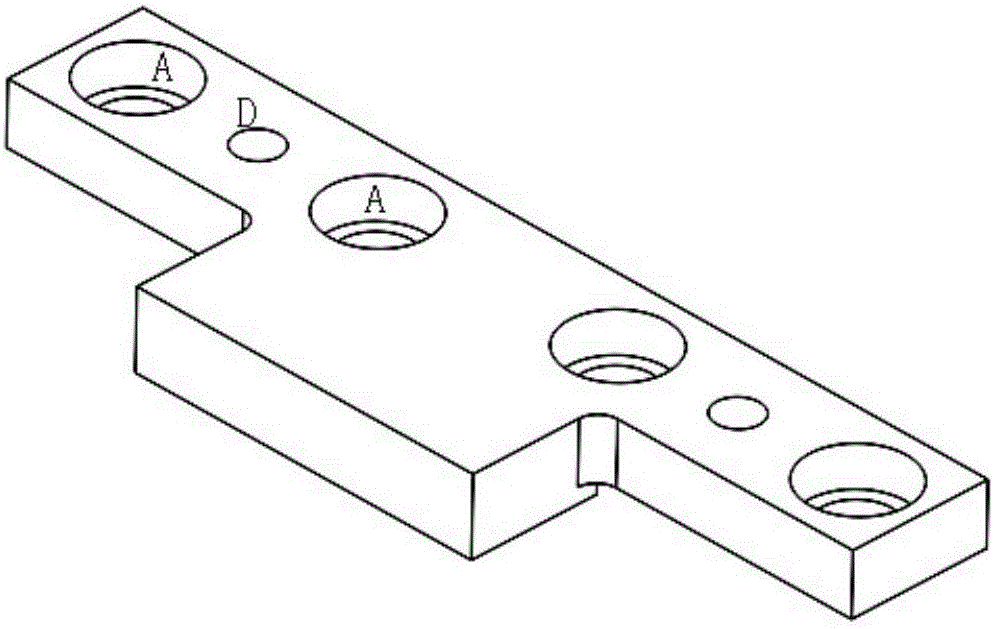

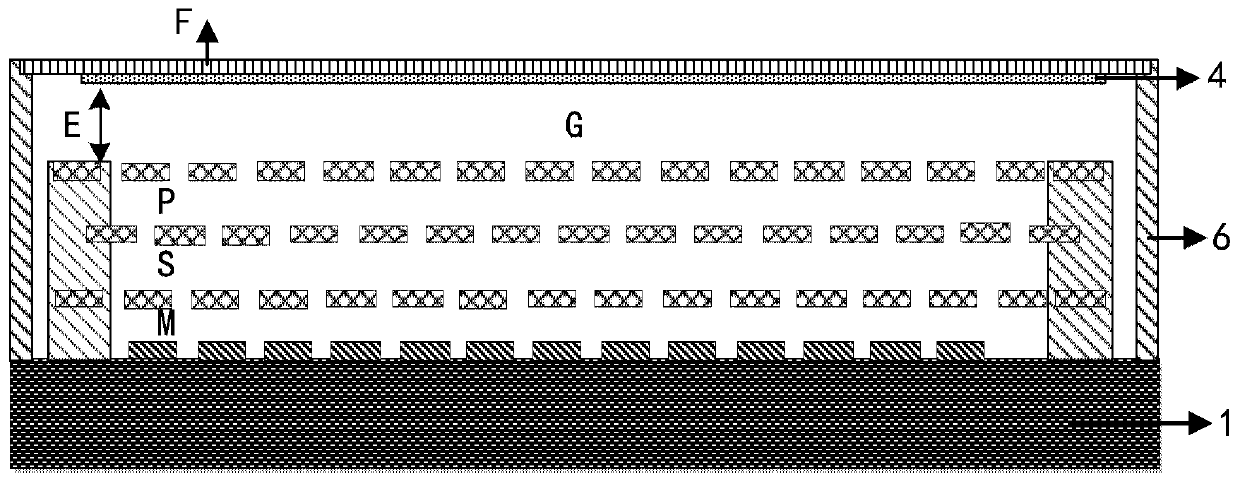

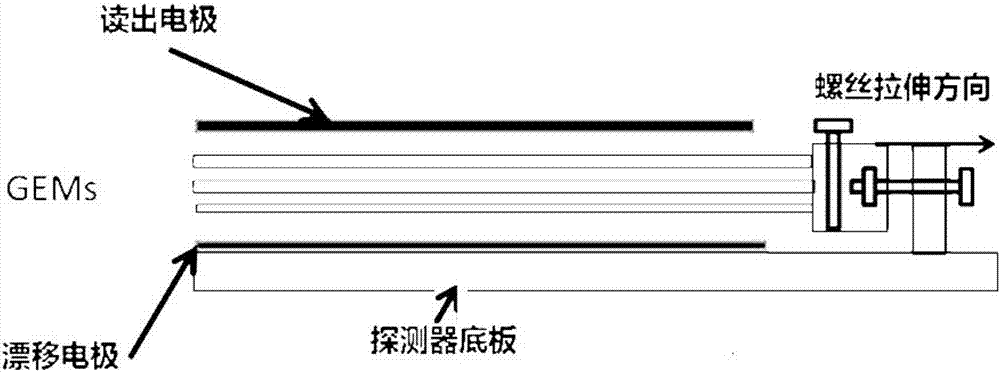

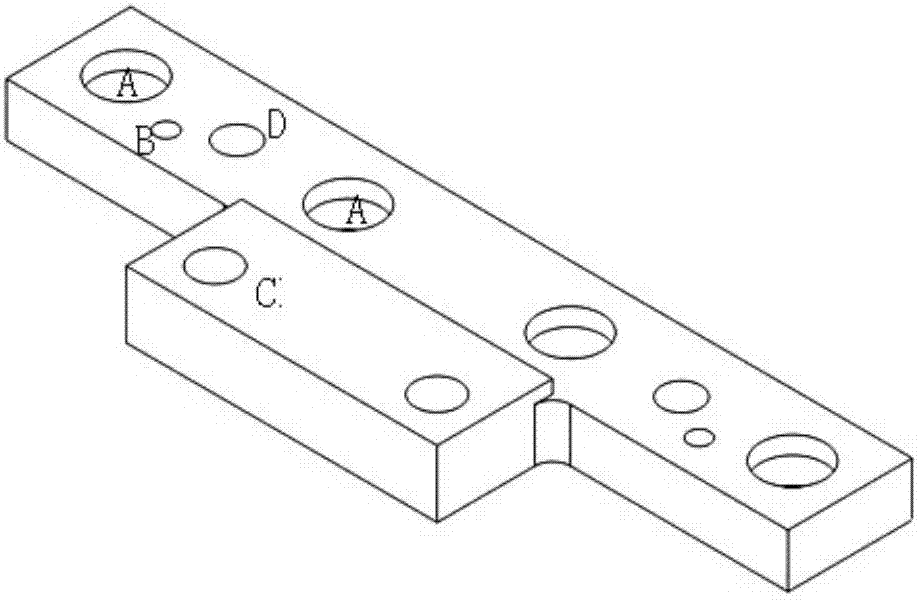

Sliding type self-tensioning method for installing and manufacturing large-area GEM detector

ActiveCN106024552AImprove design flexibilityElectric discharge tubesInstalling/removing discharge tube/lamp auxillary deviceEngineeringElectrode

The invention discloses a sliding type self-tensioning method for installing and manufacturing a large-area gas electron multiplier (GEM) detector. The sliding type self-tensioning method comprises a GEM film fixing method and a method for applying a tension force on the GEM film. Two kinds of pad strips are used for fixing a drift electrode and four edges of a GEM film. The first kind of pad strips are arranged in the middle between the drift electrode and the GEM film edge; and the second kind of pad strips are arranged at positions, approaching corner, of the two ends of the drift electrode and the GEM film edge. Sliding blocks are fixed at the outer sides of the two kinds of pad strips; and screw holes are formed in the outer sides of the sliding blocks. Clamp grooves are formed in the main frame; the parts, with the screw holes, of the outer sides of the sliding blocks are clamped into the clamp grooves for positioning; and through holes are formed in the walls of the clamp grooves; and bolts pass through the through holes and are screwed into the screw holes for tensioning. According to the invention, the method has all advantages of the self-tensioning method but problems that exist when the GEM detectors with the levels above nanometer level are manufactured are solved. Therefore, the provided method has the high design flexibility and can be used for manufacturing large-area GEM detectors with all shapes and various dimensions.

