Patents

Literature

91results about "Optical/shielding coatings application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

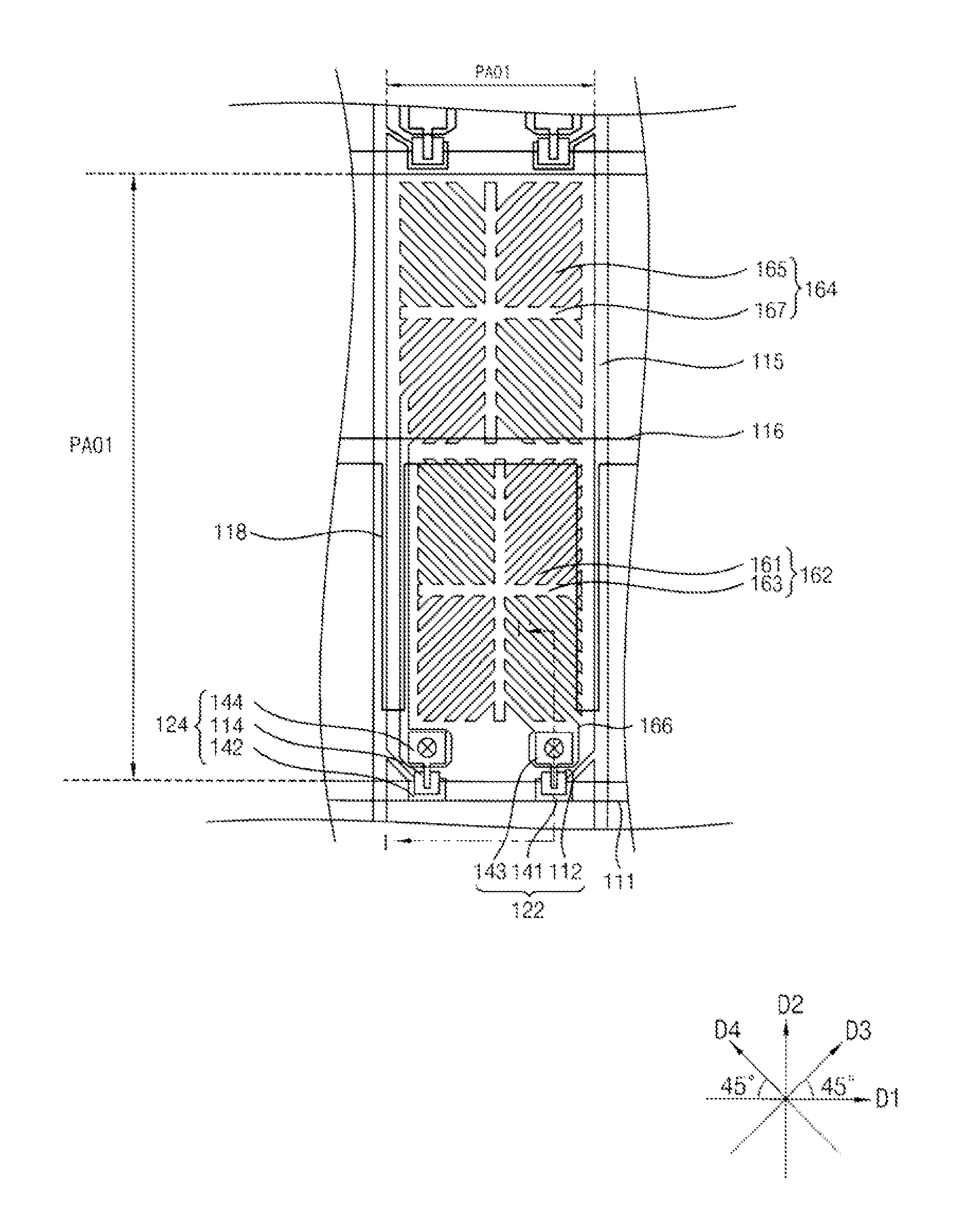

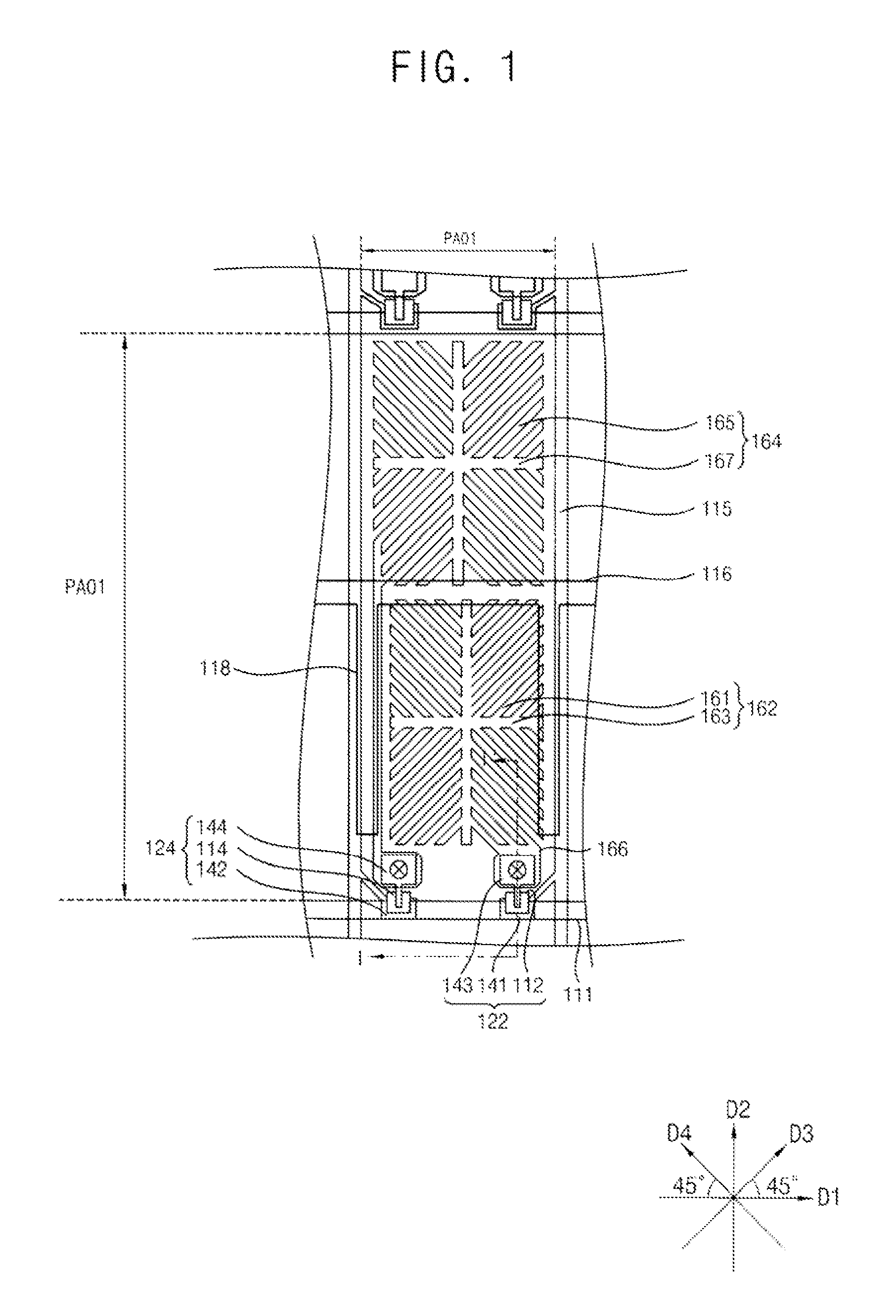

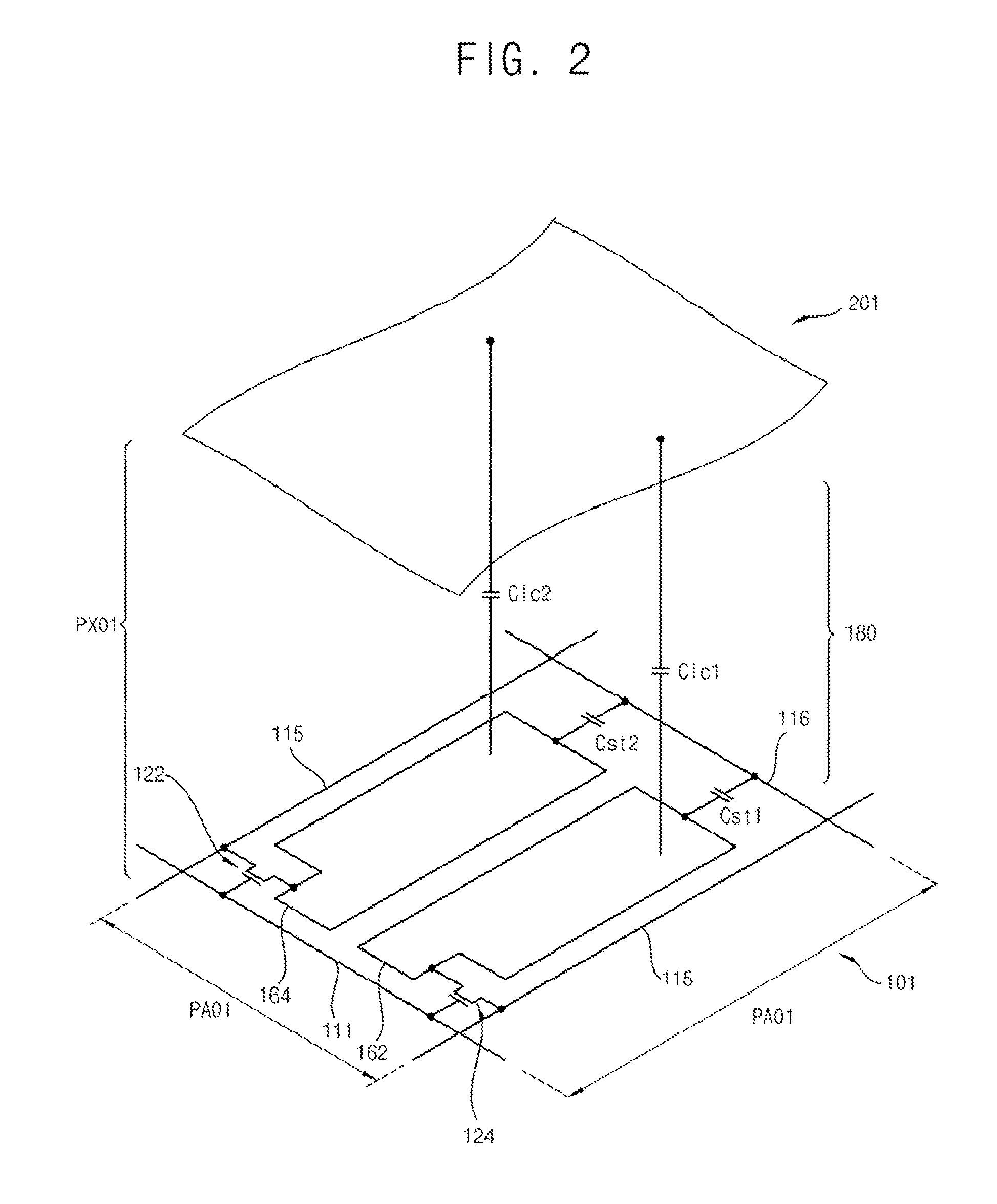

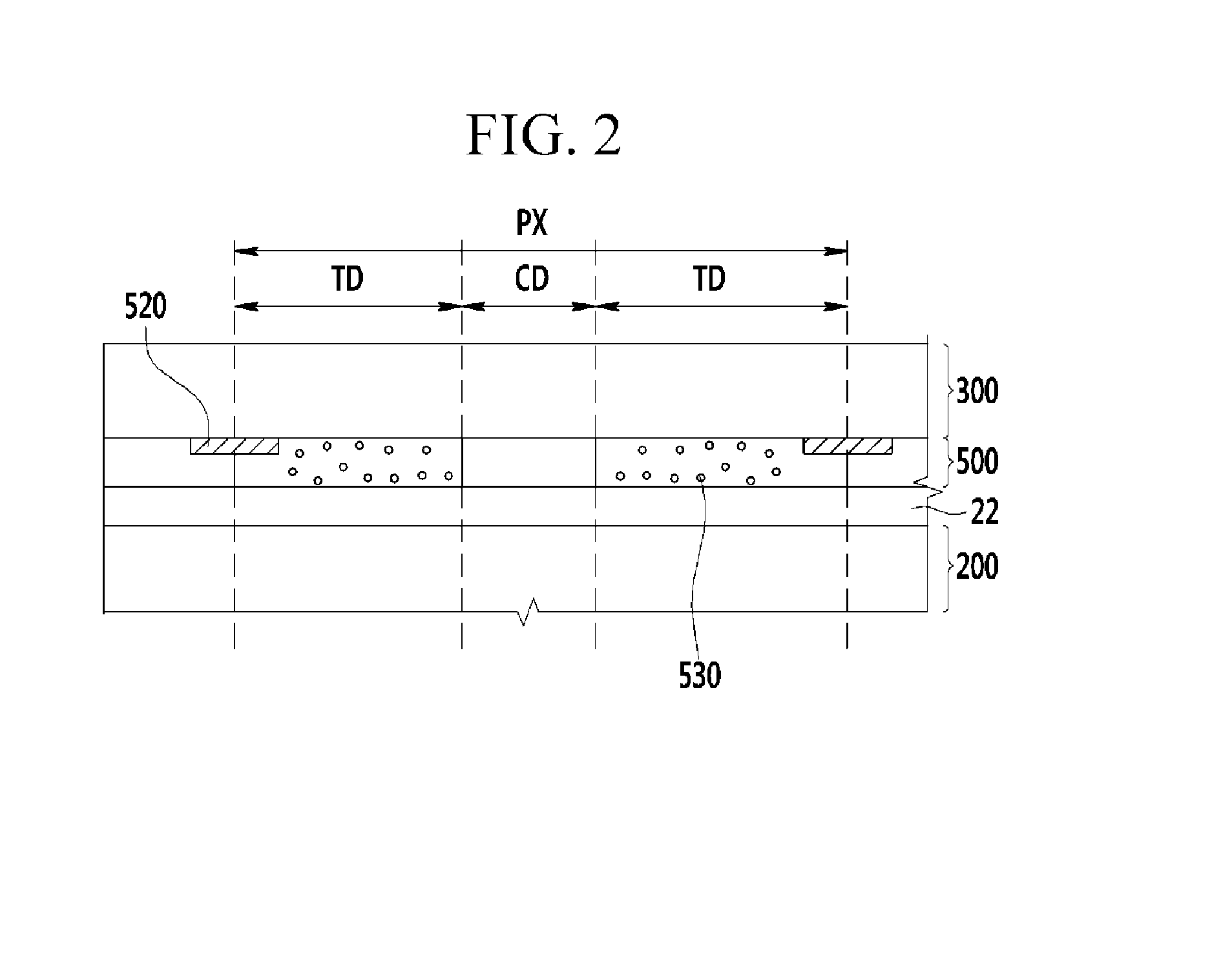

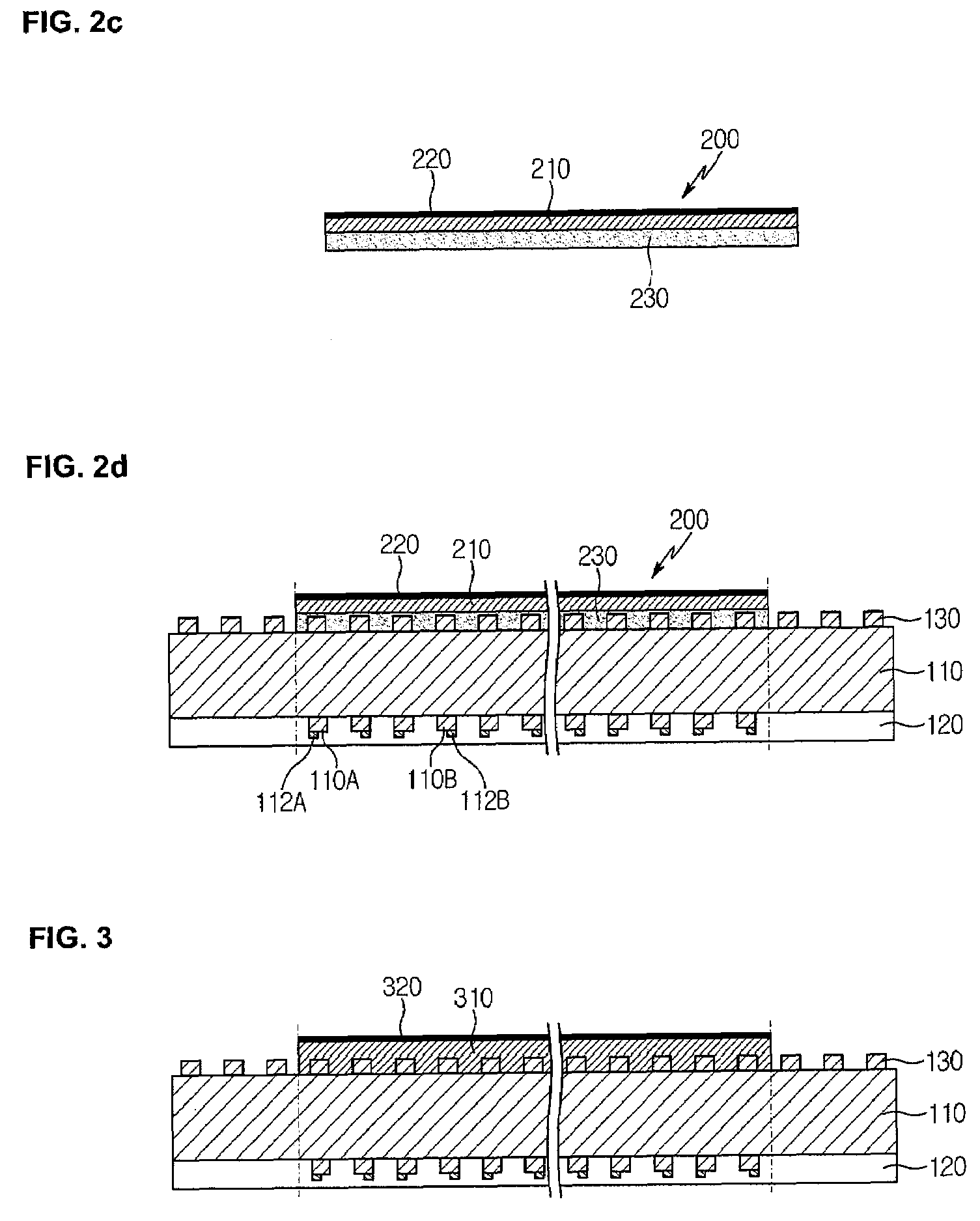

Liquid crystal display device, method of manufacturing the same and alignment layer composition for the liquid crystal display device

ActiveUS20100182556A1Increase the aperture ratioShort response timeLiquid crystal compositionsPhotoelectric/charge-storage screens manufactureUltravioletAfterimage

A liquid crystal display device that includes an array substrate, an opposite substrate and a liquid crystal display layer is described. The array substrate includes a pixel electrode and a lower alignment layer. The pixel electrode has a plurality of slit portions extending in different directions. The lower alignment layer includes a reactive mesogen (RM) diamine is formed on the pixel electrode to induce an alignment direction of the liquid crystal molecules. An upper alignment layer is formed on a common electrode of the opposite substrate. The RM is cured at surfaces of the lower and upper alignment layers in response to ultraviolet (UV) light, so that liquid crystal molecules have a pretilt angle. Therefore, the aperture ratio and the response time may be improved, and afterimages may be decreased, so that display quality may be improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

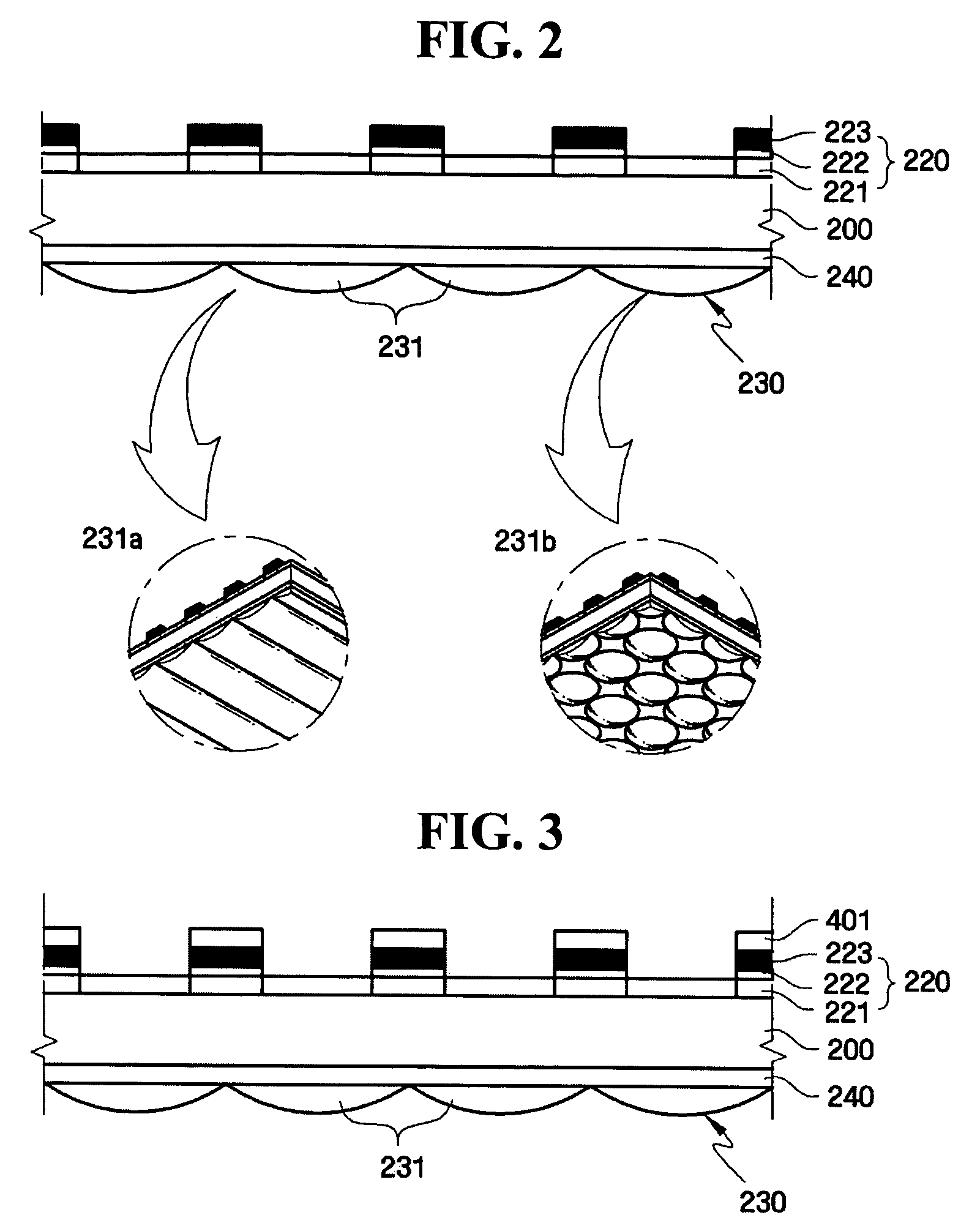

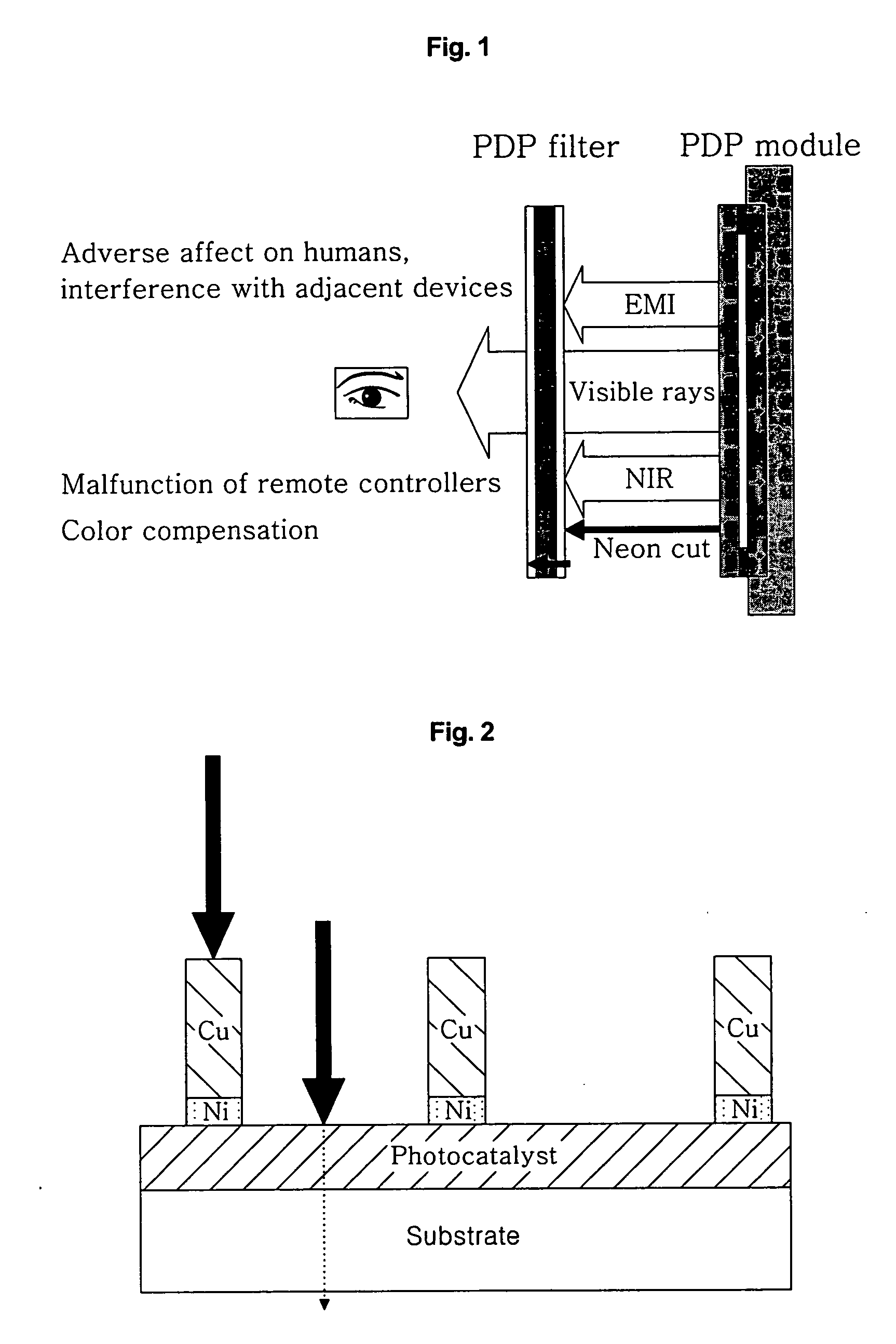

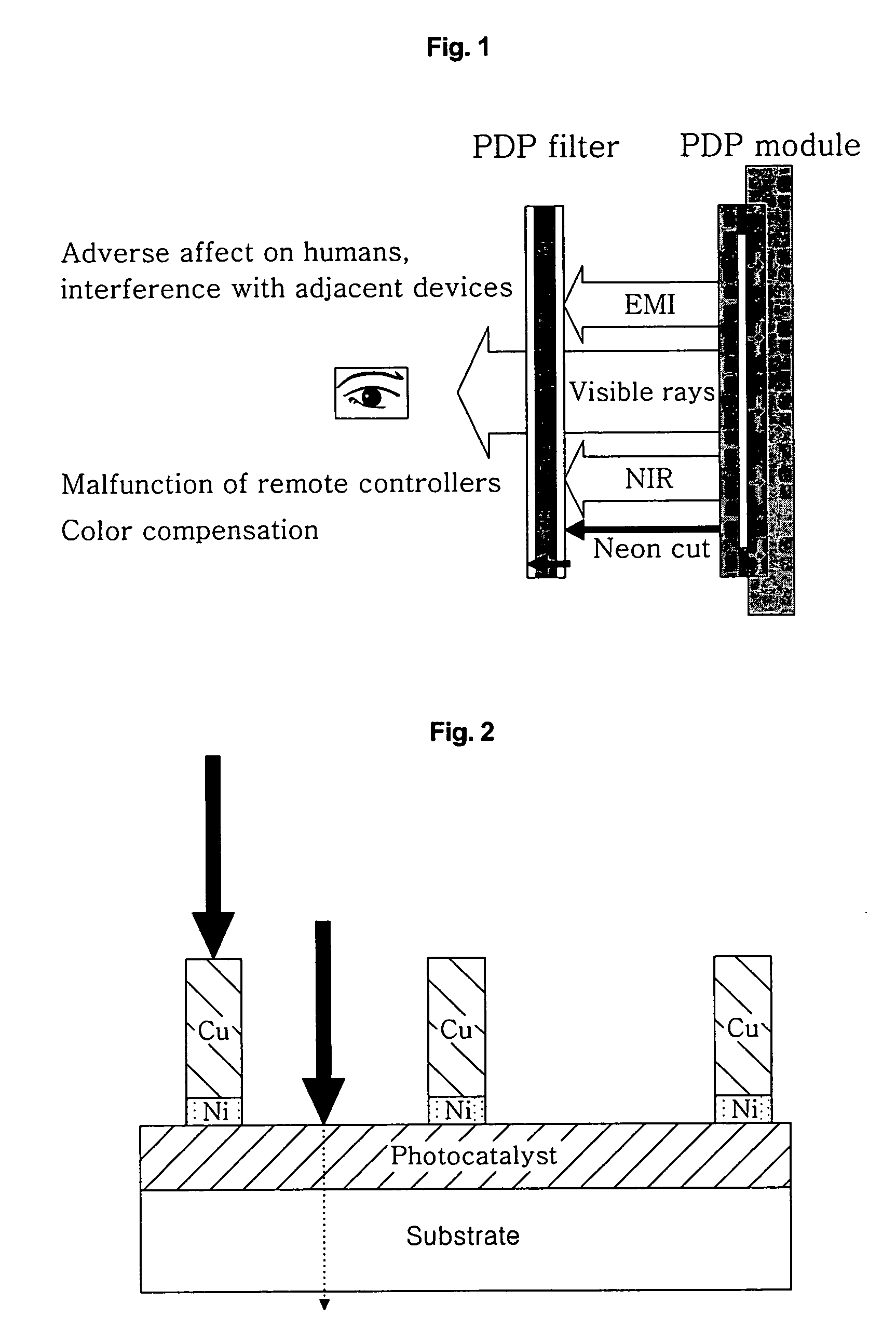

Display filter, display device including the display filter, and method of manufacturing the display filter

InactiveUS20050253493A1Increase contrastImprove shielding effectDiffusion transfer processesCathode-ray/electron-beam tube vessels/containersDisplay deviceElectromagnetic shielding

A display filter for use with a plurality of microlenses in a display system includes an external light and electromagnetic (EM)-shielding portion having a photosensitive transparent resin layer with a photocatalyst, and an external light and EM-shielding pattern formed on regions of the photosensitive transparent resin layer to prevent external light from entering the display system and to prevent EM waves generated in the display device from exiting the display device, the regions corresponding to boundaries between the plurality of microlenses.

Owner:SAMSUNG ELECTRONICS CO LTD +1

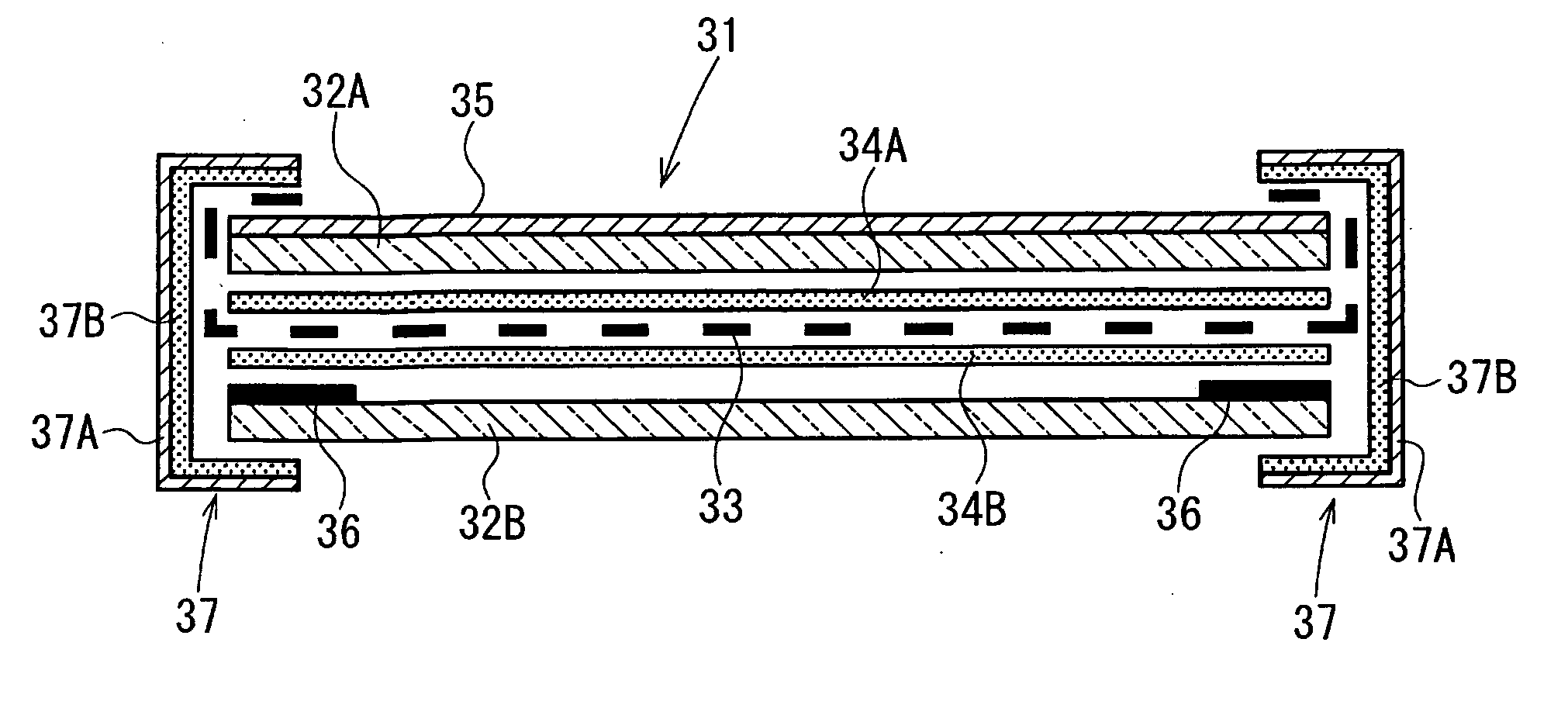

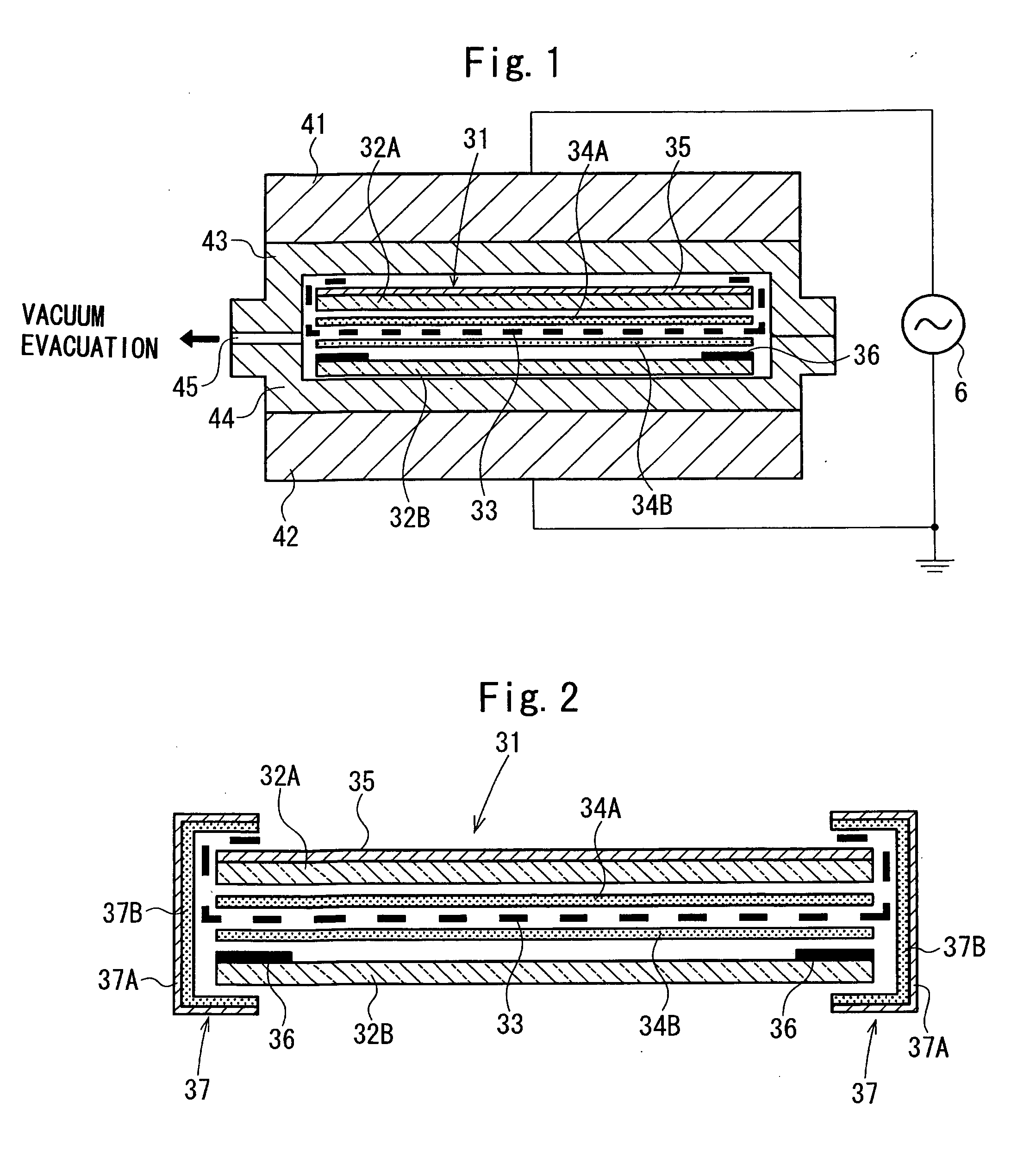

Manufacturing methods of electromagnetic-wave shielding and light transmitting window material, display panel, and solar battery module

InactiveUS20070011863A1Improve production efficiencyAddressing slow performanceGas-filled discharge tubesWave amplification devicesHigh frequency powerEngineering

In order to decrease the time (adhesion time in an adhesion step) for manufacturing an electromagnetic-wave shielding and light transmitting window material and a display panel, a top mold 43 and a bottom mold 44, which are made of a synthetic resin having high heat resistance, are disposed between a top and a bottom pressing plate 41 and 42, and a laminate is disposed between the molds 43 and 44. This laminate is formed of a transparent substrate 32A provided with an anti-reflection film 35, an adhesive interlayer film 34A used as an adhesive resin, an electrical conductive mesh 33, an adhesive interlayer film 34B, and a transparent substrate 32B provided with a black frame paint 36. While air in a molding space between the molds 43 and 44 is vacuum-evacuated via an exhaust port 45, a high-frequency voltage is simultaneously applied to the pressing plates 41 and 42 from a high-frequency power source 46, and in addition, the above laminate is pressed by the pressing plats 41 and 42 for a predetermined time. Accordingly, the interlayer films 34A and 34B is heated by induction heating and is cured, and as a result, the laminate is integrated.

