Method for making gas electron multiplier polymer film grid

A technology of gas electron multiplication and polymer film, which is applied in the field of X-ray detection and can solve the problems of high equipment requirements, impact, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

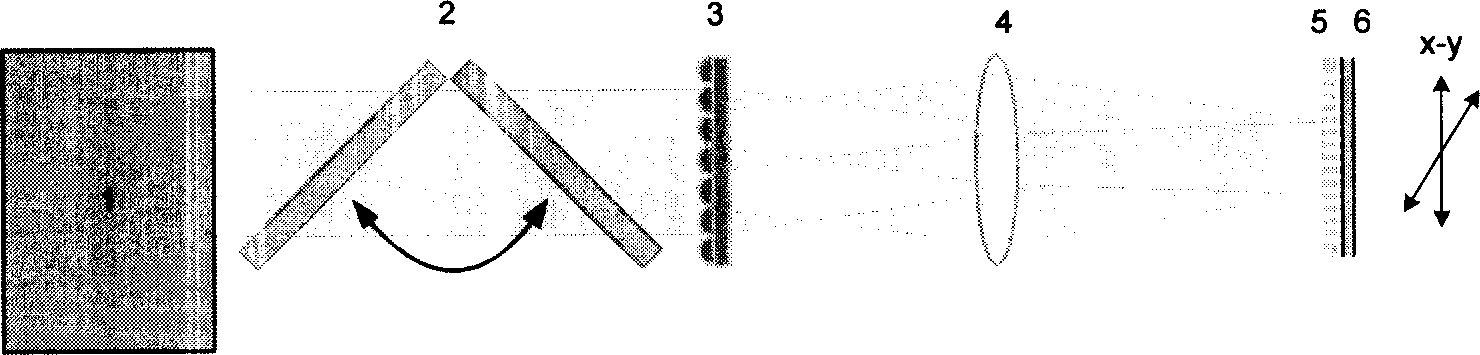

[0014] figure 2 It is a schematic diagram of an embodiment of the present invention. 308nm excimer laser 1 passes through the attenuator 2 and the fly-eye homogenizer 3, passes through the converging lens 4, and irradiates the polyimide (PI) film 6 coated with copper film on both sides, which is one piece before the PI film 6 The microhole array mask plate 5 obtained by drilling holes with a YAG laser. The microhole size of the microhole array 5 is 70 μm, the hole spacing is 140 μm, and the mask plate thickness is 70 μm. The PI film is 50 μm thick, and each side is coated with 10 μm copper film. The effective spot size irradiated on the PI thin film 6 is 3.5mm×3.5mm, the laser single pulse energy is 120mJ, and the working frequency is 10Hz.

[0015] Microwell grids of any size can be obtained by scanning the x-y platform.

[0016] Actually what we make is a grid of 20mm×20mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com