Owner:UNIV OF SCI & TECH OF CHINA

Centroid apparatus and method for sub-pixel X-ray image resolution

InactiveUS6847042B2Increased X-ray detection efficiencyDecrease in image resolutionTelevision system detailsCathode ray tubes/electron beam tubesSoft x rayImage resolution

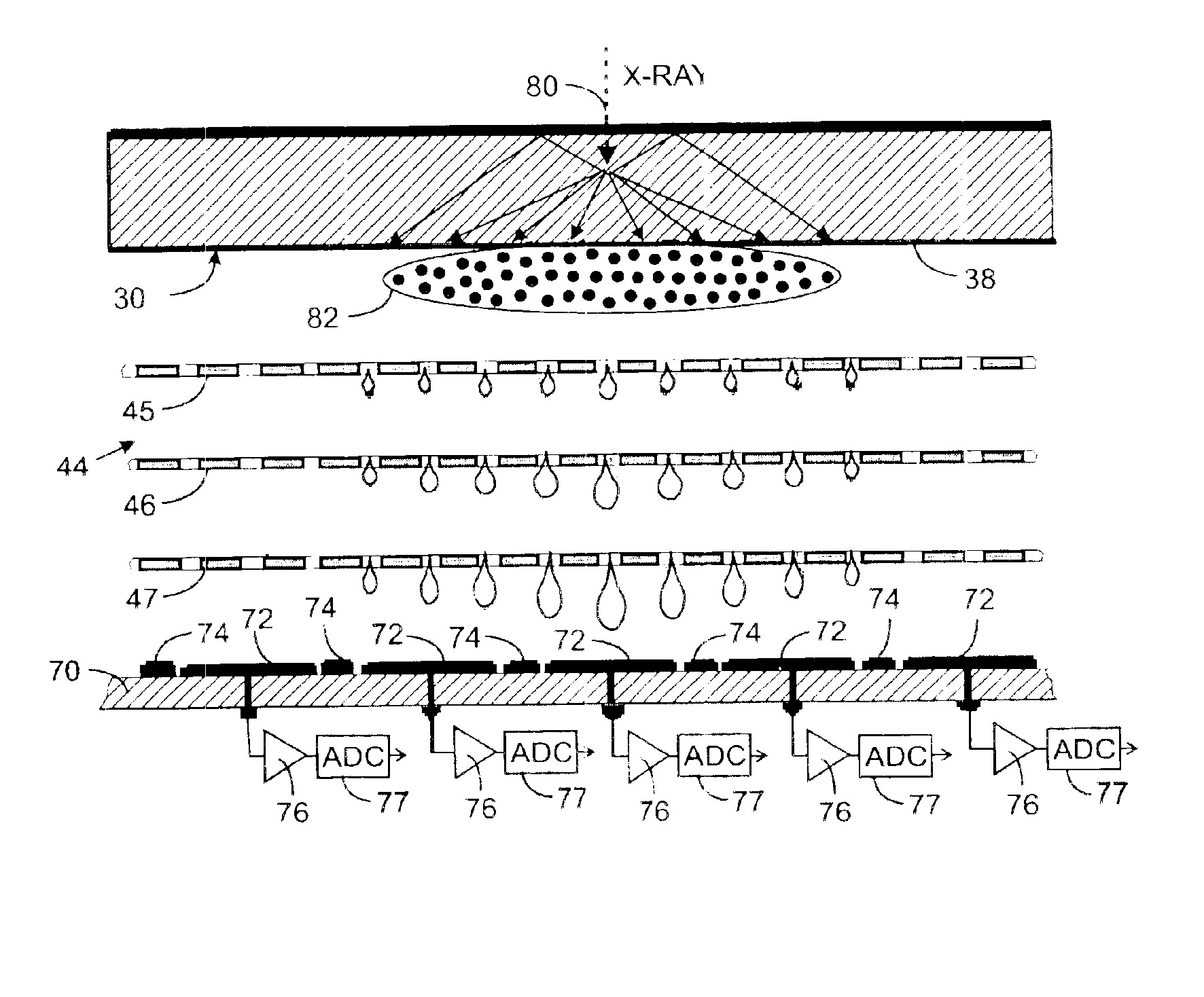

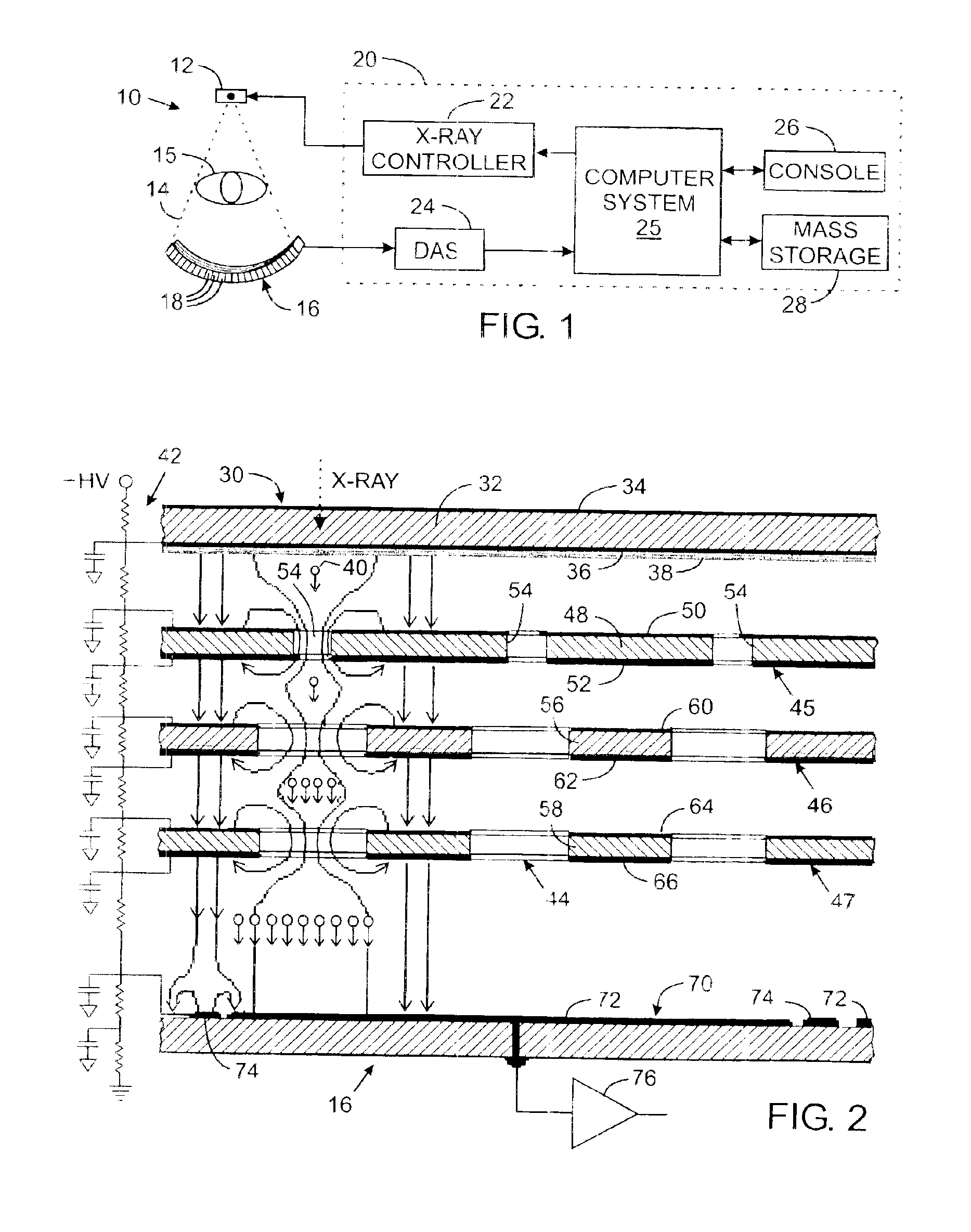

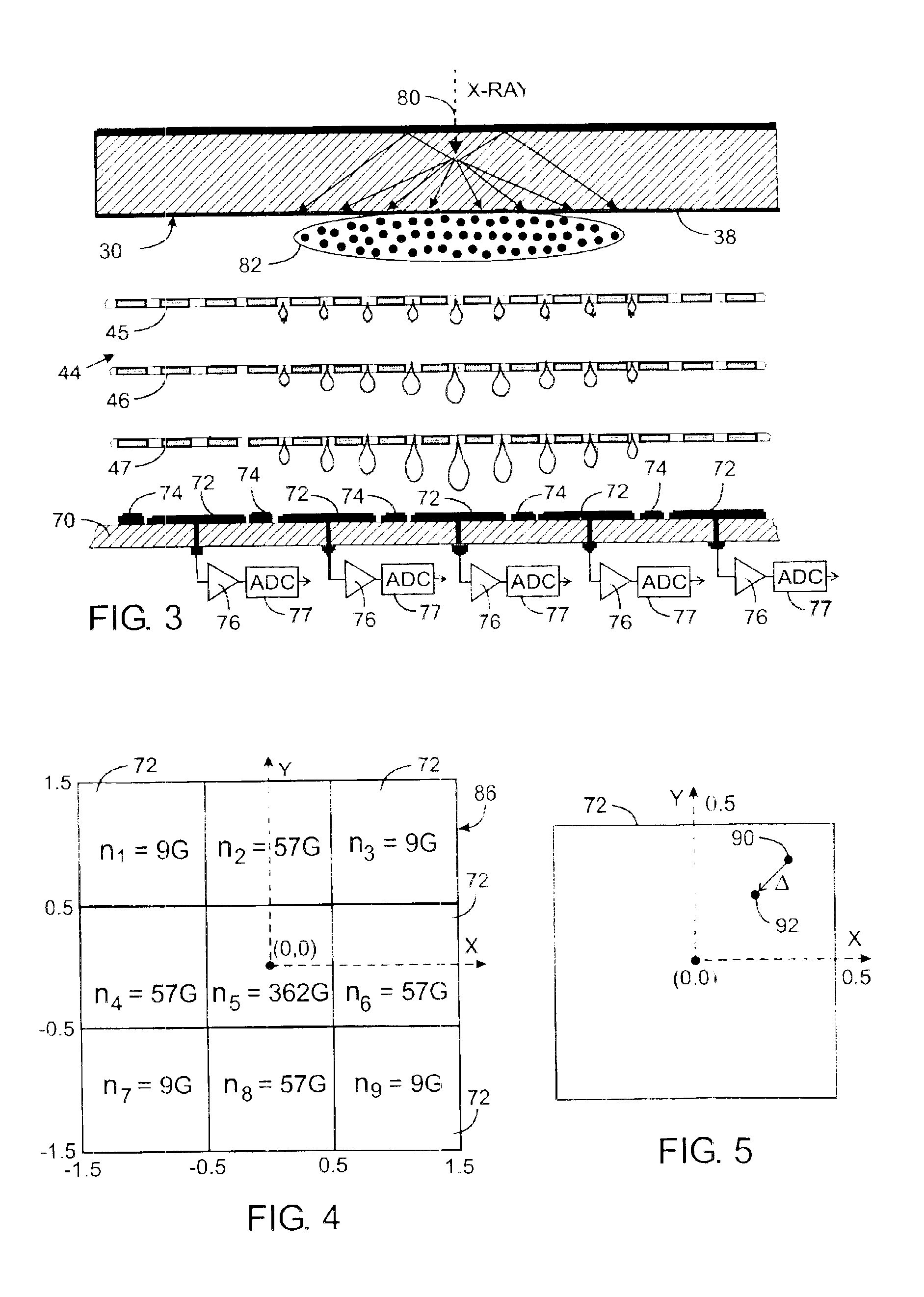

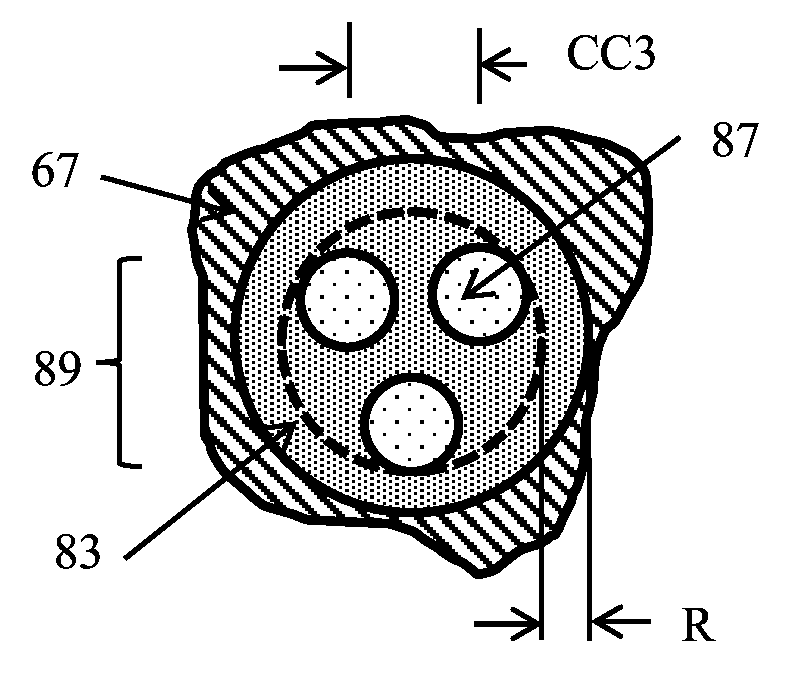

An apparatus for detecting X-rays comprises a scintillator which emits a plurality of photoelectrons upon being impacted by an X-ray photon. The photoelectrons are amplified in a gas electron multiplier and the resultant photoelectrons are accumulated on a two dimensional array of charge collection electrodes. Electrical signals