Owner:BRIDGESTONE CORP

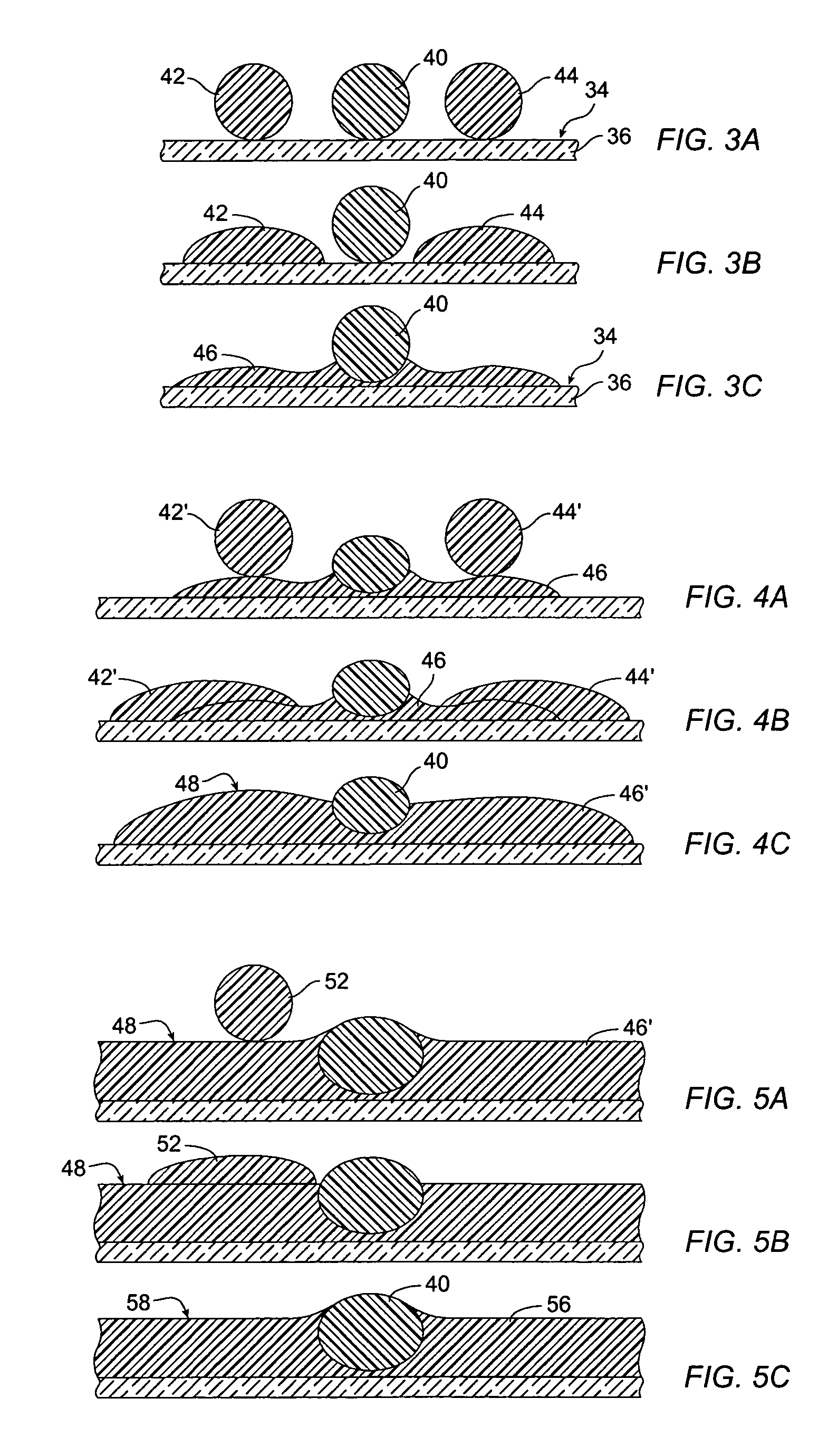

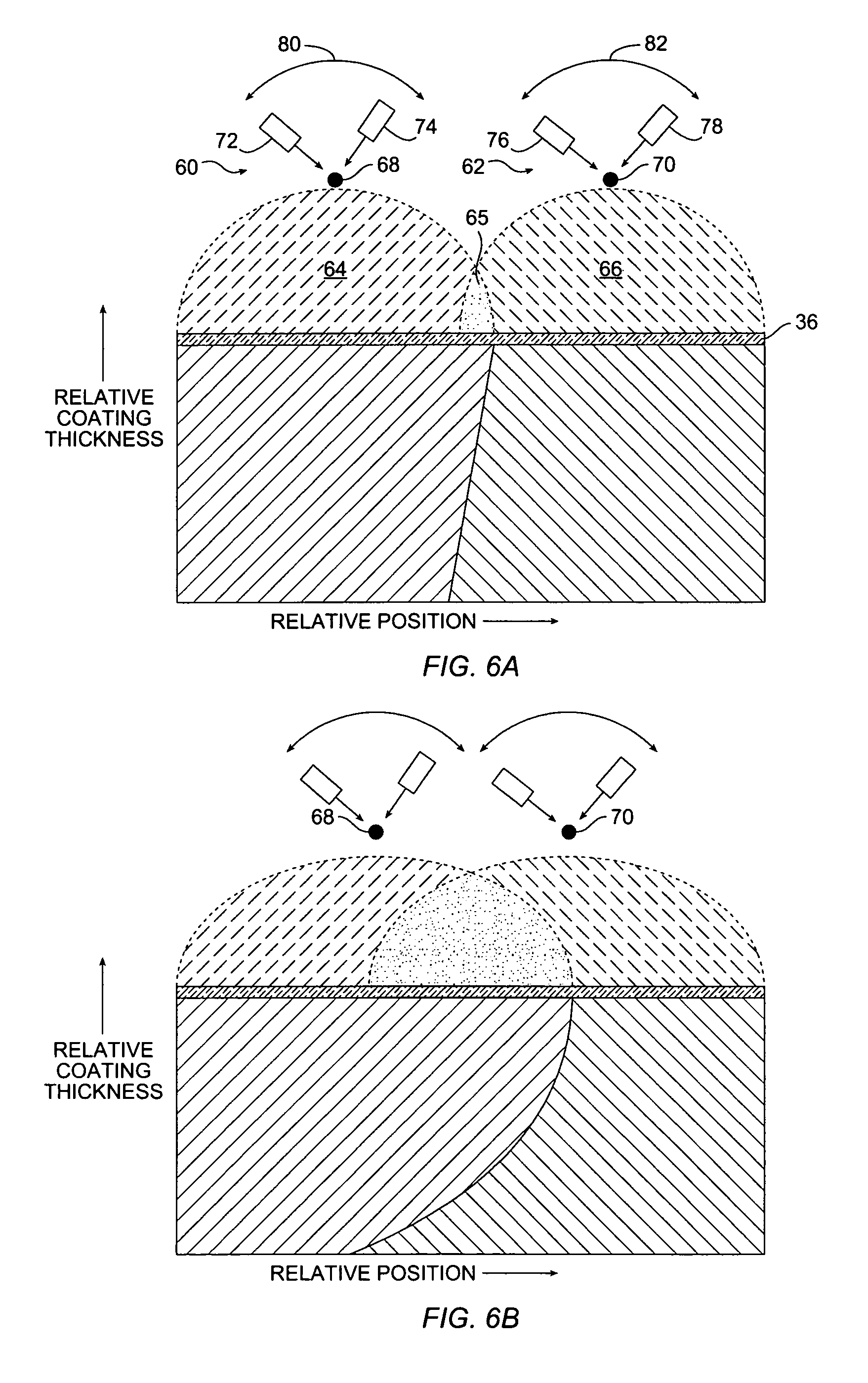

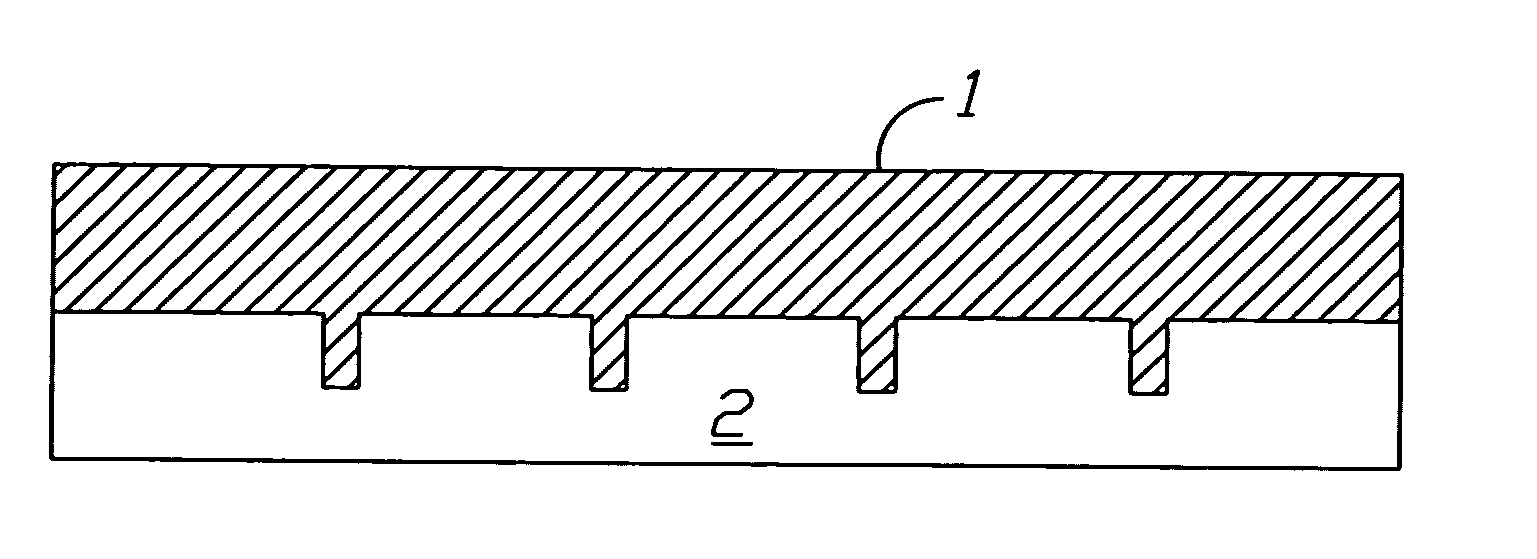

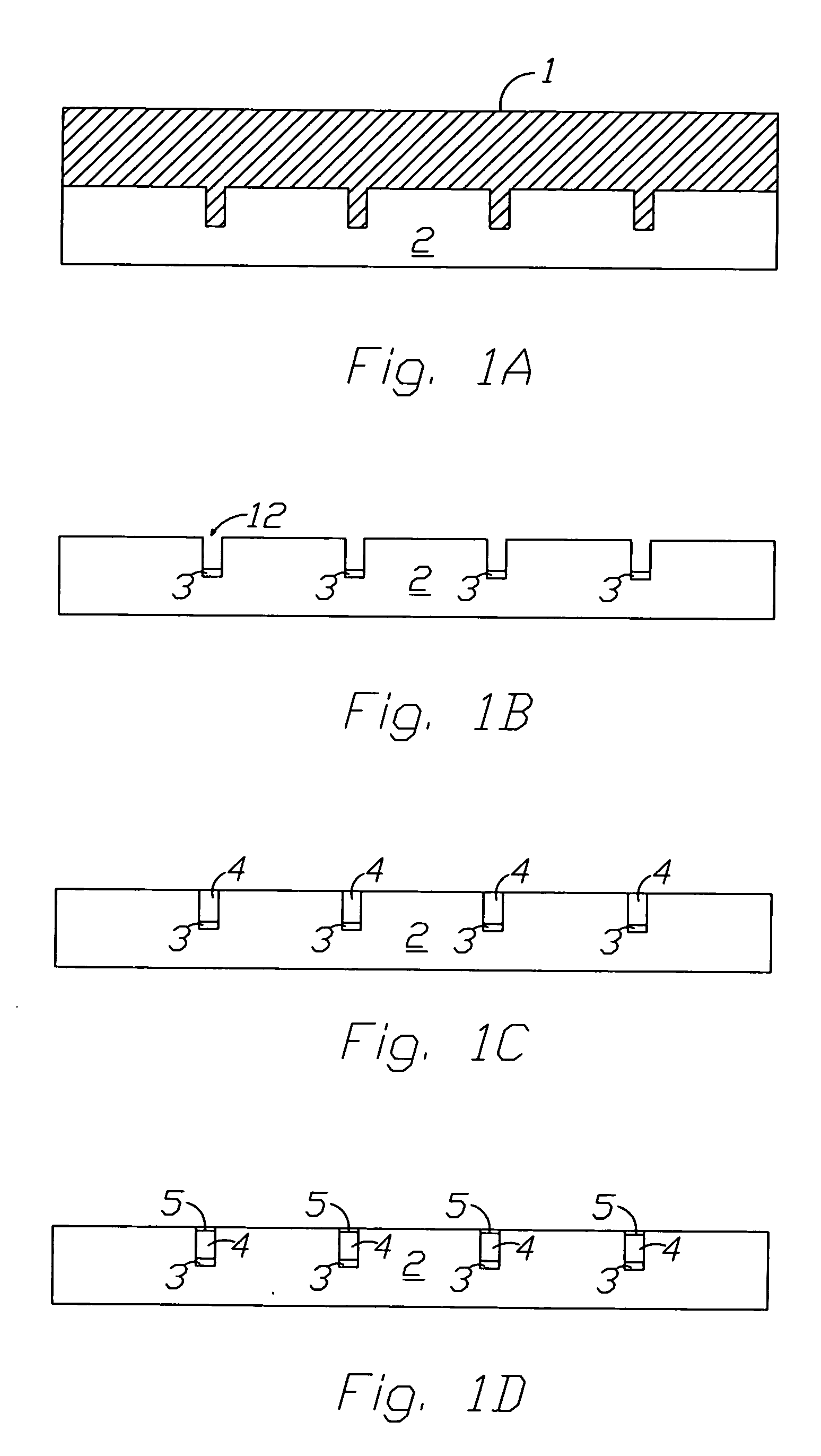

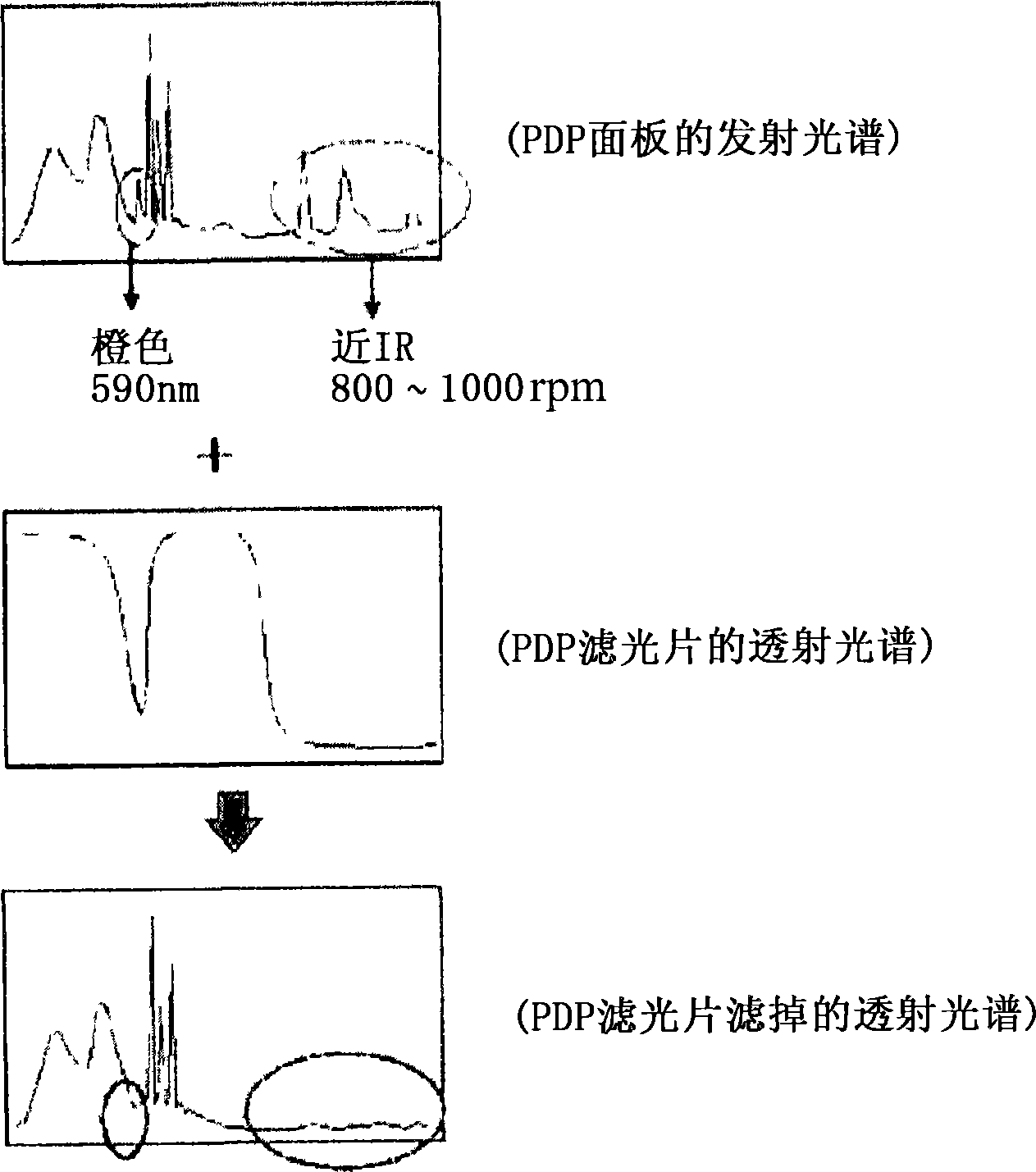

Method of applying a uniform polymer coating

ActiveUS20050100667A1Improve color balanceIncrease contrastPrismsElectric discharge tubesUltrasonic nebulizersPolymer coatings

A method of applying a polymer coating uses a nebulized aerosol of solubilized polymer solution having high-viscosity droplets and low-viscosity droplets to form a textured antireflective surface. Air or other gas is used to direct the nebulized aerosol toward the surface of an object. In some embodiments, heated or dried air, such as from an air curtain, is used to promote the formation of high-viscosity droplets. In a particular embodiment, multiple ultrasonic nebulizers are used in combination with synchronized air jets to apply a uniform polymer coating onto a glass panel used in a large-format display system. Dye is optionally added to the solubilized polymer solution to provide a notch filter at 585 nm and / or infrared filter.

Owner:VIAVI SOLUTIONS INC

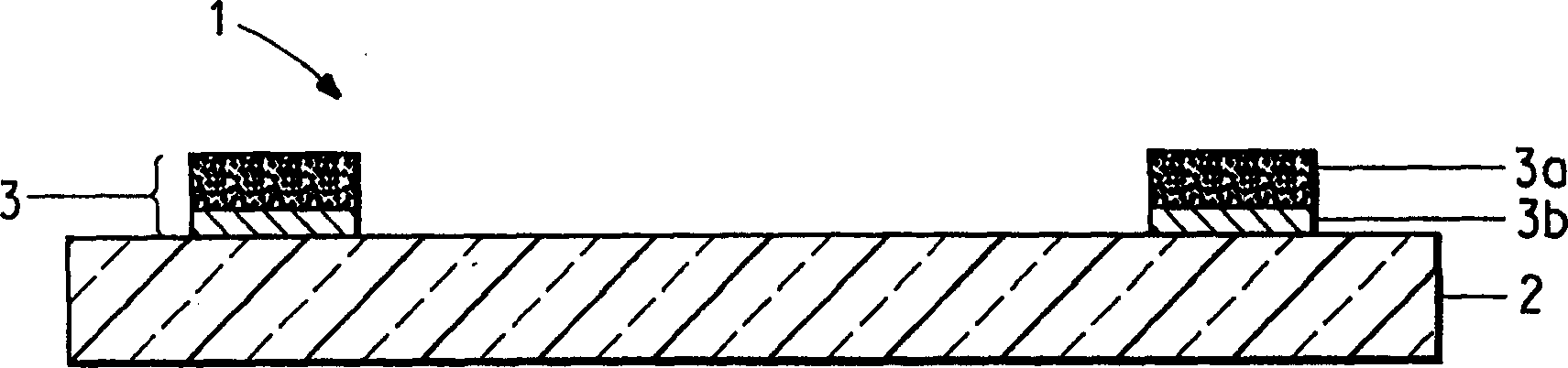

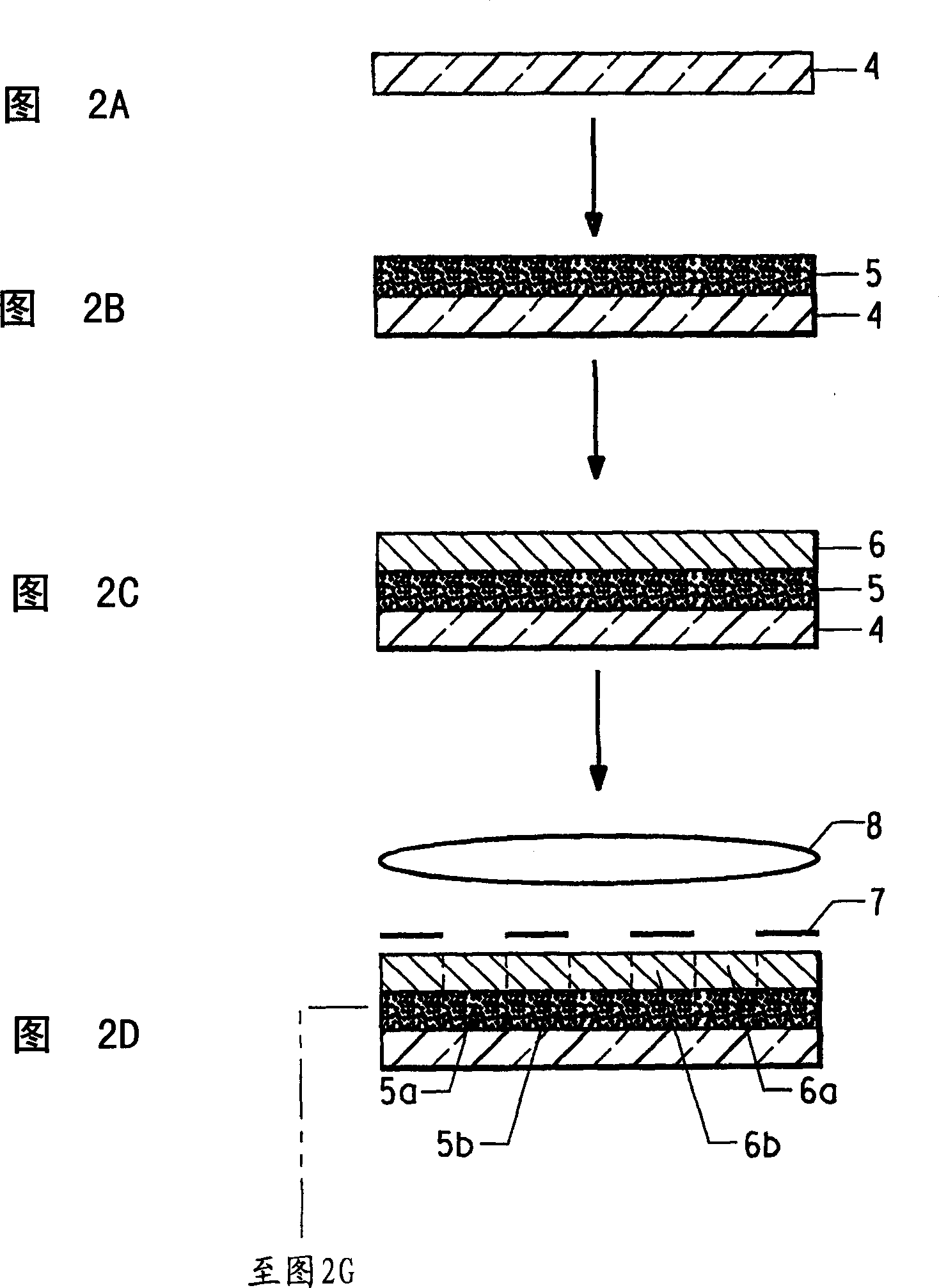

Structure of an electromagnetic shield layer for a plasma display panel and method for manufacturing the same

InactiveUS20070128412A1Avoid influenceGood light transmissionElectric discharge tubesMagnetic/electric field screeningDisplay boardPlastic materials

A structure of an electromagnetic shield layer for a plasma display panel and a method for manufacturing the same. The manufacturing method of the electromagnetic shield layer uses integrated technologies of hot embossing, coating, and electroplating. The structure according to the present invention is a metal layer with an electromagnetic-wave shielding effect and is built in a plastic material. The aspect ratios of the geometric patterns on the metal layer are above 75%.

Owner:NAT CHUNG SHAN INST SCI & TECH

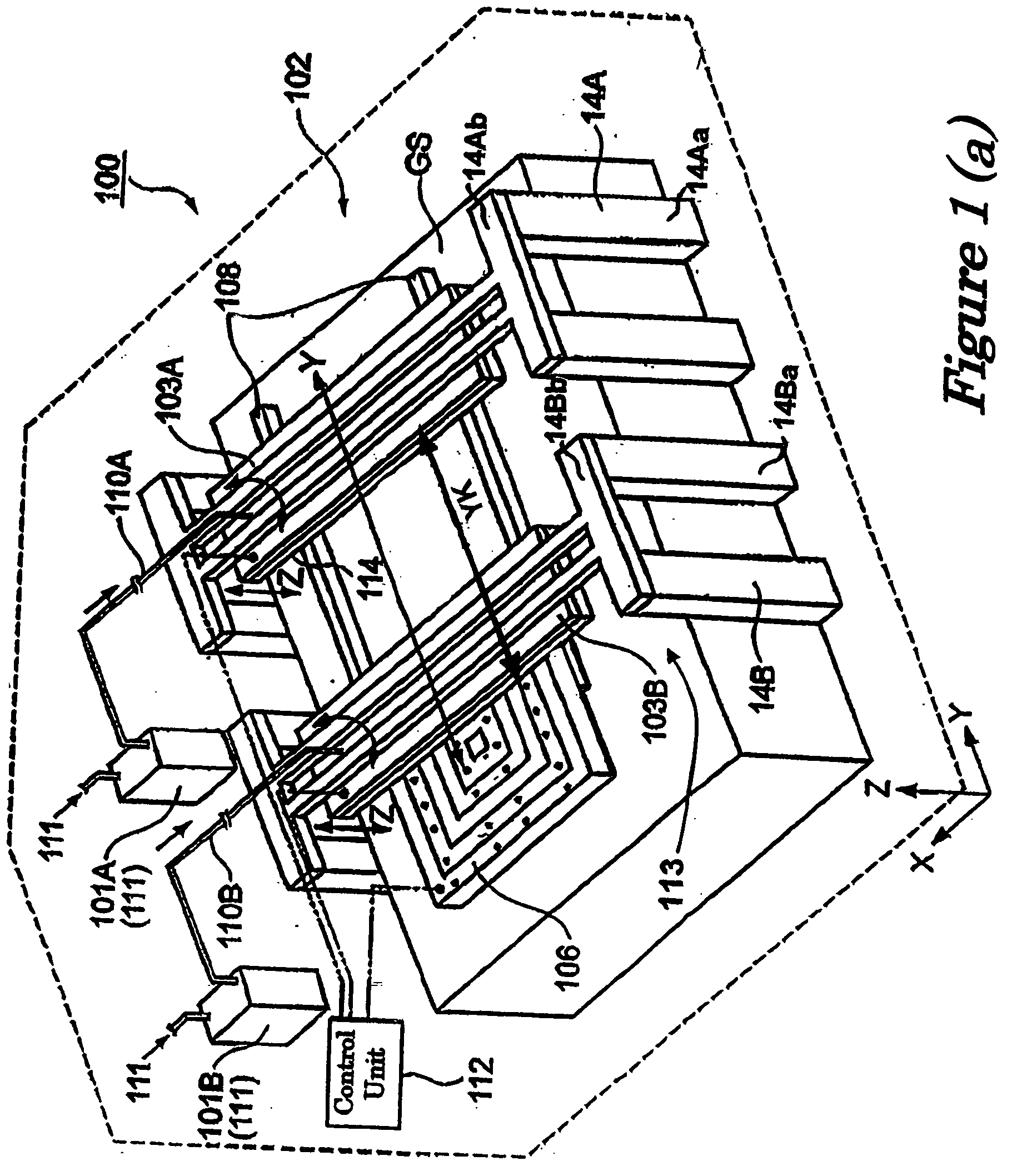

Drawing method, drawing apparatus and display apparatus

InactiveUS20050093902A1Obtain goodEfficiently provideInking apparatusElectric discharge tubesSpray nozzleEngineering

Owner:KATEEVA

Process for Preparing Front Filter for Plasma Display Panel

InactiveUS20080230173A1High transparencyMagnetic/electric field screeningOptical filtersMetal meshAutoclave

A plasma display panel (PDP) filter having a high transparency and no exterior defect can be simply prepared by a method comprising the steps of a) laminating a conductive mesh film having a metallic mesh layer formed on a base film, on a transparent glass substrate such that the base film of the conductive mesh film comes in contact with the transparent glass substrate, to obtain laminate A; b) forming a transparent adhesive layer on one surface of an optic film, to obtain laminate B; c) laminating laminate A and laminate B such that the adhesive layer of laminate B comes in contact with the metallic mesh layer of laminate A, to obtain laminate C; and d) heating and pressing laminate C in an autoclave to allow the adhesive layer of laminate B attach to the metallic mesh layer of laminate A.

