Pervaporation hybridigation composite film as well as preparation method and application thereof

A hybrid composite and pervaporation technology, applied in the field of membrane separation, can solve the problem of low filling area, and achieve the effect of increasing the filling area, simple membrane production process and rapid membrane formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

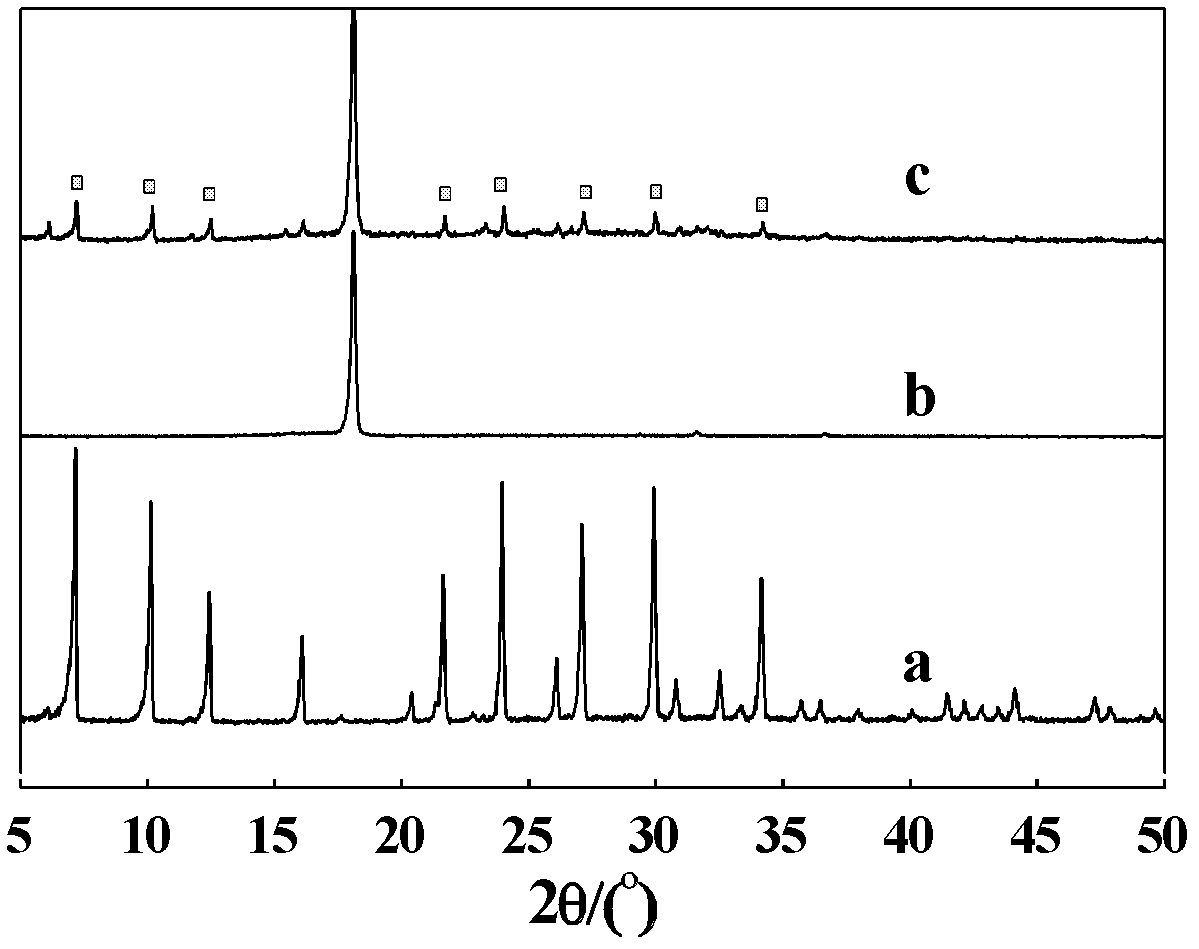

[0035] Take Na 2 SiO 3 9H 2 O is the silicon source, Al 2 SO 3 18H 2 O is the source of aluminum, NaOH is the source of alkali, in molar ratio n(Na 2 O):n(SiO 2 ):n(Al 2 o 3 ):n(H 2 O)=6:2:1:750 to prepare molecular sieve synthesis solution. Crystallize in a polytetrafluoroethylene-lined stainless steel reactor at 85°C for 20 hours, take it out for quenching, filter with suction, wash with deionized water until neutral, and dry to obtain nano-sized NaA molecular sieves. XRD pattern of NaA molecular sieve and PTFE support layer figure 1 (a) and figure 1 (b) shown.