are produced which indicate the quantity of photoelectrons which strike each charge collection electrode. A processor determines a location of the X-ray photon strike by analyzing the spatial distribution of the photoelectrons accumulated by the array of charge collection electrodes. The intensity of the X-ray photon is determined from the number of accumulated photoelectrons.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC +1

Ionizing radiation detecting device

Owner:BEAMOCULAR AB

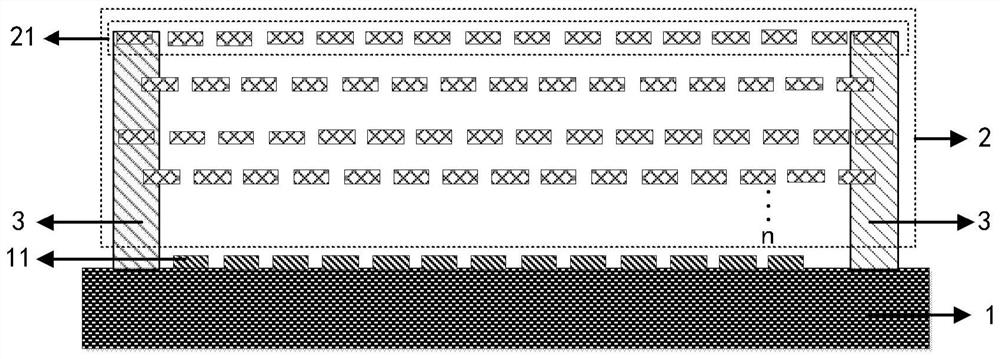

Gas electron multiplier, gas photomultiplier and gas X ray image intensifier

ActiveCN110600358AHigh gainReduce feedback rateMutiple dynode arrangementsImage-conversion/image-amplification tubesCounting ratePhotovoltaic detectors