Owner:SKC HAAS DISPLAY FILMS CO LTD

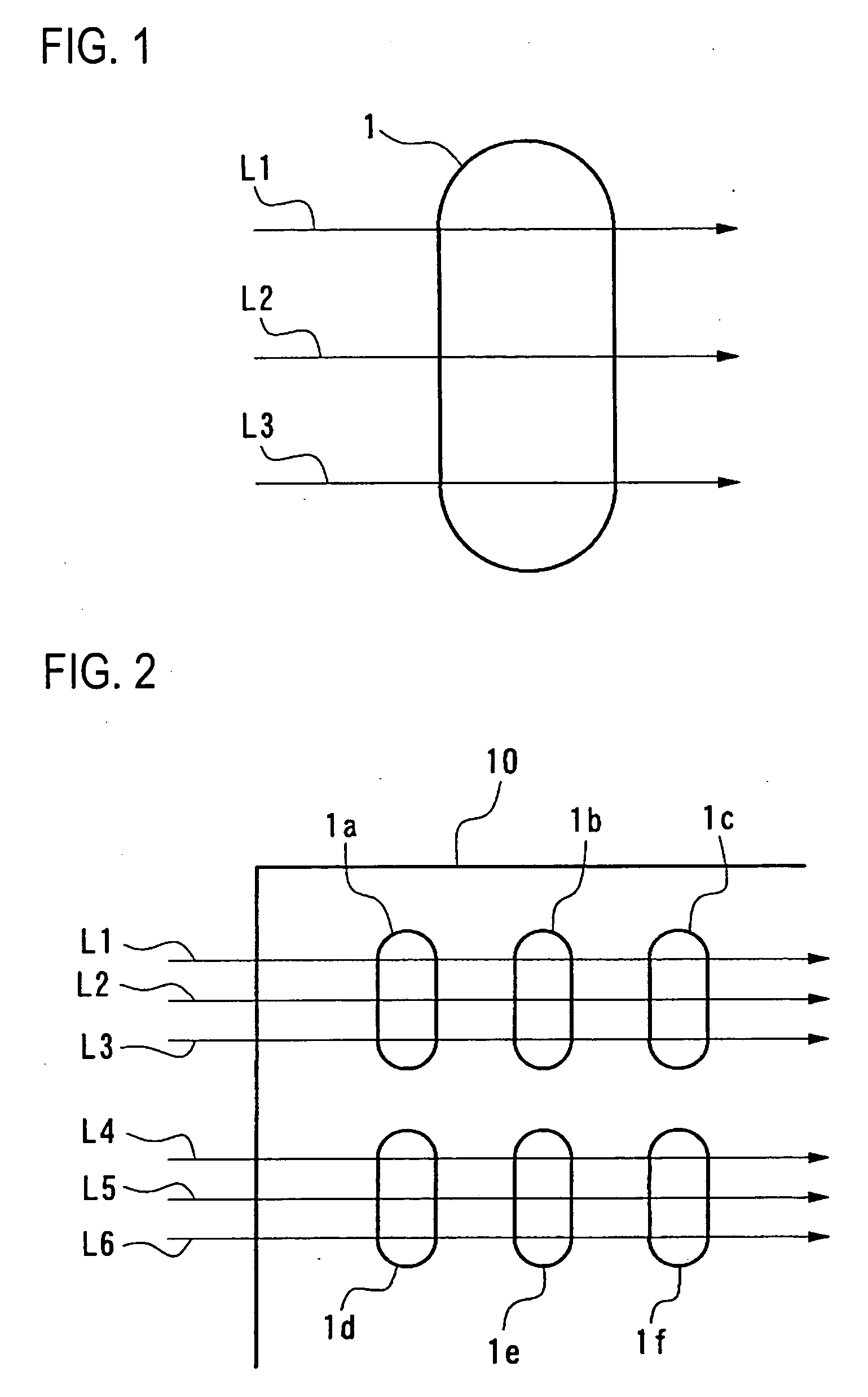

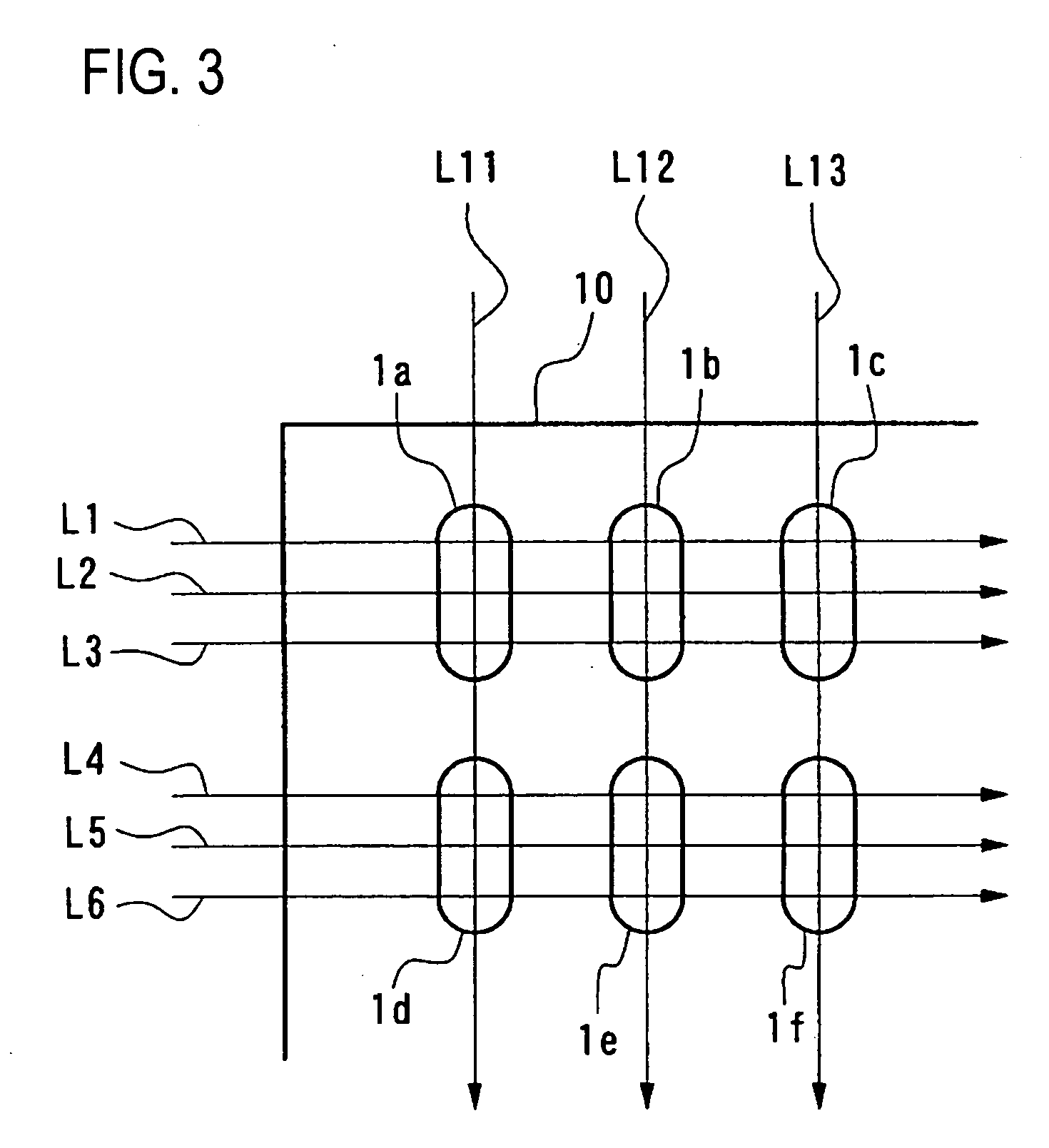

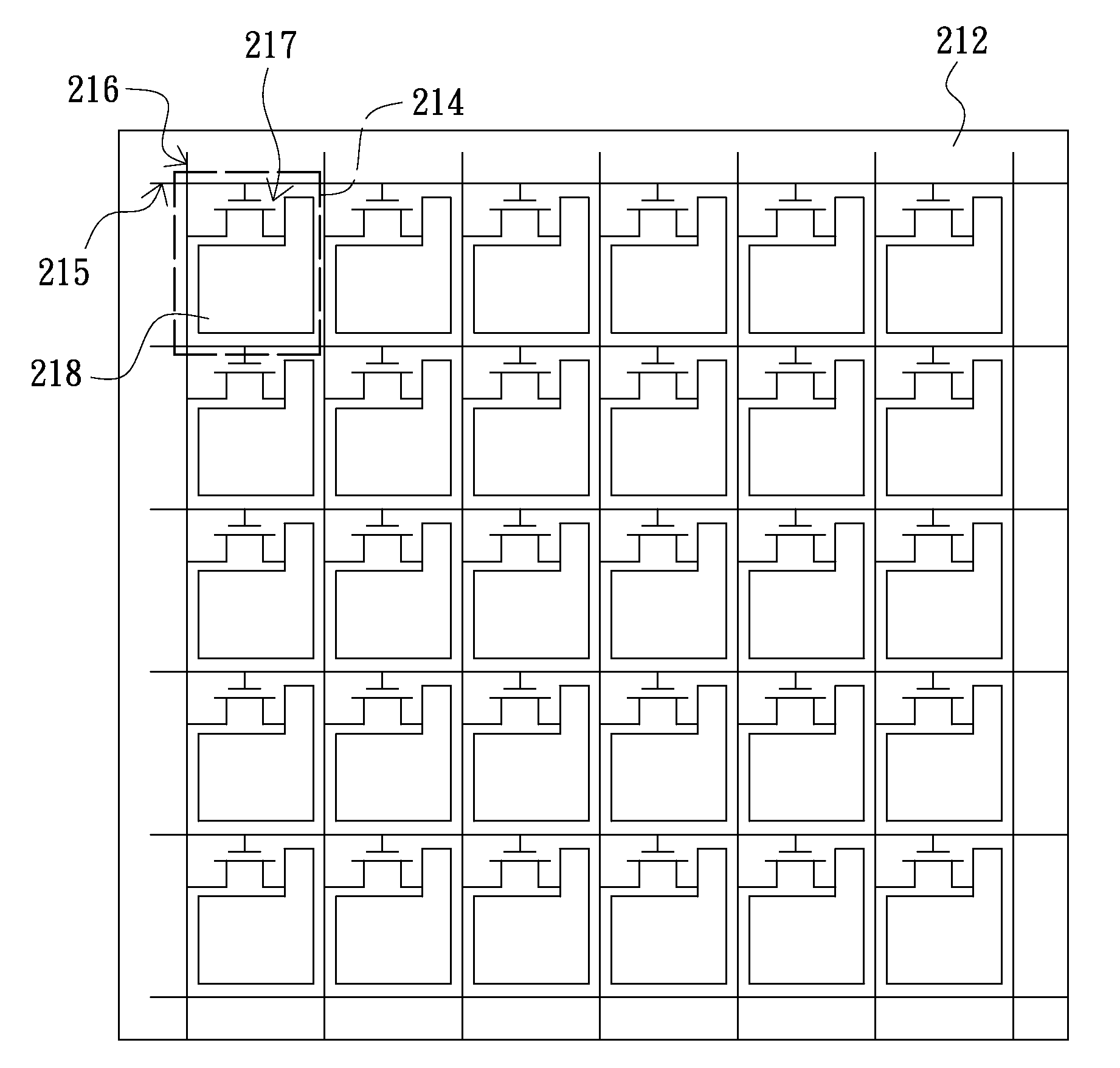

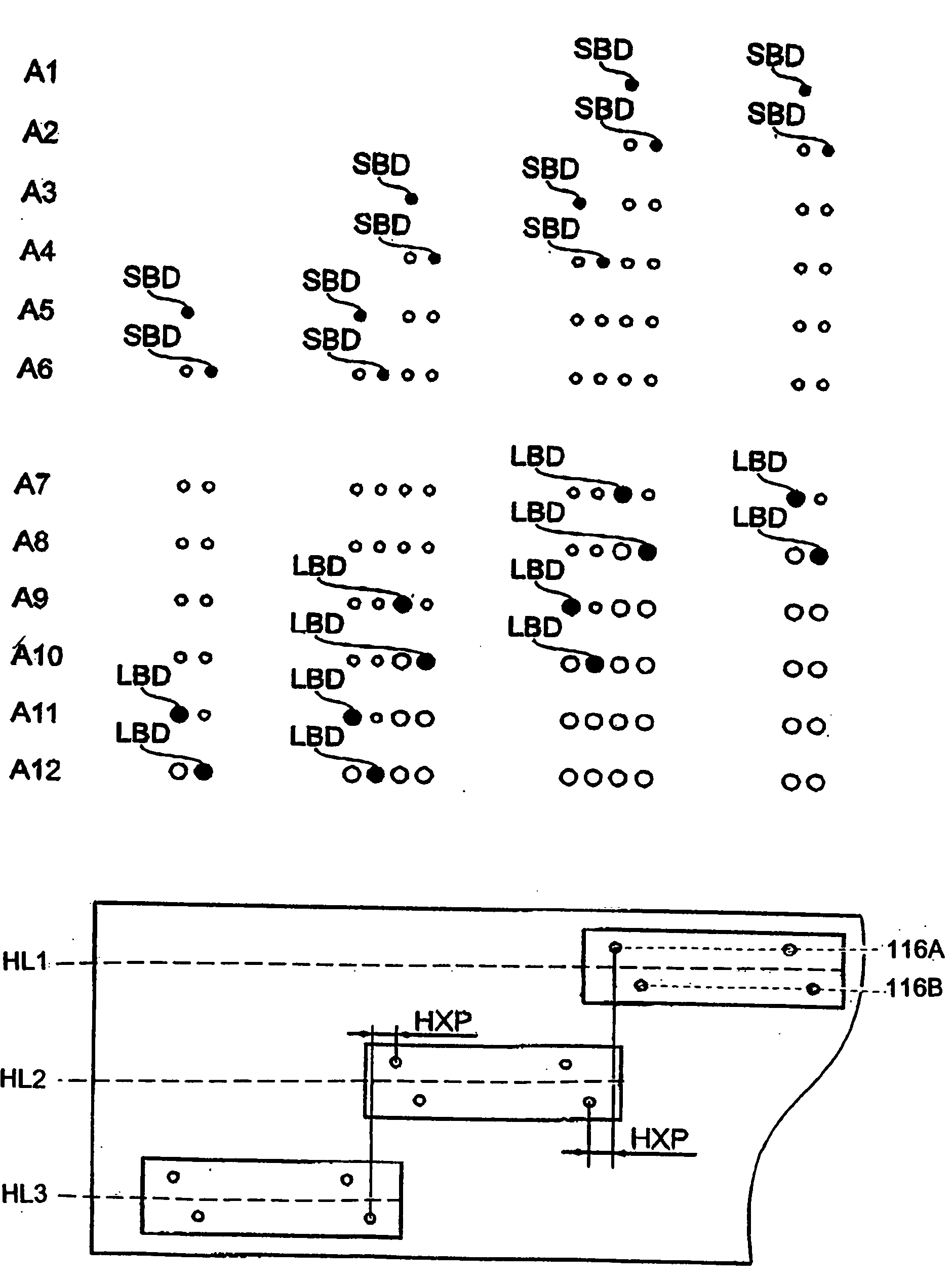

Methods of manufacturing wiring pattern, organic electro luminescent element, color filter, plasma display panel, and liquid crystal display panel, and electronic apparatus

InactiveUS20050008769A1Keep for a long timeMass production efficiency is lowAddress electrodesSustain/scan electrodesDisplay boardLiquid-crystal display

Methods of manufacturing a thin film pattern, an organic electro-luminescent element, a color filter, a plasma display panel, and a liquid crystal display panel, and an electronic apparatus in which the generation of streak unevenness in a thin film pattern can be reduced or prevented or the streak unevenness can be dispersed are provided when the thin film pattern constituting a pixel is formed using a droplet ejecting method. A liquid applying treatment where a liquid material is applied to a pixel area having a major axis and a minor axis by a droplet ejecting method, and an ejecting treatment along minor axis direction where, in the liquid applying treatment, a nozzle head of a droplet ejecting apparatus is scanned along a minor axis direction of the pixel area (a direction of scanning lines L1, L2, and L3), and a droplet is ejected to the pixel area from an inkjet nozzle included in the nozzle head in the scanning process.