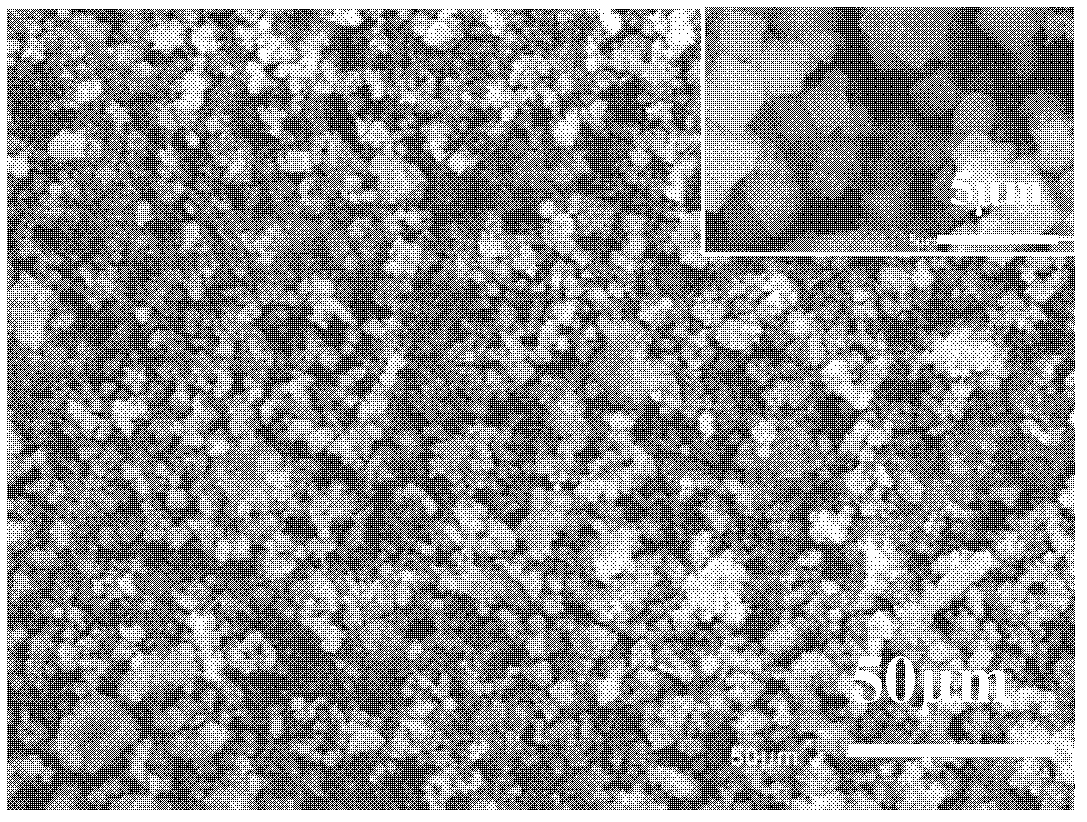

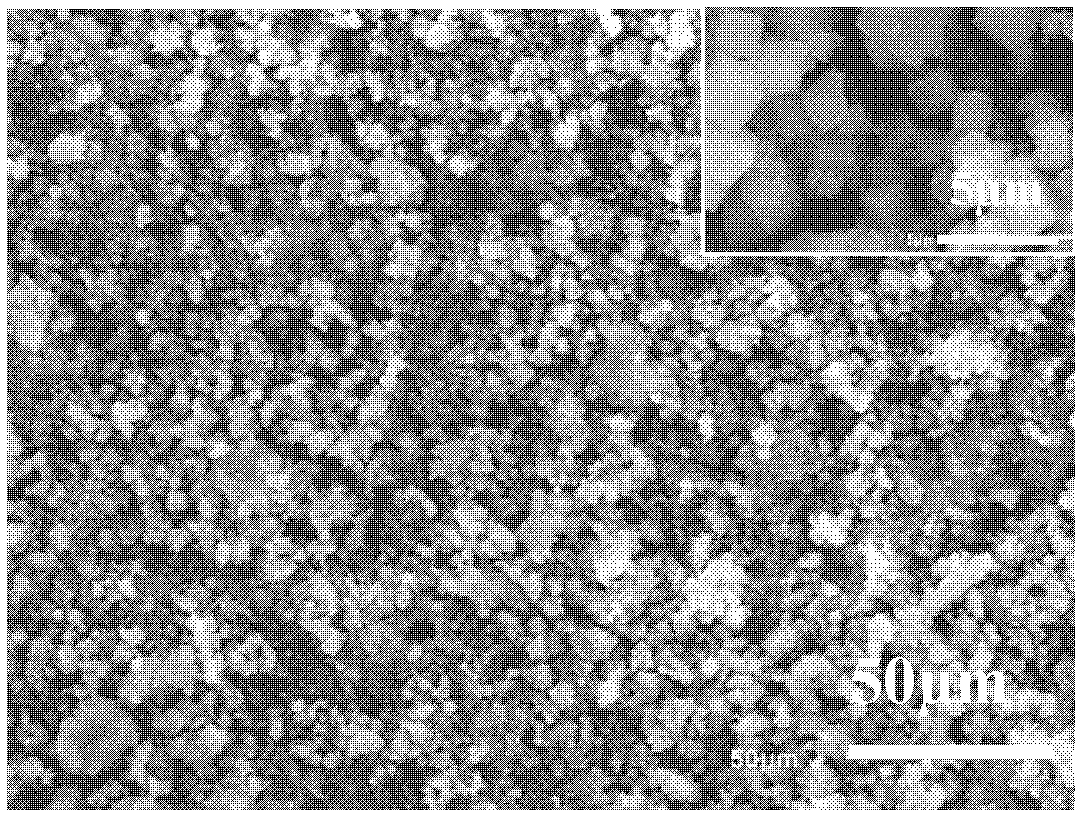

[0036] Add 20 g of 40% NaA molecular sieve aqueous solution into 20 g of 40% PVA aqueous solution, add 16 g of deionized water, and ultrasonically vibrate for 15 minutes to obtain a casting solution with a NaA:PVA:solvent ratio of 1:1:5 . α-Al 2 o 3 Coating film on the support layer, drying at 30°C for 12 hours, repeating the film coating 3 times to get NaA / PVA / α-Al 2 o 3 Composite film. The XRD p...

Embodiment 2

[0038] Take Na 2 SiO 3 9H 2 O is the silicon source, Al 2 SO 3 18H 2 O is the source of aluminum, NaOH is the source of alkali, in molar ratio n(Na 2 O):n(SiO 2 ):n(Al 2 o 3 ):n(H 2 O)=7:2:1:800 to prepare molecular sieve synthesis solution. Crystallize in a polytetrafluoroethylene-lined stainless steel reactor at 80°C for 24 hours, take it out for quenching, filter with suction, wash with deionized water until neutral, and dry to obtain nano-sized NaA molecular sieves.

[0039] 10g mass fraction of 40% NaA molecular sieve suspension (ethanol as solvent) was added into 30g mass fraction of 40% PVA aqueous solution, then 12g of absolute ethanol was added, and ultrasonic vibration was performed for 15min to obtain NaA: PVA: the solvent ratio was 1: 3:6 casting