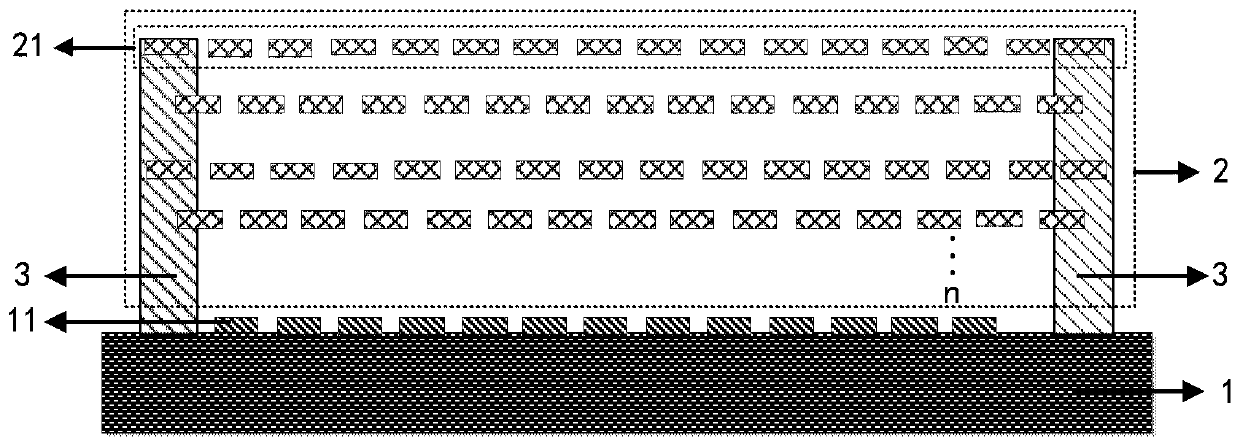

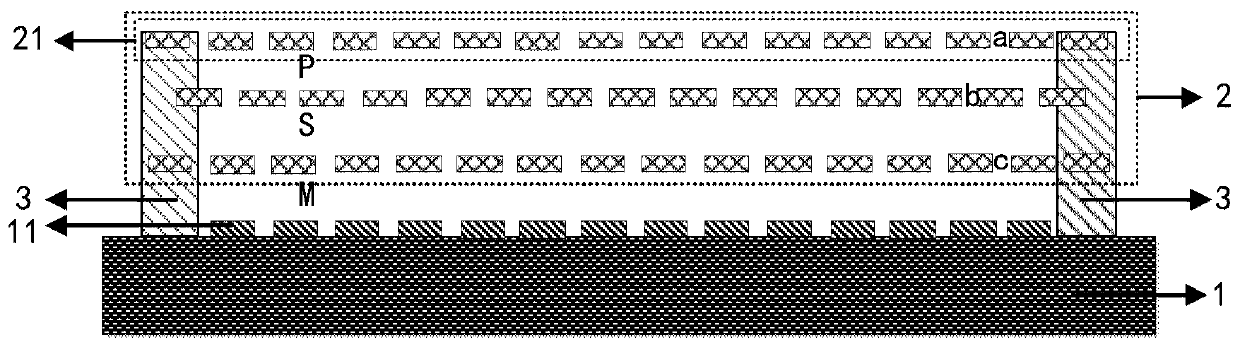

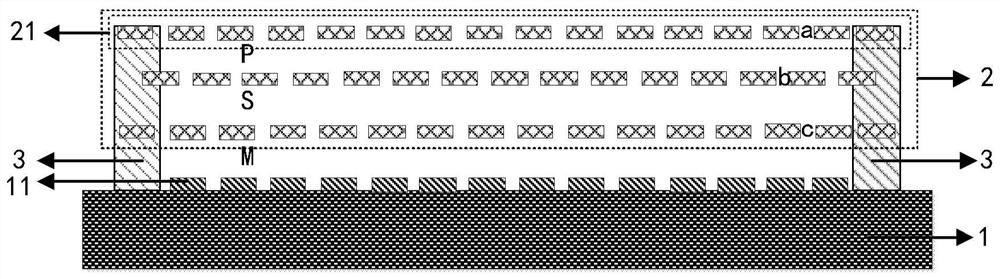

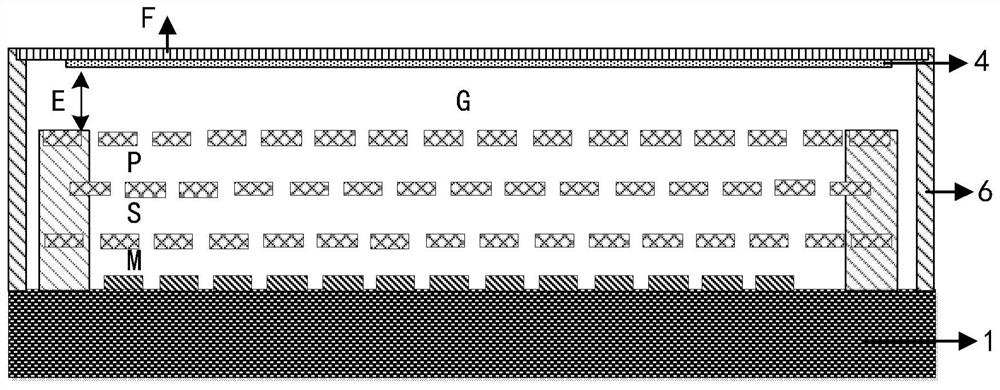

A gas electron multiplier comprises a read-out positive anode plate (1) and a micro grid electrode structure (2), the micro grid electrode structure (2) is formed by cascading of n layers of micro grid electrodes (21) through a support structure (3), and the support structure (3) is fixed on the read-out positive anode plate (1), wherein micropores of the micro grid electrode (21) of an upper layer are staggered with the micropores of the micro grid electrode (21) of a lower layer, a gas avalanche amplification region is formed among the micro grid electrodes (21), and n is an integer greaterthan 3. The gas electron multiplier can improve total gain of the of electron multiplication and simultaneously reduce ion feedback rate. A photoelectric detector can be manufactured based on the gaselectron multiplier, and thus, problems, such as increase of cost and decline of counting rate, caused by resistive electrodes are avoided, gain stability is improved, moreover, a problem that a photocathode material sensitive to visible light is liable to be damaged by ion feedback is solved.

Owner:UNIV OF SCI & TECH OF CHINA +4

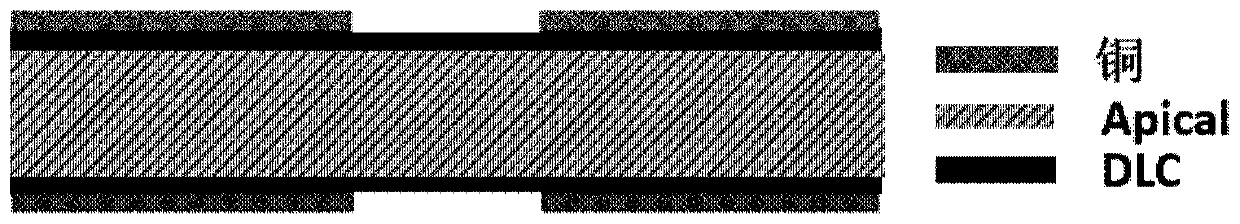

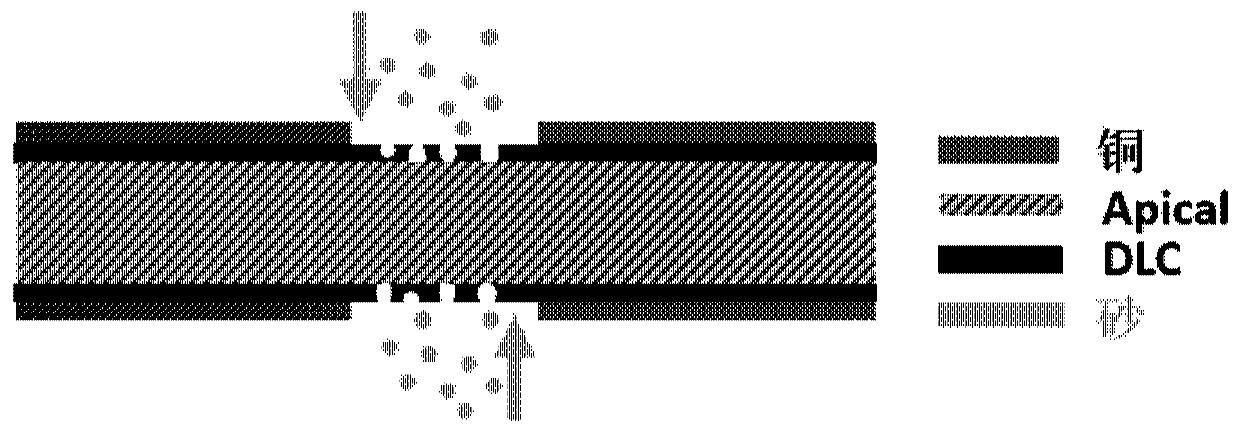

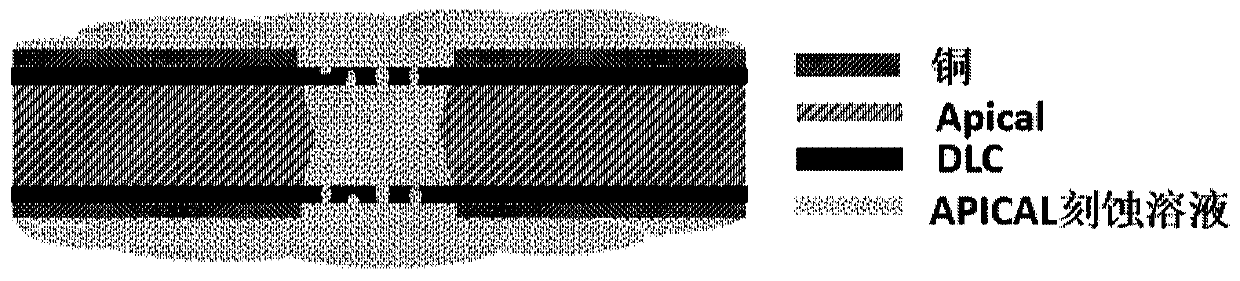

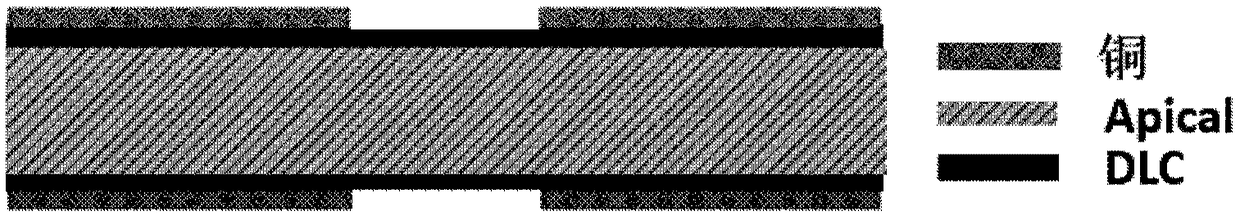

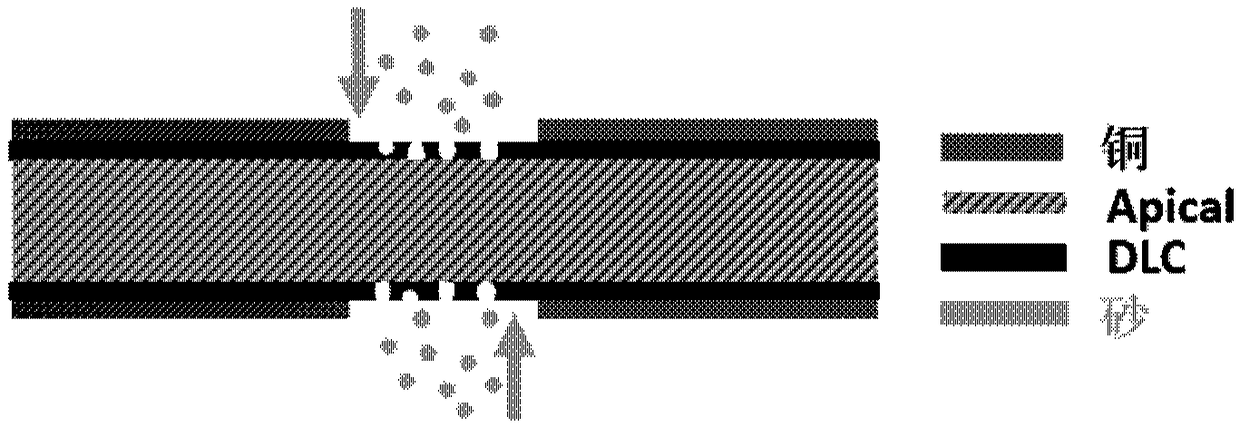

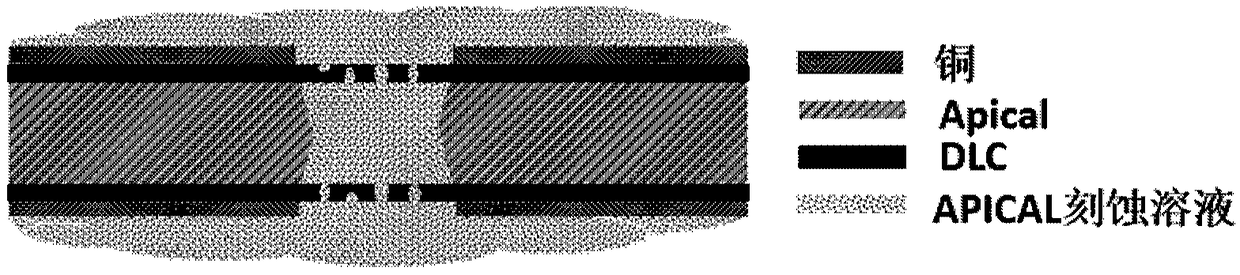

Method for preparing resistive gas electron multiplier thin film and resistive gas electron multiplier thin film

ActiveCN109148253BCause physical damageExcellent and stable performanceElectric discharge tubesMaterial resistanceDiamond-like carbonEtching

The present invention provides a method for preparing a resistive gas electron multiplier film which can form a resistive gas electron multiplier film including a first diamond-like carbon layer, a polyimide-based film and a second diamond-like carbon layer stacked in this order and having a through-hole array. The method includes forming a through hole using a combination of a protective layer, asandblasting treatment, and wet etching. The resistive gas electron multiplier film containing diamond-like carbon layer formed by the method of the invention has few defects and stable performance.The invention also provides a gas electron multiplier film and a gas electron multiplier.