Owner:SEIKO EPSON CORP

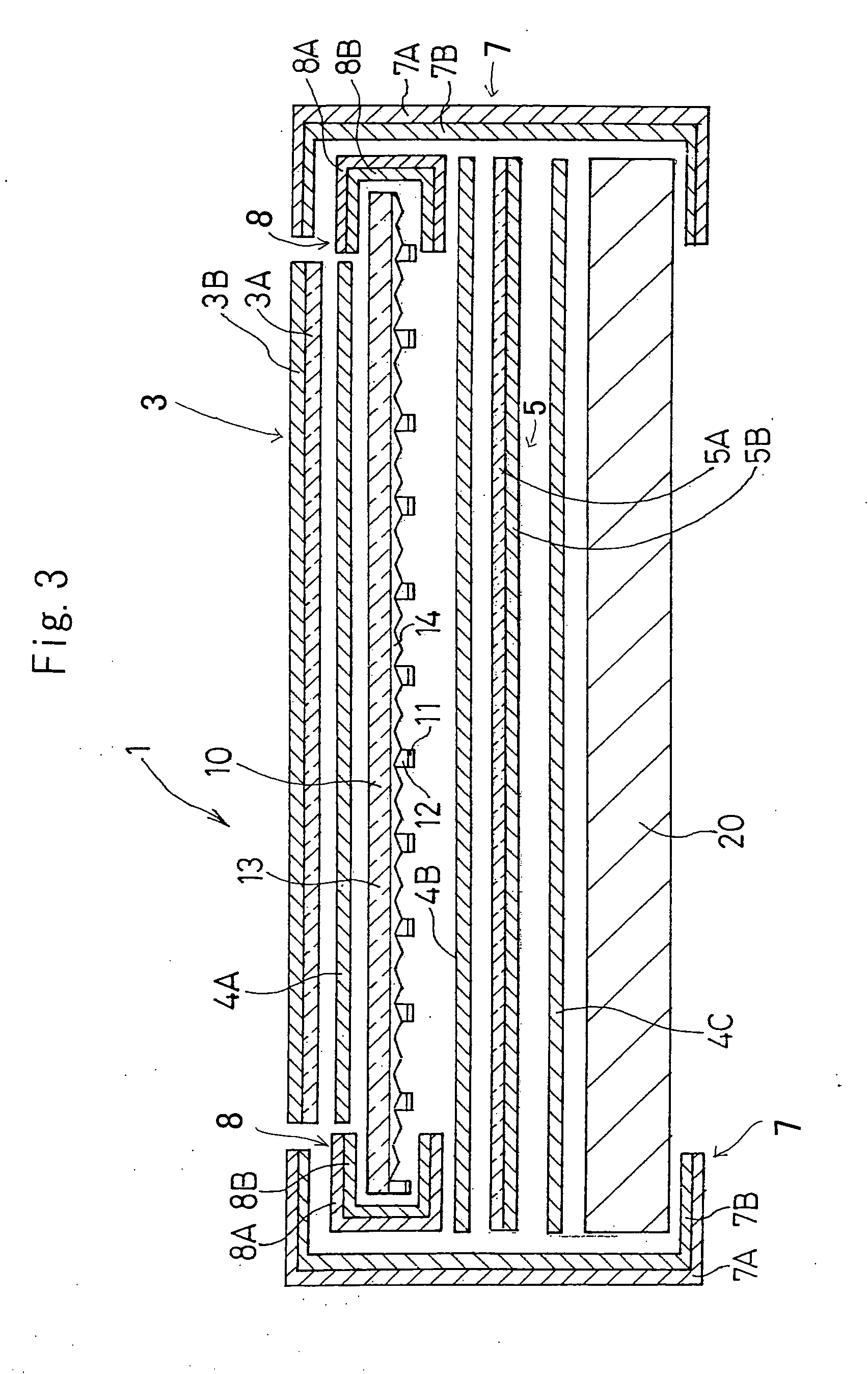

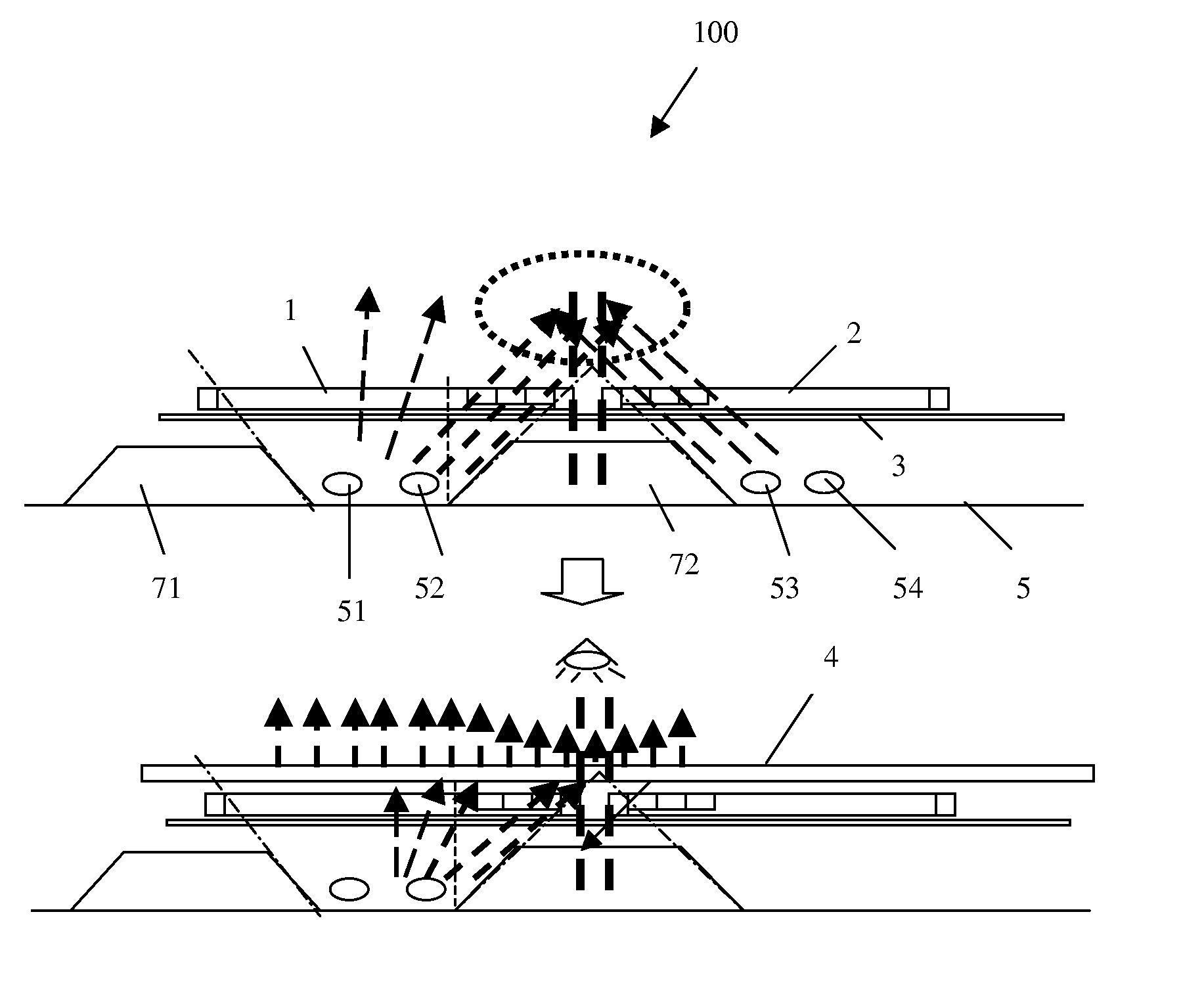

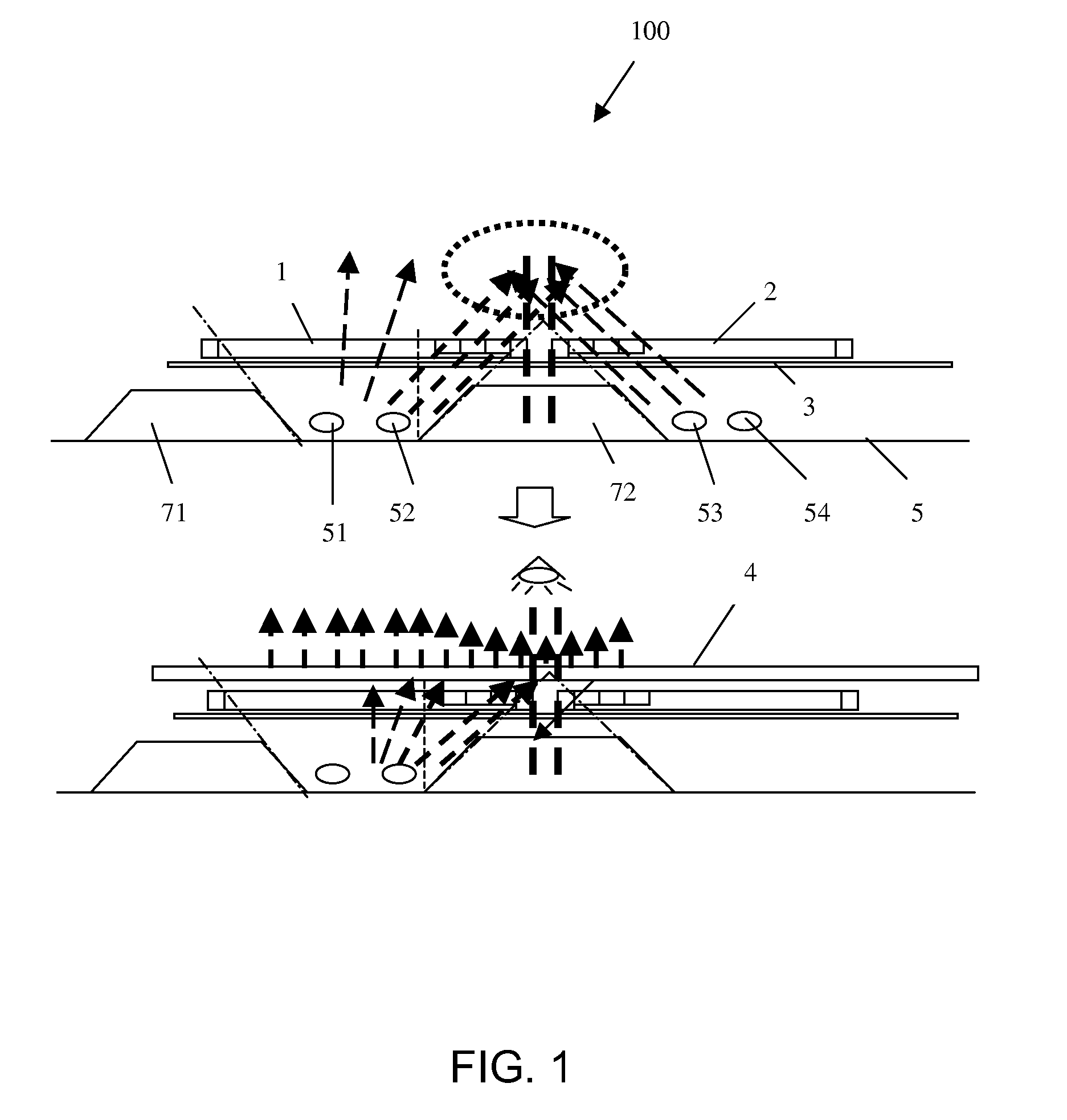

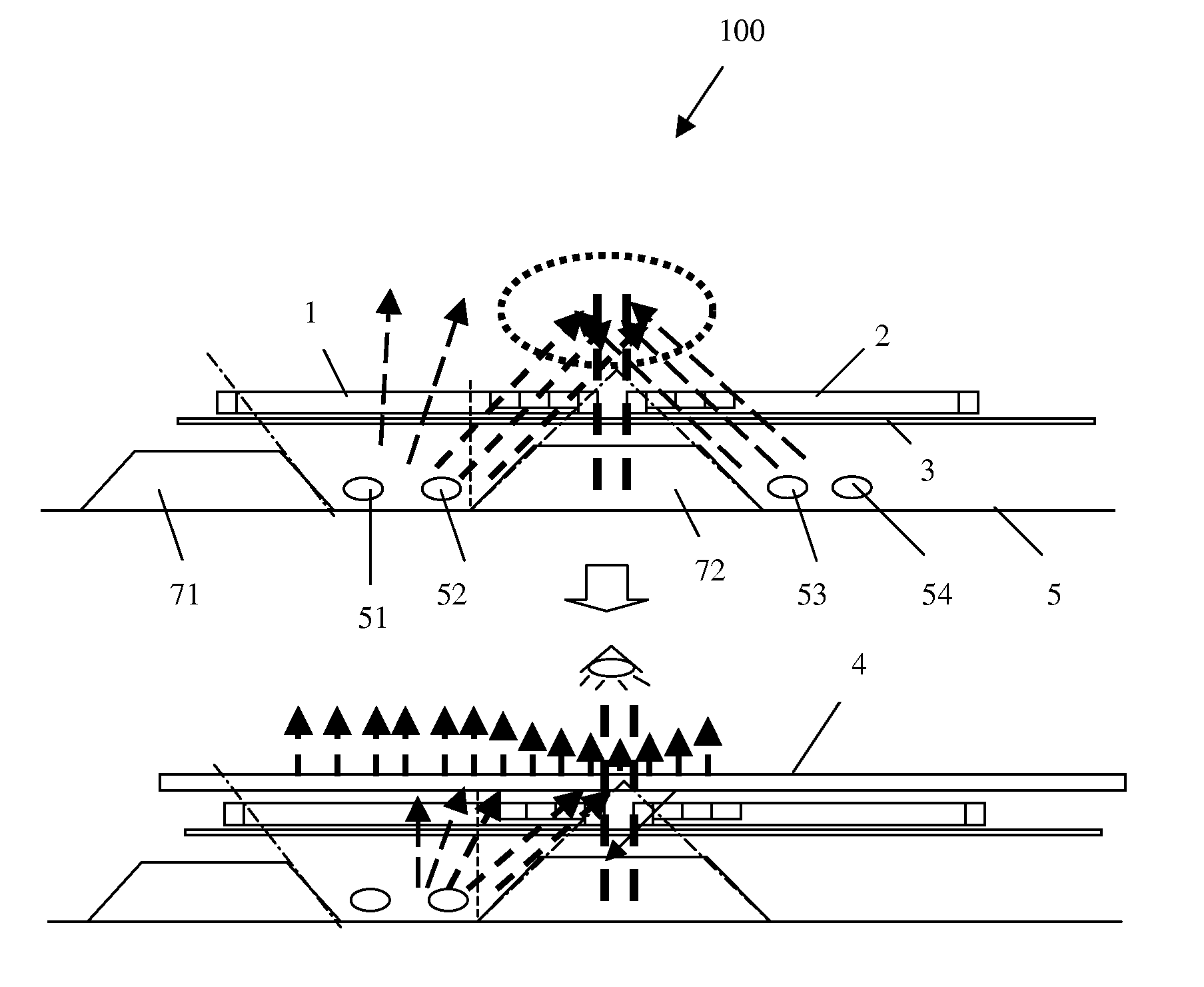

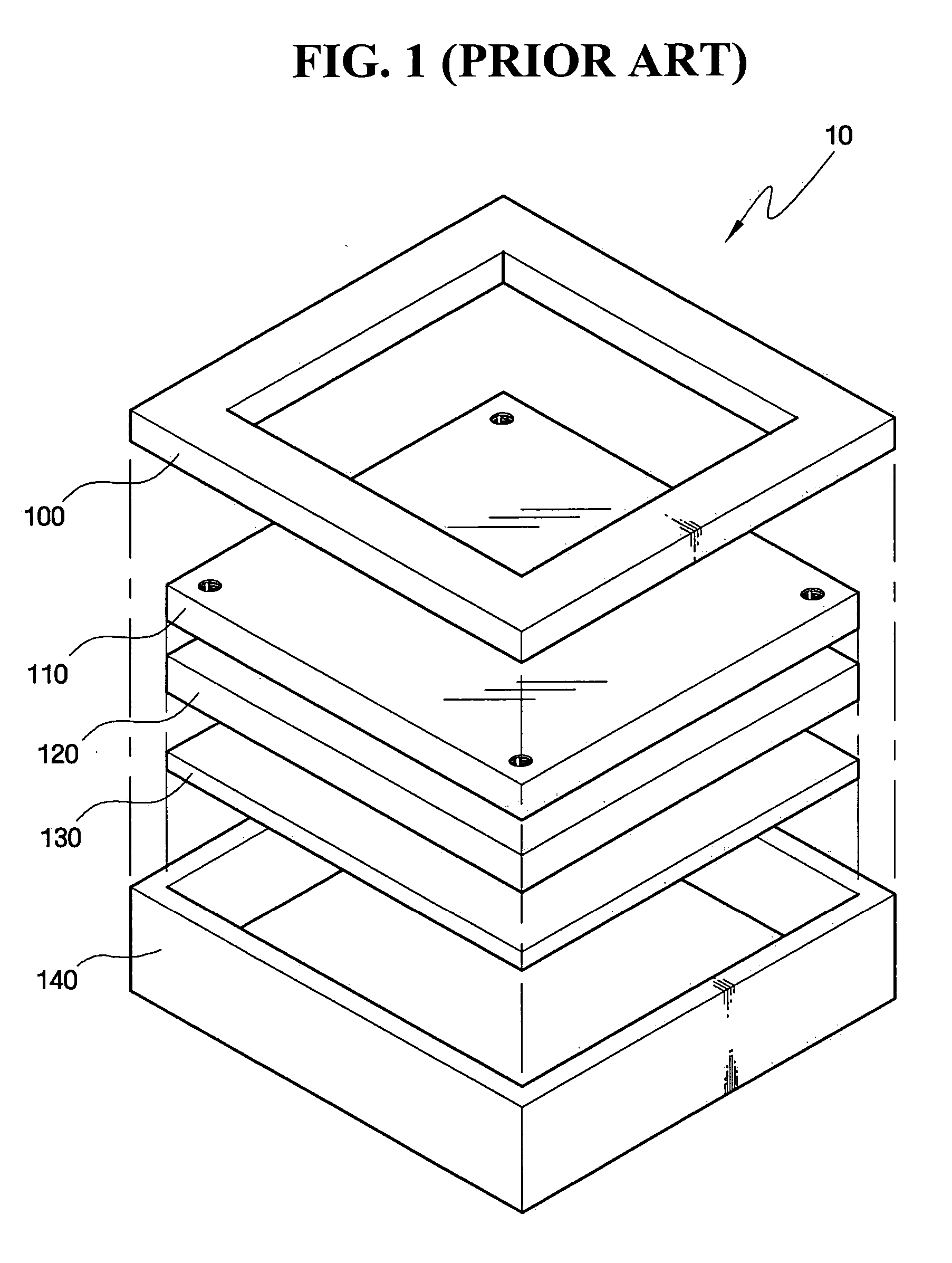

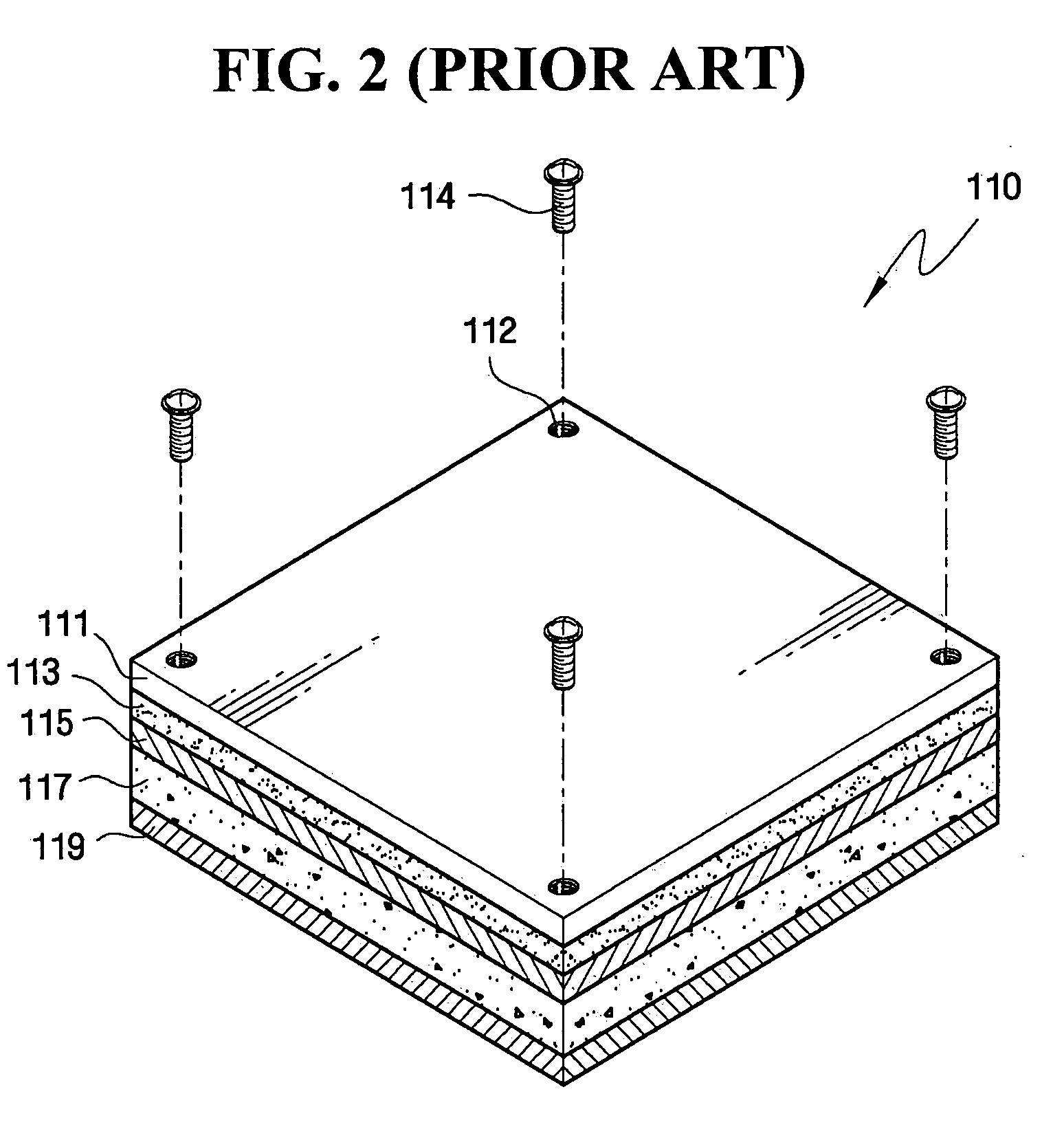

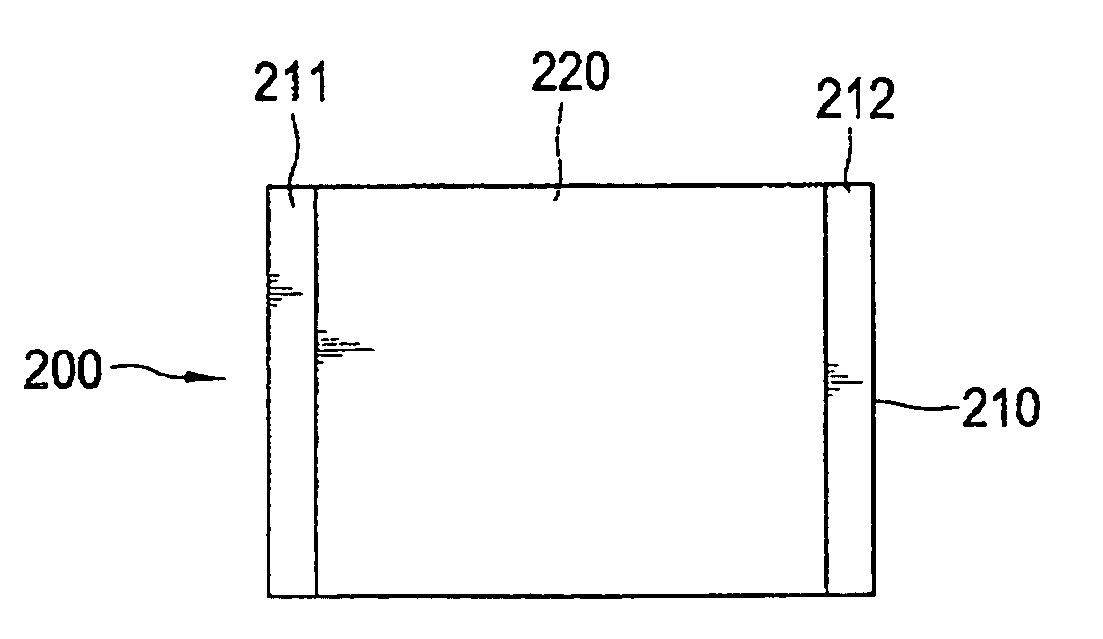

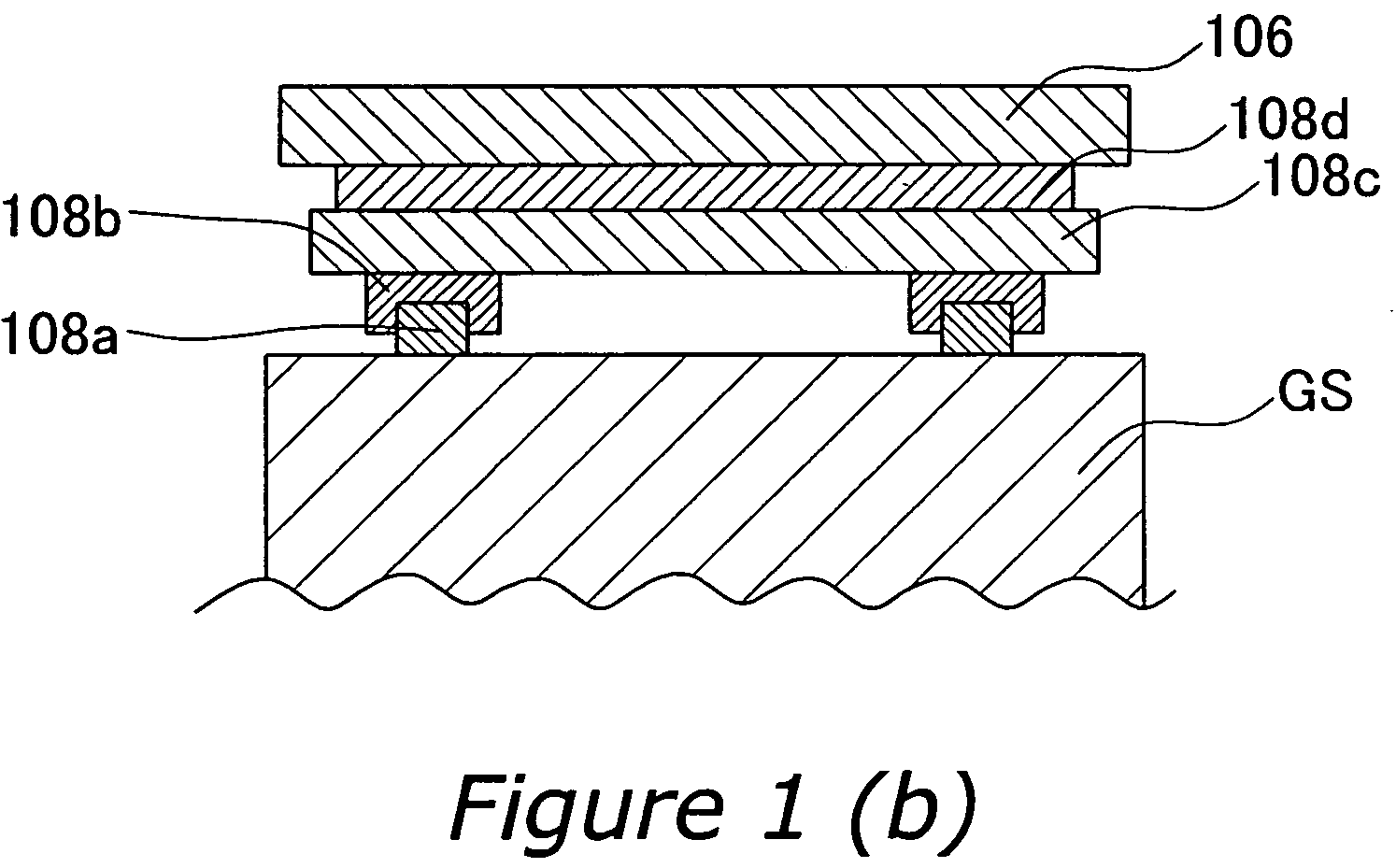

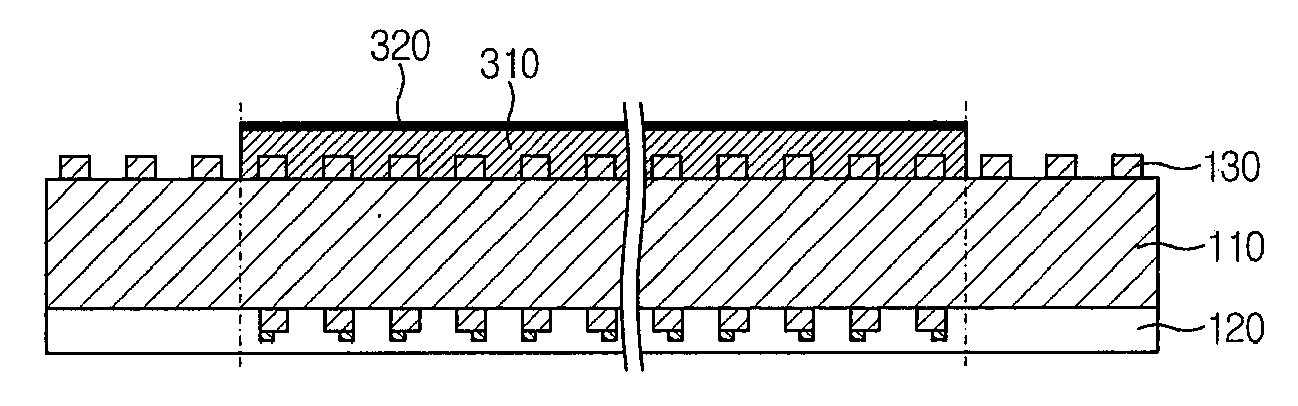

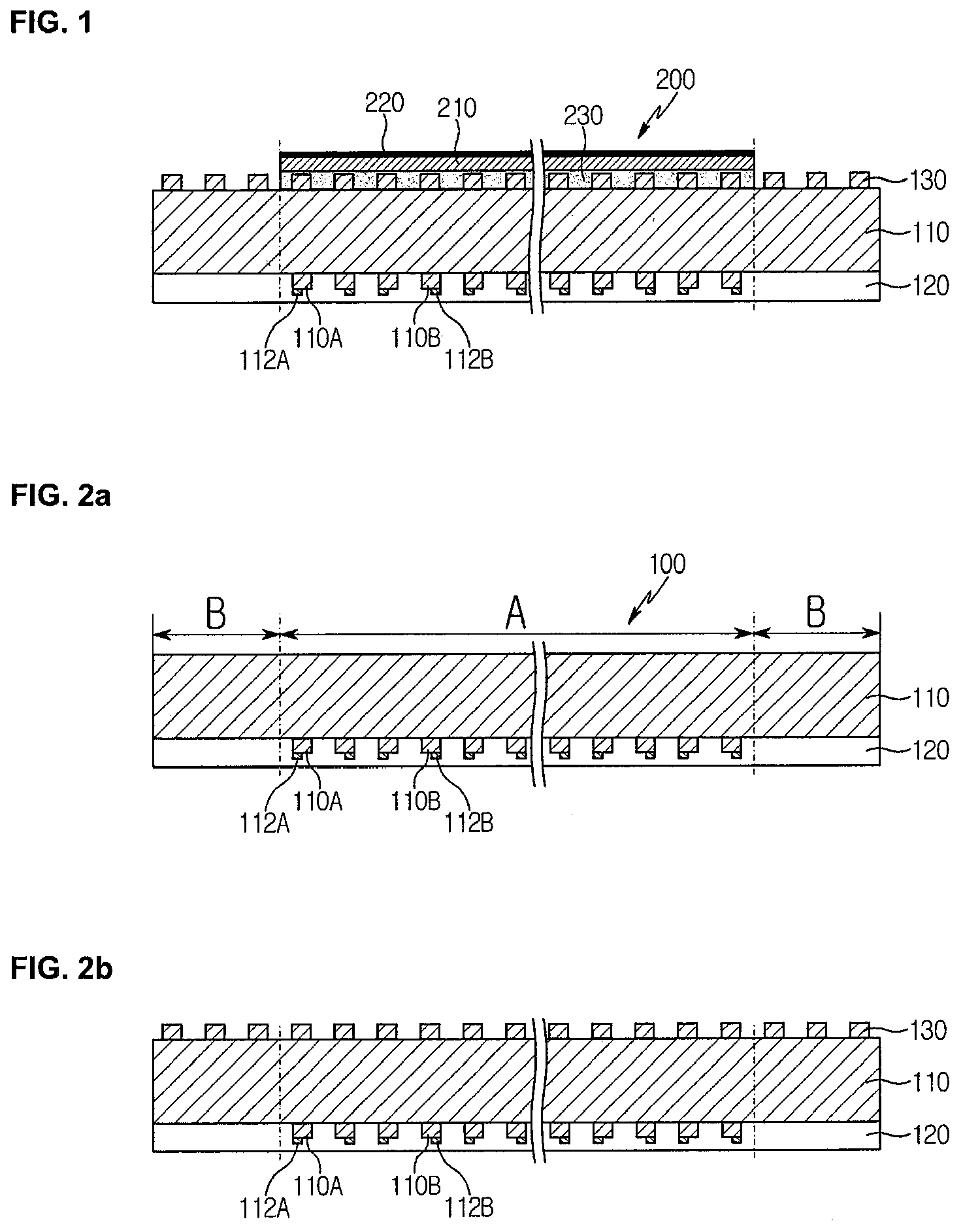

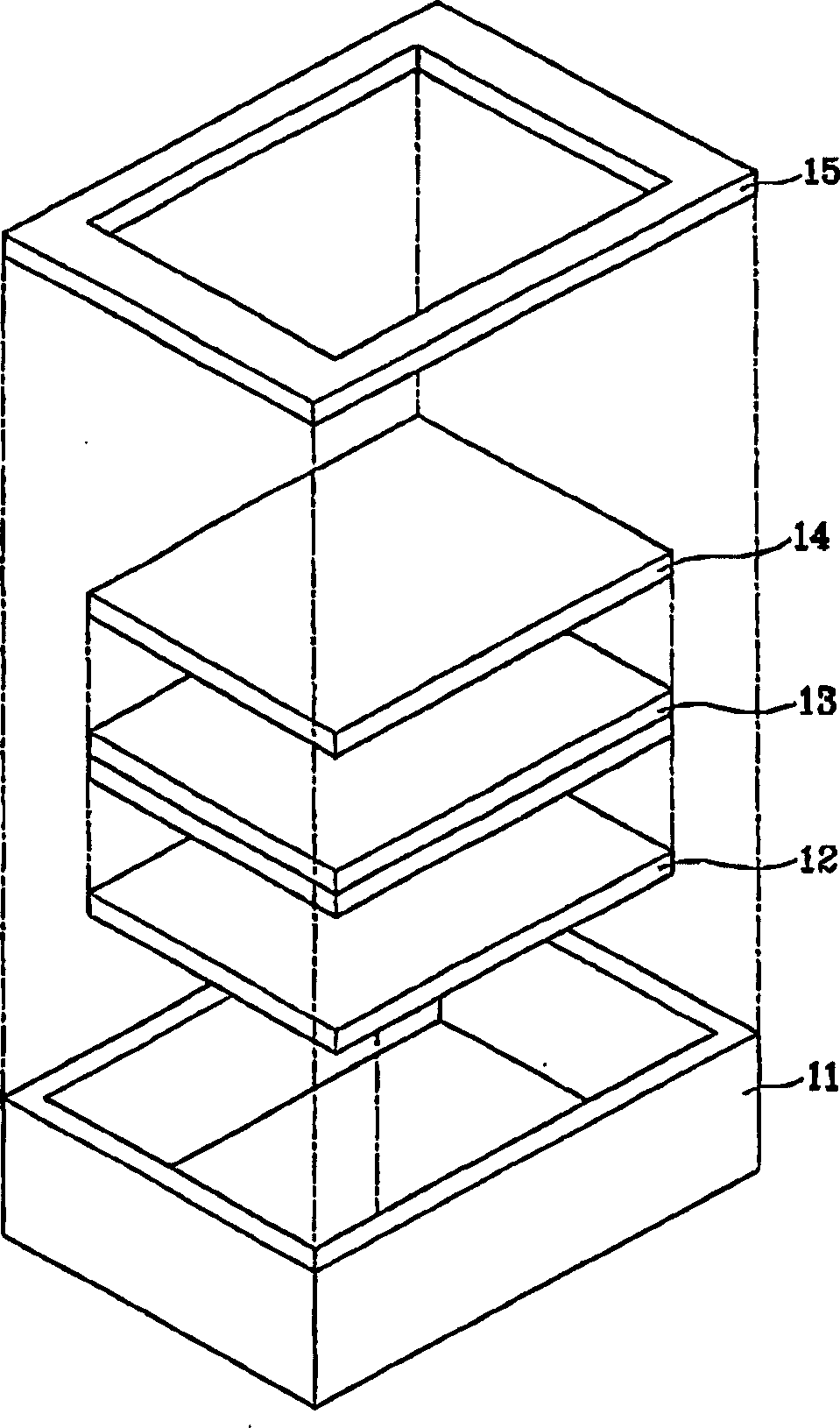

Seamless display manufacturing method

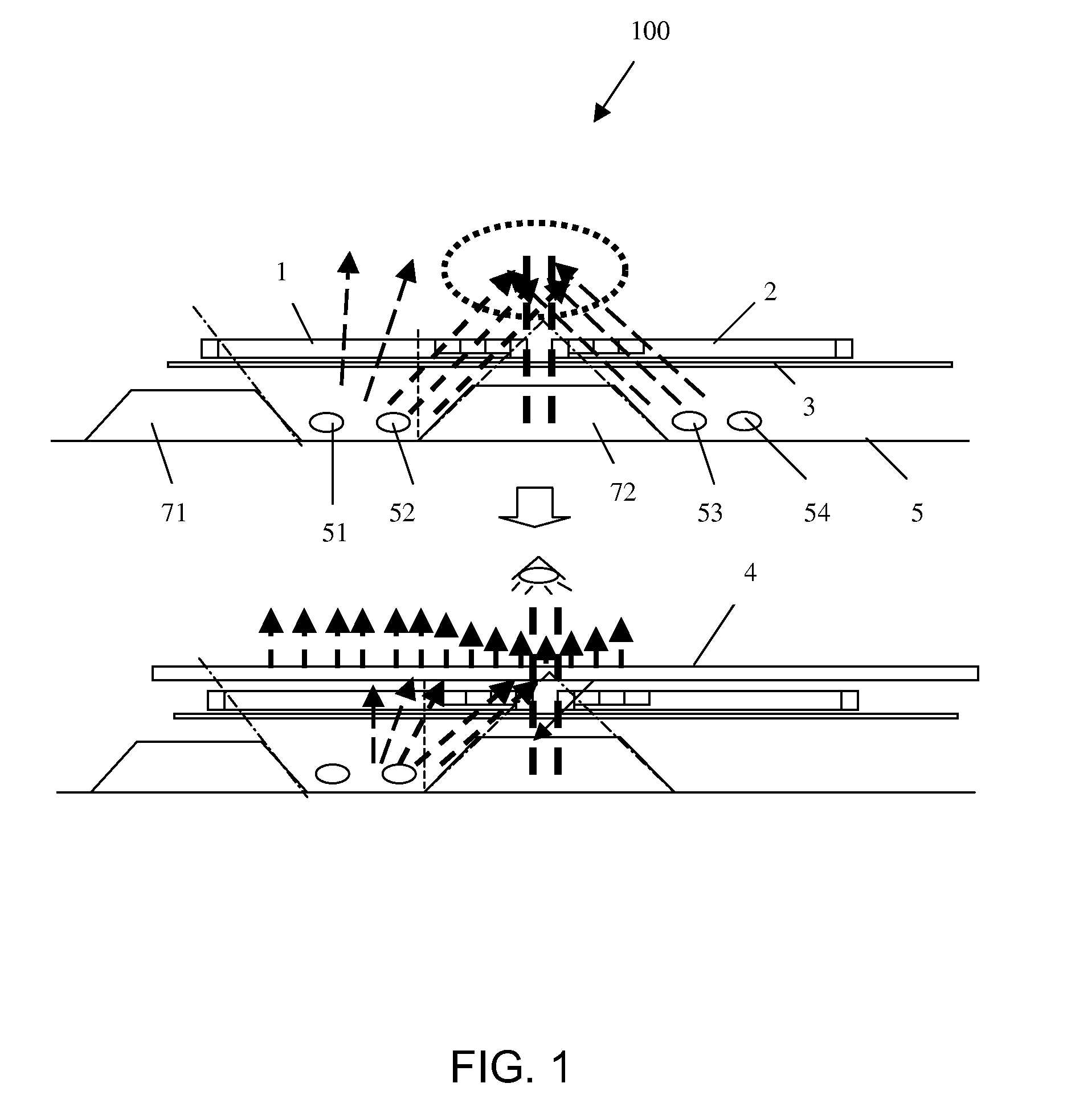

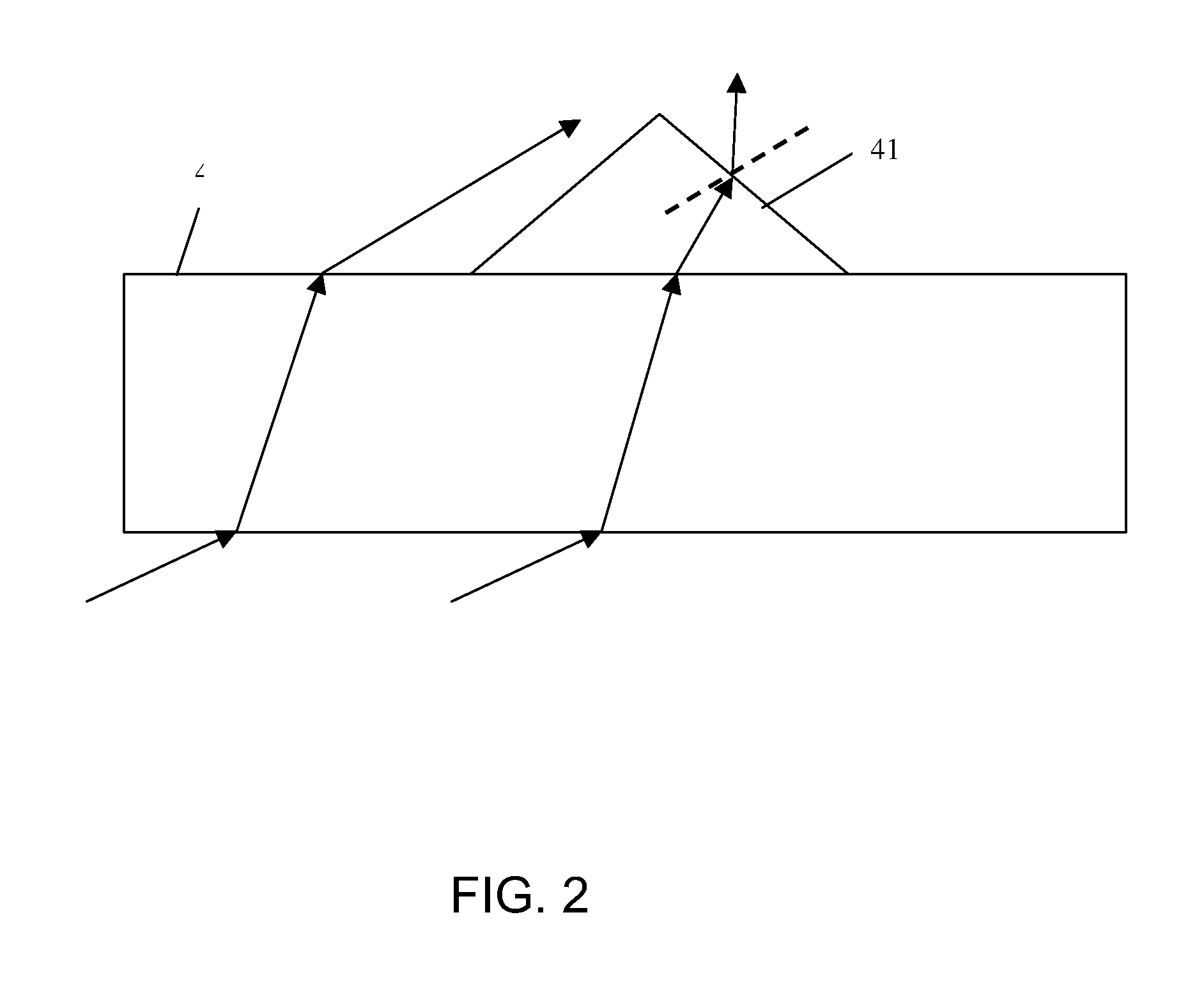

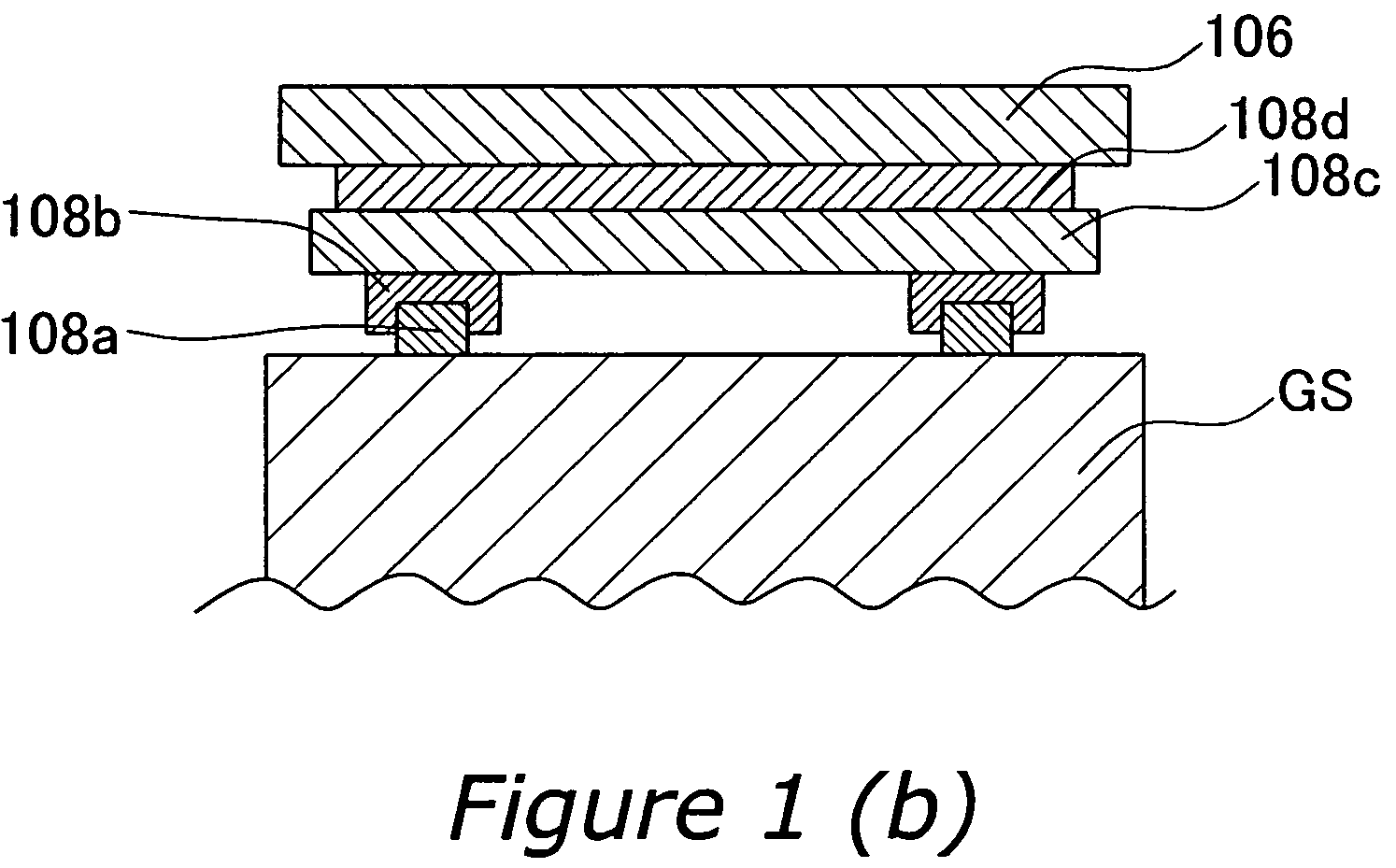

ActiveUS7744289B2Maintaining luminance uniformityEqually distributedStatic indicating devicesGas discharge lampsMicro structureDisplay device

A seamless display manufacturing method includes fixing a light emitting source in a backlight module; fixing an optical film on the light emitting source; placing a partitioned structure on the optical film; aligning or overlapping the side edges of main bodies of adjacent liquid crystal panels, and putting them over the partitioned structure; and providing a protection layer having a micro-structure over a main body of a liquid crystal panel, thus forming an LCD display. A seamless display, comprises: a backlight module, that includes a plurality of light emitting sources; an optical film; a partitioned structure; a plurality of LCD panel main bodies; a protection layer having a micro-structure; and a locking portion. The main bodies of a plurality of liquid crystal panels are put together through aligning or overlapping their respective side edges, and then are covered over the partitioned structure.

Owner:HU CHUNG MING

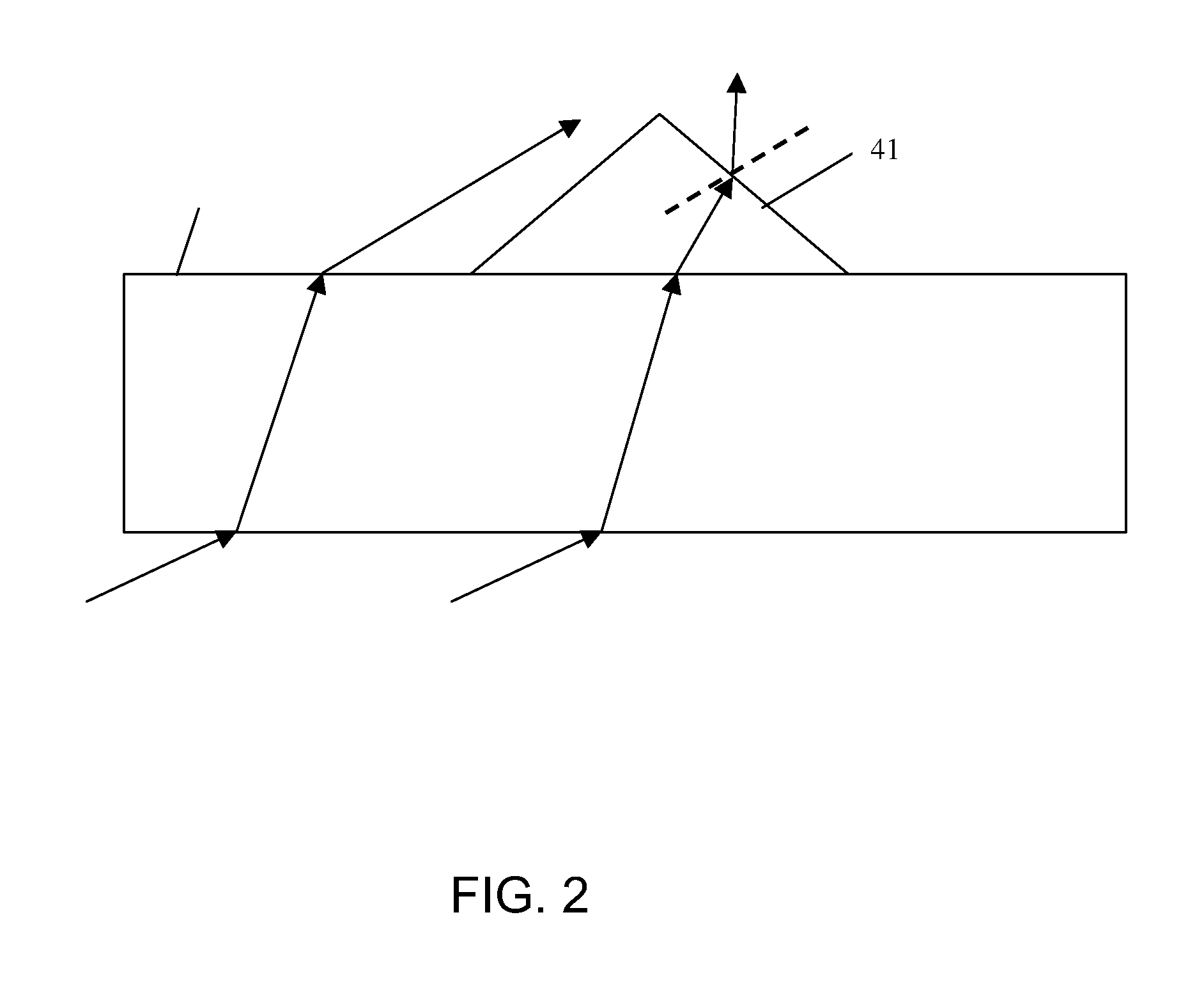

Seamless display manufacturing method

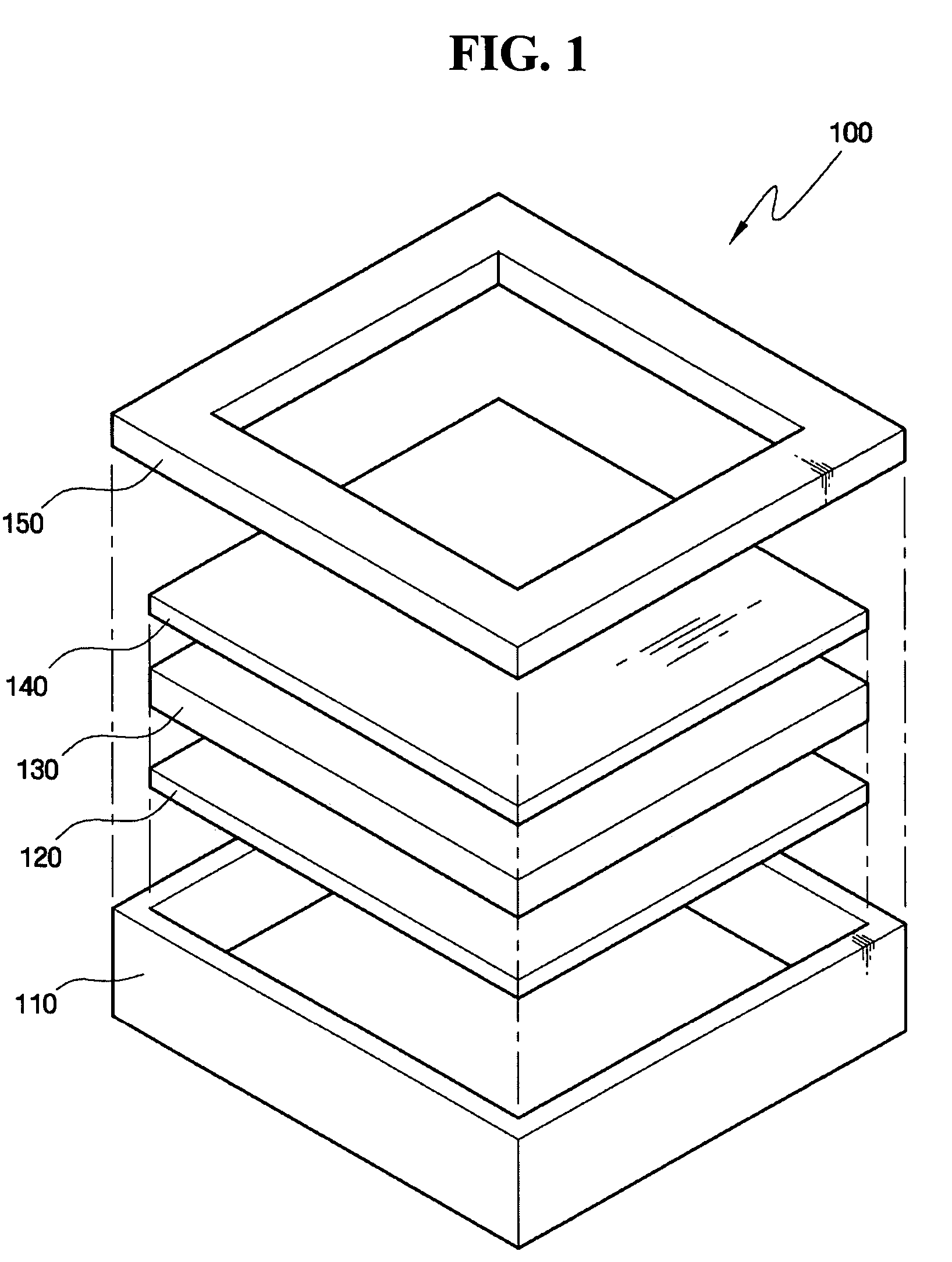

ActiveUS20080129923A1Maintaining luminance uniformityEqually distributedGas discharge lampsVessels or leading-in conductors manufactureDisplay deviceComputer module

Disclosed is a seamless display manufacturing method, comprising the following steps: fixing a light emitting source in a backlight module; fixing an optical film on the light emitting source; placing a partitioned structure on the optical film; aligning or overlapping the side edges of main bodies of adjacent liquid crystal panels, and putting them over the partitioned structure; and providing a protection layer having a micro-structure over a main body of a liquid crystal panel, thus forming an LCD display. Wherein, more than one LCD displays can be assembled to form an assembled LCD. The present invention also relates to a seamless display, comprising: a backlight module, that includes a plurality of light emitting sources; an optical film; a partitioned structure; a plurality of LCD panel main bodies; a protection layer having a micro-structure; and a locking portion, hereby forming a display unit. Wherein, the main bodies of a plurality of liquid crystal panels are put together through aligning or overlapping their respective side edges, and then are covered over the partitioned structure. The disclosure can be applied to form seamless large-sized image displaying panel, thus achieving the reduction of gap size between panel side edges in a large assembled panel and high quality image display.