solution; wherein, the mass ratio of water:ethanol in the solvent is 1:1. The PTFE film was coated twice by the dip coating method, and dried at 25°C for 12 hours to obtain a NaA / PVA / PTFE composite film. Membra...

Embodiment 3

[0041] Take Na 2 SiO 3 9H 2 O is the silicon source, Al 2 SO 3 18H 2 O is the source of aluminum, NaOH is the source of alkali, in molar ratio n(Na 2 O):n(SiO 2 ):n(Al 2 o 3 ):n(H 2 O)=7:2:1:800 to prepare molecular sieve synthesis solution. Crystallize in a polytetrafluoroethylene-lined stainless steel reactor at 80°C for 24 hours, take it out for quenching, filter with suction, wash with deionized water until neutral, and dry to obtain nano-sized NaA molecular sieves.

[0042] 30g mass fraction of 40% NaA molecular sieve suspension (ethanol as solvent) was added into 15g mass fraction of 40% PVA aqueous solution, then 9g of absolute ethanol was added, and ultrasonic vibration was performed for 15min to obtain NaA:PVA:solvent ratio of 1: 0.5:3 casting solution; wherein, the mass ratio of water:ethanol in the solvent is 1:3. The PTFE film was coated three times by dip coating, and dried at 25°C for 12 hours to obtain a NaA / PVA / PTFE composite film. Membrane area is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com