Owner:UNIV OF SCI & TECH OF CHINA

Capacitive spreading readout board

InactiveUS8575561B2Reduces cost and overall complexity of readoutIncreased physical sizeElectric discharge tubesMaterial analysis by optical meansDielectricCapacitance

A readout board for use in a micropattern gas detector comprises a plurality of detector pads arranged into a plurality of consecutive layers that are separated by dielectric spacer material. An electron cloud hitting the front side of the readout board will induce a charge on one of the detector pads of the uppermost layer. By capacitive coupling, the signal will propagate downwards through the consecutive layers until it reaches the bottom layer, from which the charges are read out and analyzed. The position of the impact can be determined by comparing the charges that have spread to neighboring readout pads. Since only the bottommost layer of the readout pads needs to be connected to readout electronics, incident particles can be localized at high precision despite the relatively large size of the readout pads in the bottom layer. The invention is effective both in a gas electron multiplier (GEM) and in a MicroMegas detector.

Owner:EUROPEAN ORGANIZATION FOR NUCLEAR RESEARCH

Method for preparing resistive gas electron multiplier film and resistive gas electron multiplier film

ActiveCN109148253ACause physical damageExcellent and stable performanceElectric discharge tubesMaterial resistanceDiamond-like carbonEtching

The present invention provides a method for preparing a resistive gas electron multiplier film which can form a resistive gas electron multiplier film including a first diamond-like carbon layer, a polyimide-based film and a second diamond-like carbon layer stacked in this order and having a through-hole array. The method includes forming a through hole using a combination of a protective layer, asandblasting treatment, and wet etching. The resistive gas electron multiplier film containing diamond-like carbon layer formed by the method of the invention has few defects and stable performance.The invention also provides a gas electron multiplier film and a gas electron multiplier.

Owner:UNIV OF SCI & TECH OF CHINA

Sliding self-tensioning method for installation and fabrication of large area gem detectors

ActiveCN106024552BImprove design flexibilityElectric discharge tubesInstalling/removing discharge tube/lamp auxillary deviceEngineeringElectrode

The invention discloses a sliding type self-tensioning method for installing and manufacturing a large-area gas electron multiplier (GEM) detector. The sliding type self-tensioning method comprises a GEM film fixing method and a method for applying a tension force on the GEM film. Two kinds of pad strips are used for fixing a drift electrode and four edges of a GEM film. The first kind of pad strips are arranged in the middle between the drift electrode and the GEM film edge; and the second kind of pad strips are arranged at positions, approaching corner, of the two ends of the drift electrode and the GEM film edge. Sliding blocks are fixed at the outer sides of the two kinds of pad strips; and screw holes are formed in the outer sides of the sliding blocks. Clamp grooves are formed in the main frame; the parts, with the screw holes, of the outer sides of the sliding blocks are clamped into the clamp grooves for positioning; and through holes are formed in the walls of the clamp grooves; and bolts pass through the through holes and are screwed into the screw holes for tensioning. According to the invention, the method has all advantages of the self-tensioning method but problems that exist when the GEM detectors with the levels above nanometer level are manufactured are solved. Therefore, the provided method has the high design flexibility and can be used for manufacturing large-area GEM detectors with all shapes and various dimensions.