Owner:HU CHUNG MING

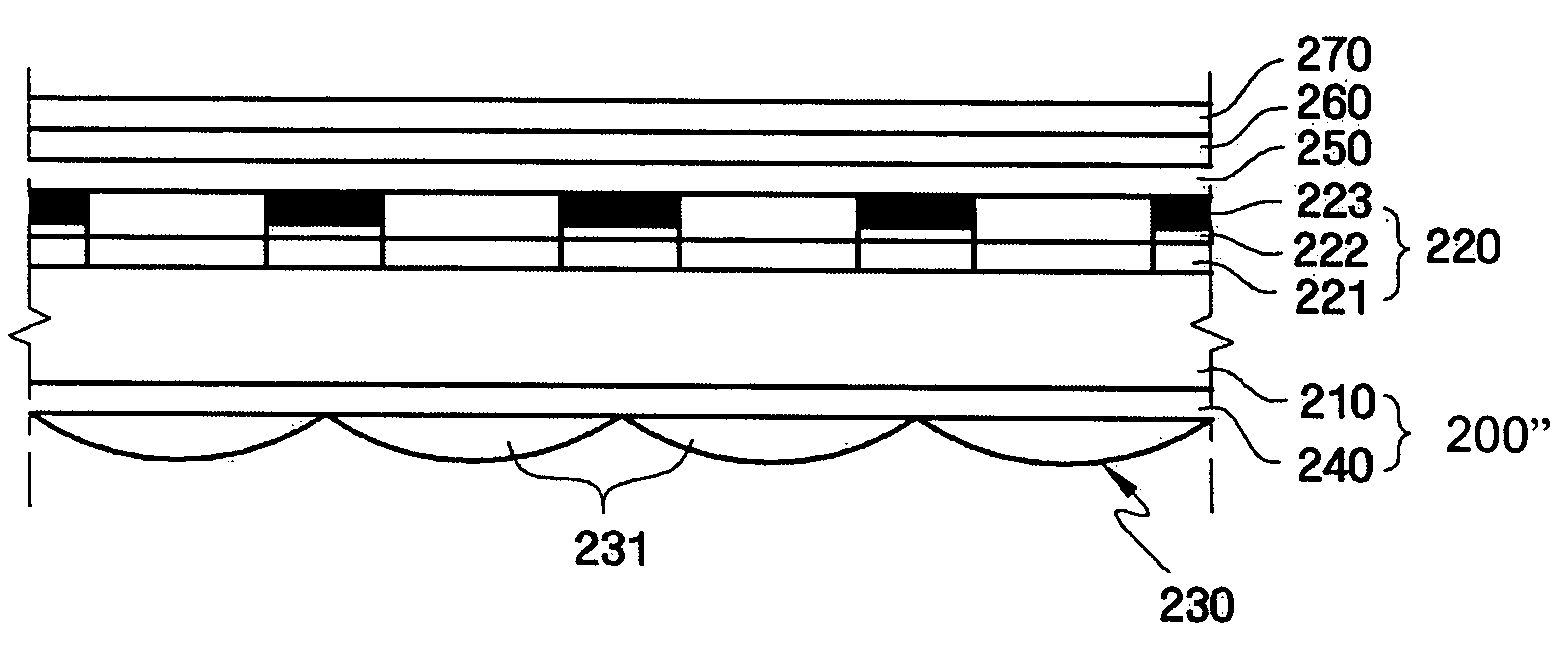

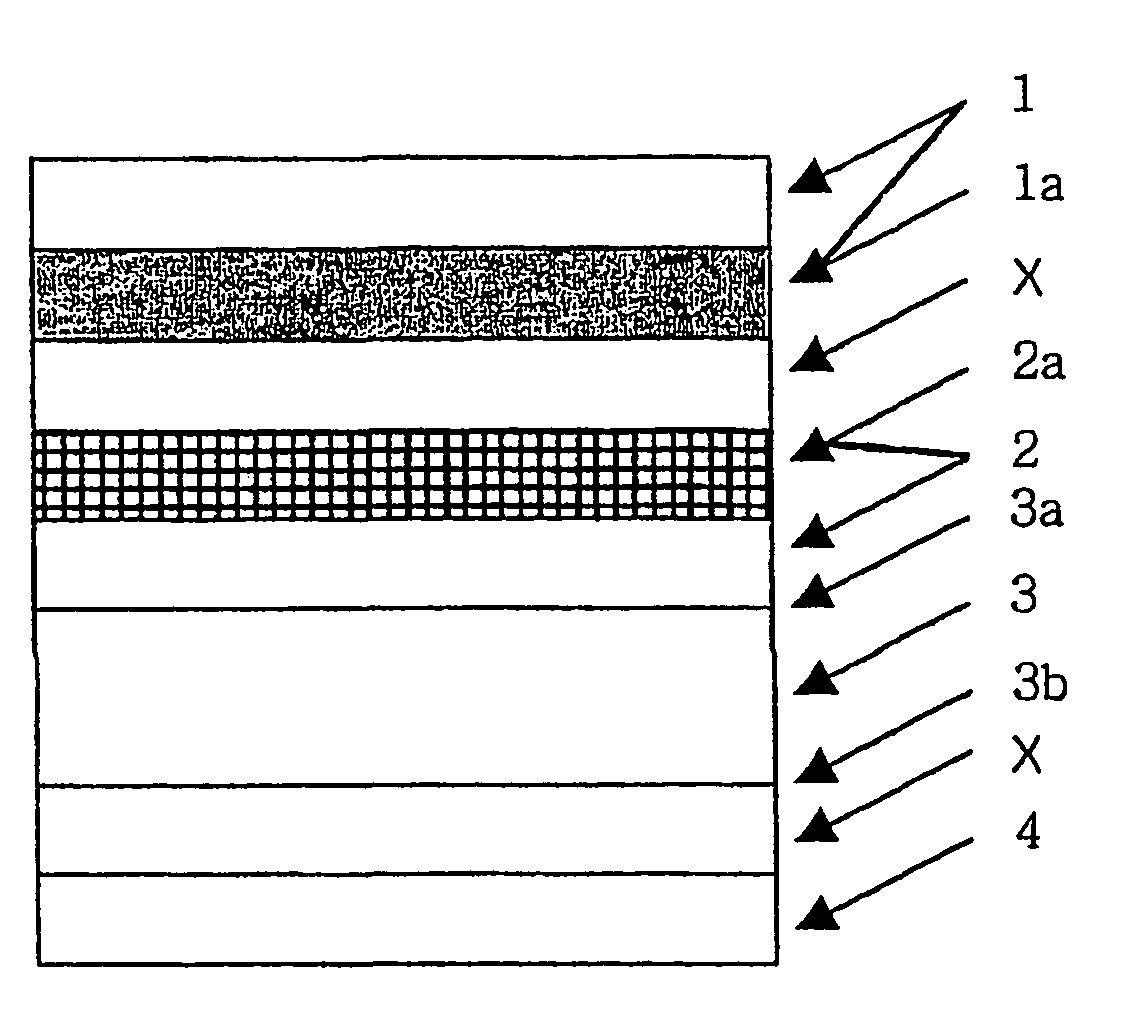

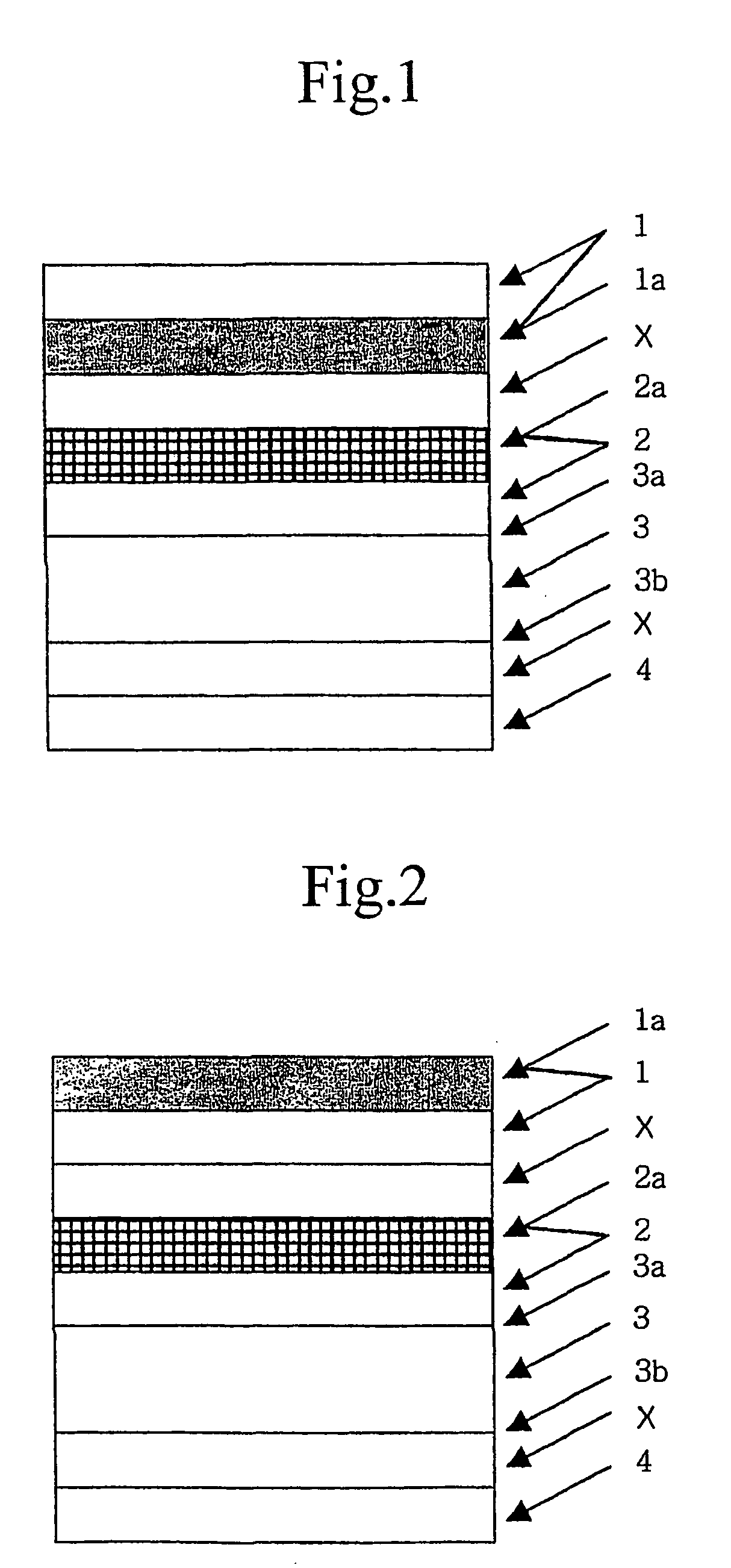

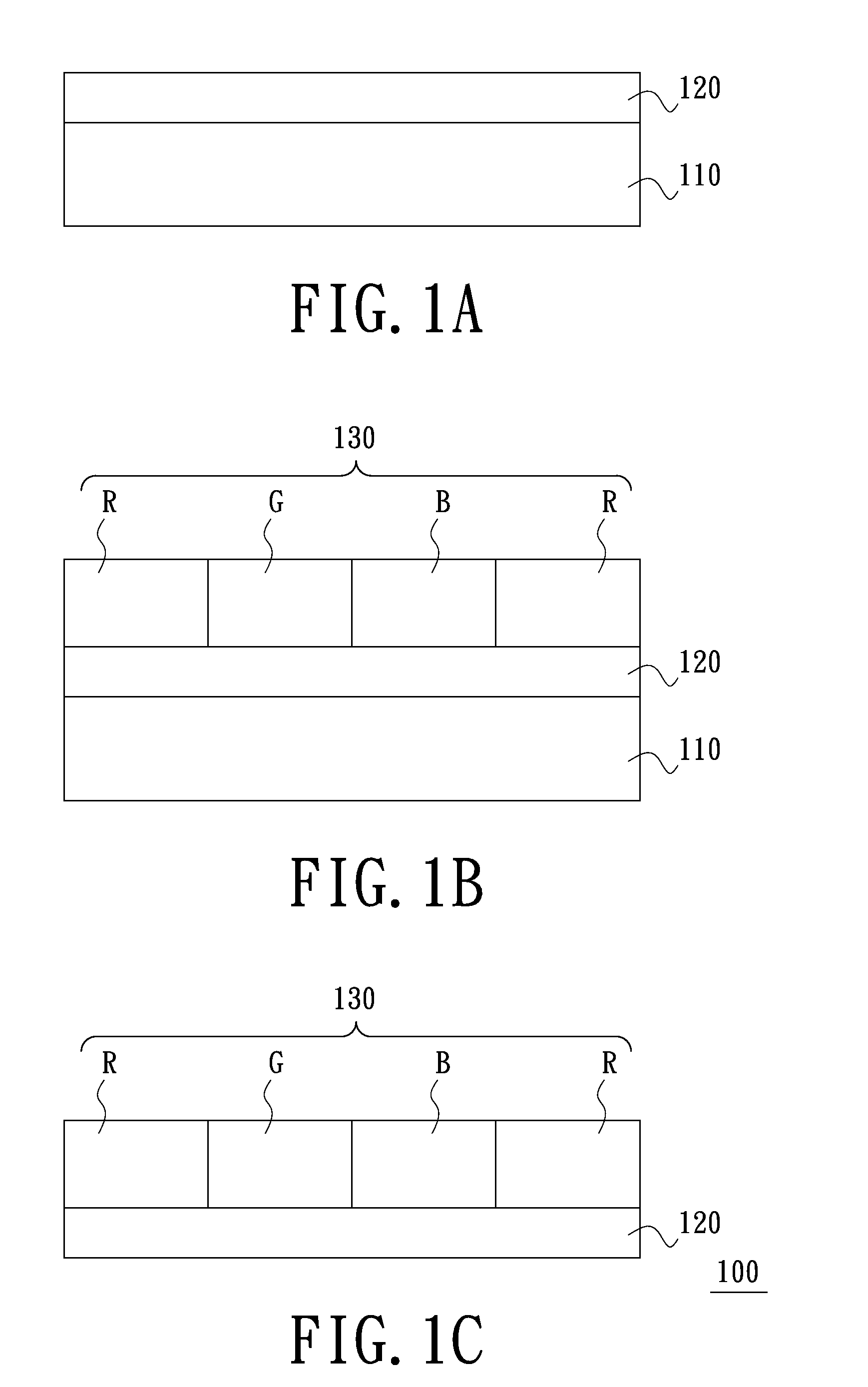

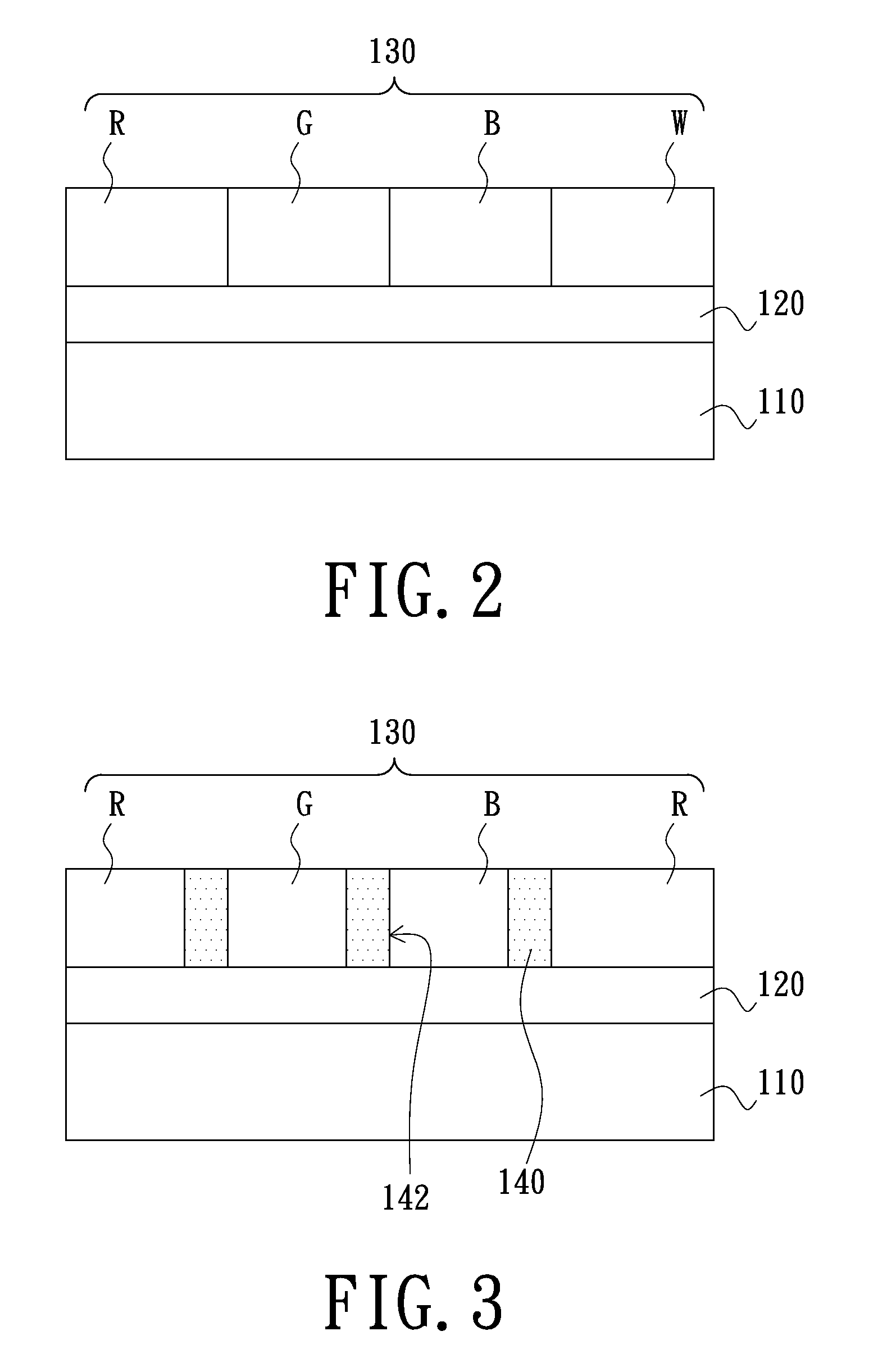

Display device and the method thereof

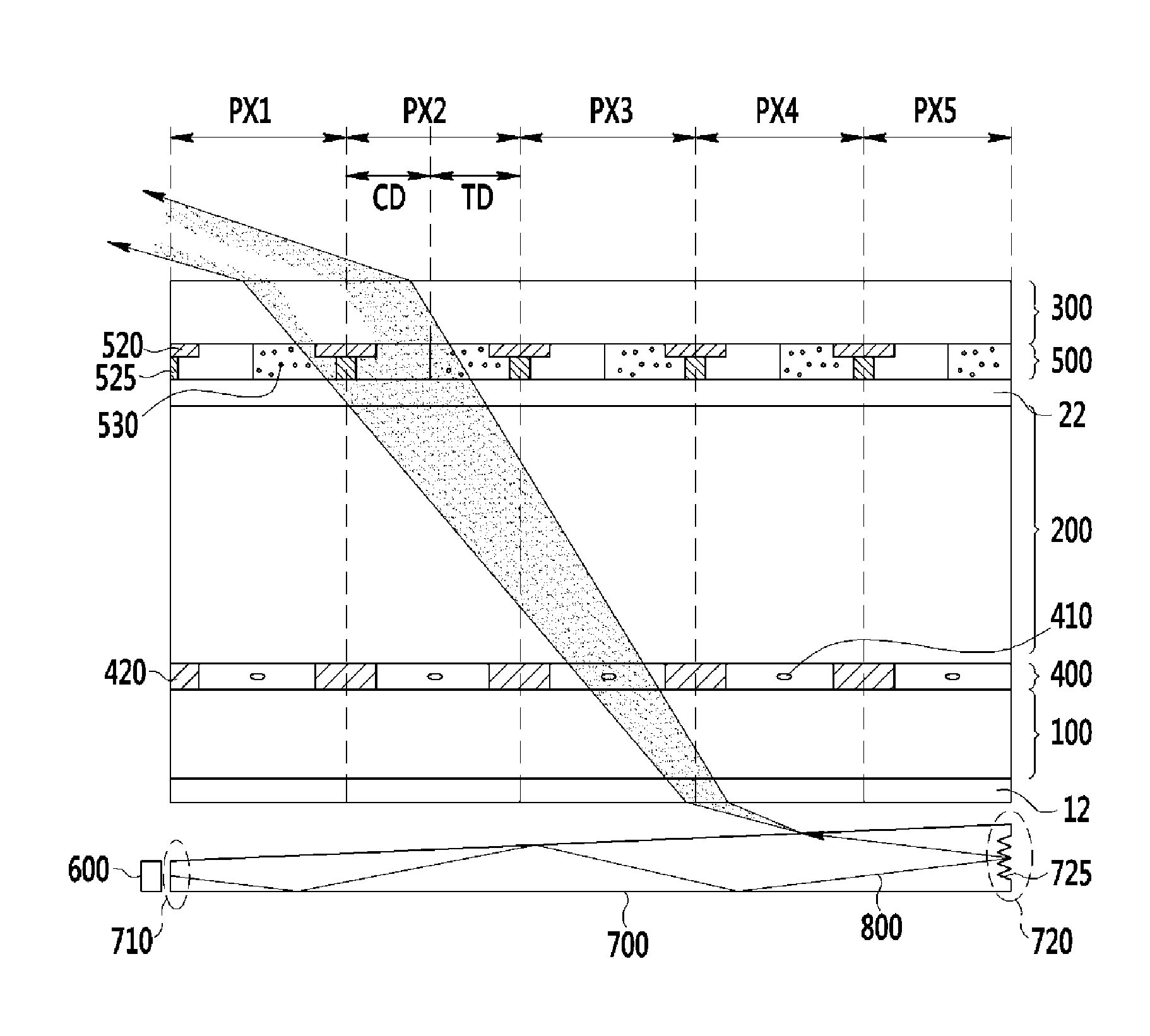

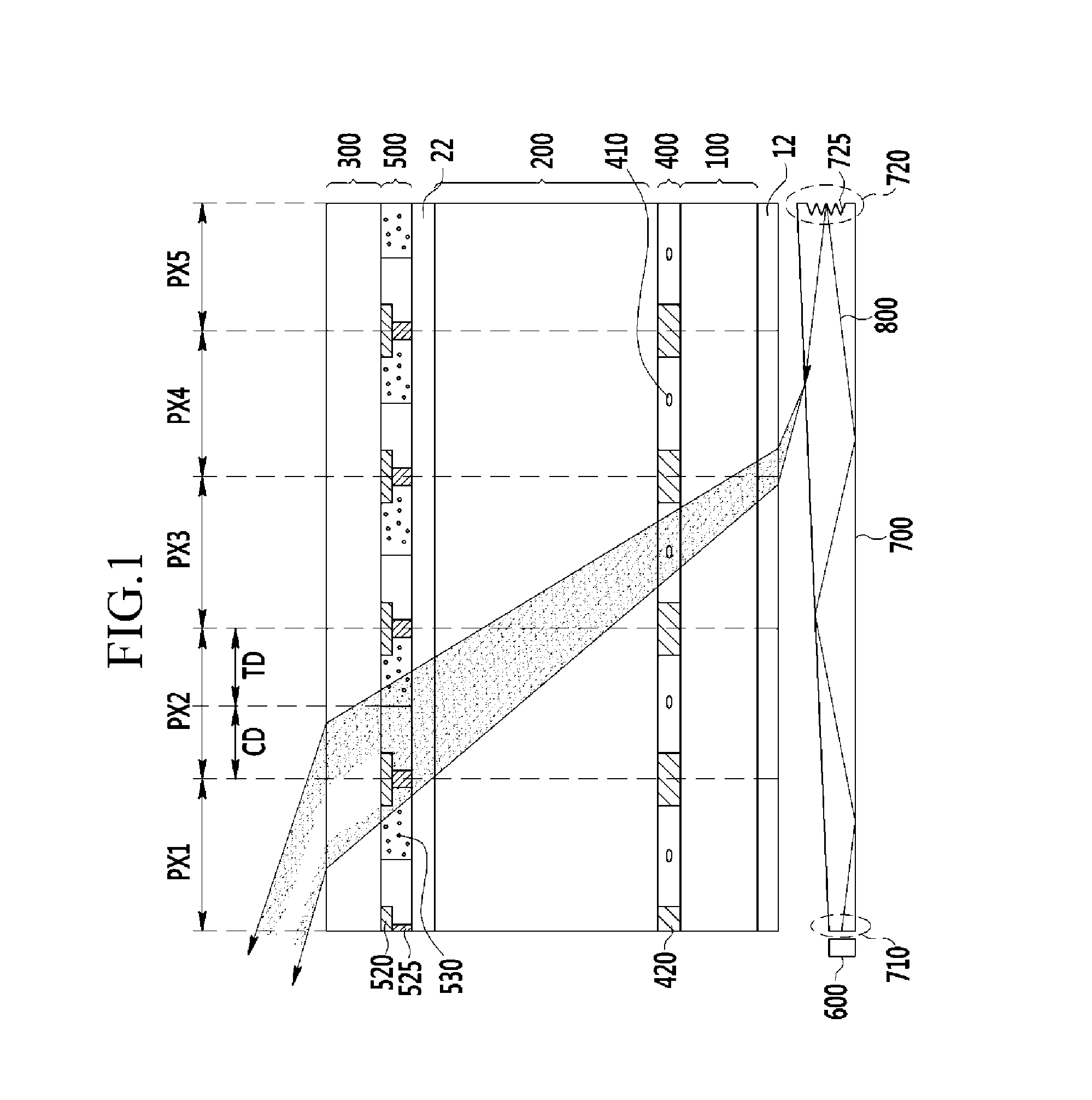

ActiveUS20140009723A1Avoid mixing colorsEffectively prevented from being leakedVessels or leading-in conductors manufactureOptical/shielding coatings applicationControl layerLight guide

A display device including: first, second and third substrates, where the second substrate is between the first and third substrates; a light amount controlling layer between the first and second substrates; a color providing layer between the second and third substrates; a light source unit which provides light; and a light guide plate disposed below the first substrate, where the light guide plate guides the light from the light source to the first substrate, where the light amount controlling layer and the color providing layer include pixels corresponding to each other, light from the light guide plate and passed through a pixel of the light amount controlling layer to pass through an adjacent pixel of the color providing layer, and the pixels of the color providing layer include a color conversion region and a transparent region.

Owner:SAMSUNG DISPLAY CO LTD

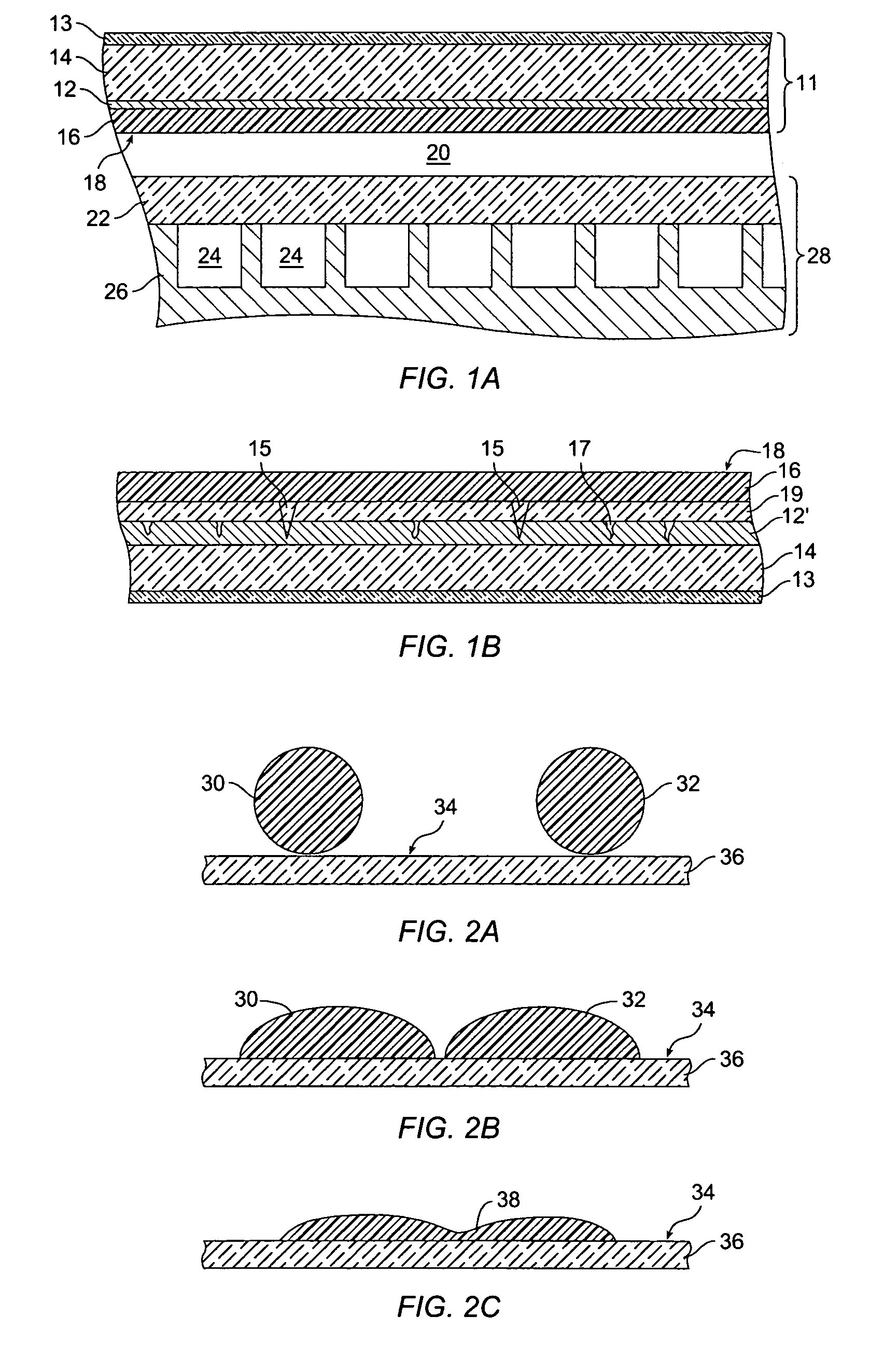

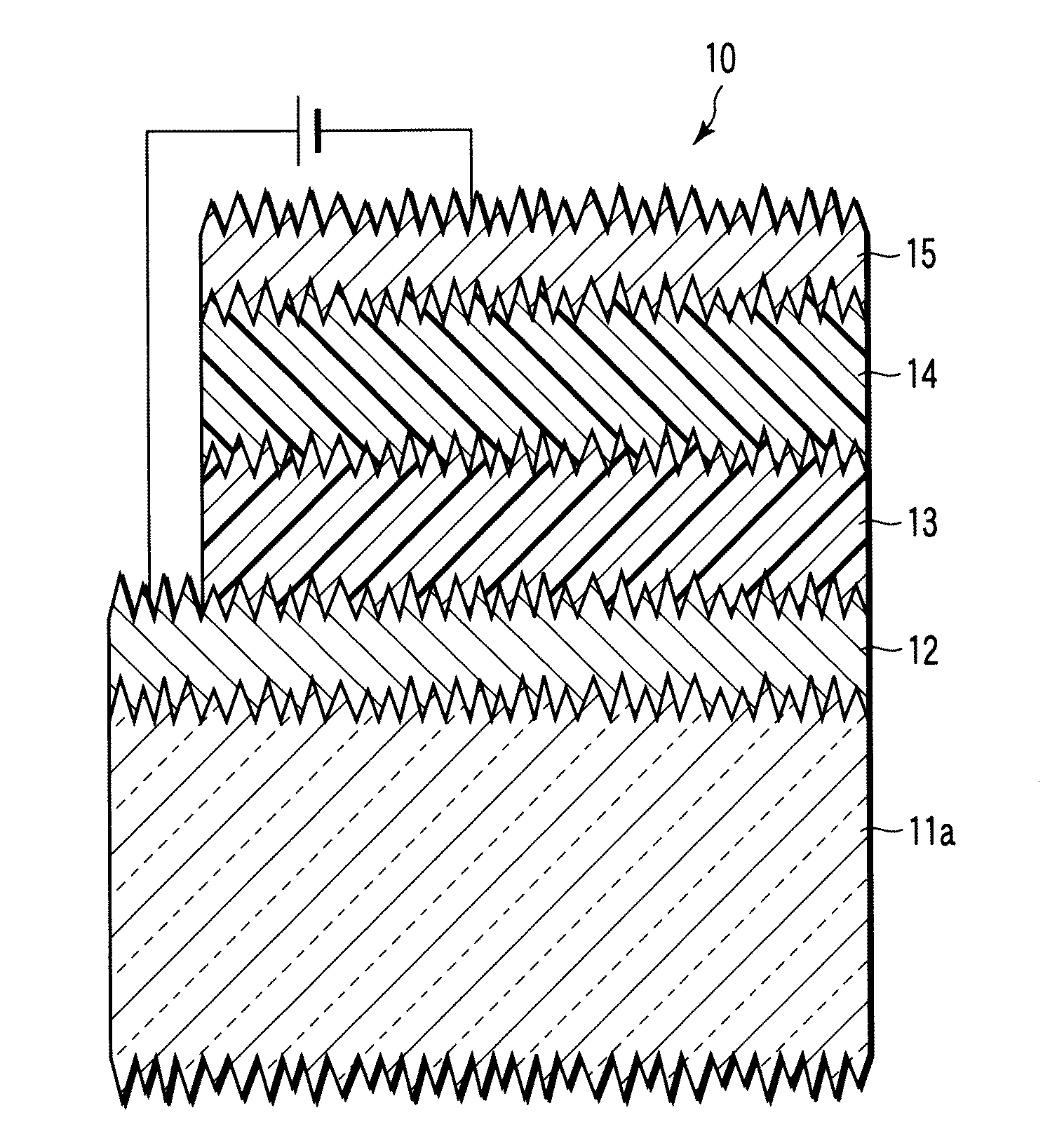

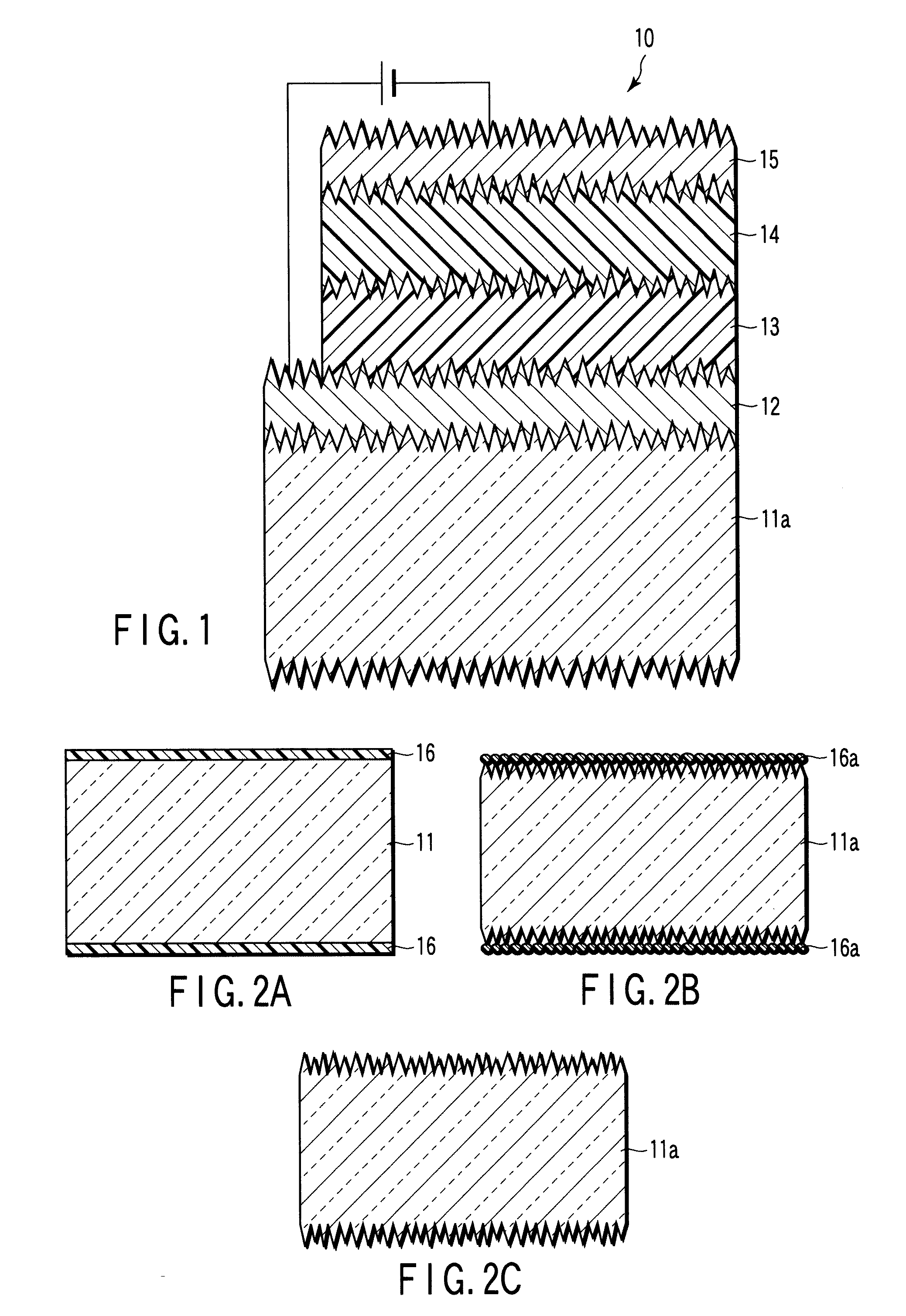

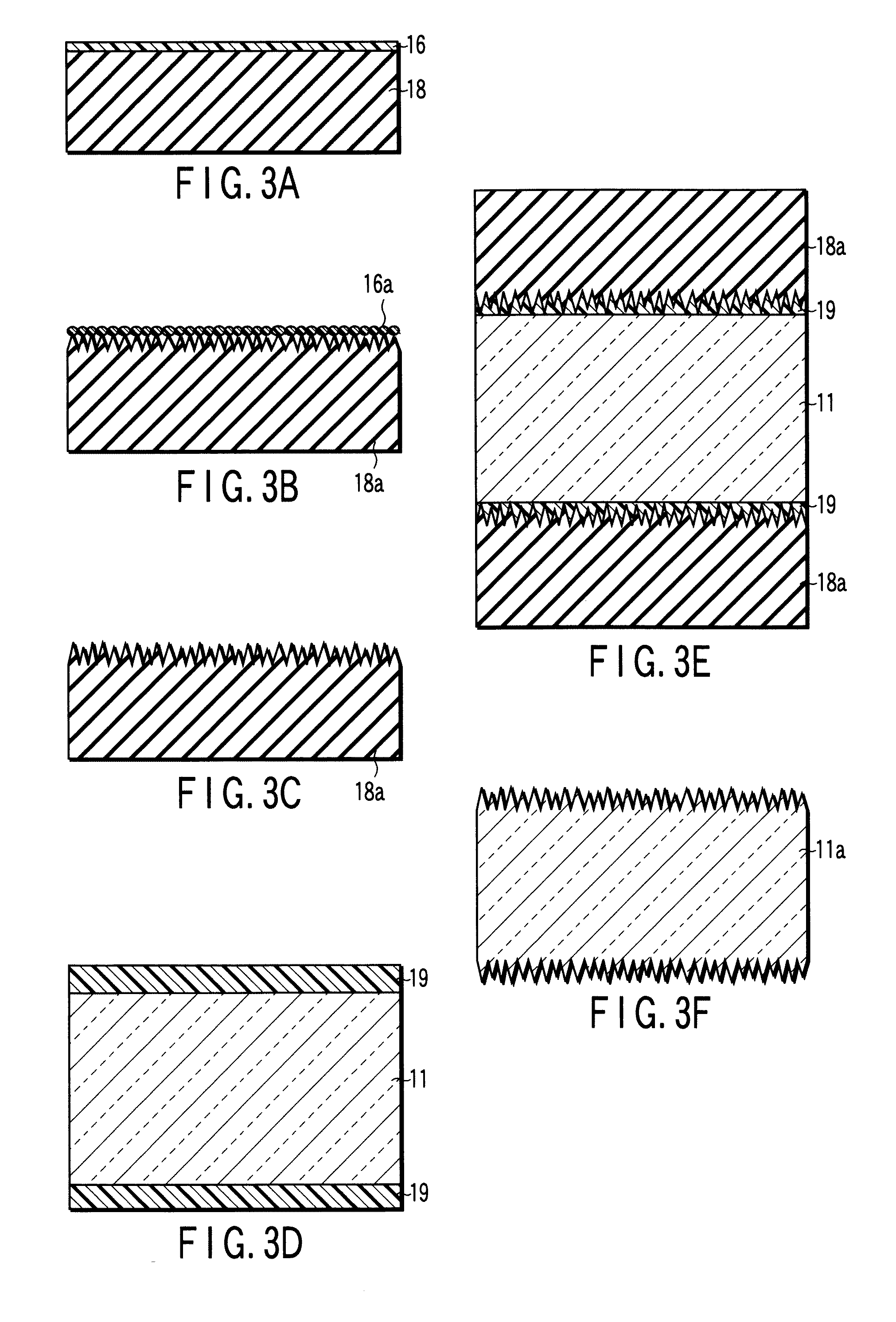

Display device and method of manufacturing transparent substrate for display device

InactiveUS20090179543A1Solid-state devicesAlternating current plasma display panelsDisplay deviceOptoelectronics

A display device comprises a substrate and a laminate structure formed on the substrate and comprising a plurality of layers including a display region. The laminate structure has a recessed / projected portions at least one of an outermost surface of display side and an interface between the layers. The projected portions of the recessed / projected portions have a mean circle-equivalent diameter ranging from 50 nm to 250 nm with the standard deviation of circle-equivalent diameter of the projected portions being within the range of 10 to 50% of the mean circle-equivalent diameter, and a mean height ranging from 100 nm to 500 nm with the standard deviation of height being within the range of 10 to 50% of the mean height. The projected portions have a circularity coefficient ranging from 0.6 to 1, and an area ratio ranging from 20 to 75%.

