Adhesive film functionalizing color compensation and near infrared ray (nir) blocking and plasma display panel filter using the same

A display panel, near-infrared technology, applied in film/sheet adhesive, optical/shielding coating applications, instruments, etc., can solve unsatisfactory durability, dye reduction, and no near-infrared absorption Membrane near-infrared blocking efficacy and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Membrane Preparation Including Near Infrared Blocking Dyes

[0077] The butyl acrylate (BA) / hydroxyethyl methacrylate (HEMA) copolymer solution of 100 parts by weight (15.5wt%) is dissolved in the ethyl acetate of 84.5ml, and 0.05 parts by weight of chemical formula 4 is represented as nearly Diimonium dye (CIR1081, JapanCarlit Co.) of infrared ray retarding dye, 0.05 parts by weight of T-39M as an isocyanate crosslinking agent, and 0.07 parts by weight of T-789J as a silane coupling agent were added to 45 parts by weight of methyl ethyl ketone (MEK), and then mixed to obtain a coating solution. The coating solution was applied onto the base film to a thickness of 23 μm, thereby obtaining a multifunctional adhesive film.

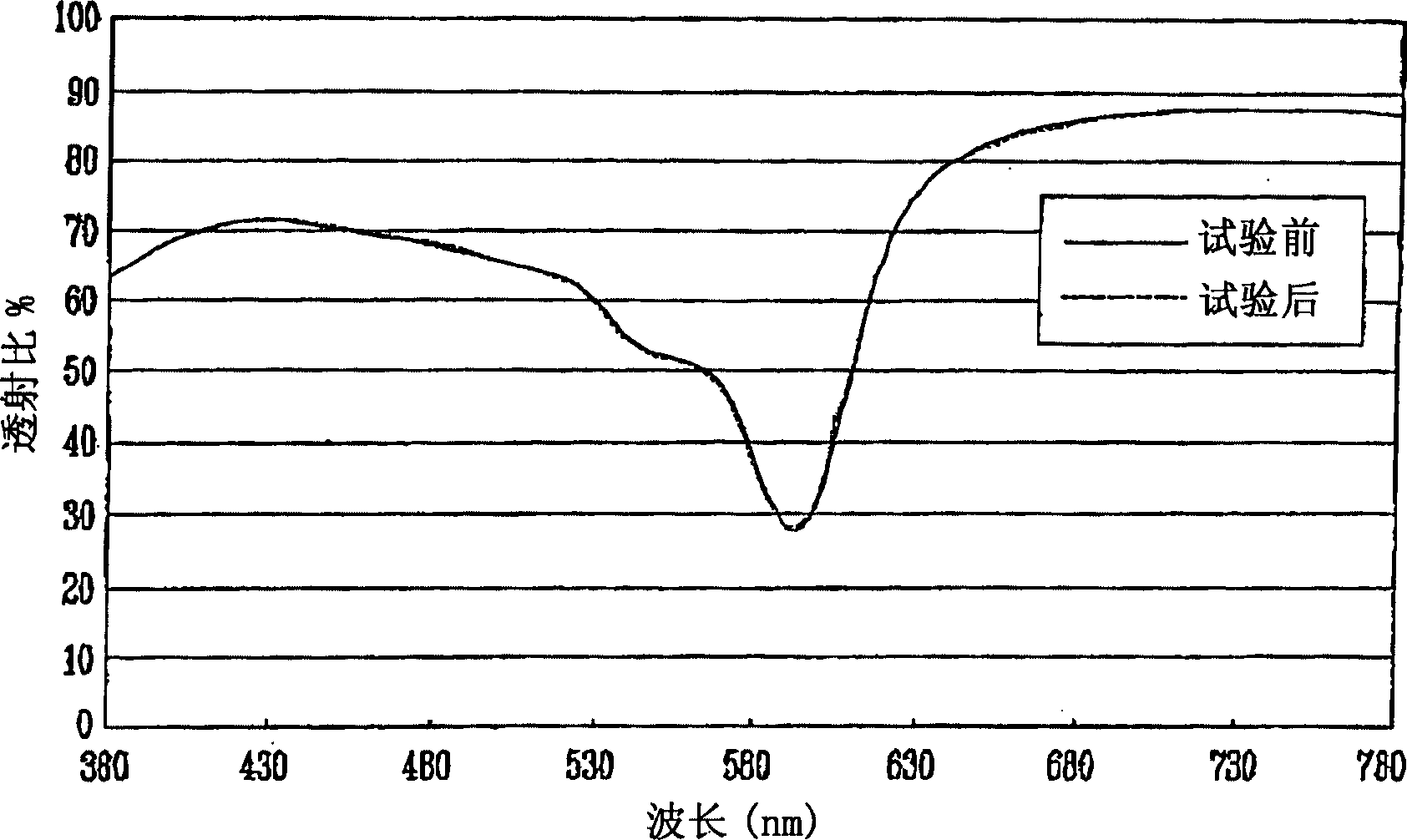

[0078] Durability was tested as above. The results are given in Table 1 below.