Owner:UNIV OF SCI & TECH OF CHINA

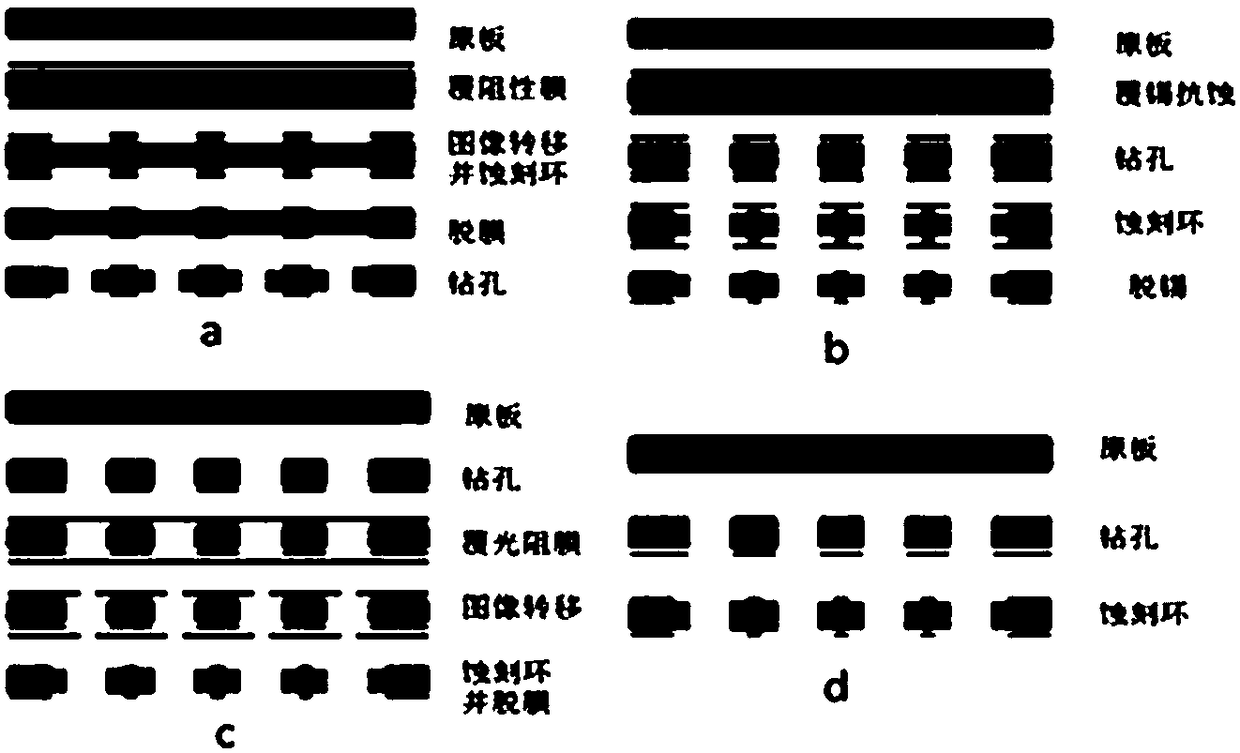

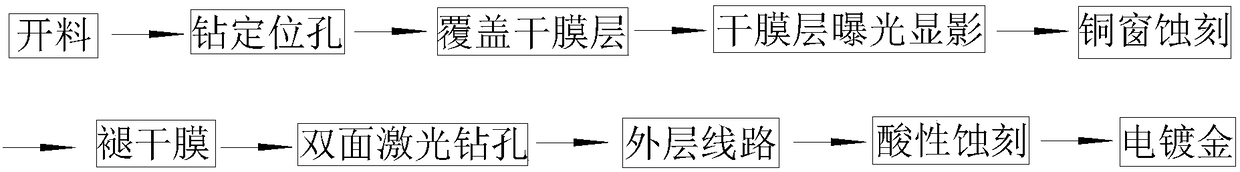

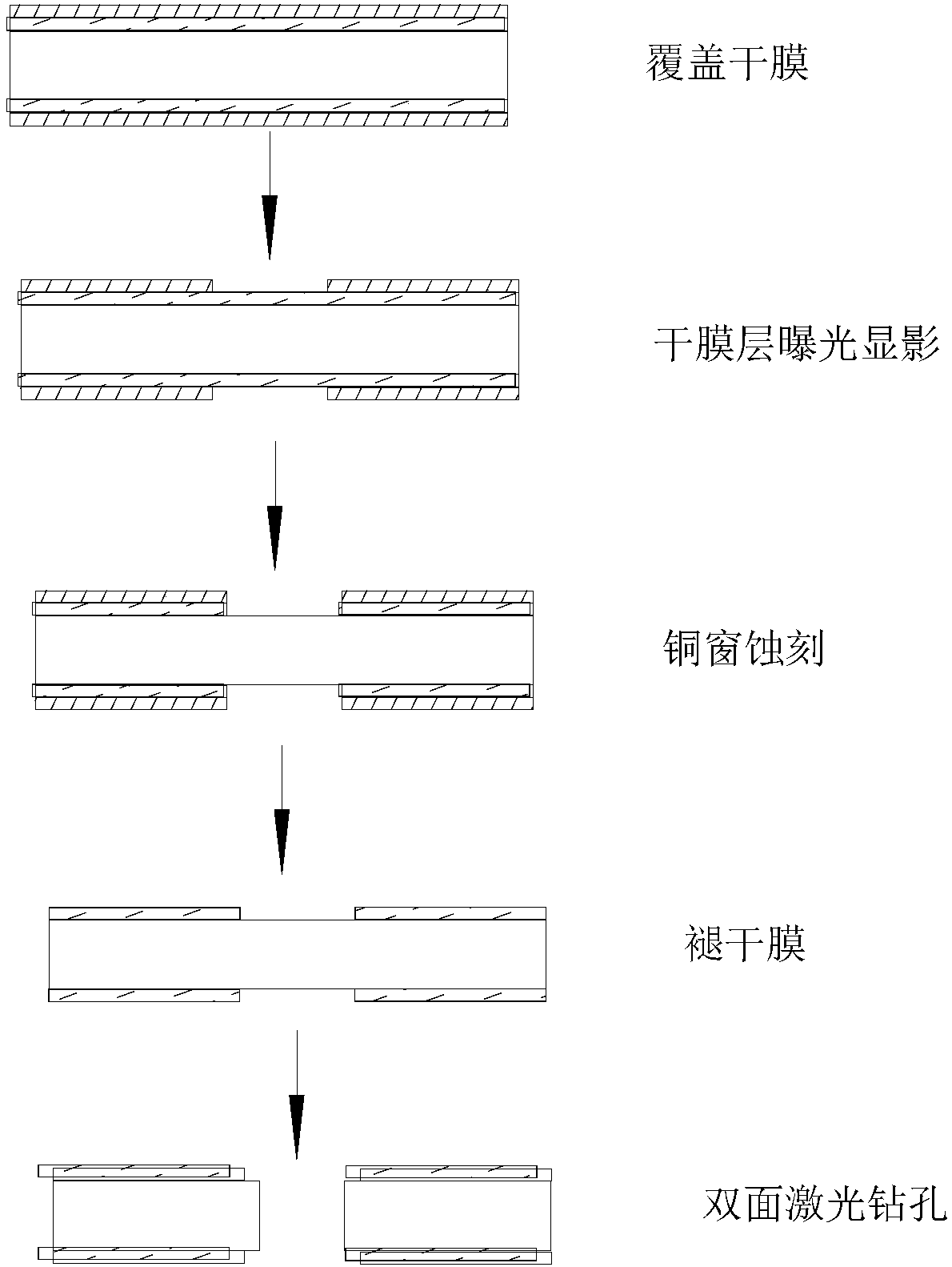

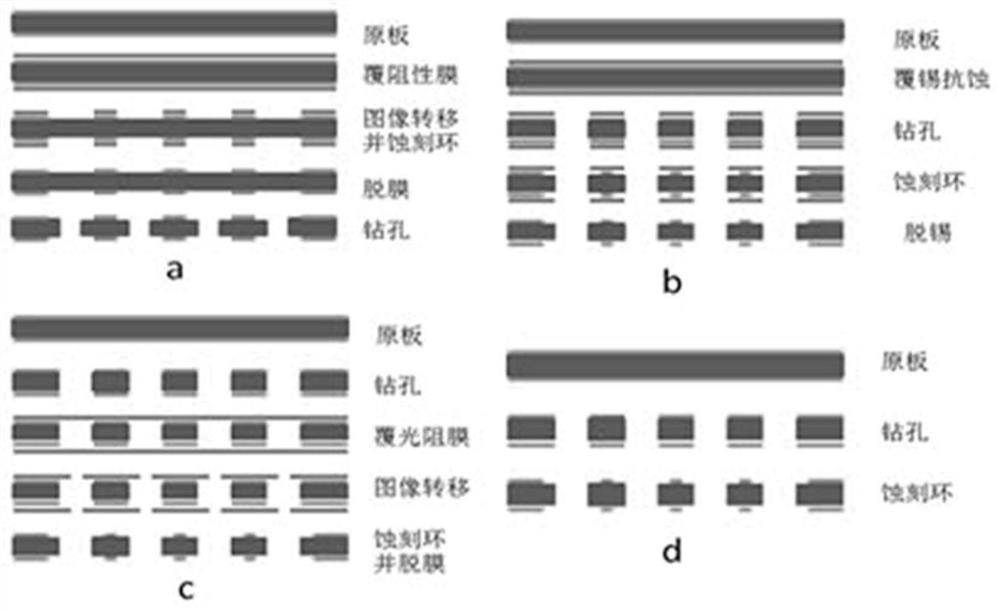

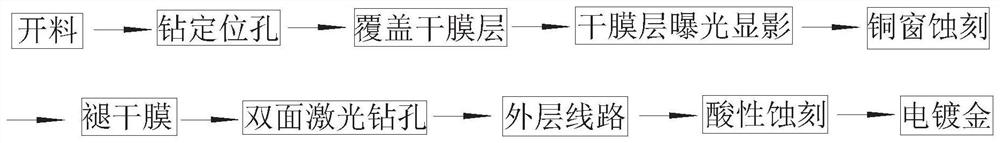

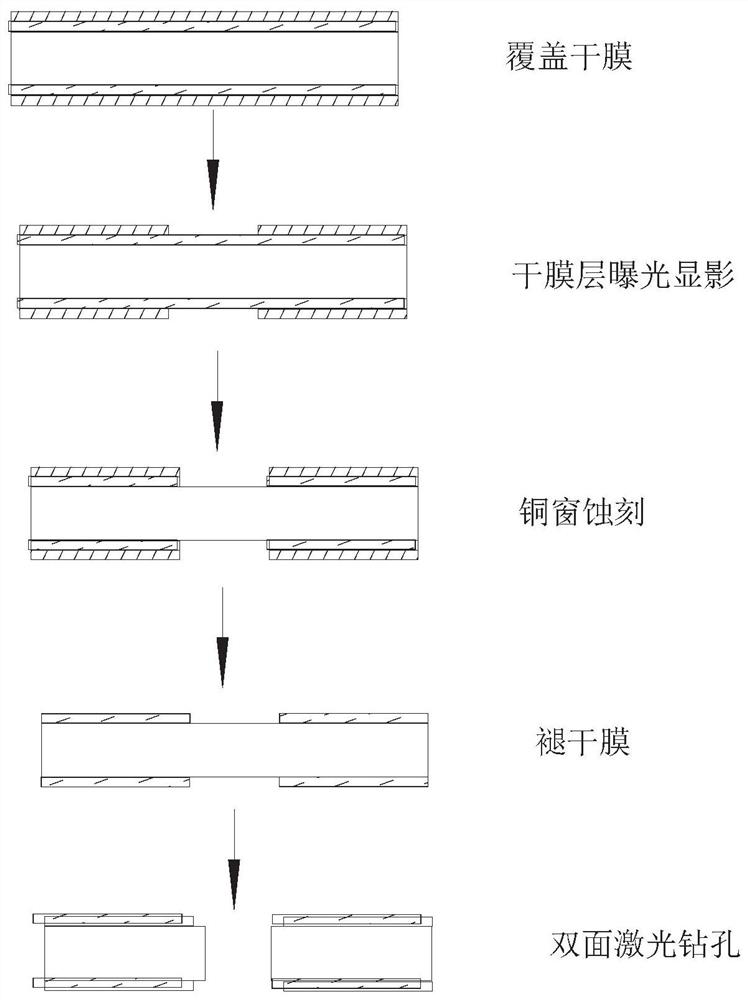

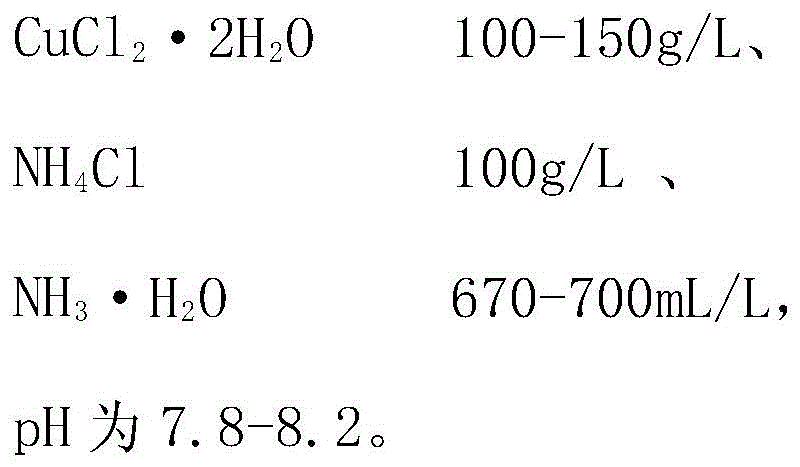

Circuit board partition block seamless laser processing method for thick gas electron multiplier

ActiveCN108551723AReduce consumptionReduce processing complexityPrinted circuit manufactureAfter treatmentLaser processing

The invention discloses a circuit board partition block seamless laser processing method for a thick gas electron multiplier. The method comprises steps that 1), rough shape cutting is carried out according to design requirements to acquire an original plate; 2) a positioning hole is drilled in the original plate acquired through rough shape cutting in the step 1); 3) the original plate after treatment in the step 1) is covered with a dry film layer, and the dry film layer is exposed and developed; 4) the original plate after treatment in step 3) is subjected to copper window etching, and a dry film is removed; 5) laser drilling on the original plate after treatment in the step 4) is carried out; 6), an outer layer line is prepared on the original plate after treatment in the step 5), andacid etching is carried out; and 7), gold plating on the surface of the original plate after treatment in the step 6) is carried out. The method is advantaged in that product quality is improved, compatibility is improved, and production difficulty is reduced.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +1