Owner:KK TOSHIBA

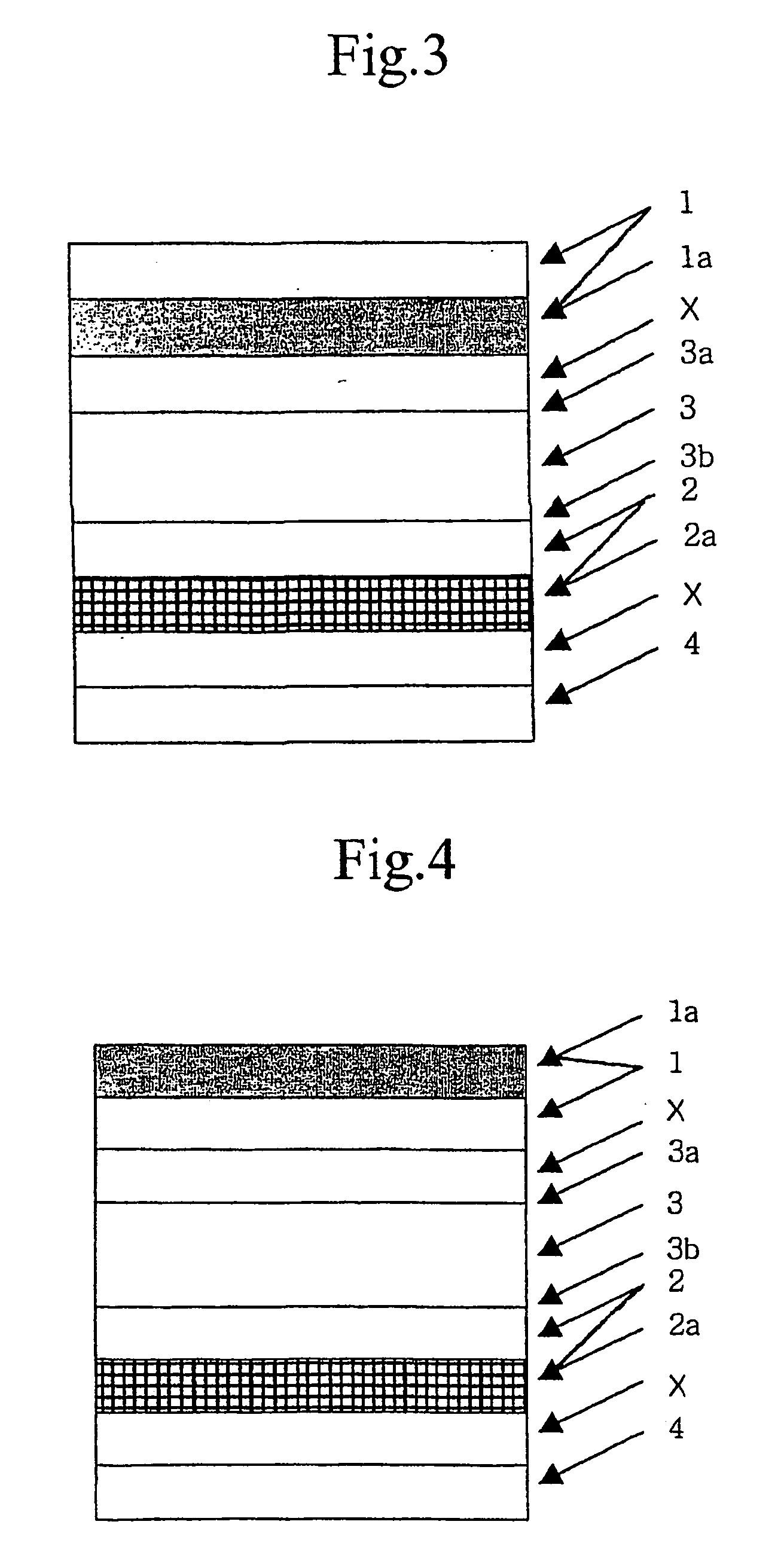

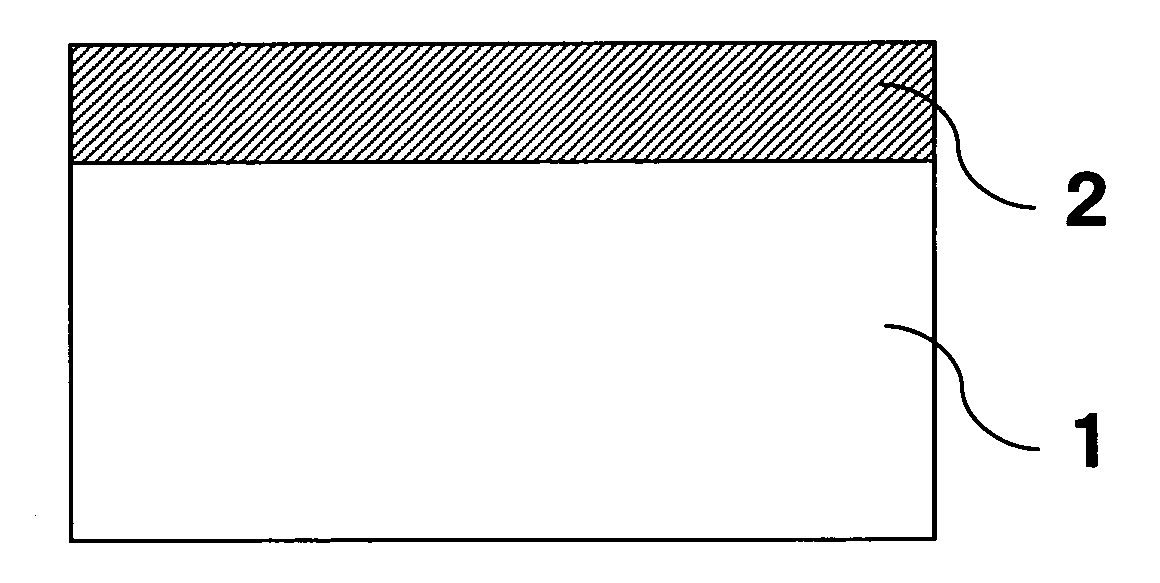

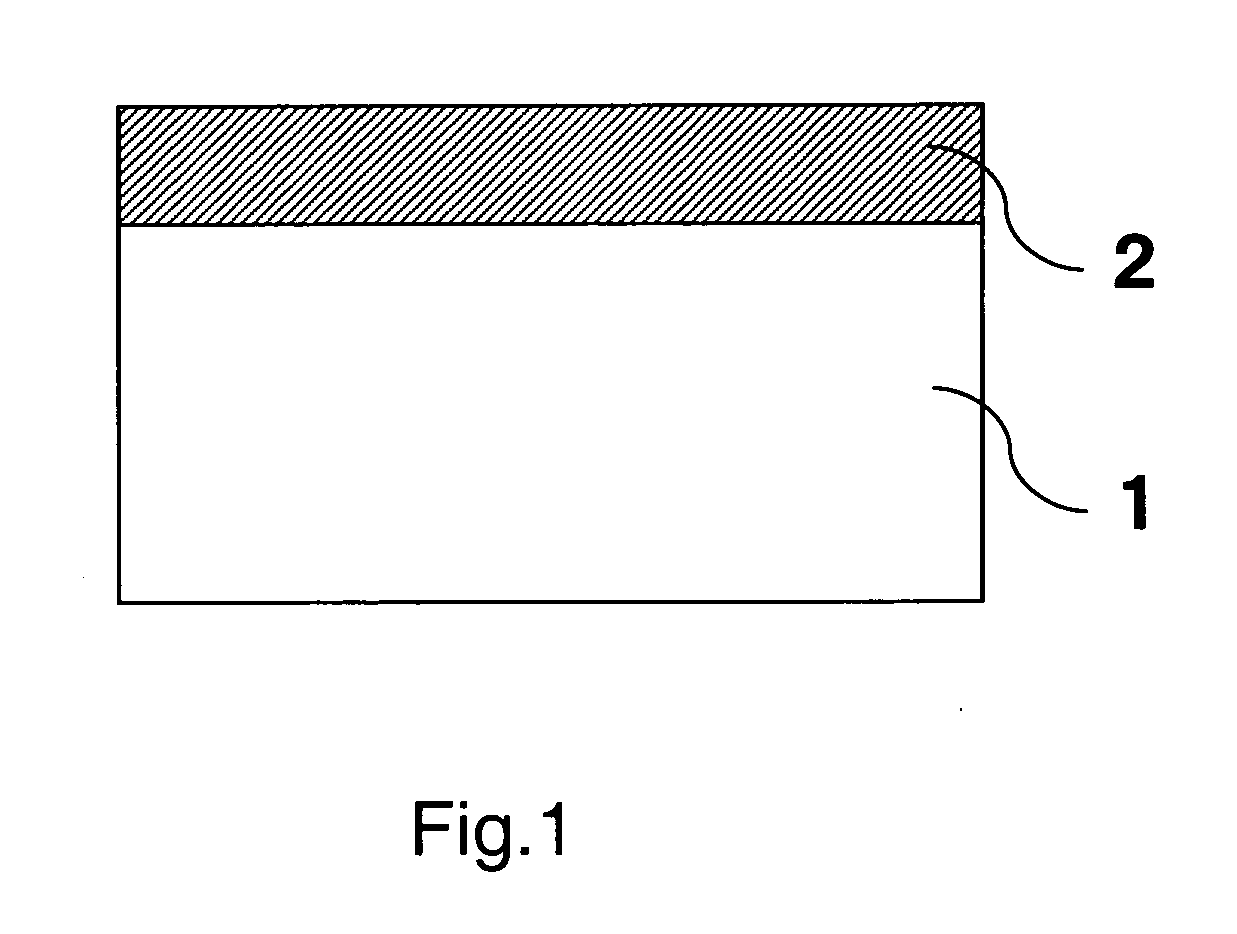

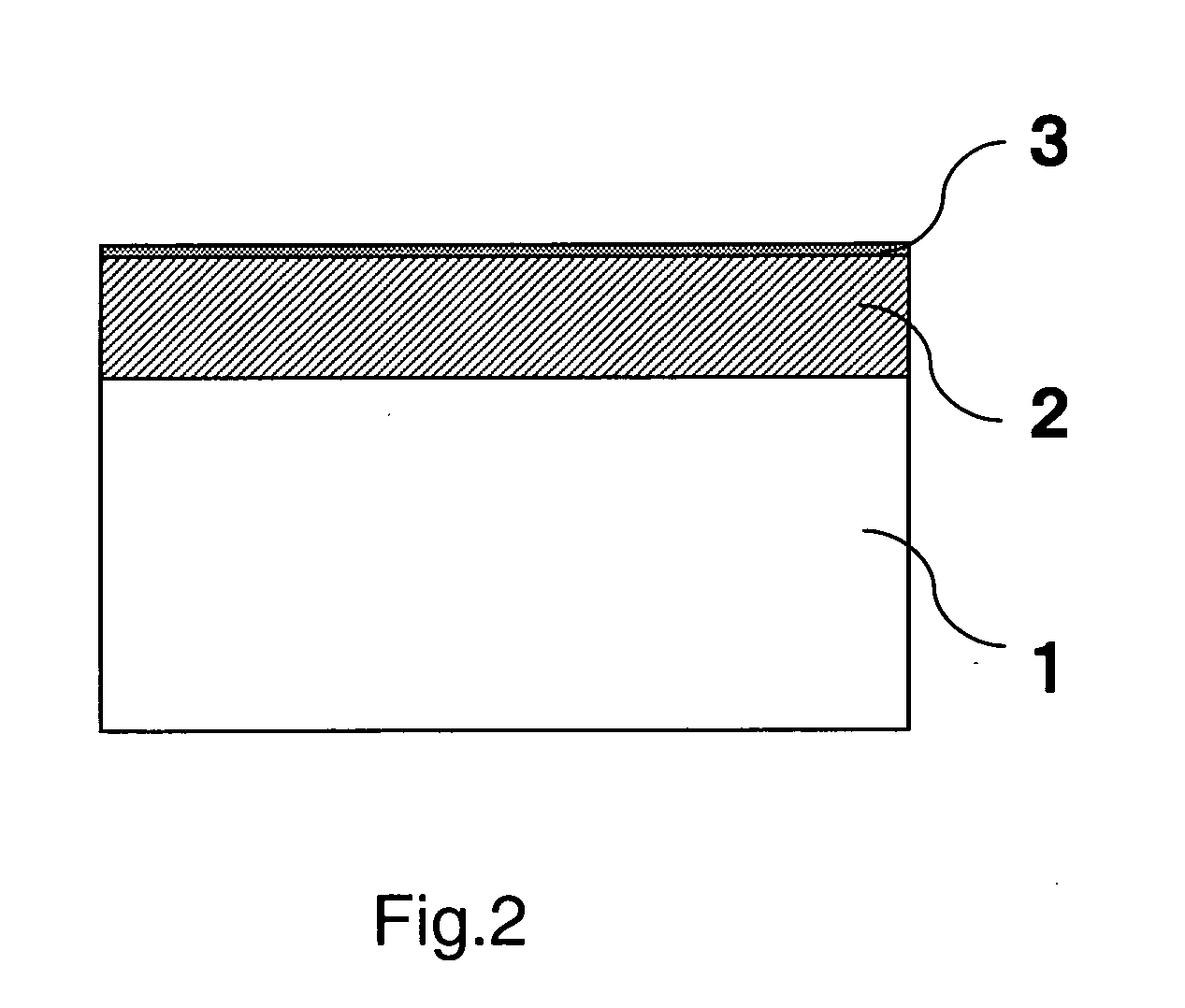

Method for manufacturing coating film

InactiveUS20080233305A1Sufficient surface hardnessLittle curlPretreated surfacesOptical/shielding coatings applicationUltraviolet radiationUltraviolet

A method for manufacturing a coating film having a coating layer on a transparent base material. The method includes a step of forming a coated film by coating a coating liquid having a material for forming a coating layer that is curable by ultraviolet radiation on the transparent base material, and a step of irradiating the coated film composed by the coating liquid and formed on the transparent base material with pulsed ultraviolet radiation to form the coating layer.

Owner:TOPPAN PRINTING CO LTD

Process for producing transparent electroconductive member

InactiveUS20100296166A1High transparencyExcellent in electroconductivityElectric discharge tubesMagnetic/electric field screeningElectroless platingReducing agent

[Problems] To provide a process for producing a transparent electroconductive member, which can produce a transparent electroconductive member having excellent light transparency and electroconductivity at low cost.[Means for Solving Problems] (a) Pattern printing is carried out on a transparent base material using an ink containing a reducing agent to form a reducing agent-containing pattern layer. Next, (b) a metal ion solution containing metal ions, which can function as an electroless plating catalyst upon reduction, is coated on the reducing agent-containing pattern layer, and the metal ion is reduced by contact between the reducing agent and the metal ion to form an electroless plating catalyst layer. Thereafter, (c) an electroconductive metal layer is formed by plating treatment on the electroless plating catalyst layer to produce a transparent electroconductive member.

Owner:SEIREN CO LTD

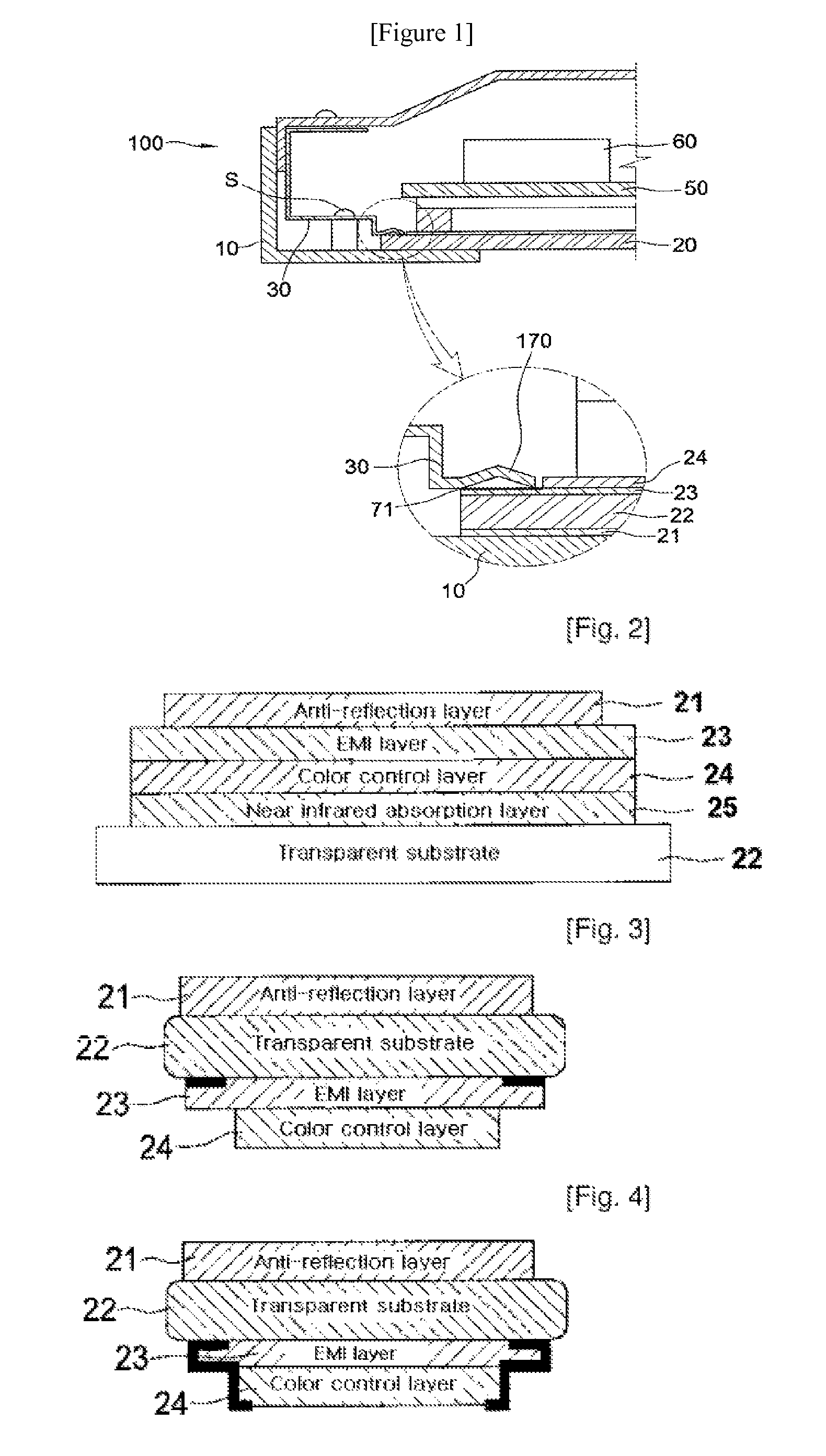

Front-side filter and plasma display panel device including the front-side filter

InactiveUS20060119244A1Good adhesionIncadescent screens/filtersMagnetic/electric field screeningDisplay deviceEngineering

Provided is a front-side filter which can be easily attached to a cover of a display device, but is difficult to detach from the cover even after long term use and further provided is a PDP device including the same filter. The front-side filter includes a filter base having at least one function among a near-infrared ray shielding function, and a neon light shielding function, and an electromagnetic wave shielding function; and an antireflective layer with an edge pattern, formed on a side of the filter base in such a way that the entire edge portion or a part of the edge portion of the filter base is exposed through the edge pattern to provide a fixing means formed in the edge pattern. The plasma display panel device includes a case, a cover for covering an upper surface of the case, a driving circuit board enclosed by the case, a panel assembly disposed on the driving circuit board and enclosed by the case, and a front-side filter including a filter base having at least one function among a near-infrared ray shielding function, and a neon light shielding function, and an electromagnetic wave shielding function; and an antireflective layer with an edge pattern, formed on a side of the filter base in such a way that the entire edge portion or part of the edge portion of the filter base is exposed through the edge pattern to provide a fixing means formed in the edge pattern.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

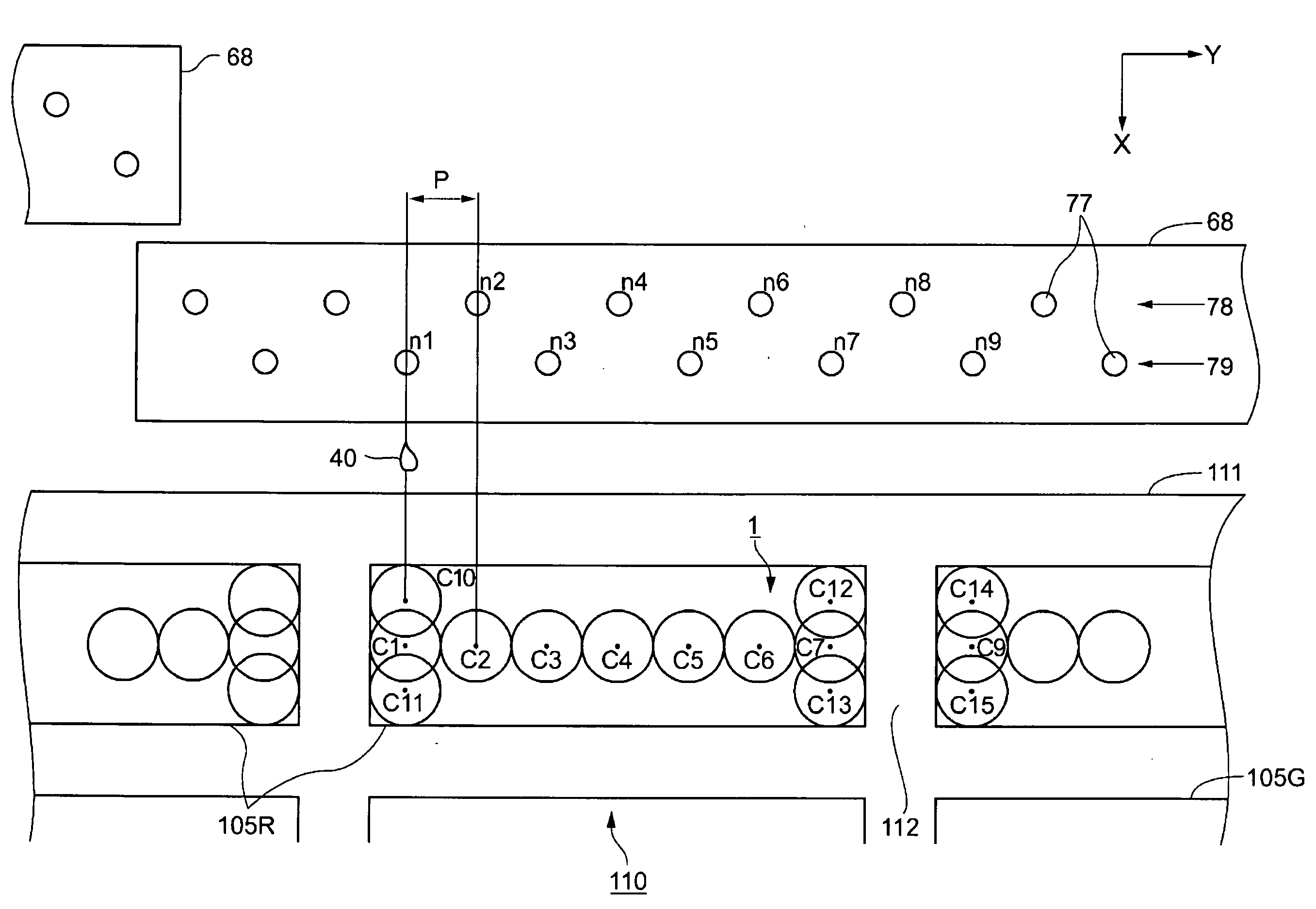

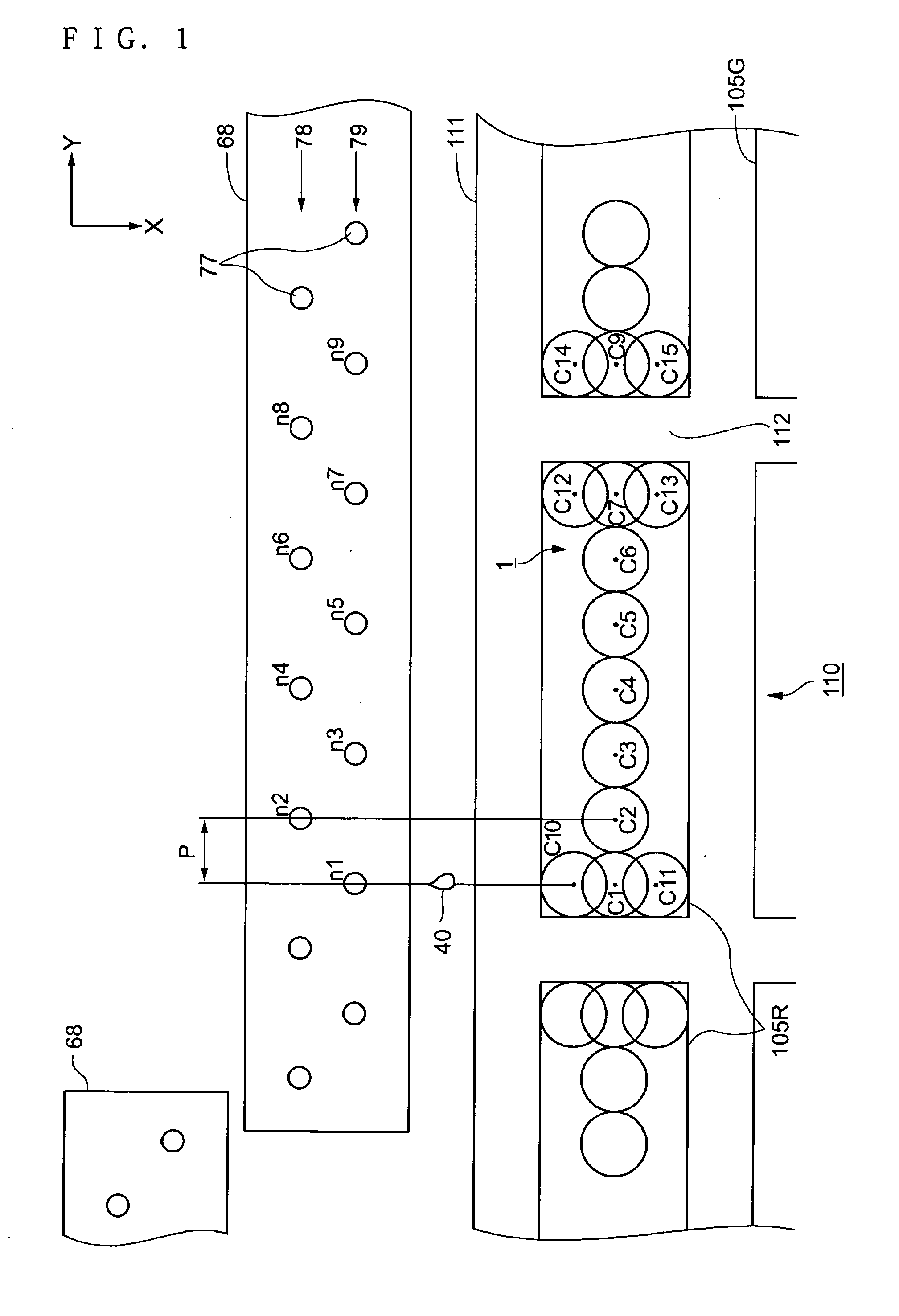

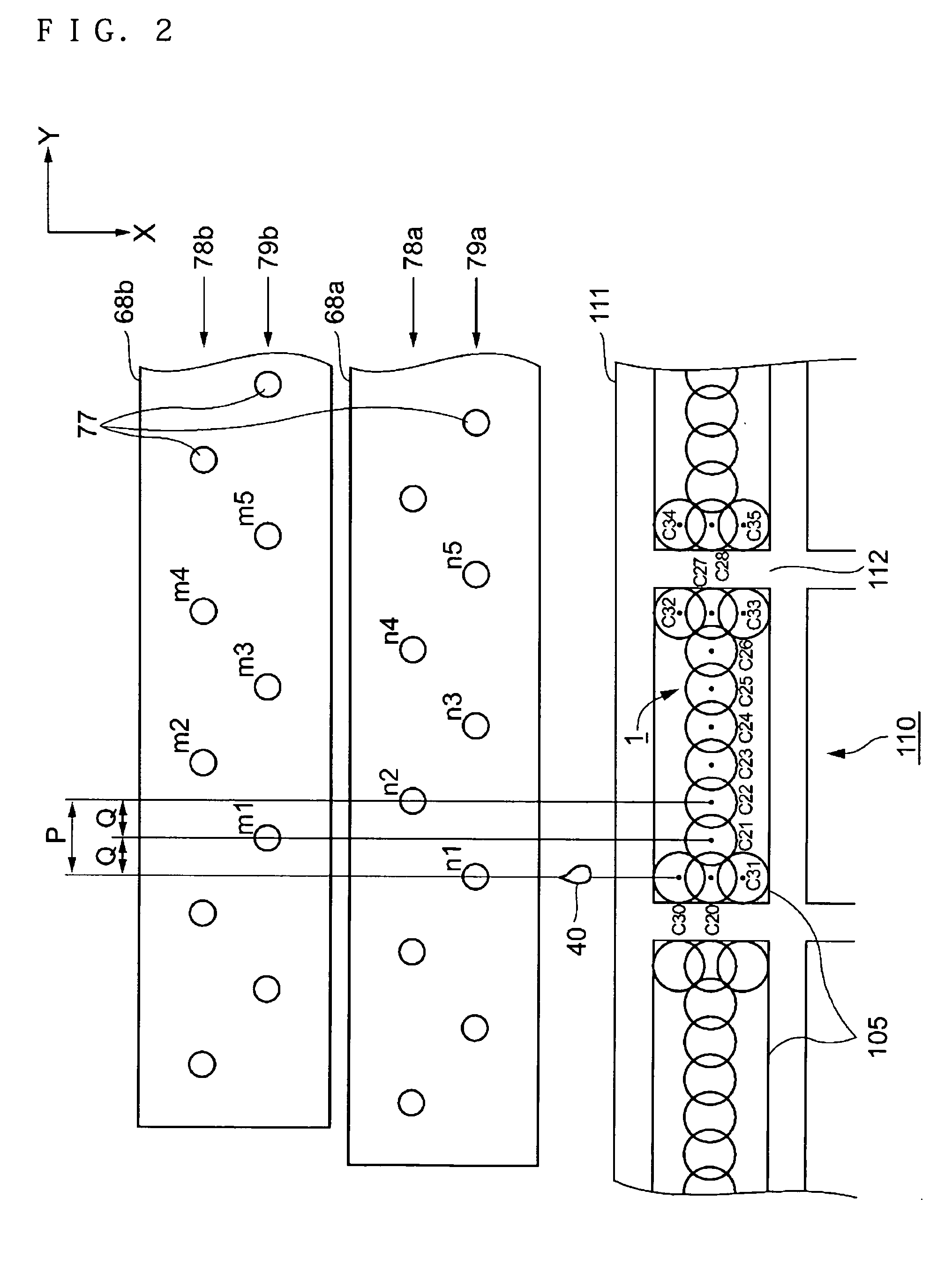

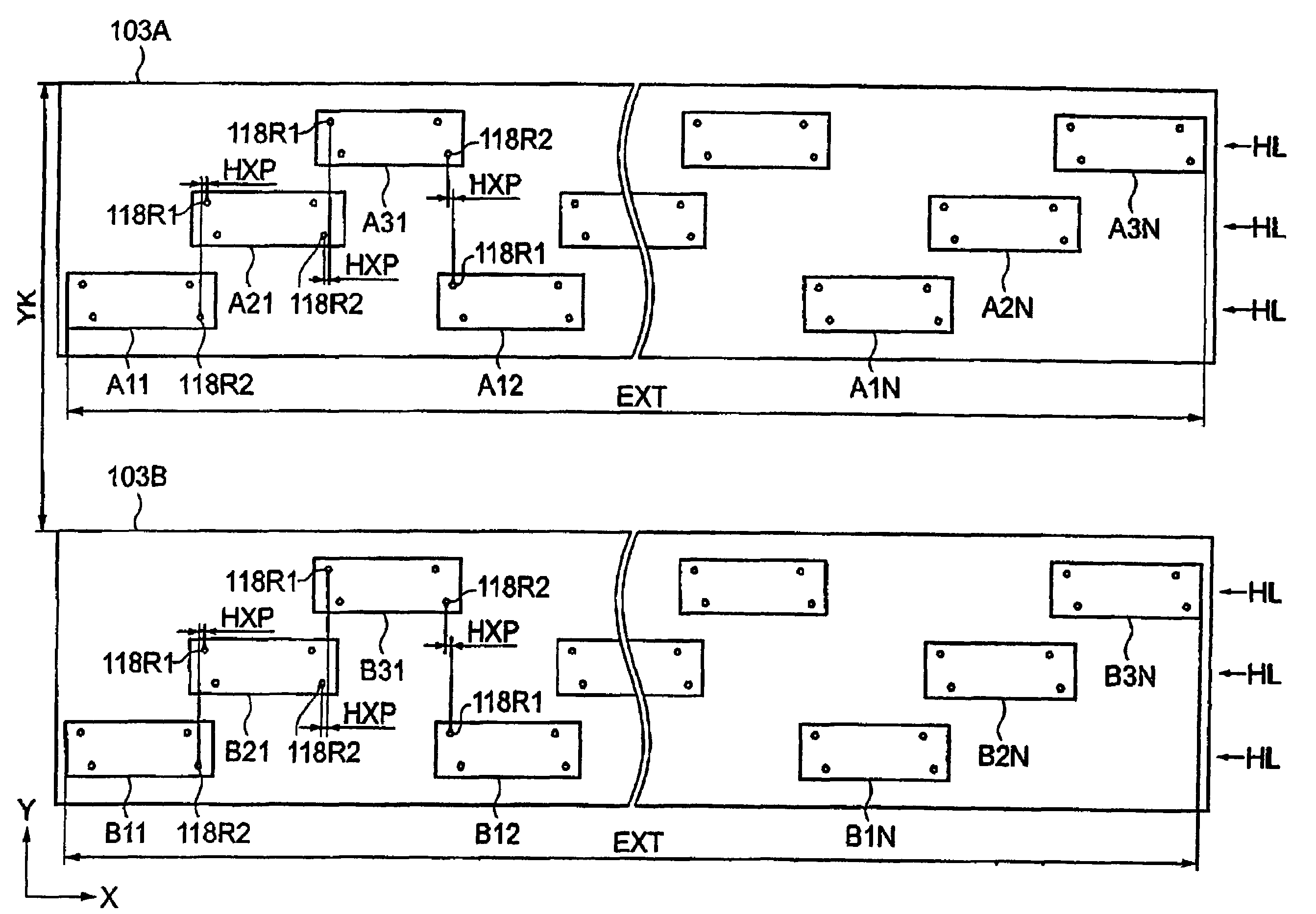

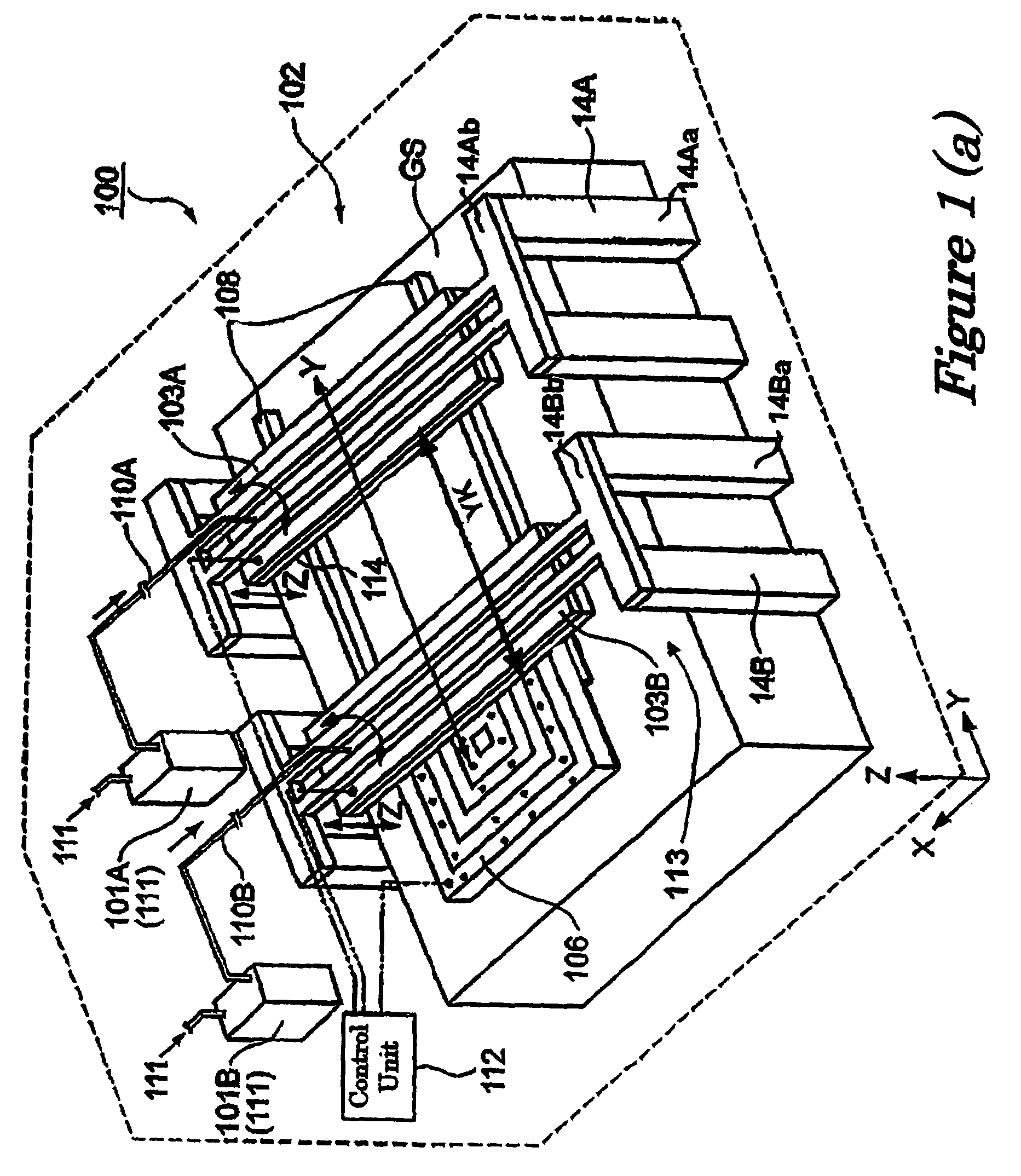

Discharge apparatus, material application method, manufacturing method for color filter substrate, manufacturing method for electroluminescence display apparatus, manufacturing method for plasma display apparatus, and wiring manufacturing method

ActiveUS7350899B2Shorten the timeLiquid surface applicatorsInking apparatusEngineeringRelative motion

In the discharge apparatus, a stage on which a substrate having target discharge areas is placed moves relative to a discharge head unit. When at least one of a plurality of first discharge nozzles of the discharge head unit reaches one of the target discharge areas, the first nozzle discharges a first droplet of fluid material to the target discharge area. When one of a plurality of second nozzles of the discharge head unit reaches the target discharge area to which the first droplet has been discharged, the second nozzle discharges a second droplet of the fluid material to the target discharge area. A first nozzle row of the first nozzles and a second nozzle row of the second nozzles are separated by a predetermined distance in a direction of the relative movement of the stage and the discharge head unit.

Owner:KATEEVA

Methods of Fabricating Display Panel and Flexible Color Filter thereof

ActiveUS20100178832A1Improve processing yieldImprove accuracyCathode ray tubes/electron beam tubesDecorative surface effectsImage resolutionEngineering

Owner:E INK HLDG INC

Photosensitive thick-film paste materials for forming light-transmitting electromagnetic shields, light-transmitting electromagnetic shields formed using the same, and method of manufacture thereof

InactiveCN1620245ASufficient electromagnetic shielding effectExcellent light-transmissionElectric discharge tubesMagnetic/electric field screeningDisplay deviceElectromagnetic shielding

The present invention relates to a light-transmitting electromagnetic shield having an electromagnetic shield that reduces the emission of electromagnetic waves when mounted in front of a display such as a plasma display panel (PDP), cathode ray tube (CRT) or electroluminescent (EL) display performance, with high visible light visibility, low reflectivity to ambient light, and excellent durability.

