Sliding type self-tensioning method for installing and manufacturing large-area GEM detector

A detector and sliding technology, which is applied in the field of manufacturing large-area GEM detectors, can solve the problems of easy wrinkles on the membrane edge, uneven membrane tension, and inability to lock bolts, etc., and achieve the effect of strong design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

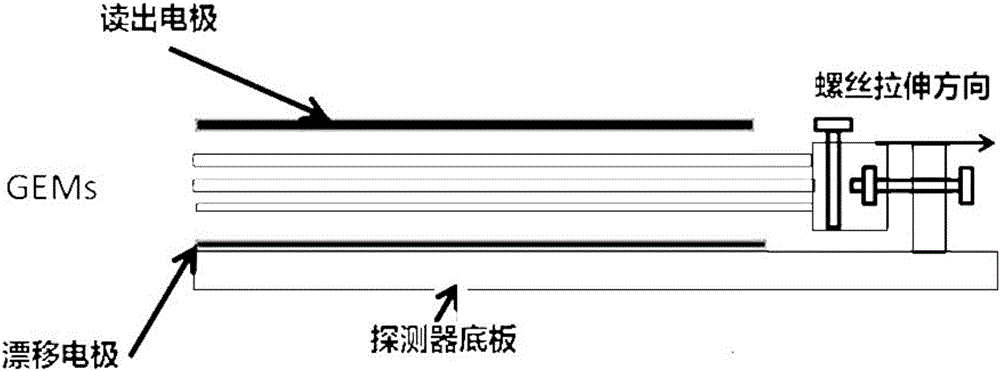

[0039] The sliding type self-tensioning method for the installation and manufacture of large-area GEM detectors of the present invention, its preferred specific implementation is:

[0040] Including the method of fixing the GEM film and the method of applying tension to the GEM film;

[0041] The fixed method of the GEM film comprises:

[0042] Two types of pads are used to fix the four edges of the drift electrode and the GEM film respectively, wherein the first type of pad is located in the middle of the edge of the drift electrode and the GEM film, and the second type of pad is located between the drift electrode and the GEM film. The positions of the two ends of the edge of the film near the corners;

[0043] The method for applying tension to the GEM film includes:

[0044] The slider fixed on the outside of the two types of pads and the main frame with a slot, the outside of the slider is provided with a screw hole, the main frame is provided with a slot, and the outsi...

specific Embodiment

[0049] Taking a GEM detector with an effective area of 100cm×50cm stretched simultaneously by the drift electrode and the three-layer GEM film as an example, its air gap structure is "3-3-2-2-2", that is, between the drift electrode and the transom The air gap of the detector is 3mm, the air gap of the drift zone of the detector is 3mm, and the air gap of the first, second transmission zone and guide zone is 2mm.

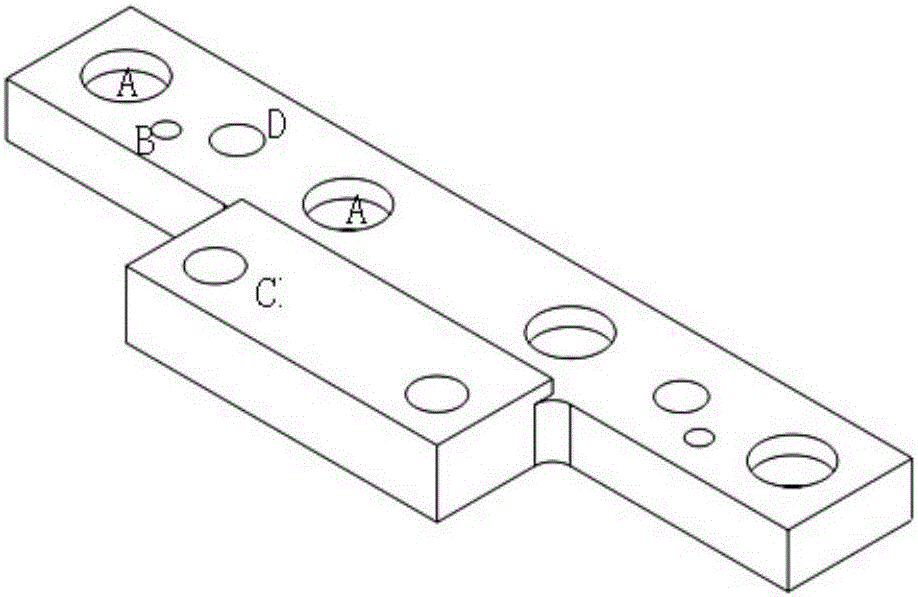

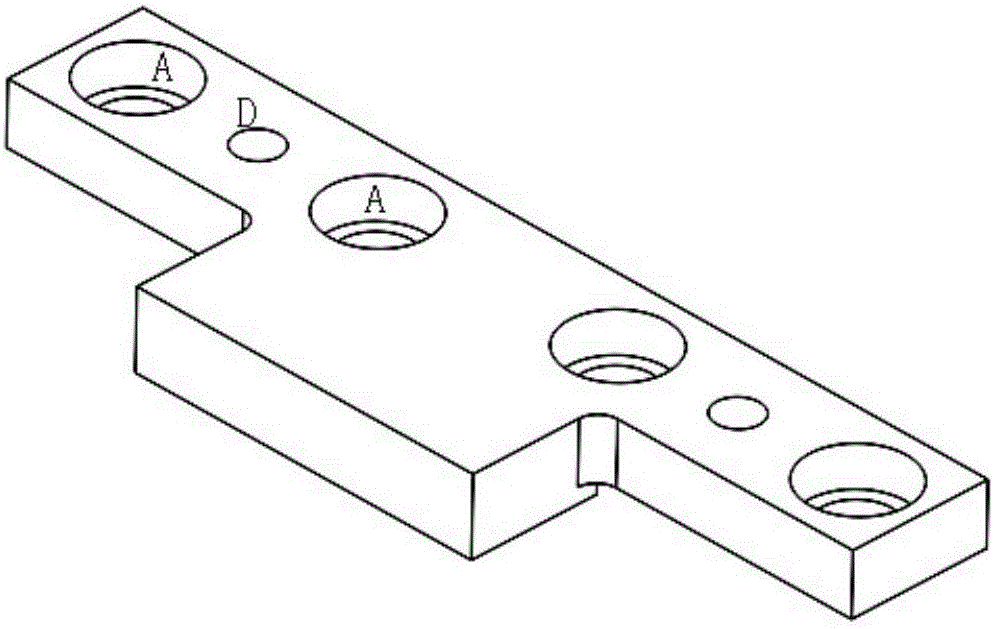

[0050] 1. The design scheme of the internal movable pad:

[0051] The internal spacer is used to fix the GEM film in the vertical direction, and when it is pulled by the external bolt, it is responsible for driving the GEM film to move in the direction of the force until the internal tension of the GEM film is balanced with the external tension. The pads can be divided into two types according to the length. The first type is placed on the non-corner area of the edge of the GEM film, and the length is relatively large (about 44mm); the second type is used to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com