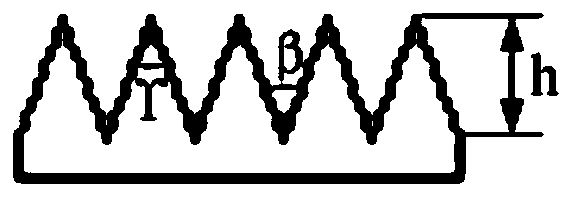

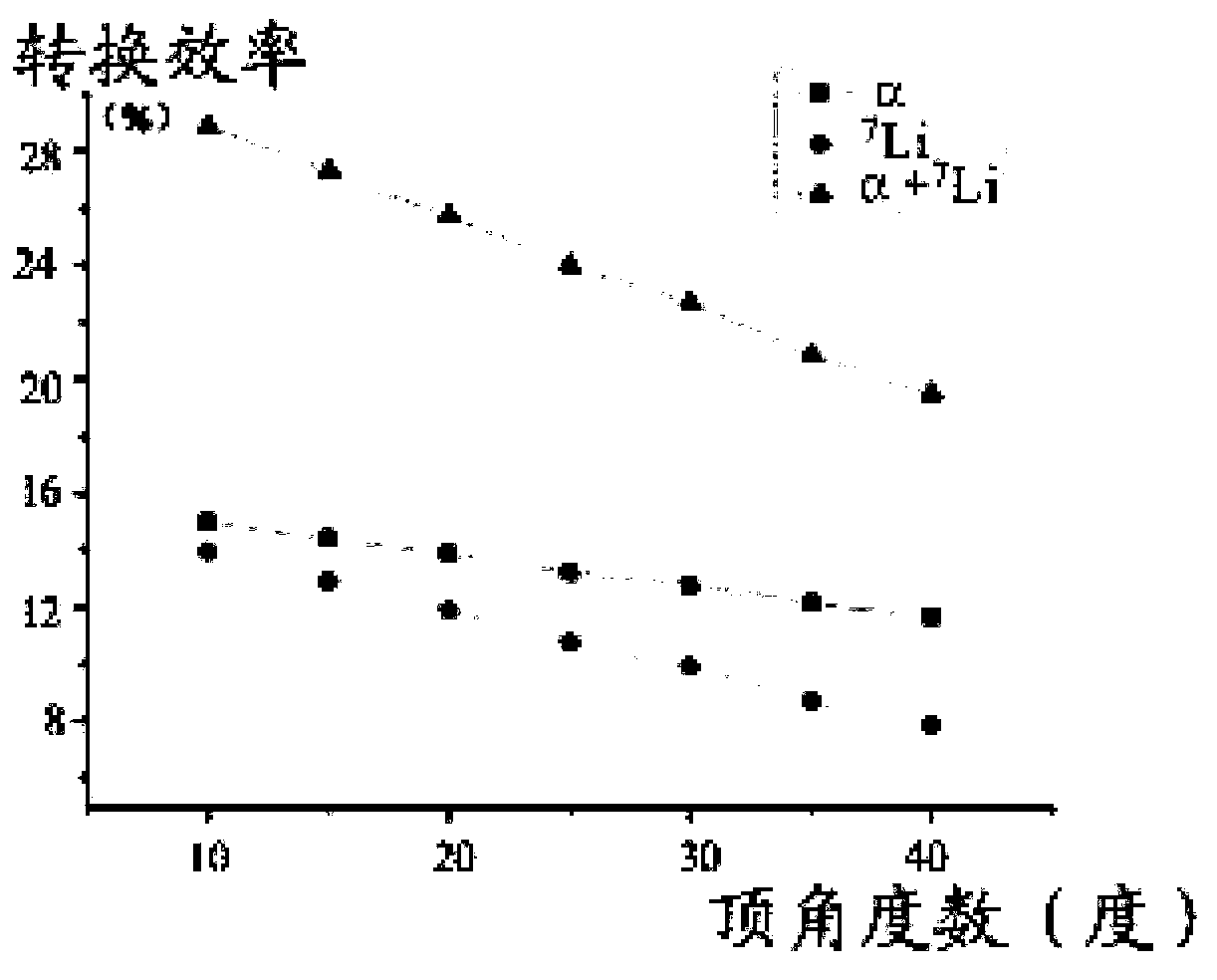

Neutron detector based on thick gem and multilayer boron-coated mesh

ActiveCN108037524BWon't wasteGuaranteed conversion efficiencyRadiation intensity measurementBoronGSM

The invention discloses a multilayer net boron-coating thick GEM (Gas Electron Multiplier) neutron detector, which comprises a drifting electrode and a reading electrode, wherein the drifting electrode and the reading electrode are arranged in parallel side by side; a neutron transformation body is arranged between the drifting electrode and the reading electrode in parallel; the neutron transformation body comprises at least one layer of metal net; the surface of the metal net is coated with boron; the surface, which faces the reading electrode, of the drifting electrode is coated with the boron; a thick gas GEM is arranged between the neutron transformation body and the drifting electrode in parallel. According to the multilayer net boron-coating thick GEM neutron detector disclosed by the invention, a transformation area and a multiplication area are separated, the transformation area can be based on a plurality of boron-coating metal substrates, neutron detection efficiency can begreatly improved, no expensive boron 10 materials are wasted, the thick GSM of the multiplication area is durable, and gain can be easily controlled.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

Gas electron multiplier, gas photomultiplier tube and gas X-ray image intensifier

ActiveCN110600358BHigh gainReduce feedback rateMutiple dynode arrangementsImage-conversion/image-amplification tubesPhotodetectorPhotocathode

A gas electron multiplier, comprising: a readout anode plate (1); a microgrid electrode structure (2), formed by cascading n layers of microgrid electrodes (21) through a support structure (3), the support structure (3 ) is fixed on the readout anode plate (1); wherein, the micropores of the upper layer of microgrid electrodes (21) and the micropores of the lower layer of microgrid electrodes (21) are misplaced, forming between the microgrid electrodes (21) Gas avalanche amplification area, n is an integer greater than or equal to 3. This gas electron multiplier increases the overall gain of electron multiplication while reducing the ion feedback rate. The photodetector based on the gas electron multiplier avoids the problems of cost increase and count rate decrease caused by the resistive electrode, the gain stability is improved, and the problem that the photocathode material sensitive to visible light is easily damaged by ion feedback is solved.

Owner:UNIV OF SCI & TECH OF CHINA +4

Block-by-block seamless laser processing method for circuit boards for thick gas electron multipliers

ActiveCN108551723BImprove product qualityImprove through-hole alignment accuracyPrinted circuit manufactureLaser processingEngineering

The invention discloses a block-by-block seamless laser processing method for a circuit board used in a thick gas electron multiplier, which comprises the following steps: 1) Cutting the material according to the design requirements to obtain the original board; 2) Drilling the original board obtained in the step 1) cutting Positioning holes; 3) Cover the dry film layer with the original plate treated in step 1), and expose and develop the dry film layer; 4) Carry out copper window etching on the original plate treated in step 3) and remove the dry film; 5) In step 4) Laser drilling on the treated original board; 6) preparing the outer circuit on the treated original board in step 5), and acid etching; 7) electroplating gold on the surface of the original board after step 6). The invention provides a block-by-block seamless laser processing method for a thick gas electron multiplier circuit board that improves product quality, improves compatibility of processing methods, and reduces processing difficulty.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +1