Owner:EI DU PONT DE NEMOURS & CO

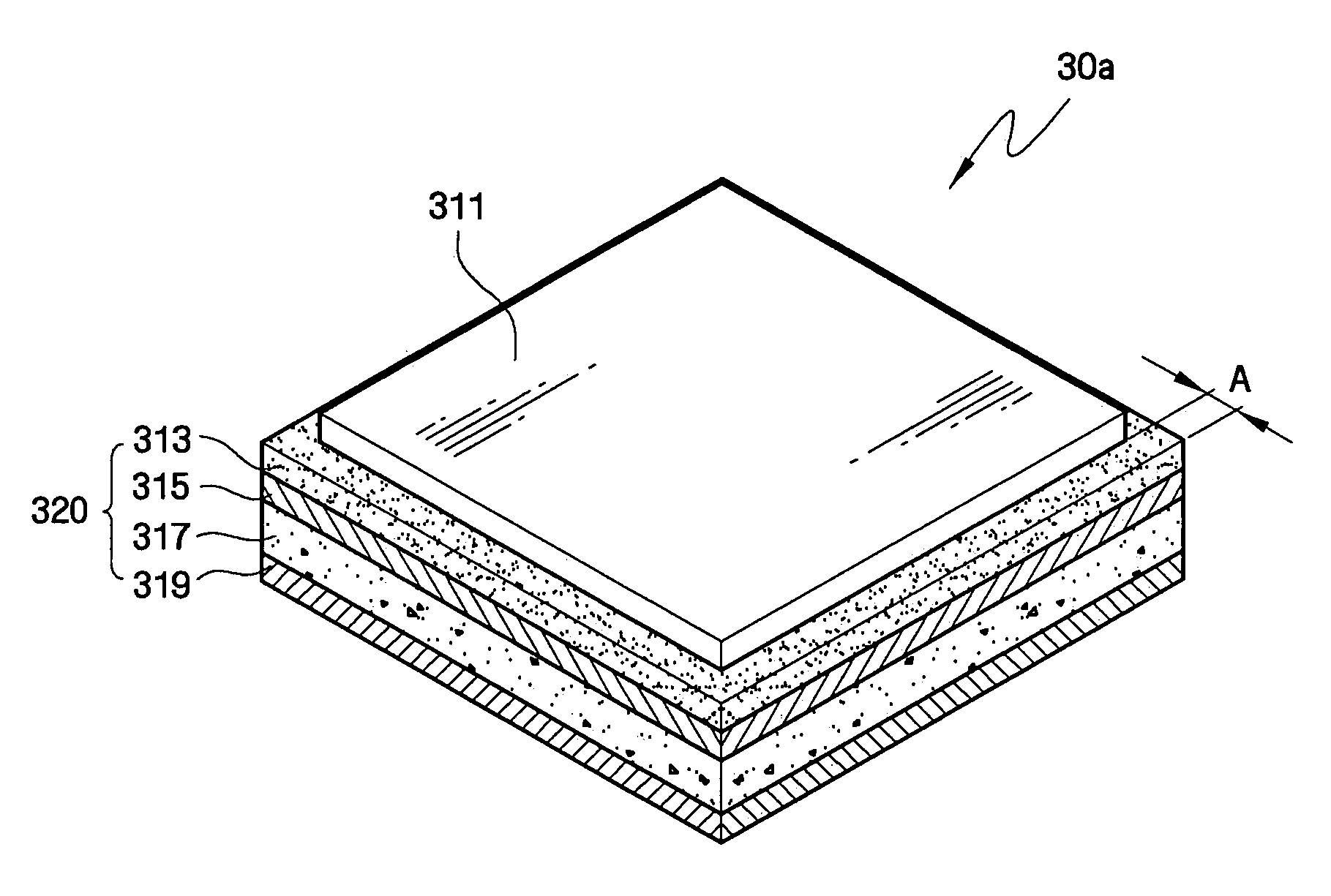

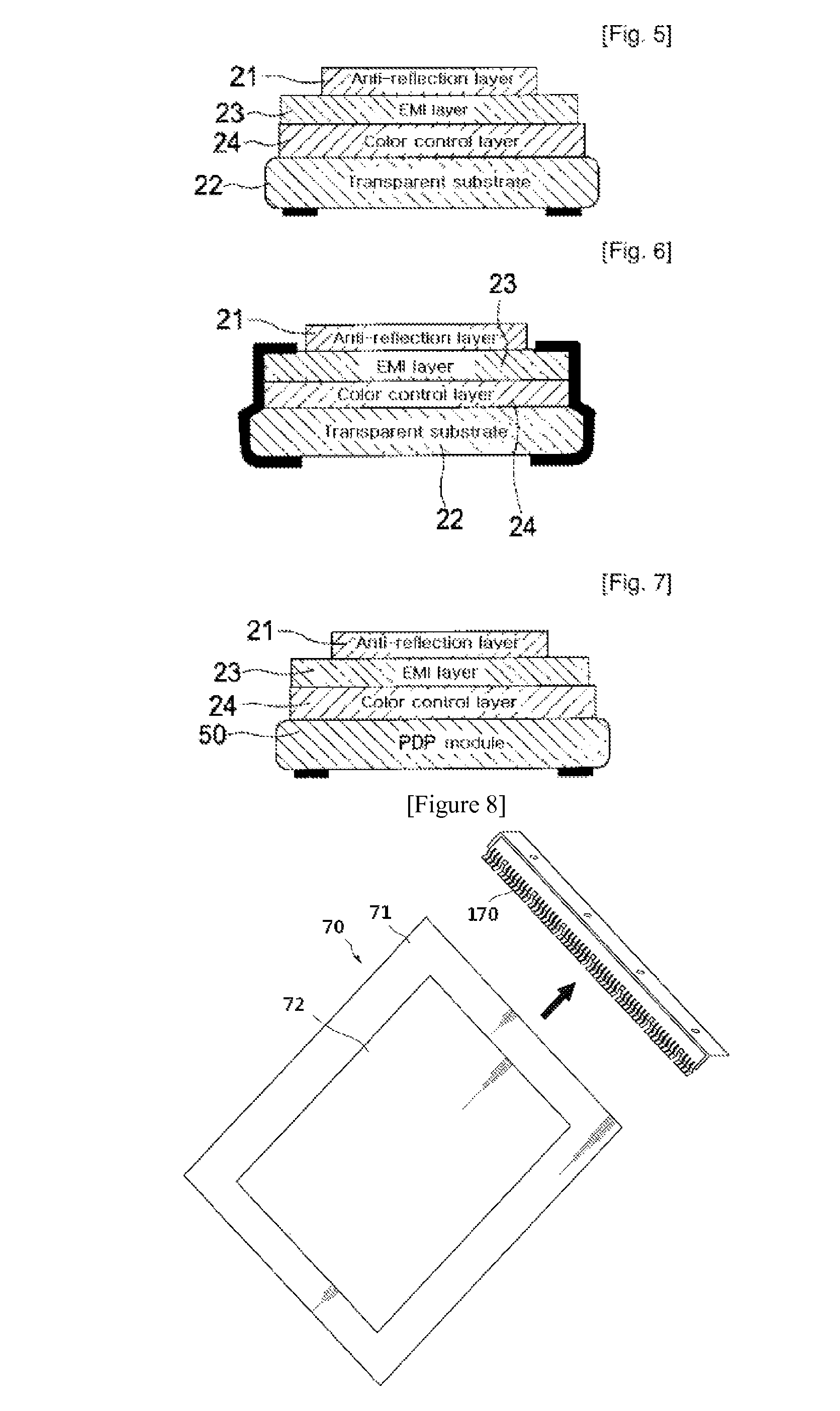

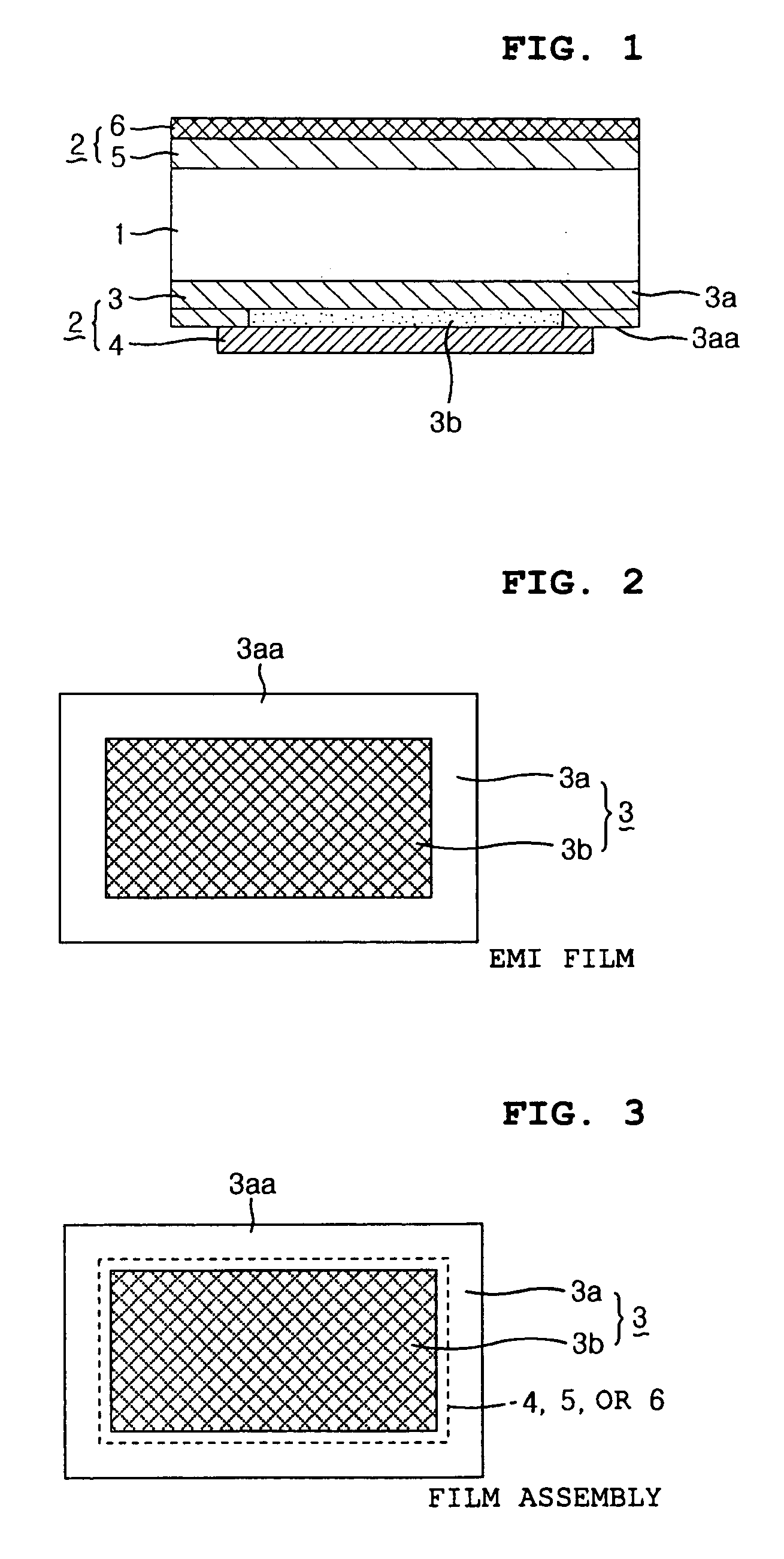

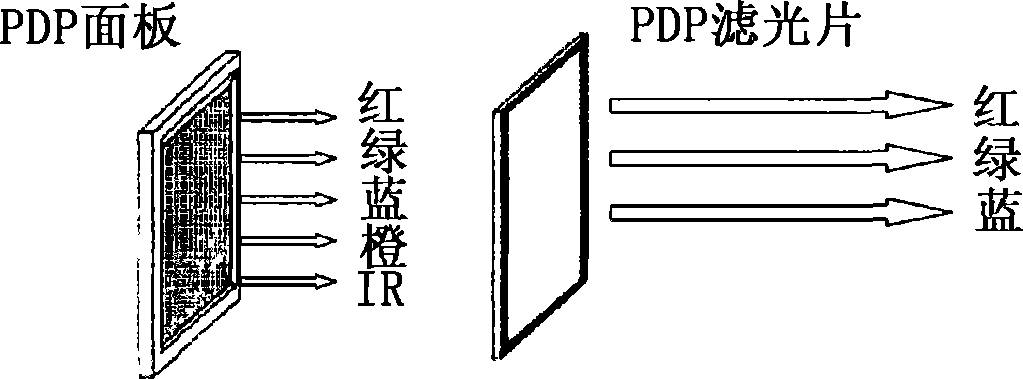

PDP filter and manufacturing method thereof

ActiveUS8004763B2Improve productivityEasy to manufactureMagnetic/electric field screeningOptical filtersEngineeringTransparent conducting film

Disclosed herein is a PDP filter having a laminated structure of a transparent conductive film type electromagnetic wave-shielding layer and one or more other functional layers, in which at least two edge portions of the surface of the transparent conductive film type electromagnetic wave-shielding layer, which is in contact with the functional layer, are not exposed outside the laminated structure of the PDP filter.

Owner:LG CHEM LTD

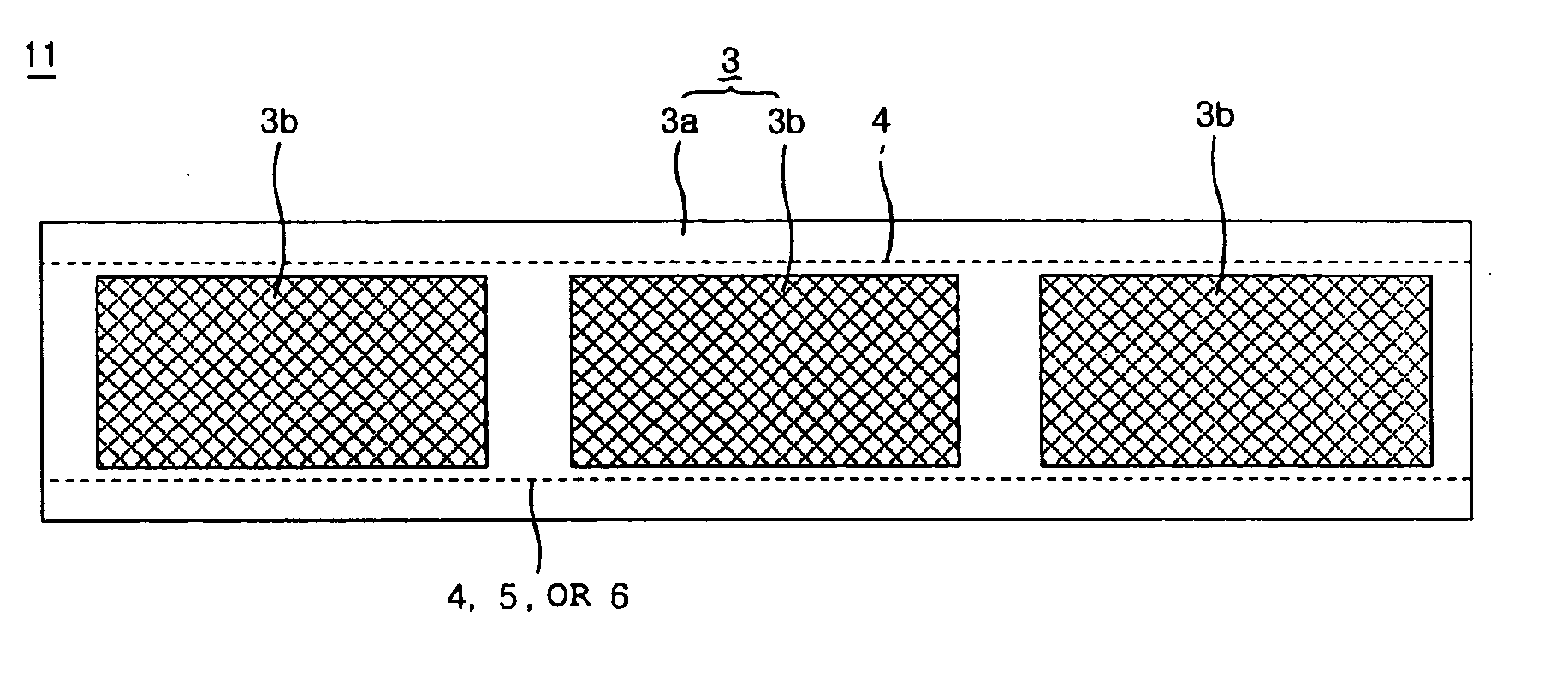

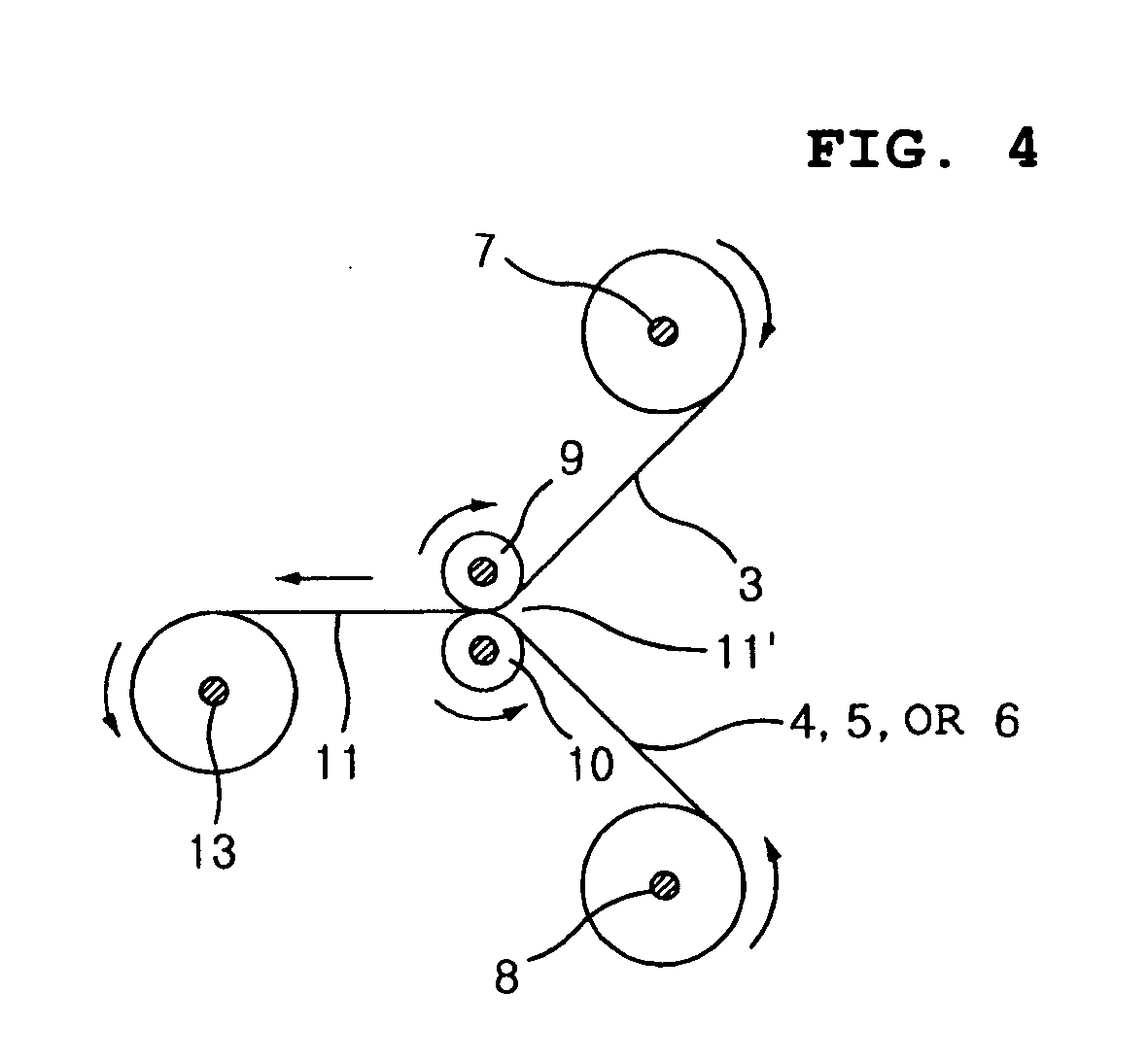

Method for making film assembly used in PDP filter, film assembly manufactured by the method, and PDP filter with the film assembly

ActiveUS20050162056A1Incadescent screens/filtersMagnetic/electric field screeningPolymer resinEngineering

Disclosed is a method for making a film assembly used in a PDP filter positioned on the front surface of a PDP, a film assembly manufactured by the method, and a PDP filter using the film assembly. The method includes providing a roll of an EMI film formed on a surface of a long transparent polymer resin film with a predetermined spacing and mounting the wound roll of the EMI film on a first feed roller; providing a roll of at least one long transparent functional film capable of covering at least partially the effective screen portions of the EMI film and mounting the wound roll of the functional film on a second feed roller which is spaced a predetermined distance from the first feed roller; and integrating the EMI film with the functional film by feeding them into a gap between the first and second compression rollers.

Owner:LG CHEM LTD

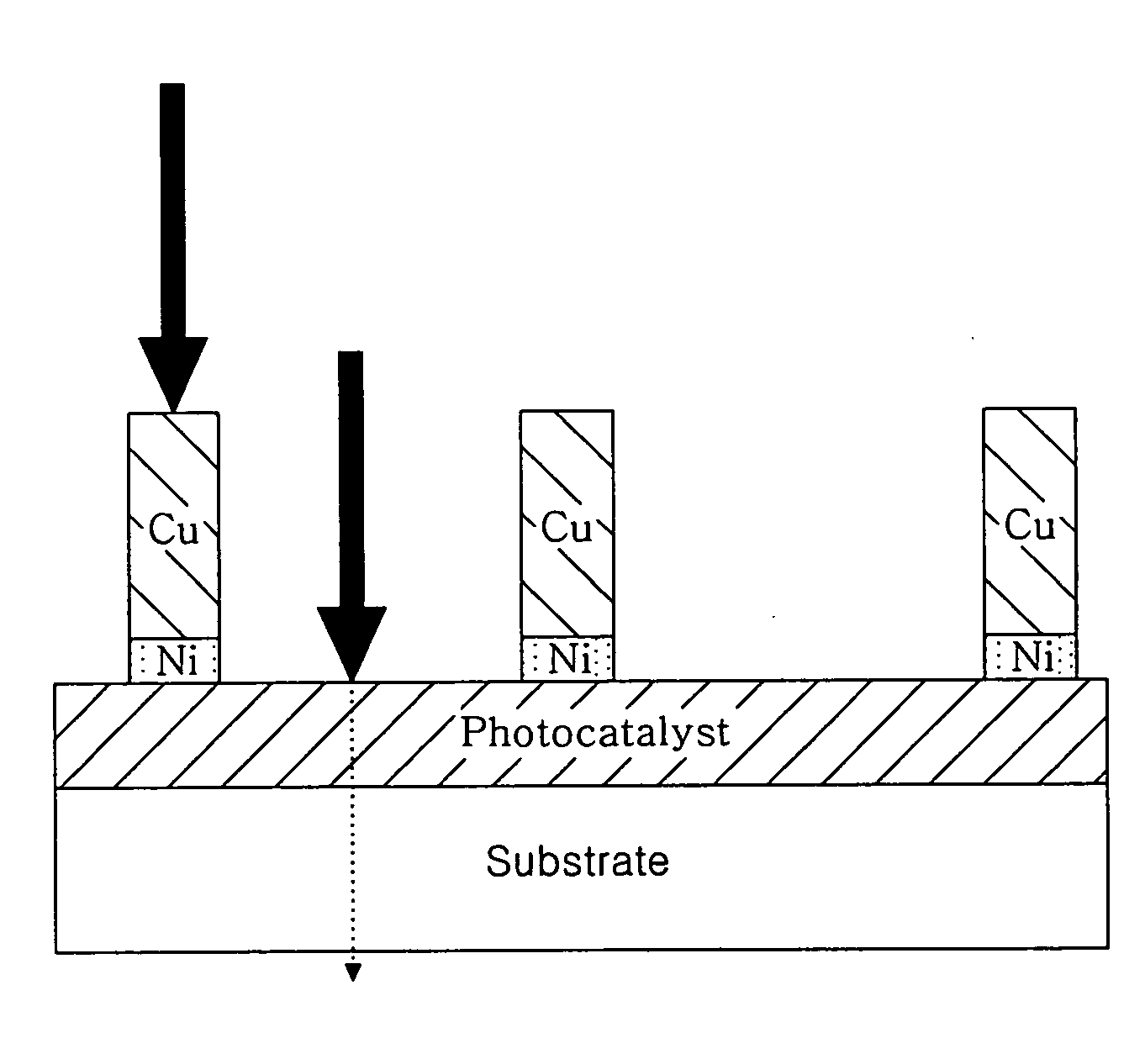

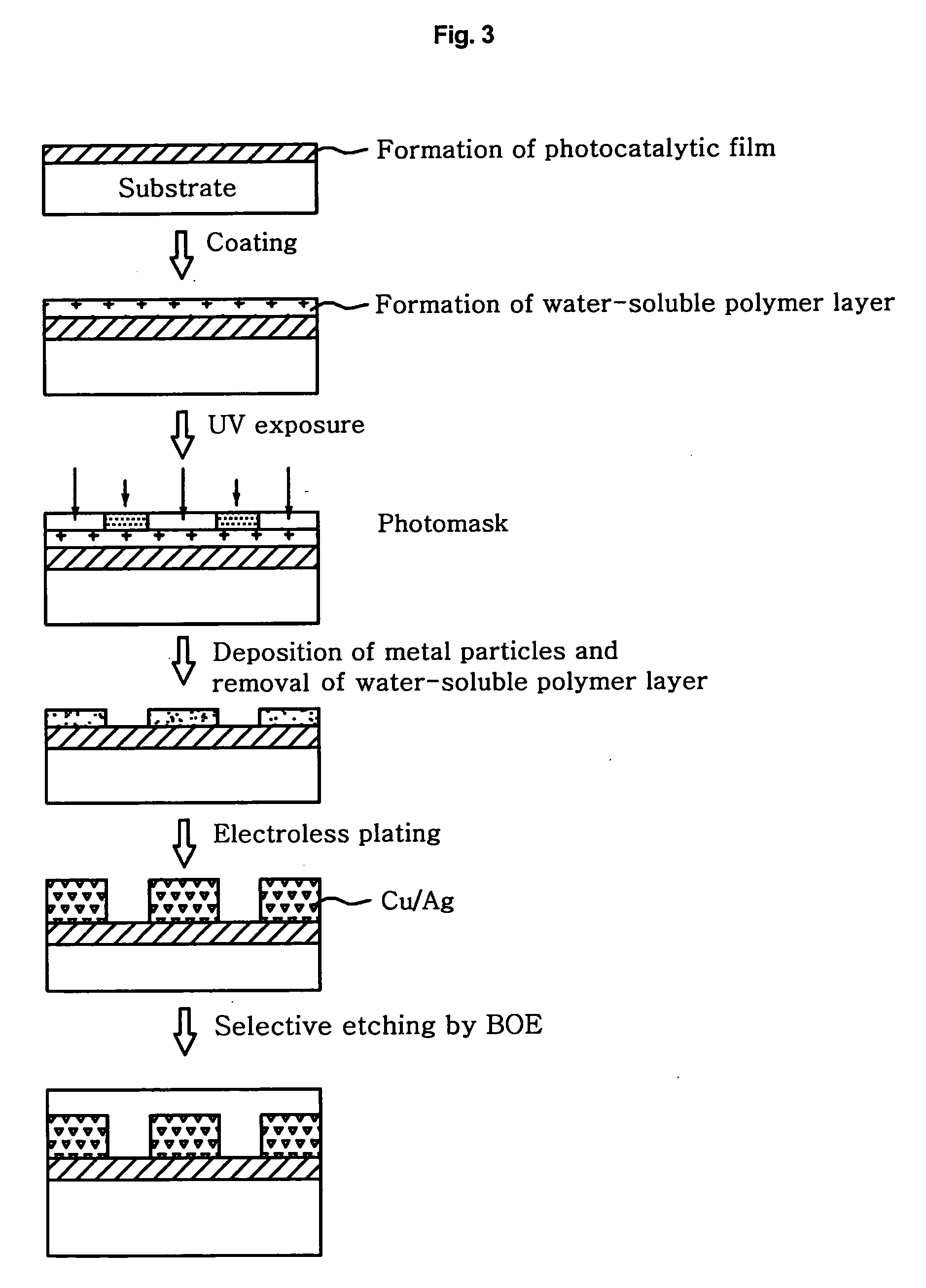

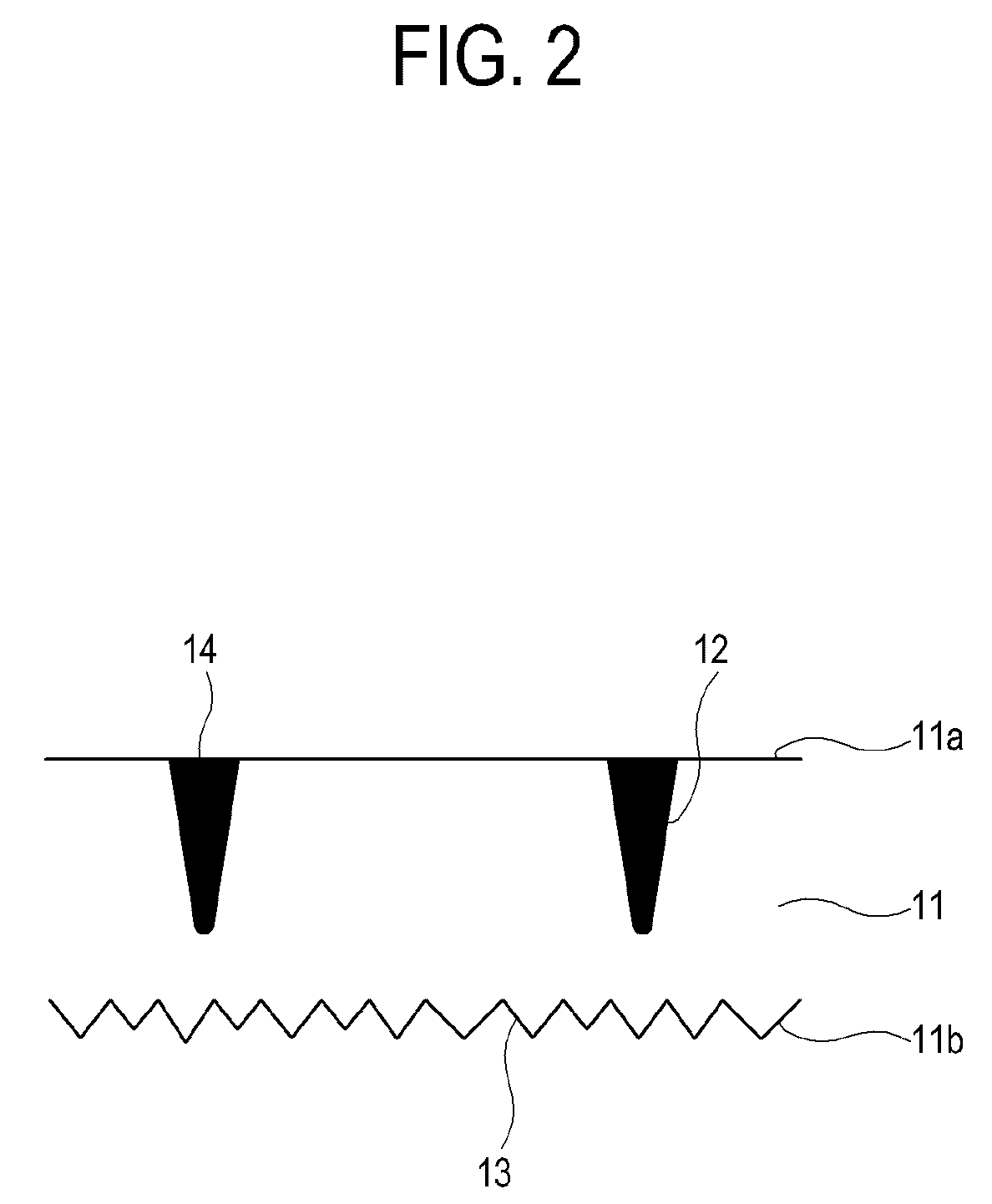

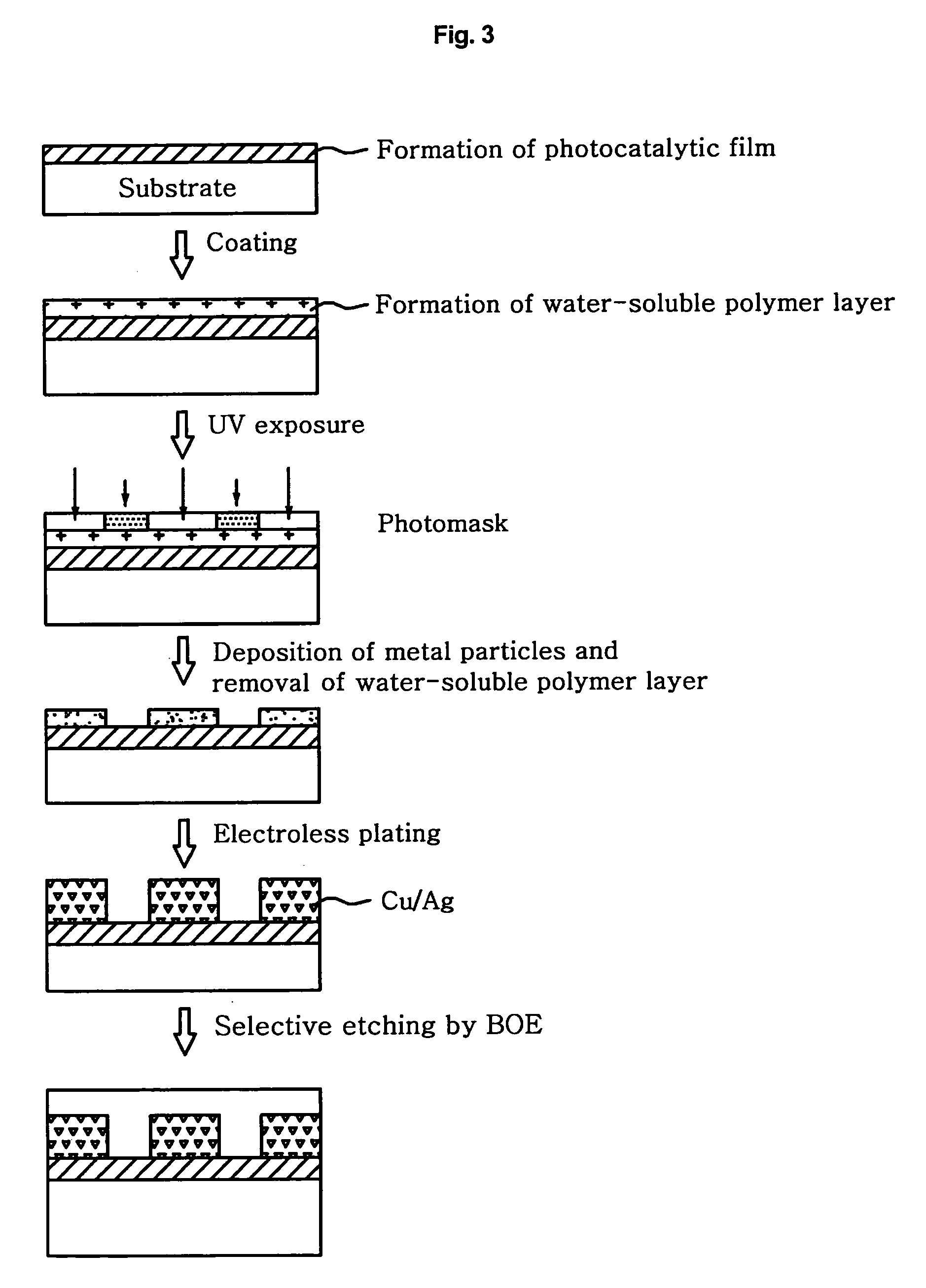

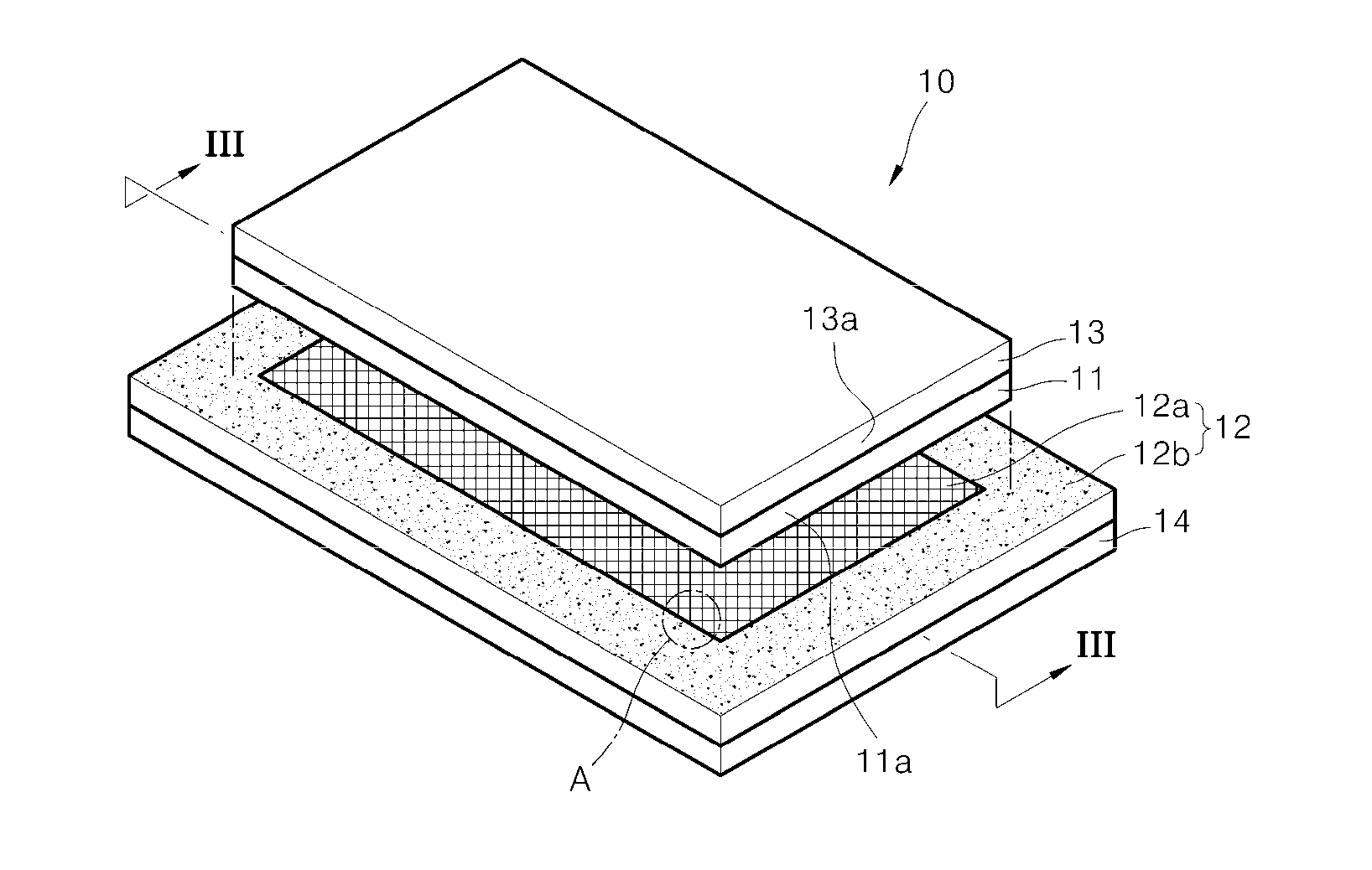

Method for manufacturing high-transmittance optical filter for image display devices

InactiveUS20060127818A1High light transmittanceGood effectMagnetic/electric field screeningPretreated surfacesImage resolutionDisplay device