[0079] Visible area transmittance (%)

[0080] As can be seen from Table 1, the adhesive film exhibited excellent transmittance maintenance in the visible ...

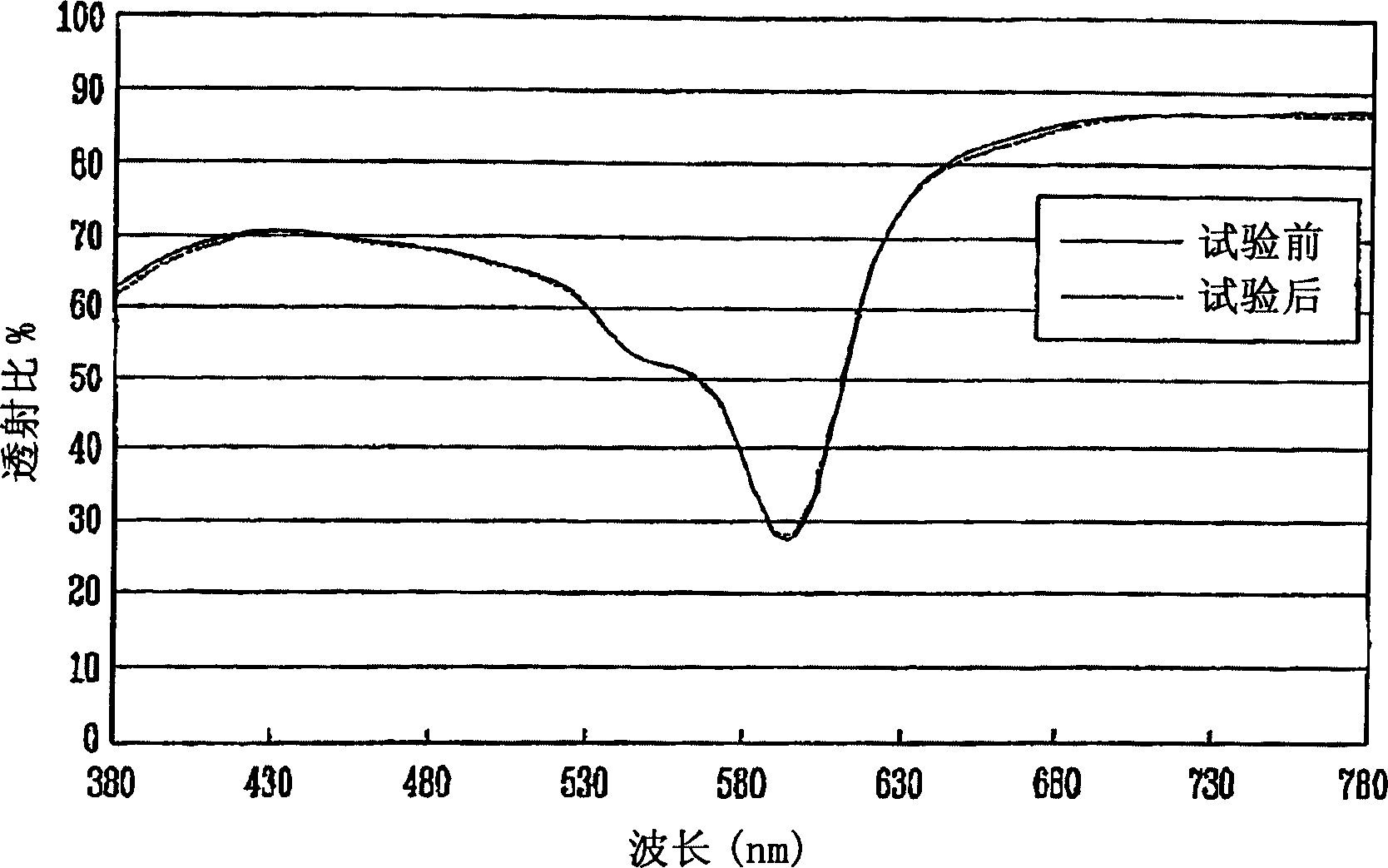

Embodiment 2

[0082] An adhesive film was prepared in the same manner as in Example 1, except that a phthalocyanine dye represented by Chemical Formula 5 (IP12, Japan catalyst Co.) was used as a near-infrared ray retarding dye.

Embodiment 3

[0084] Prepared in the same manner as in Example 1, except that butyl acrylate / acrylic acid copolymer solution was used instead of butyl acrylate (BA) / hydroxyethyl methacrylate (HEMA) copolymer solution as the acryl-based adhesive sticky film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com