Light bioreactor for culturing microalgae systematically

A photobioreactor and microalgae technology, applied in photobioreactor, bioreactor/fermenter for specific purposes, bioreactor/fermenter combination, etc. Insufficient gas exchange, wide area and other problems, to achieve the effect of reducing the greenhouse effect, saving human capital, and reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

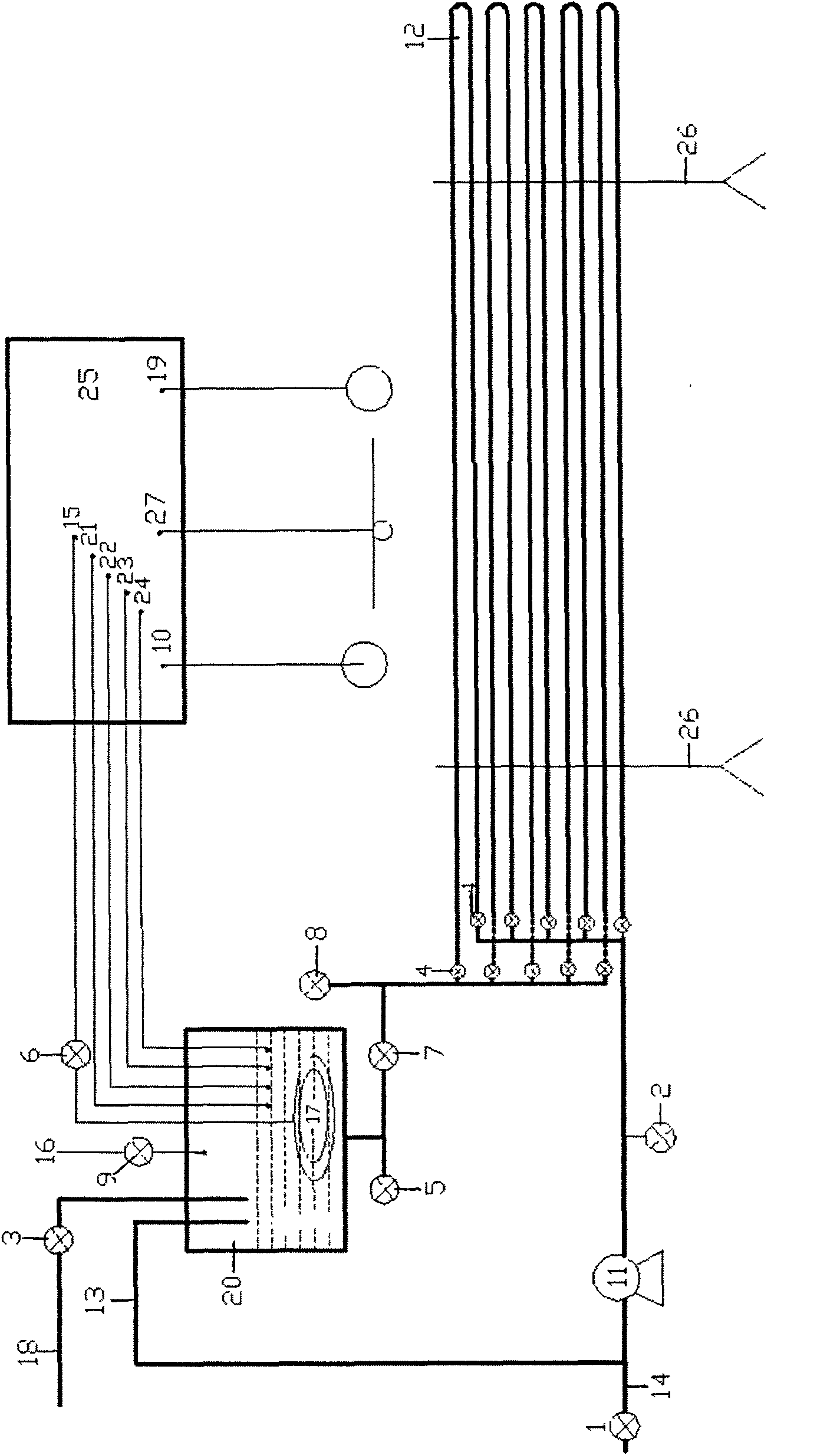

[0026] The photobioreactor for systematically cultivating microalgae of the present invention is composed of a pipeline group, a valve, a condition controller, a liquid storage tank and a console. Pipeline 17, culture medium pipe 18, exhaust pipe 16; One end of parallel parallel pipeline 12 links to each other with pipeline pump 11, and the other end links to each other with liquid storage tank 20, and pipeline pump 11 links to each other with liquid storage tank 20 feeding pipe 13; 11 connects discharge pipe 14 with liquid storage tank 20; Disc-shaped microporous pipe 17 is installed in liquid storage tank 20, and microporous pipe 17 links to each other with air inlet pipe 15 again, and the other end is connected with filtered air pipeline; Culture medium pipe 18 and Located at the inlet of the liquid storage tank 20. The valve includes an intake valve 6, a gas check valve 9, an emergency switch 4, a discharge valve 7, a sampling valve 5, a discharge valve 1, and a drain valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com