Microchannel plate type fast neutron position gas detector and detection method thereof

A technology of gas detector and micro-channel plate, which is applied in nuclear technology application and non-destructive testing field, can solve the problem of long signal collection time and achieve the effect of low cost and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

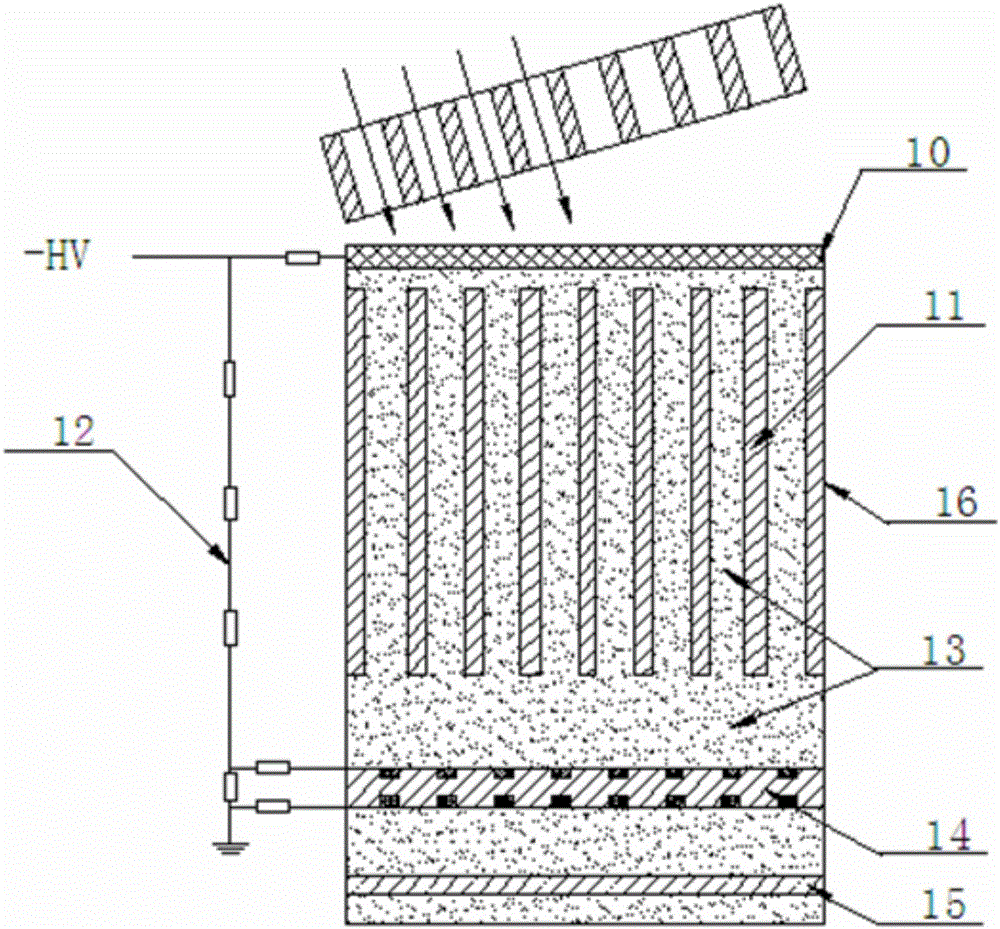

[0041] figure 1 It is a schematic principle diagram of a microchannel plate type fast neutron position gas detector according to a preferred embodiment of the present invention. Such as figure 1As shown, the microchannel plate type fast neutron position gas detector includes a gas chamber 16 , a drift cathode 10 , a microchannel structural plate 11 , a gas electron multiplier 14 , a high voltage divider circuit 12 , a readout PCB 15 , and a working gas 13 .

[0042] Specifically, the gas chamber 16 provides an airtight working environment for the detector, and acts as a shield to prevent it from being disturbed by external electric fields. At the same time, the positions of the drift cathode 10, the microchannel structural plate 11, the gas electron multiplier 14, and the readout PCB 15 are fixed and the precise positional relationship among them is ensured. The gas chamber 16 can be made of any material suitable for providing a sealed environment and shielding the external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com