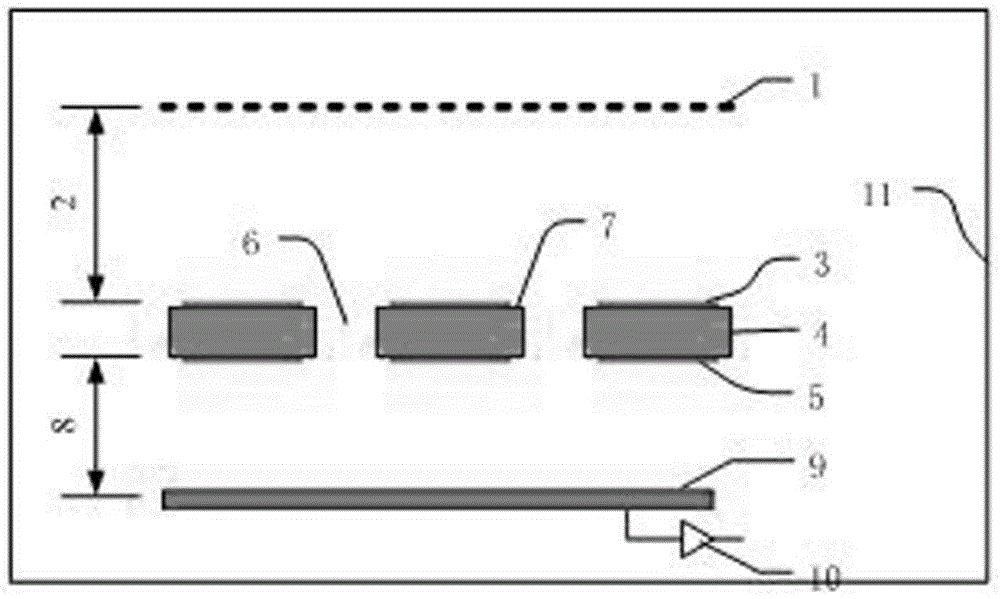

Fabrication method of thick gas electron multiplier detector diaphragm

A technology of gas electron multiplication and production method, which is applied in the direction of removing conductive materials by chemical/electrolytic methods, which can solve the problems affecting the working performance of the detector and increasing the difficulty of making THGEM membranes, and achieve uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

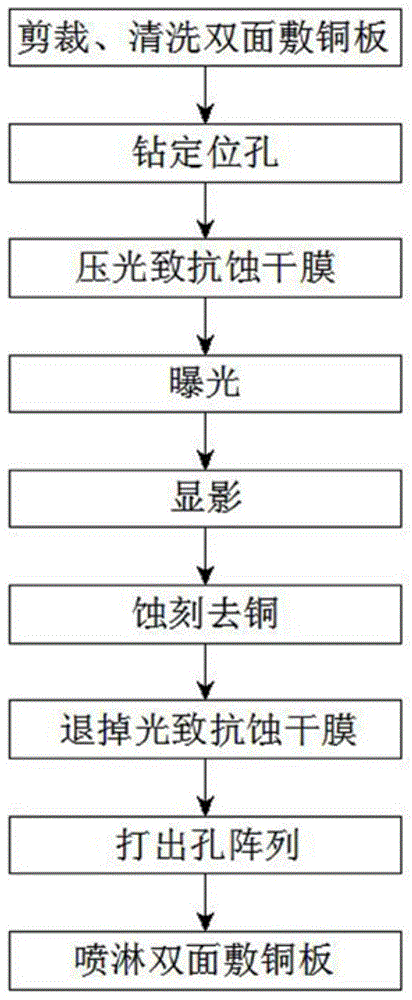

Embodiment 1

[0032] 1. Cut the double-sided copper-clad PCB board into a production board with a processing size of 300mm×300mm, scrub and clean it with a board brushing machine, and use a cleaning agent to remove grease, etc., and wait for use.

[0033] 2. Drill positioning holes on the double-sided copper clad board for the installation and fixing of THGEM membrane board.

[0034] 3. Simultaneously press the photoresist dry film on both sides of the double-sided copper clad board.

[0035] 4. Align the outer graphics film with the circuit board with the photoresist dry film pressed, put it on the exposure machine for exposure, and bake at 100°C for 3 minutes.

[0036] 5. Use NaCO with a concentration of 1% (w / v) 3 The solution was developed at a spray speed of 0.8m / min.

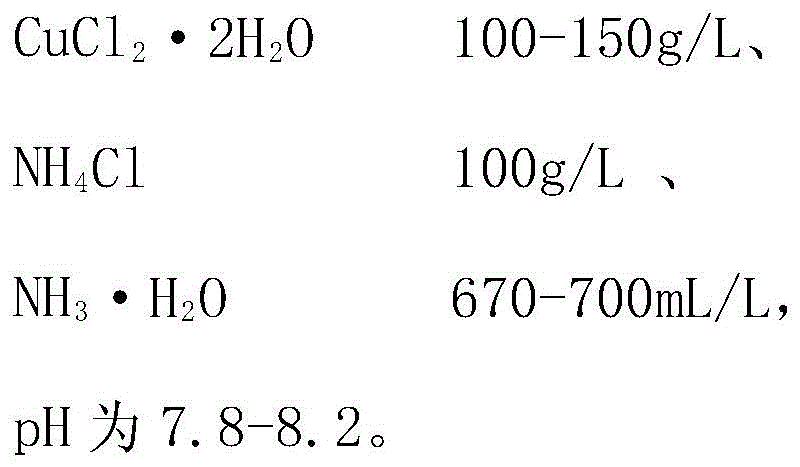

[0037] 6. Etch copper with etching solution, the composition of etching solution is:

[0038]

[0039] 7. Remove the photoresist dry film with film removing solution. At this time, the upper layer copper foil, th...

Embodiment 2

[0046] 1. Cut the double-sided copper-clad PCB board into a production board with a processing size of 300mm×300mm, scrub and clean it with a board brushing machine, and use a cleaning agent to remove grease, etc., and wait for use.

[0047] 2. Drill positioning holes on the double-sided copper clad board for the installation and fixing of THGEM membrane board.

[0048] 3. Simultaneously press the photoresist dry film on both sides of the double-sided copper clad board.

[0049] 4. Align the outer graphics film with the circuit board with the photoresist dry film pressed, put it on the exposure machine for exposure, and bake at 100°C for 3 minutes.

[0050] 5. Use NaCO with a concentration of 1% (w / v) 3 The solution was developed at a spray speed of 0.8m / min.

[0051] 6. Etch copper with etching solution, the composition of etching solution is:

[0052]

[0053] 7. Remove the photoresist dry film with film removing solution. At this time, the upper layer copper foil, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com