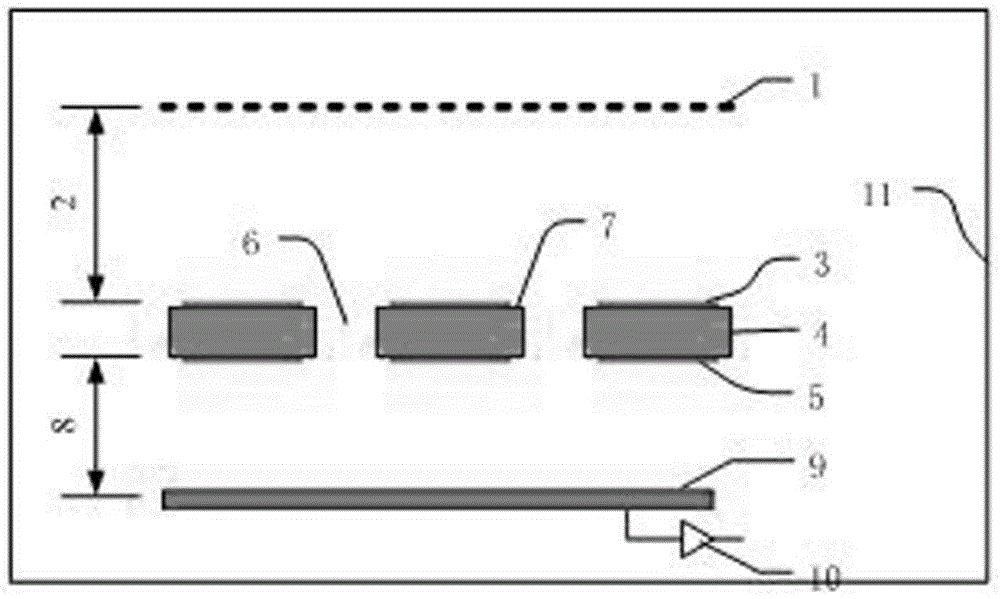

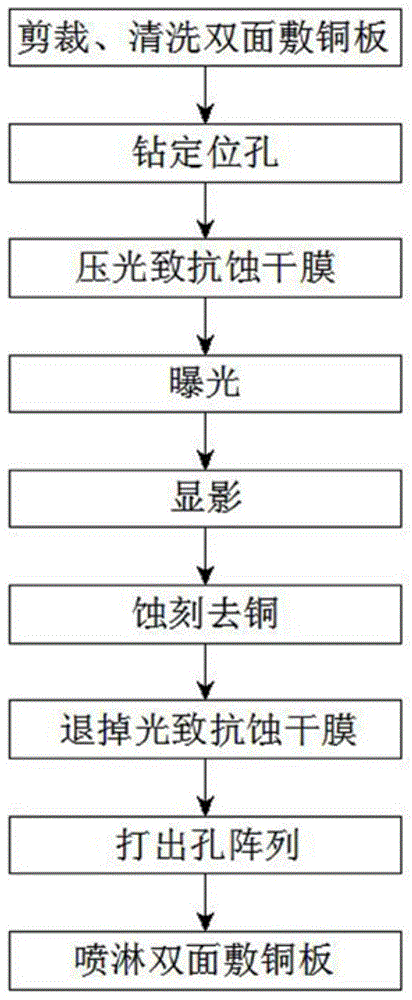

Fabrication method of thick gas electron multiplier detector diaphragm

ActiveCN103635026BEasy to prepare in large areaRim uniformityConductive material chemical/electrolytical removalNumerical controlEtching

The invention discloses a method for manufacturing a thick gas electron multiplication detector membrane plate, which is characterized in that it comprises the following steps: cutting and cleaning double-sided copper-clad plates; drilling positioning holes; pressing photoresist dry films on both sides simultaneously; The outer graphic film and the circuit board with the photoresist dry film pressed are aligned and placed on the exposure machine for exposure; develop, etch to remove copper, and remove the photoresist dry film; CNC machine tools punch out holes on the double-sided copper clad board Array; spray double-sided copper-clad board. The advantage of the present invention is that: it adopts the whole board micro-etching process to manufacture THGEM diaphragms in a large area, and has successfully produced THGEM diaphragms of 300mm×300mm, and the uniformity of the rim is consistent; the use of fully automatic circuit board manufacturing equipment , can be mass-produced, and the yield rate is above 95%; THGEM membrane plate and readout anode plate are independent of each other, and can be designed and processed into different sizes and shapes according to needs.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES +1

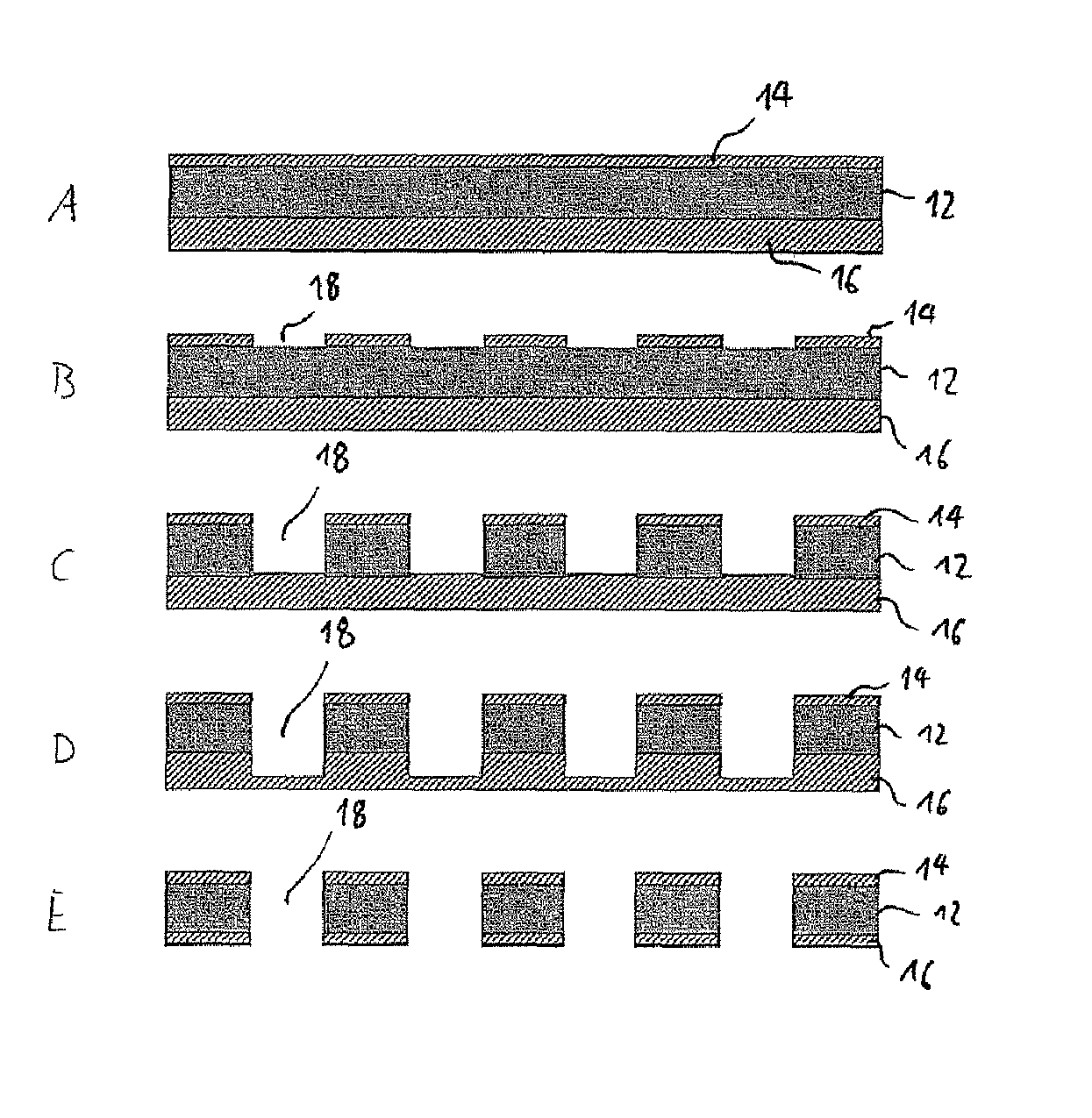

Method of manufacturing a gas electron multiplier

InactiveUS8597490B2Quality improvementHigh yieldElectrolysis componentsElectric discharge tubesPhotolithographyMetal

Methods for manufacturing a gas electron multiplier. One method comprises a step of preparing a blank sheet comprised of an insulating sheet with first and second metal layers on its surface, a first metal layer hole forming step in which the first metal layer is patterned by means of photolithography, such as to form holes through the first metal layer, an insulating sheet hole forming step, in which the holes formed in the first metal layer are extended through the insulating layer by etching from the first surface side only, and a second metal layer hole forming step, in which the holes are extended through the second metal layer. Alternatively, the second metal layer hole forming step is performed by electrochemical etching, such that the first metal layer remains unaffected during etching of the second metal layer. In another embodiment, in the second metal layer hole forming step, the first and second metal layers are etched from the outside, thereby reducing the initial thicknesses of the first and second metal layers and the second metal layer is simultaneously etched through the holes in the first metal layer and the insulating sheet, said etching being maintained until the holes extend through the second metal layer, wherein said initial average thickness of the first and second metal layers is between 6.5 μm and 25 μm, preferably between 7.5 μm and 12 μm.

Owner:EUROPEAN ORGANIZATION FOR NUCLEAR RESEARCH

Detector for radiation, particularly high energy electromagnetic radiation

InactiveUS9594171B2Accurate measurementSmall sizeElectric discharge tubesRadiation intensity measurementHigh energyElectromagnetic radiation

A detector for radiation, particularly high energy electromagnetic radiation is provided. The detector includes a converting section including a cathode for converting the radiation incident on the converting section in electrons by the photoelectric effect. The detector further includes a gas electron multiplier for generating an electron avalanche from electrons which are generated by the converting section and enter the gas electron multiplier, the gas electron multiplier including a first electrode, a dielectric layer and a second electrode, the first electrode being disposed at a first side of the dielectric layer adjacent to the converting section and the second electrode being disposed at a second side of the dielectric layer opposite to the first side. The gas electron multiplier includes a number of holes filled with gas, the holes extending through the first electrode, the dielectric layer and the second electrode.

Owner:SIEMENS AG

Multilayer thick gas electron multiplier with suppressed charging effect and preparation method thereof

ActiveCN110137070BImprove job stabilityEffective Gain StabilizationMeasurement with semiconductor devicesOptical/shielding coatings applicationDiamond-like carbonThin membrane

A multilayer thick gas electron multiplier for suppressing a charging effect and a preparation method thereof are provided. The multilayer thick gas electron multiplier comprises a substrate unit anda diamond-like carbon-based film, wherein a plurality of arrayed through holes are disposed on the substrate unit; isolating rings are disposed in the circumferential direction of the through holes and are located on the upper and lower surfaces of the substrate unit; the diamond-like carbon-based film is formed in a surface of the substrate unit not covered by the isolating rings. The multilayerthick gas electron multiplier is improved in working stability, greatly increased in gain, and expanded in application range.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com