A method for manufacturing a high-transmittance optical filter for image display devices, which may include the steps of coating a photocatalytic compound on a transparent substrate to form a photocatalytic film, selectively exposing the photocatalytic film to light and growing a metal crystal thereon by plating to form a metal pattern, and selectively etching and removing the photocatalytic compound remaining on the transparent substrate using a buffered oxide etchant (BOE). According to the method, a high-transmittance, high-resolution and low-resistivity optical filter can be manufactured in a simple manner at low costs.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

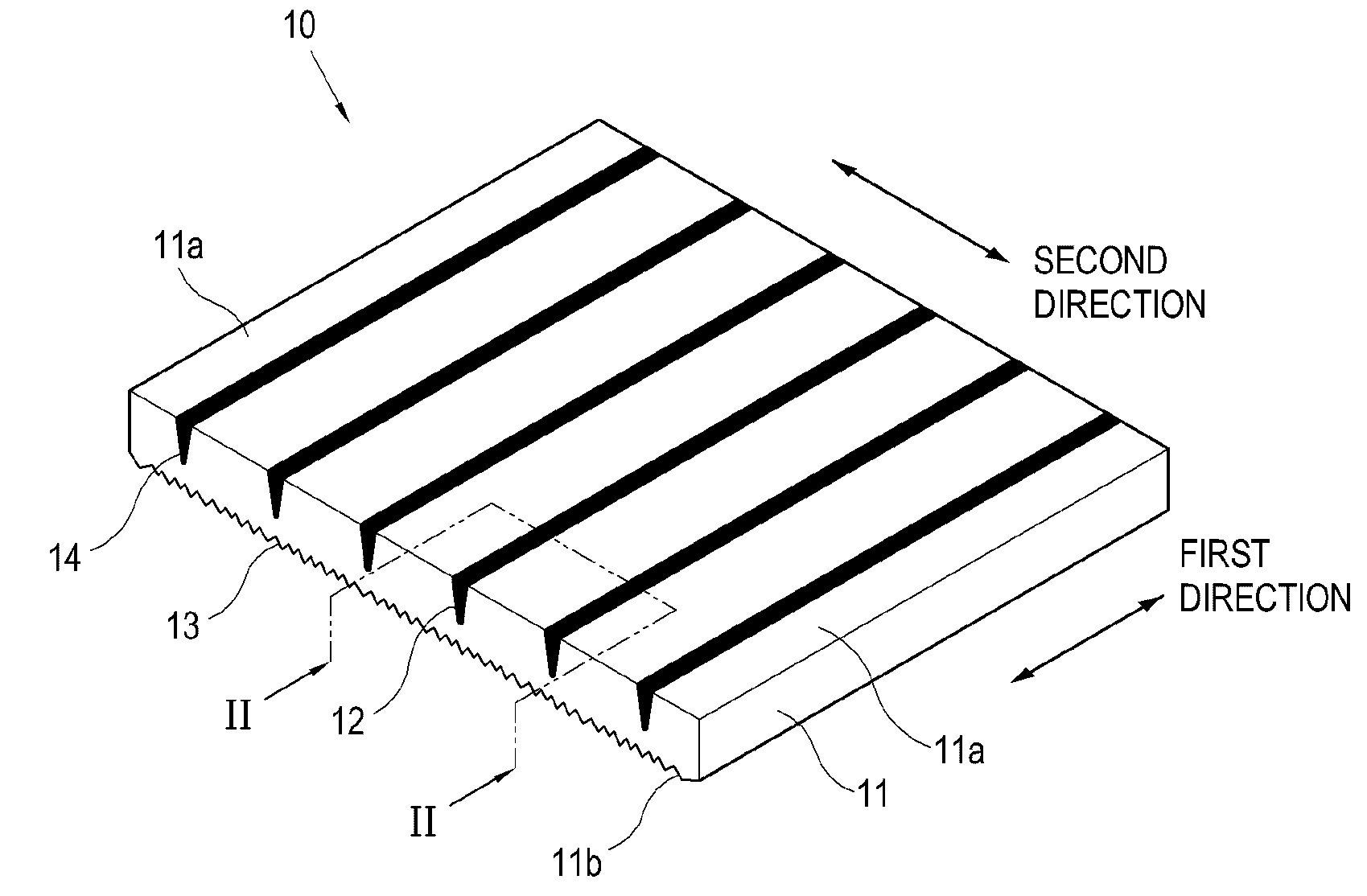

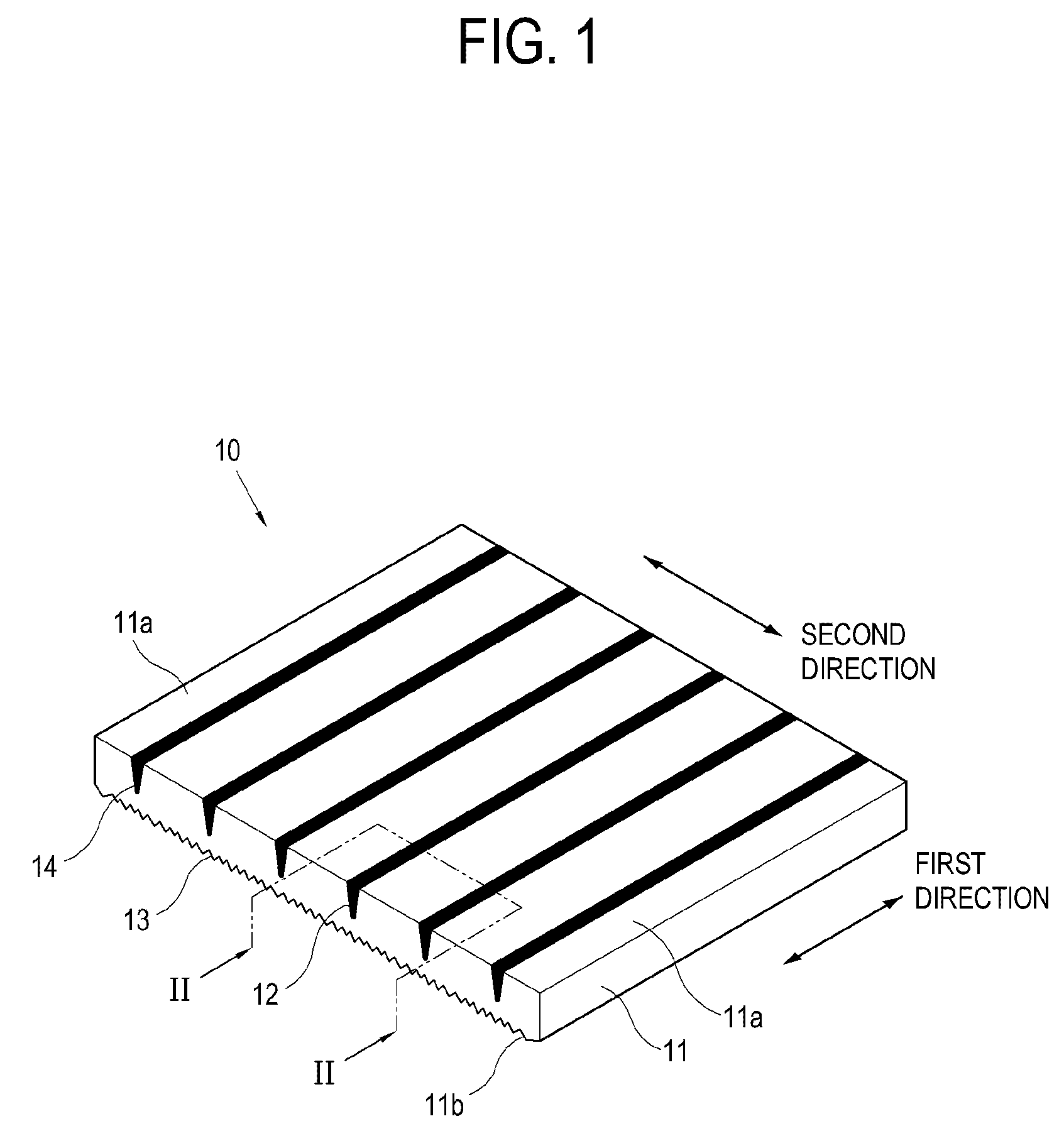

Optical film, manufacturing method of the same, and display device having the optical film

InactiveUS20090059379A1Simple manufacturing methodLow production costOptical filtersAlternating current plasma display panelsDisplay deviceEngineering

An optical film includes: a film body having a first surface formed with a groove pattern and a second surface formed with a bump pattern, which are formed in a single body; and a light absorption member formed inside the groove pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for manufacturing high-transmittance optical filter for image display devices

InactiveUS7205098B2Good effectHigh light transmittanceMagnetic/electric field screeningOptical filtersImage resolutionDisplay device

A method for manufacturing a high-transmittance optical filter for image display devices, which may include the steps of coating a photocatalytic compound on a transparent substrate to form a photocatalytic film, selectively exposing the photocatalytic film to light and growing a metal crystal thereon by plating to form a metal pattern, and selectively etching and removing the photocatalytic compound remaining on the transparent substrate using a buffered oxide etchant (BOE). According to the method, a high-transmittance, high-resolution and low-resistivity optical filter can be manufactured in a simple manner at low costs.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

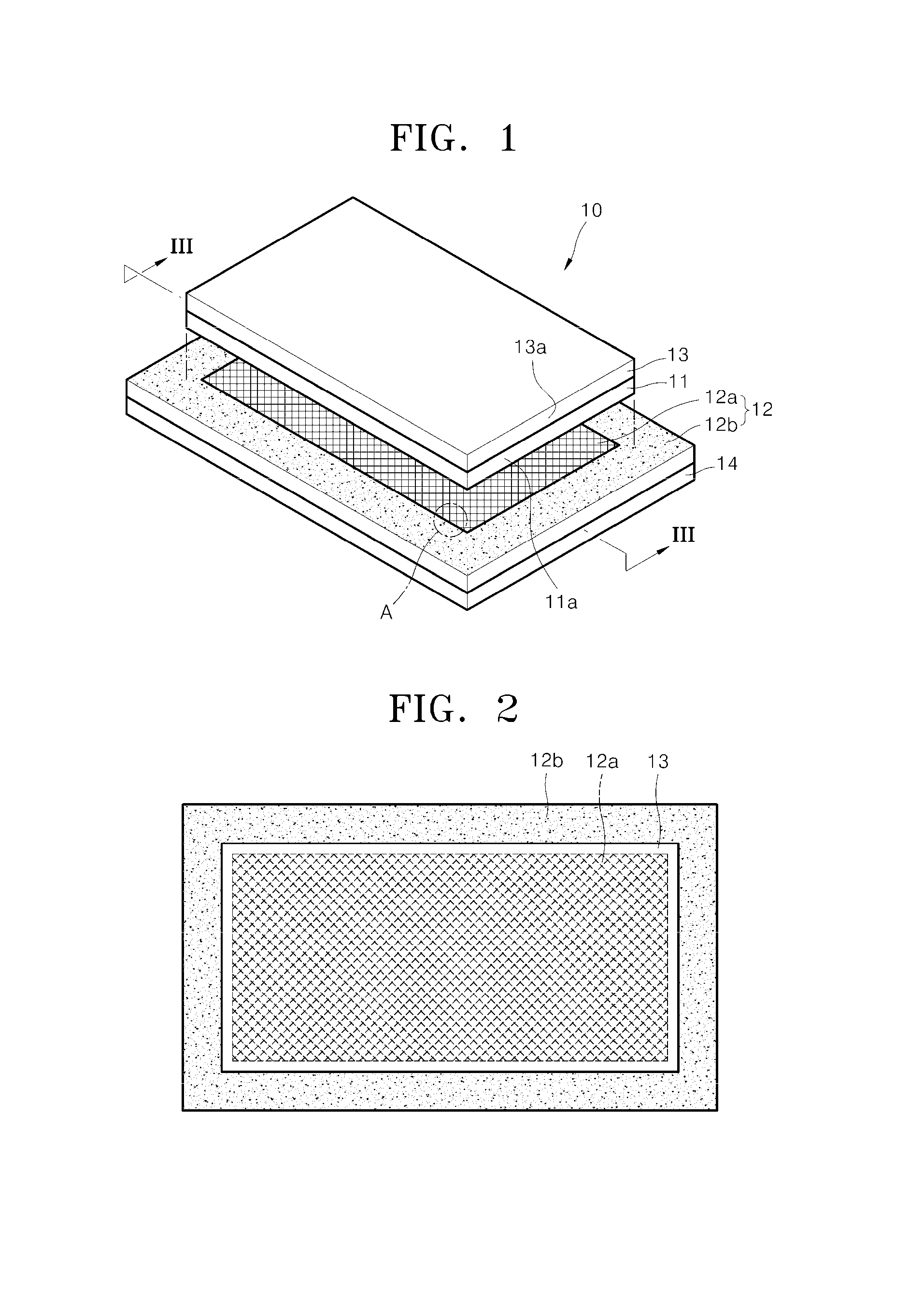

Film-type filter, plasma display apparatus comprising the film-type filter, and method of manufacturing the plasma display apparatus

InactiveUS20080297021A1Increase surface areaIncadescent screens/filtersMagnetic/electric field screeningLight reflectionEngineering

A film-type filter, a plasma display apparatus comprising the film-type filter, and a method of manufacturing the plasma display apparatus. The film-type filter includes: a base film, an external light reflection reduction layer disposed on a first side of the base film, and an electromagnetic wave shielding layer disposed on an opposing second side of the base film, which comprises an electromagnetic wave shielding unit and a grounding unit surrounding the electromagnetic wave shielding unit. At least a portion of the grounding unit is exposed, and extends around side surfaces of the external light reflection reduction layer and the base film. Portions of the external light reflection reduction layer and the base film are removed at a cutting line, to expose the grounding unit.

Owner:SAMSUNG SDI CO LTD

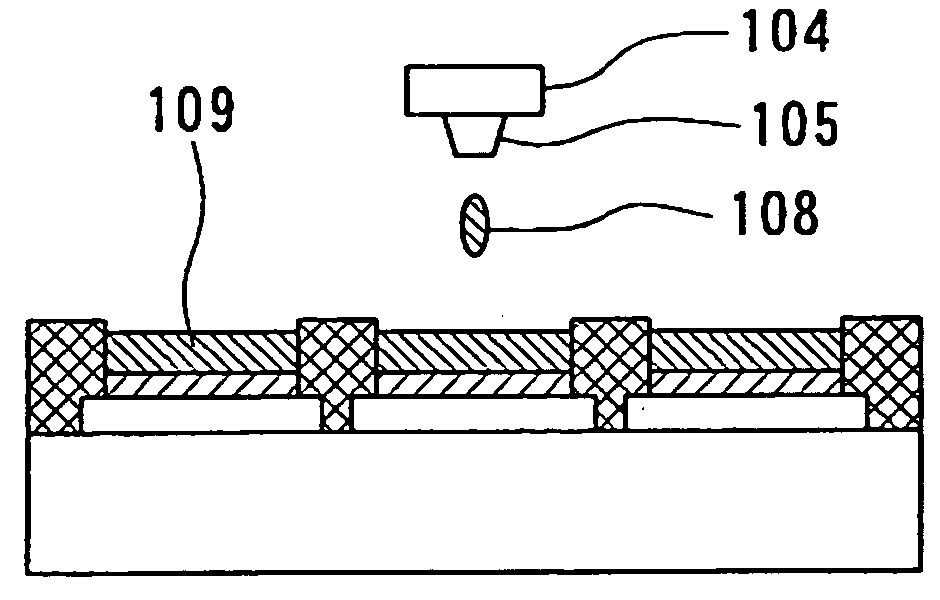

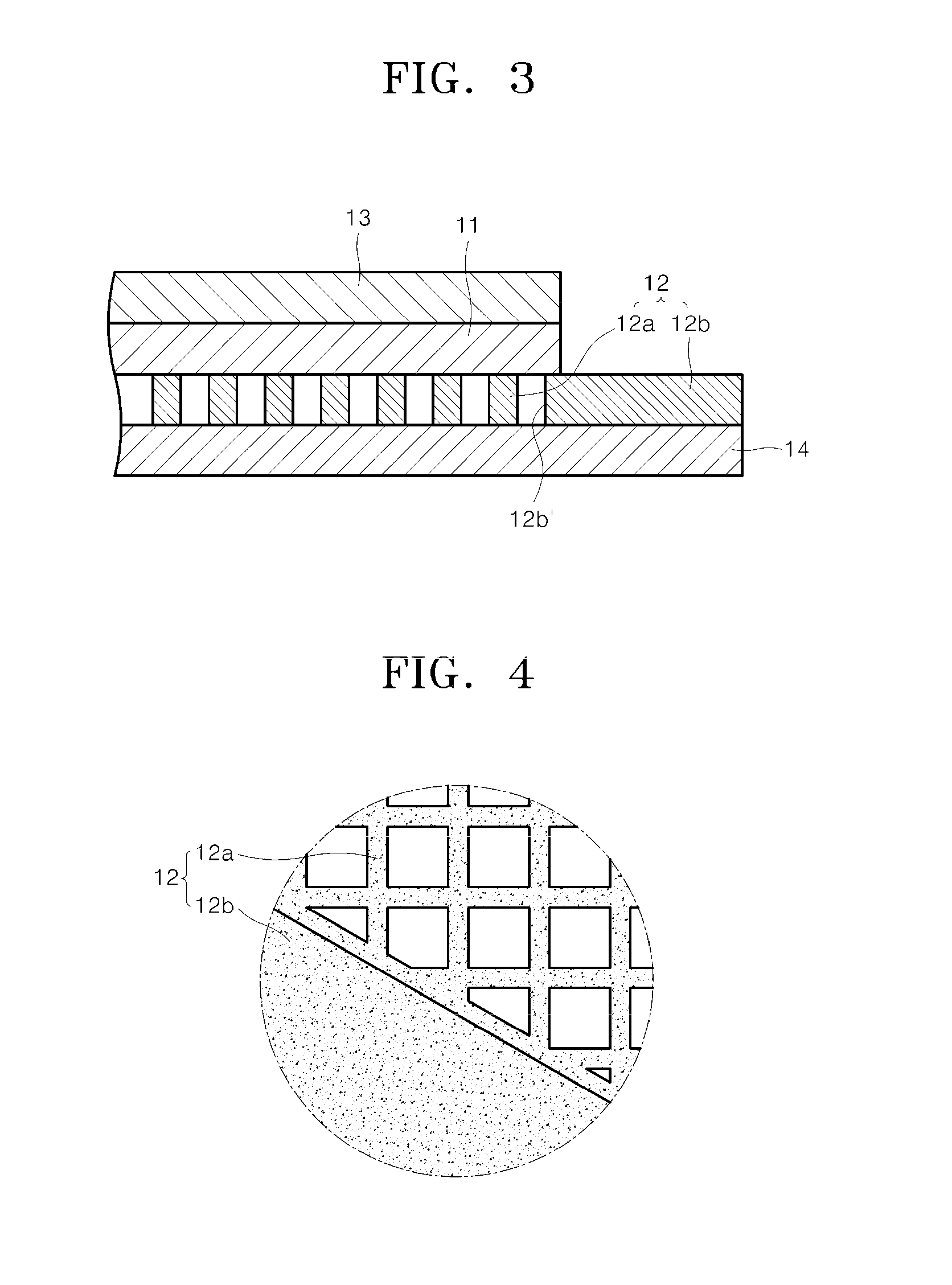

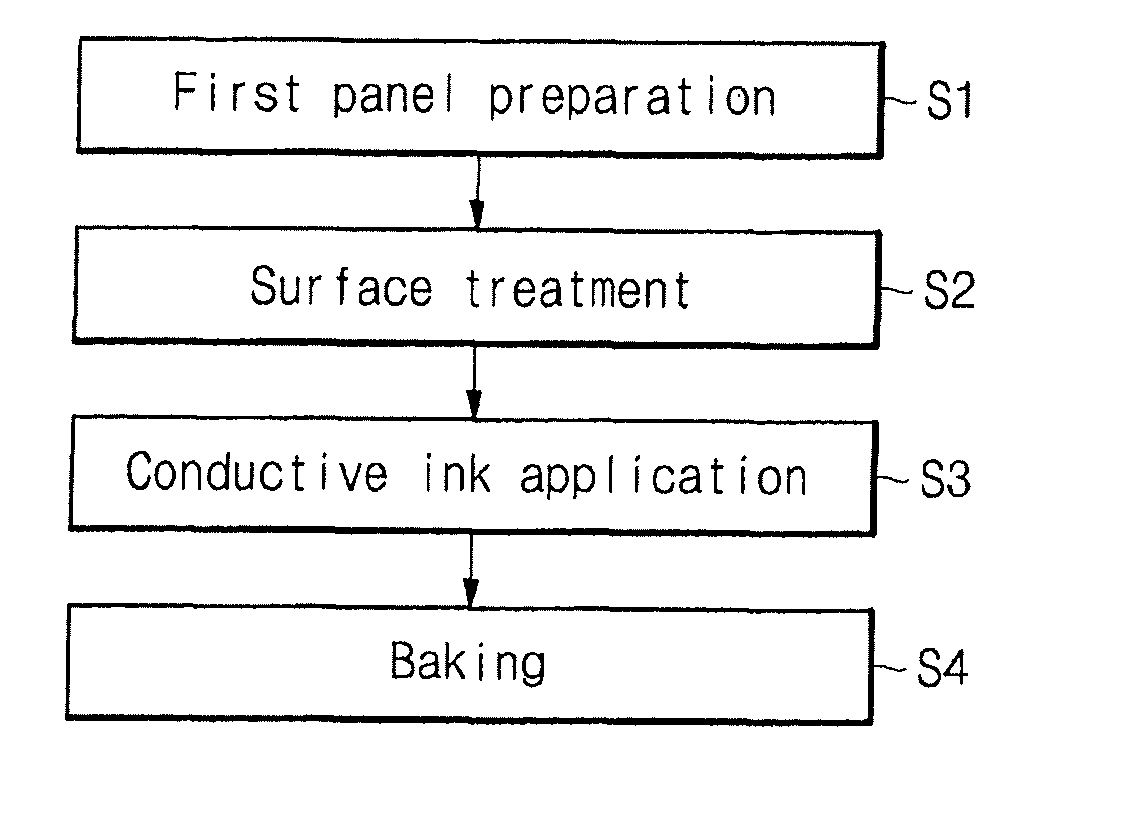

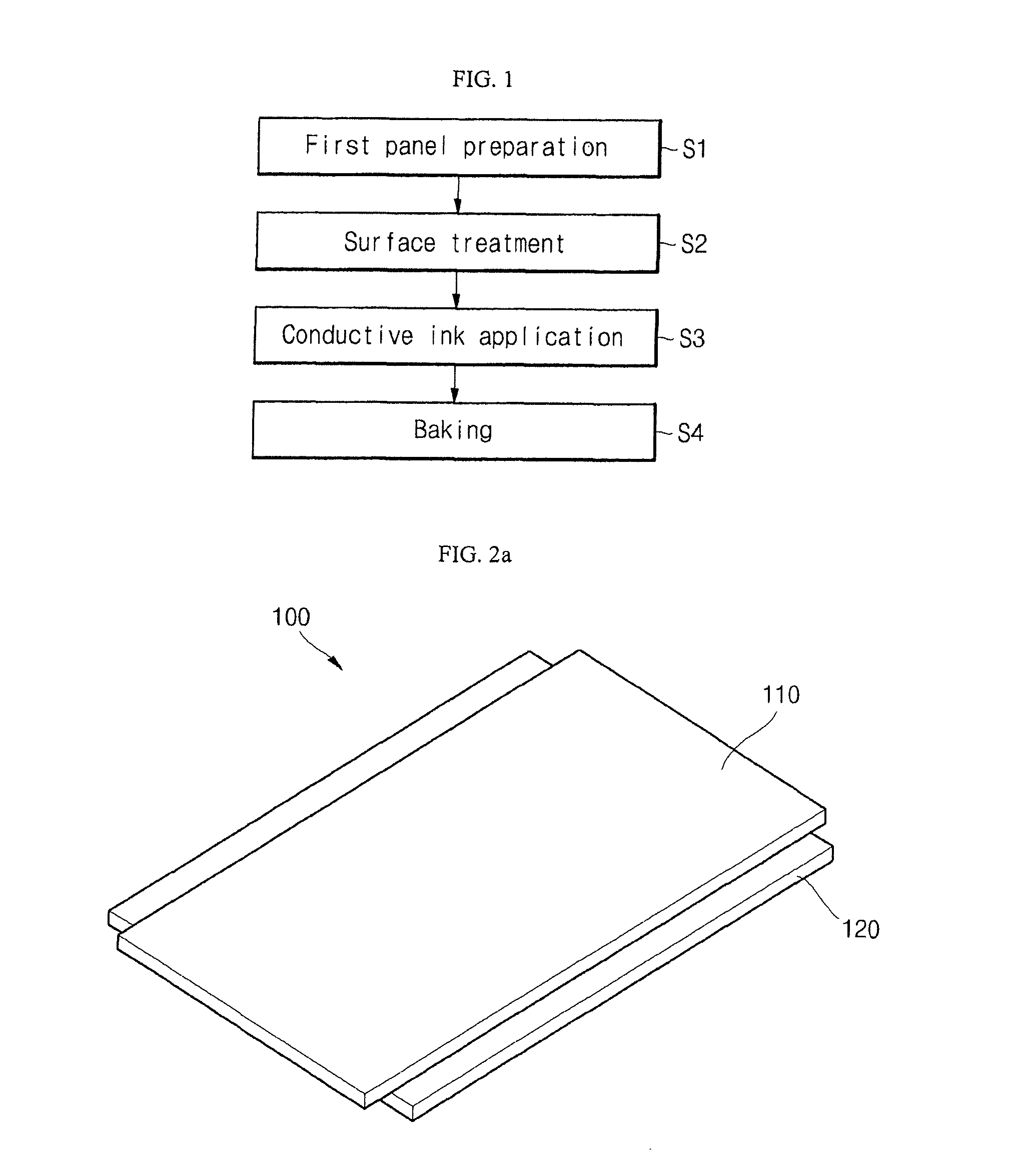

Method of manufacturing electromagnetic interference (EMI) shielding filter for plasma display panel and EMI shielding filter for plasma display panel using the same

InactiveUS20100164354A1Easy to produceLow production costControl electrodesStatic indicating devicesElectromagnetic interferenceEngineering

A method of manufacturing an electromagnetic wave shield for a plasma display panel having a first panel having an image-displaying surface, the method including coating the image-displaying surface of the first panel with a coating solution to form a hydrophobic layer; applying a conductive ink to the hydrophobic layer utilizing an ink-jet applicator to form a pattern of the conductive ink; and heating the conductive ink and the hydrophobic layer to form a conductive mesh pattern on the hydrophobic layer.

Owner:SAMSUNG SDI CO LTD

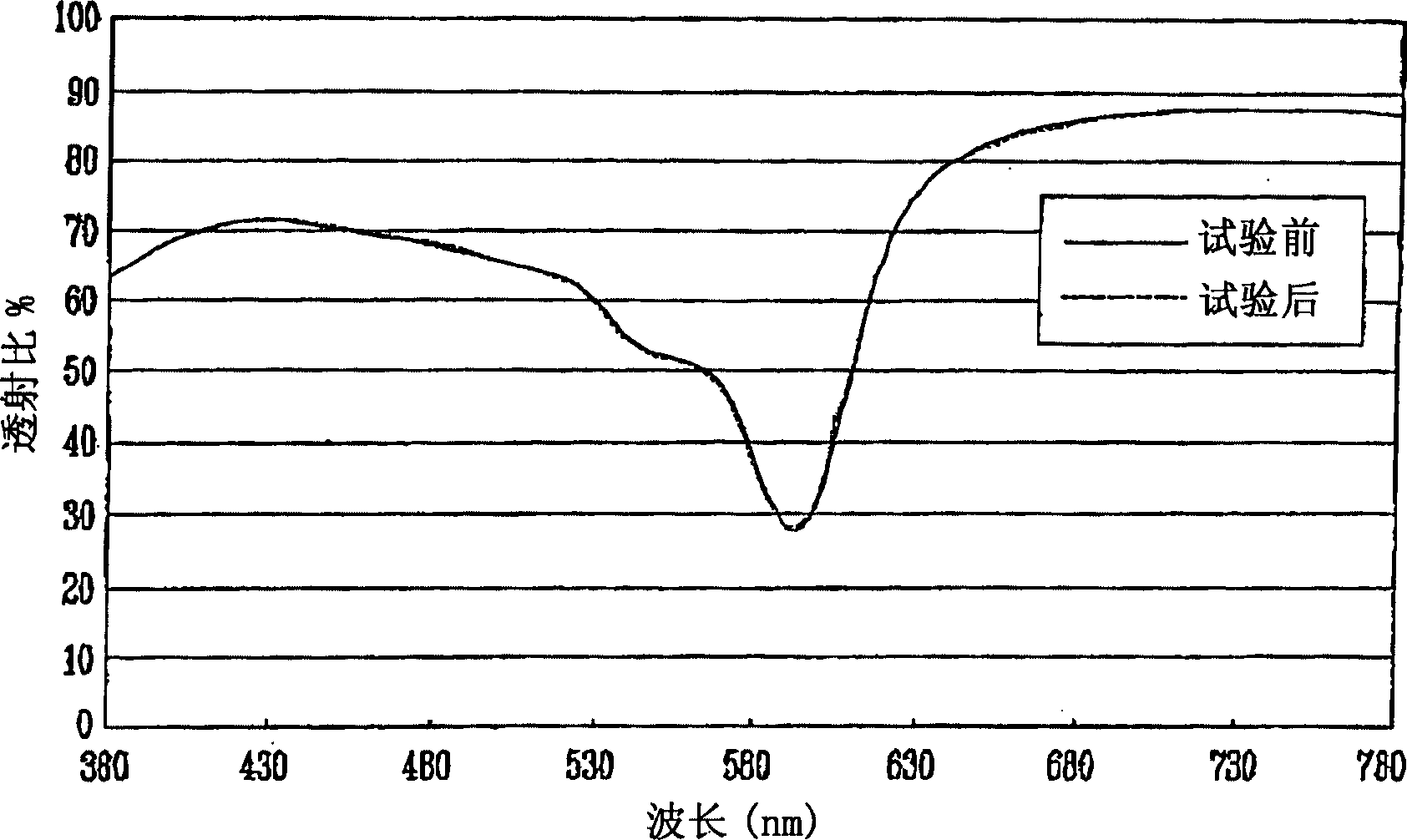

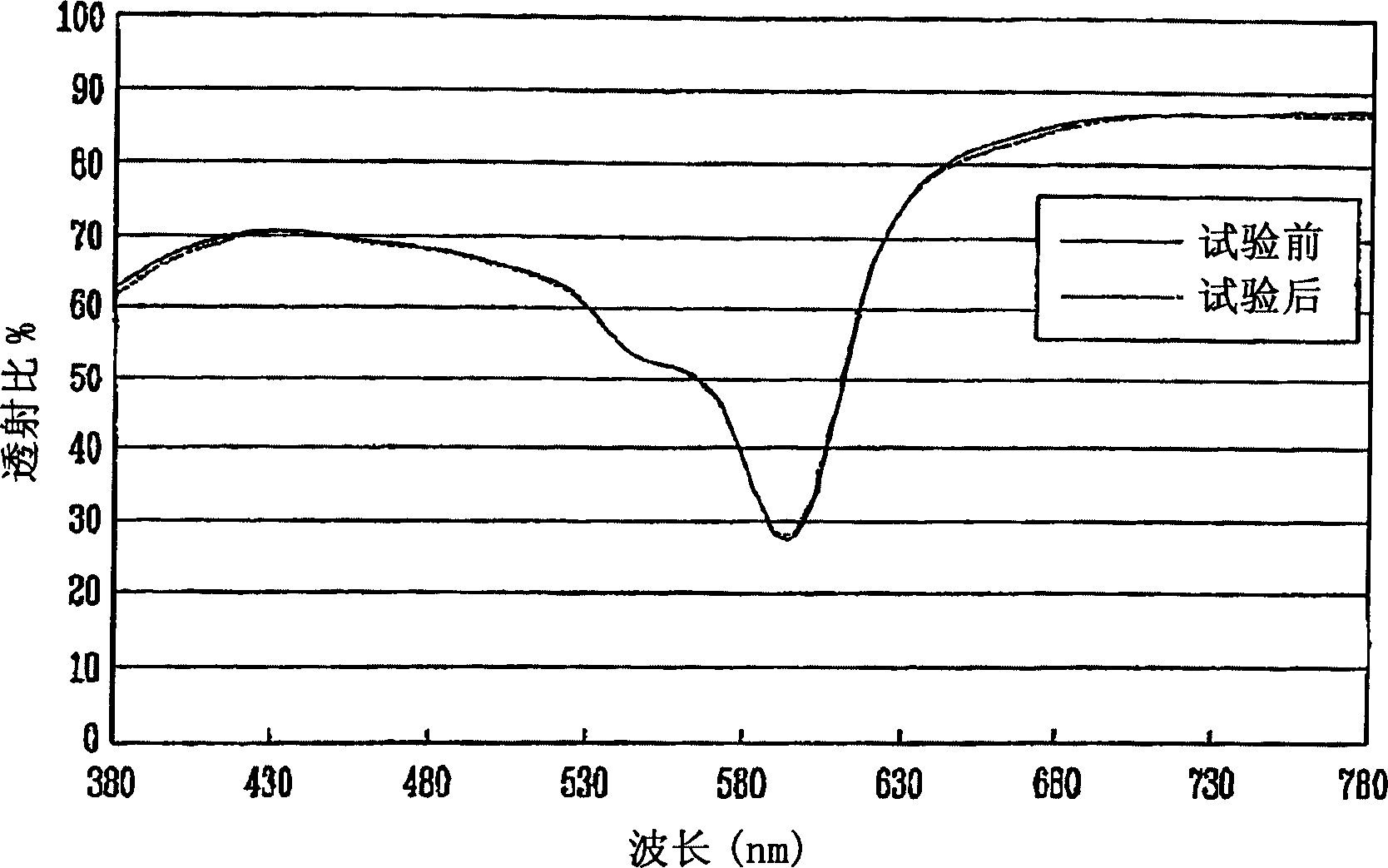

Film for PDP filter, PDP filter comprising the same and plasma display panel produced by using the PDP filter

InactiveCN1910723AReduce pollutionNo need to removeOptical/shielding coatings applicationCold-cathode tubesHigh humidityOrganic solvent

A film for a PDP filter including a binder resin composed of a styrene-acrylonitrile (SAN) copolymer, and a dye selected from the group consisting of a near infrared ray (NIR) absorbing dye, a Neon cut dye, a color control dye, and a mixture thereof is provided. The film for a PDP filter includes the SAN copolymer as a binder resin, and thus a change in transmittance is little under a high-temperature condition or a high-temperature and high-humidity condition, resulting in good durability and thermal stability and high transmittance in a visible light range. Further, since a general organic solvent can be used in the formation of the film, environmental pollution is reduced and the removal of a poisonous solvent is not required, thereby simplifying a process of forming the film.

Owner:LG CHEM LTD

Method for producing light-transmitting electromagnetic wave-shielding film, light-transmitting electromagnetic wave-shielding film and plasma display panel using the shielding film

InactiveUS20080176173A1Improve electromagnetic interference shielding effectLow costCathode-ray/electron-beam tube vessels/containersMagnetic/electric field screeningFine lineMetal particle

A silver salt-containing layer containing a silver salt and provided on a support is exposed and developed to form a metal silver portion and a light-transmitting portion, and then the metal silver portion is further subjected to physical development and / or plating to form a conductive metal portion consisting of the metal silver portion carrying conductive metal particles. A method for producing a light-transmitting electromagnetic wave-shielding film which enables production of an electromagnetic wave-shielding material simultaneously having high EMI-shielding property and high transparency in a fine line pattern and also enables mass production of such films at a low cost, and a light-transmitting electromagnetic wave-shielding film obtained by the production method and free from the problem of moire are provided.

Owner:FUJIFILM CORP

Discharge apparatus, material application method, manufacturing method for color filter substrate, manufacturing method for electroluminescence display apparatus, manufacturing method for plasma display apparatus, and wiring manufacturing method

ActiveUS20050156978A1Shorten the timeInking apparatusLiquid surface applicatorsEngineeringPlasma display

In the discharge apparatus, a stage on which a substrate having target discharge areas is placed moves relative to a discharge head unit. When at least one of a plurality of first discharge nozzles of the discharge head unit reaches one of the target discharge areas, the first nozzle discharges a first droplet of fluid material to the target discharge area. When one of a plurality of second nozzles of the discharge head unit reaches the target discharge area to which the first droplet has been discharged, the second nozzle discharges a second droplet of the fluid material to the target discharge area. A first nozzle row of the first nozzles and a second nozzle row of the second nozzles are separated by a predetermined distance in a direction of the relative movement of the stage and the discharge head unit.

Owner:KATEEVA

Plasma display apparatus and method of manufacturing the same

InactiveUS20070210711A1Television system detailsMagnetic/electric field screeningElectromagnetic interferenceEngineering

A plasma display apparatus and a method of manufacturing the same are disclosed. The plasma display apparatus includes a plasma display panel, an electromagnetic interference (EMI) shielding layer positioned on the plasma display panel, and a filter positioned on the EMI shielding layer. The filter includes an adhesive layer positioned on the EMI shielding layer and a base film layer positioned on the adhesive layer.

Owner:LG ELECTRONICS INC

Adhesive film functionalizing color compensation and near infrared ray (nir) blocking and plasma display panel filter using the same

The present invention relates to an adhesive film functionalizing color compensation and near infrared ray blocking and a plasma display panel filter employing the same. The present invention provides a multifunctional adhesive film for a plasma display panel comprising an acryl-based adhesive and a near infrared ray blocking dye. The present invention also provides a multifunctional adhesive film for a plasma display panel comprising an acryl-based adhesive and a neon-cut dye. The adhesive film may further comprise a near infrared ray blocking dye. The multifunctional adhesive film of the present invention has superior durability at high temperature and humidity with little transmittance change and superior thermal stability. When further comprising a near infrared ray blocking dye, it exerts both color compensation and near infrared ray blocking performances. Because the film has superior adhesivity in itself, an additional adhesive layer is unnecessary, which simplifies the manufacturing process of a plasma display panel filter and a plasma display panel.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com